PAM-FORM 2G 2013 - Feiplar Composites & Feipur · Title: Product presentation Author:...

Transcript of PAM-FORM 2G 2013 - Feiplar Composites & Feipur · Title: Product presentation Author:...

Copyright © ESI Group, 2012. All rights reserved. Copyright © ESI Group, 2012. All rights reserved.

PAM-FORM 2G 2013 Thermoforming of dry textiles and prepregs

July 23rd, 2013

Mathilde Chabin

1

Copyright © ESI Group, 2012. All rights reserved.

Introduction to ESI Composites Manufacturing Suite

PAM-FORM 2G product presentation

References

CONTENT

2

Copyright © ESI Group, 2012. All rights reserved.

Introduction to ESI Composites Manufacturing Suite

PAM-FORM 2G product presentation

References

CONTENT

3

Copyright © ESI Group, 2012. All rights reserved.

ESI Composites Manufacturing Suite

4

(1) Standalone version or CATIA V5 embedded

Note: ESI solution can use draping results from non-ESI applications as Fibersim, Composites Design by DS… ESI chain

Courtesy: AAR, Cranfield University, EADS/M, ENISE

FORMING PAM-QUIKFORM(1)

PAM-FORM2G

PREFORM PAM-QUIKFORM(1)

PAM-FORM2G

LCM PAM-RTM(1)

DISTORTION PAM-DISTORTION

CURING

In Autoclave CFD-ACE

Out-Of-Autoclave PAM-RTM

Copyright © ESI Group, 2012. All rights reserved.

Introduction to ESI Composites Manufacturing Suite

PAM-FORM 2G product presentation

What is new in 2013 version

References

CONTENT

5

Copyright © ESI Group, 2012. All rights reserved.

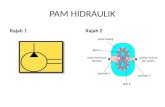

PAM-FORM 2G

Process Schematic

6

SOFTEN PLIES PLACE IN TOOLS FORM EJECT PREFORM

PLACE IN TOOLS

HEAT PLIES

FORM

PLACE IN TOOLS FORM

COMPRESSION

EJECT PREFORM

LIQUID

COMPOSITE

MOLDING

CURE IN AUTOCLAVE CURE IN TOOLS OR

PAM-RTM / PAM-DISTORTION PAM-FORM

TE

XT

ILE

PR

EF

OR

MIN

G

TH

ER

MO

SE

T

FO

RM

ING

TH

ER

MO

PL

AS

TIC

FO

RM

ING

CRISTALLISATION

Copyright © ESI Group, 2012. All rights reserved.

PAM-FORM 2G simulation

What for?

To define and optimize:

Forming strategy: stamping, thermoforming, diaphragm forming…

Process parameters: tool velocity, holding system and force,

temperature cycle, pressure cycle, material type and thickness for

diaphragms…

Through the prediction of:

Wrinkling

Bridging

Thickness

Optimum flat pattern

Final fiber orientation

With material models for NCF, UD and woven fabrics

7

Automotive B-Pillar

Copyright © ESI Group, 2012. All rights reserved.

PAM-FORM 2G simulation

Material data requirements

Material data are needed for each ply of the laminate

Data should cover temperature range of the process

8

DEFORMATION MODE REPRESENTATION SIMULATION INPUT COMMENTS

Fiber extension Young’s modulus

(E1, E2)

To be done for both fiber

directions

Fiber buckling Young’s modulus = f(strain)

(E1, E2)

To be done for both fiber

directions

In-plane shear Force/Displacement

(G)

To be done for positive and

negative shear

Bending

Simulations for Bending

Stiffness calibration

(B1, B2)

To be done for both fiber

directions

Compaction Thickness = f(pressure) Can be done for different

shear angles

Sliding Friction coefficient

Can be temperature, velocity

and pressure dependent

To be done between plies

and between plies and tools

In-plane shear viscosity Viscosity Can be temperature

dependent

Copyright © ESI Group, 2012. All rights reserved. 9

UD thermoforming: 20 plies of carbon unidirectional

thermoplastic matrix –APC2-AS4

Courtesy: Dassault Aviation

PAM-FORM2G simulation

Top and Bottom ply (End view)

Top

View

Bottom

View

Wrinkle

Smooth

surface

PAM-FORM 2G simulation

Example 1: Wrinkling prediction

Copyright © ESI Group, 2012. All rights reserved.

PEI-CETEX; 8 plies

Woven fabrics thermoforming: impact of punch

velocity

PUNCH VELOCITY= 5.mm/s PUNCH VELOCITY=40.mm/s

Courtesy: Dassault Aviation

PAM-FORM 2G simulation

Example 2: Process definition

Copyright © ESI Group, 2012. All rights reserved.

+ - 45 0/90 Clamping system definition

Laminate definition

Courtesy: Dassault Aviation

PAM-FORM 2G simulation

Example 3: Material definition

Copyright © ESI Group, 2012. All rights reserved.

PAM-FORM 2G simulation

Example 4: Shearing prediction

on preform

12

Copyright © ESI Group, 2012. All rights reserved. 13

Courtesy: Delft University of Technology

Fabric / 6 plies / PPS Matrix

PAM-FORM2G simulation

Highlights on bridging risks

PAM-FORM 2G simulation

Example 5: Bridging prediction

Copyright © ESI Group, 2012. All rights reserved.

Introduction to ESI Composites Manufacturing Suite

PAM-FORM 2G product presentation

References

CONTENT

14

Copyright © ESI Group, 2012. All rights reserved.

AUDI

Lamborghini

Bilcare

BMW

DLR

DOW

EUROCOPTER

Some References

15

GE

Mercedes-Benz

Letov

Minoru Kasai

NCC

VW

Visteon

Copyright © ESI Group, 2012. All rights reserved.

Copyright © ESI Group, 2012. All rights reserved. Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM 2013

Product presentation

17

Copyright © ESI Group, 2012. All rights reserved.

Liquid Composites Molding

Process Schematic

18

SOFTEN PLIES PLACE IN TOOLS FORM EJECT PREFORM

TRIM PREFORM LOAD PREFORM INJECT RESIN CURE PART

DEMOLD PART FINAL PART

PA

M-F

OR

M 2

G

PA

M-R

TM

S

YS

PLY

Copyright © ESI Group, 2012. All rights reserved.

Liquid Composite Molding simulation

To do what and how?

To define and optimize:

LCM strategy (RTM, CRTM, VARI…)

Location of injection gates, vents and vacuum ports

Size, type and location of flow media

Temperature cycle

Through the prediction of:

Filling and Curing time

Dry spots

Flow front velocity

Pressure in the mold

Taking into account

Fiber angle variation (permeability variation) of the preform

19

B-Pillar injection

Copyright © ESI Group, 2012. All rights reserved.

Liquid Composite Molding simulation

PAM-RTM flow model

Resin flow in a porous medium using

20

Resin

inlet Resin

outlet

Section A

L

p

K

A

Q q

= = .

m3/s m2 Pa

m2 m/s Pas m

DARCY’S LAW

Copyright © ESI Group, 2012. All rights reserved.

Liquid Composites Molding

Process variants with PAM-RTM

RTM: Resin Transfer Molding

Material data for simulation

21

RTM HEATED RTM

OR

RTM HEATED RTM (added data)

Reinforcement Permeability tensor (K1,K2,K3) Constant OR f(shear angle)

Density Constant

Specific heat Constant OR f(temperature)

Thermal conductivity tensor (K1, K2, K3) Constant OR f(temperature)

Effective conductivity tensor (K1, K2, K3) Constant OR f(temperature) OR f(temperature, degree of cure)

Resin Density Constant

Viscosity constant OR f(time) OR f(material age)

Viscosity f(temperature) OR f(temperature, degree of cure) OR User defined

Specific heat Constant OR f(temperature) OR f(temperature, degree of cure)

Heat conductivity Constant OR f(temperature) OR f(temperature, degree of cure)

Enthalpy constant

Curing Kinetics 5 models including Kamal-Sourour OR User Defined

Floor panel TECABS project

Copyright © ESI Group, 2012. All rights reserved.

Liquid Composites Molding

Process variants with PAM-RTM

VARI: Vacuum Assisted Resin Infusion

Material data for simulation (added data)

VARI (added data)

Reinforcement Permeability tensor (K1,K2,K3) f(fiber content)

Compressibility curve Pressure of compaction=f(fibre content)

VACUUM INFUSION

Wind blade infusion

Flexible membrane

Copyright © ESI Group, 2012. All rights reserved.

Liquid Composites Molding

Process variants with PAM-RTM

CRTM: Compression Resin Transfer Molding

Material data for simulation

23

INJECT RESIN PARTIAL MOLD CLOSURE COMPRESSION STROKE

CRTM

Reinforcement Permeability tensor (K1,K2,K3) f(fiber content)

Automotive hood – A-CRTM

Courtesy: CCHP of Ecole Polytechnique of Montréal

Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM simulation

Post-Processing examples

Filling time

24

30 meters wind spar cap infusion

Curing time

Fan blade of an aircraft engine RTM

Fuselage panel infusion

Filling degree

Courtesy: Airbus

Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM simulation

Post-Processing examples

Dry spots

Final part

Courtesy: Cranfield University

injection

injection

vent

racers injection Injection simulation / filling result

Dry spot prediction with PAM-RTM

Initial state Intermediate state Final state

Modified injection strategy

To avoid dry spots

vent

vent

injection

Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM simulation

Additional functionalities

Porosity prediction and reduction:

Principle: Critical impregnation velocity:

26

critfront vv

max

Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM simulation

Additional functionalities

Porosity prediction and reduction:

PAM-RTM input data:

27

0%

2%

4%

6%

8%

10%

12%

14%

0 0.002 0.004 0.006 0.008 0.01 0.012 0.014 0.016 0.018 0.02

Flow velocity (m/sec)

Vo

ids

co

nte

nt

20 psi

30 psi

45 psi

2,5 ml/s

1.26+100.55*(V)

Chomarat - Roviply

12.824-1573.7*(V)

Macro-void

Micro-void

Optimum velocity

Based on experiment

Ca= viscosity*velocity/surface tension/contact angle

Experimental data PAM-RTM input curve

Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM simulation

Additional functionalities

Porosity prediction and reduction:

PAM-RTM output: injection flow rate curve

28

(a) Constant injection pressure

(b) Constant injection flow rate

(c) Optimized injection flow rate

(a) Constant injection pressure

(b) Constant injection flow rate

(c) Optimized injection flow rate

0

1

2

3

4

5

6

7

0 50 100 150

injection time [sec]

inje

cti

on

flo

w r

ate

1e-7

[m

3/s

]

1E-04

1E-03

1E-02

Cap

illa

ry n

um

ber

at

flo

w f

ron

t

Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM simulation

Additional functionalities

Trigger manager that allows conditional opening of the

gates

DMP solving capability that highly decrease the

computation time when increasing the number of

processors

Gravity effect on resin flow

29

0

2

4

6

8

0 10 20

Scale factor = f(# of processors)

CASE1700,000 elements

Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM simulation

Additional functionalities

One shot simulation (few seconds) for estimation

of last points to be filled and filling time

Automatic estimate of injection point location

30

192

second

es 93

seconde

s

62

seconde

s

192 secondes

93 secondes

62 secondes

Copyright © ESI Group, 2012. All rights reserved.

What’s new in 2013?

Consolidation of DMP solver:

Permeability as a function of shear angle

Trigger manager

Reporting improvements

Results sampling on sensors

Specific heat and effective thermal

conductivity - f(T, alpha)

Material database

31

Copyright © ESI Group, 2012. All rights reserved.

Liquid Composites Molding

PAM-RTM permeability database

Based on Nottingham University data available on ESI

customer portail: MyESI

32

Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM simulation

Workflow example (1/4)

33

Ply lay-up

Fibers orientation

Material definition

Import

PAM-RTM

Solid mesh creation

and zones definition

Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM simulation

Workflow example (2/4)

34

Inlet definition

Flow media definition

PAM-RTM

Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM simulation

Workflow example (3/4)

35

PAM-RTM

Filling prediction

Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM simulation

Workflow example (4/4)

36

PAM-RTM

Zoom-in on flow media

influence on resin flow front

Copyright © ESI Group, 2012. All rights reserved.

PAM-RTM

Some References

Aston Martin

BOMBARDIER

BMW

CCAT

Dassault-Aviation

DOW

EADS

GE R&D

GE India Technology Center

Hexcel

M-Torres

ONERA

PPE

37

Snecma and Snecma Propulsion

Solide (Safran Group)

TECSIS, IPT, FURG, Unifei

Volkswagen, VZLU

Ecole des Mines, Ecole

Polytechnique de Montréal,

Ecole Polytechnique de Nantes,

KU Leuven, Politecnico di

Milano, Shanghai Jiaotong

University, TU Clausthal, TU

Delft, TU Munchen, University of

Cranfield, University of

Nottingham, Wichita State

University…

http://www.esi-group.com/products/composites-plastics/pam-rtm/success-stories

Copyright © ESI Group, 2012. All rights reserved.