Part B Cylindrical Roller Bearing Cage Design

description

Transcript of Part B Cylindrical Roller Bearing Cage Design

Customer Training

Timken

Learn and Lead

Part B Part B Cylindrical Roller Bearing Cylindrical Roller Bearing

Cage DesignCage Design

Cylindrical Roller Bearing Product Overview

5/7/2007 CRB Product Overview 2

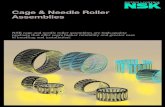

Cage Design TVP = glass fiber reinforced

nylon M = one piece, machined

bronze finger or fully milled S = one piece

stamped steel (5200 series & HJIR)

Pin type

S

Pin type

M

Customer Training

Timken

Learn and Lead

PrecisionPrecision

Cylindrical Roller Bearing Product Overview

5/7/2007 CRB Product Overview 4

ISO Class

ABMA Class Usual Symbol

Normal RBEC 1 No Symbol (PO)

6 RBEC 3 P6

5 RBEC 5 P5

4 RBEC 7 P4

2 RBEC 9 P2

Typical Precision Classes (Tolerance)

ISO 492 Section for metric roller bearings in increasing precision

Customer Training

Timken

Learn and Lead

Application ConsiderationsApplication Considerations

Cylindrical Roller Bearing Product Overview

5/7/2007 CRB Product Overview 6

Application Considerations

LubricationHeat generationSpeed/accelerationMisalignment

Cylindrical Roller Bearing Product Overview

5/7/2007 CRB Product Overview 7

Lubrication Bearing features

– Lubrication grooves and holes in OD

– Face scallops / lube from bore (stationary inner / rotating outer)• Used in multi-row CRB’s

– Spiral bore groove• Improved disassembly on

roll necks

Cylindrical Roller Bearing Product Overview

5/7/2007 CRB Product Overview 8

Torque & Heat Generation

Sources of bearing torque– Elastic deformation (roller-raceway contact)– Cage contact– Flange contact– Lubricant viscous forces

Cylindrical Roller Bearing Product Overview

5/7/2007 CRB Product Overview 9

Heat Generation

By design, generate less heat due to minimal friction

– Bearing operating temperature must not exceed 250°F (121°C)

Heat will dissipate by oil flow and conduction/convection/radiation through housing material

Cylindrical Roller Bearing Product Overview

5/7/2007 CRB Product Overview 10

Speed/Acceleration Considerations

High speeds and acceleration– Concern for large bore and eccentric

applications

Lower speeds with light loads– Skid smearing can occur due to lack of roller

traction– Min load = 2% of C1

Cylindrical Roller Bearing Product Overview

5/7/2007 CRB Product Overview 11

Misalignment

Roller/race profiles– Standard roller/race profiling designed to

withstand 0.0005 in/in of misalignment (low to moderate loads)

– More complex profiles (MRD) can be used to help reduce edge stresses that develop beyond the defined drops

Cylindrical Roller Bearing Product Overview

5/7/2007 CRB Product Overview 12

Misalignment

Flange modifications– Flanges can be heightened, tapered, or

include special profiles

Lubrication improvements– Increased oil flow rates to insure contact

points generate adequate lube film thickness

Customer Training

Timken

Learn and Lead

Part NumberingPart Numbering

Cylindrical Roller Bearing Product Overview

5/7/2007 CRB Product Overview 14

Cylindrical Roller Bearing (CRB) Part Numbering - Metric

PREFIXDIMENSION

SERIESCYLINDRICAL TYPE BEARING

BORE SIZE SUFFIX

N, NU, NF, NJ, NP, NUP, NJF, NN, NNU, NUP,

4NNU, HJ

(0)2, (0)3, (0)4, 10, 19, 22, 23, 29, 30, 49, 51, 57, 59

d = __ * 5 (mm) For d < 500mm

d = XXX (mm) For d >= 500mm

/XXX Designation

Cage Design

E.TVP, M, S

Cylindrical Roller Bearing Product Overview

5/7/2007 CRB Product Overview 15

Cylindrical Roller Bearing (CRB) Part NumberingCRB Configurations

– NJ = Cylindrical roller radial bearing (2 ribs on outer ring, 1 rib on inner ring)

– NU = Cylindrical roller radial bearing (2 ribs on outer ring, cylindrical inner ring)

– NUP = Cylindrical roller radial bearing (2 ribs on outer ring,1 fixed rib and 1 loose rib/flat washer on inner

ring)– RNU = Cylindrical roller radial bearing (2 ribs on outer ring,

without an inner ring) Series

– 10 = width series 1; diameter series 0 (dimension series 10– 2 = width series 0; diameter series 2 (dimension series 02)– 22 = width series 2; diameter series 2 (dimension series 22)– 3 = width series 0; diameter series 3 (dimension series 03)– 23 = width series 2; diameter series 3 (dimension series 23)

Customer Training

Timken

Learn and Lead

Timken Cylindrical Roller Timken Cylindrical Roller Bearing Product Overview Bearing Product Overview Part BPart B

End of ModuleClose this window and return to the main menu