Painting the pores

description

Transcript of Painting the pores

1 - Classification: Internal

Painting the poresGullfaks Diverging Pilot

Well A-35Author: Rune Instefjord,

2 - Classification: Internal

Outline

• Introduction to the Chemicals.

• How does the chemicals work.

• Planning of pilot on Gullfaks

− Selection of pilot area

− Simulation

• Implementation

• Summing up

3 - Classification: Internal

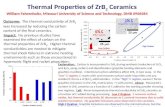

Introduction to Abio gel

• Abio gel is compound, consisting primarily of Sodium silicate. When Abio gel is brought into contact with divalent cations (i.e. Ca and Mg) in formation- or seawater it reacts to form a microcrystalline suspension which may become a stiff gel if concentration of divalent cations exceeds about 1 %. Otherwise it behaves as a cement paint coating the rock matrix.

Abiogel coat

• narrow the flow channels gradually

• keep certain permeability

• in favor of indepth fluid diversion

The following text and illustration is

provided by CNPC

Abiogel is actually a gel used in chromatography and is also a brand name for cement paint

4 - Classification: Internal 2011-08-18

Gullfaks flow diversion project

A-35

A-39A

A-38

A-38A

A-17

B-37

A-2AH

A-1H

A-5H

457200 457600 458000 458400

457200 457600 458000 458400

67

8200

06

782

400

67

8280

06

783

200

67

8360

06

784

000

67

820006

782400

67

828006

783200

67

836006

784000

Injection water

Oil 0.16

0.32

0.48

0.64

0.8

0.96

So

0 100 200 300 400 500m

1:10000

—— 01/06/2008 剩余油饱和度分布图

Bypassed oil

• 1000 ton chemicals (silica based) injected into the injector A-35.

• The chemicals is environmental classified as yellow. It is environmentally acceptable and unproblematic to use.

• The chemicals shall move into the reservoir and form micro gel particles, which will stick to the surface of the pores and thereby reducing the permeability in invaded zones.

• The water will be forced to find new paths and invade less water flooded areas.

• Hit bypassed oil and increase the oil recovery.

5

5

Illustration of water diverging

• Important issues:

- Improve the volumetric sweep efficiency.

-Reduce permeability and reduce flow of water in existing water channels. Divert water into unswept areas.

- Alternative to drilling of new wells into areas with very uncertain flooding pattern.

6 - Classification: Internal 2011-08-18

6

Illustration of water diverging

Classification

: Internal

Status: Draft

A-35

A-39A

A-38

A-38A

A-17

B-37

A-2AH

A-1H

A-5H

457200 457600 458000 458400

457200 457600 458000 458400

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

Injection water

Oil0.12

0.24

0.36

0.48

0.6

0.72

0.84

0.96

So

0 100 200 300 400 500m

1:10000

—— 01/06/2008 剩余油饱和度分布图

A-35

A-39A

A-38

A-38A

A-17

B-37

A-2AH

A-1H

A-5H

457200 457600 458000 458400

457200 457600 458000 458400

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

Injection water

Oil 0.16

0.32

0.48

0.64

0.8

0.96

So

0 100 200 300 400 500m

1:10000

—— 01/06/2008 剩余油饱和度分布图

A-35

A-39A

A-38

A-38A

A-17

B-37

A-2AH

A-1H

A-5H

457200 457600 458000 458400

457200 457600 458000 458400

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

Injection water

Oil 0.16

0.32

0.48

0.64

0.8

0.96

So

0 100 200 300 400 500m

1:10000

—— 01/06/2008 剩余油饱和度分布图

A-35

A-39A

A-38

A-38A

A-17

B-37

A-2AH

A-1H

A-5H

457200 457600 458000 458400

457200 457600 458000 458400

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

Injection water

Oil 0.16

0.32

0.48

0.64

0.8

0.96

So

0 100 200 300 400 500m

1:10000

—— 01/06/2008 剩余油饱和度分布图

layer36 layer38 layer40 layer42

A-35

A-39A

A-38

A-38A

A-17

B-37

A-2AH

A-1H

A-5H

457200 457600 458000 458400

457200 457600 458000 458400

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

Injection water

Oil 0.16

0.32

0.48

0.64

0.8

0.96

So

0 100 200 300 400 500m

1:10000

—— 01/06/2008 剩余油饱和度分布图

A-35

A-39A

A-38

A-38A

A-17

B-37

A-2AH

A-1H

A-5H

457200 457600 458000 458400

457200 457600 458000 458400

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

Injection water

Oil 0.16

0.32

0.48

0.64

0.8

0.96

So

0 100 200 300 400 500m

1:10000

—— 01/06/2008 剩余油饱和度分布图

A-35

A-39A

A-38

A-38A

A-17

B-37

A-2AH

A-1H

A-5H

457200 457600 458000 458400

457200 457600 458000 458400

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

Injection water

Oil 0.16

0.32

0.48

0.64

0.8

0.96

So

0 100 200 300 400 500m

1:10000

—— 01/06/2008 剩余油饱和度分布图

layer44 layer46 layer48 layer49

A-35

A-39A

A-38

A-38A

A-17

B-37

A-2AH

A-1H

A-5H

457200 457600 458000 458400

457200 457600 458000 458400

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

67

82

00

06

78

24

00

67

82

80

06

78

32

00

67

83

60

06

78

40

00

Injection water

Oil 0.16

0.32

0.48

0.64

0.8

0.96

So

0 100 200 300 400 500m

1:10000

—— 01/06/2008 剩余油饱和度分布图

Plane remaining oil mainly distributes out of the main water streamline region and in the bottom low permeability formations

Remaining Oil Distribution

8 - Classification: Internal

Introduction to Gullfaks

Discovered: 1978Start production: 1986 STOOIP: 599 MSm³Base oil reserves: 365 MSm3

Produced to date: 351 MSm3

• Recovery of base reserve: 96%• Overall expected recovery: 61%• Overall recovery pr. 2011: 59%

Current daily production: 14 kSm3

Current average water cut: 84 %Initial pressure/temperature: 310-

320 bar/ 71 oC at 1850m TVD MSLBubble point pressure: ~200-240

bar at 1850m TVD MSLGOR: ~ 100 Sm³/Sm³ Oil viscosity: ~ 0.5 – 1 cp

Gullfaks

Norway

Iceland

Ireland UK

North SeaSweden

Denmark

Germany

Finland

Russia

9

Pilot area: Lower Brent, segment H1

• Segment selected for a water based chemical method.

• STOOIP in lower Brent is 20,3 MSm³ oil.

• Lower Brent in H1 has ”only” 57 % recovery factor.

• Potential 2 - 5 MSm³ mobile oil left.

• Relatively isolated segment.

• A lot of data is collected in this area. It was the first production area and therefore a lot of good, initial data.

• 2 active wells in lower Brent, A-35 (injector) and A-39A (producer).

• 2 active producers in upper Brent, B-37 and A-38A.

• Pressure communication between B-37 and lower Brent. No communication with A-38A?

• Problem with H2S in A-39A. B-37 may also give a H2S

problem.

10 - Classification: Internal

One-dimensional model to simulate sand pack experiment

Parameter adjustment

Simulation

− Establish a History Matched (HM) simulation model for the H1-segment

− Understand the mechanism of the chemicals and find the relevant parameters

− Make predictions using the optimal simulation tool and – method using restart from the HM model

11 20.04.23 Classification: Internal

Operation, offshore setup

Scandi Flora at the North Shaft (NS)

Hose hanger @ BOP deck NS

Connection to Chicksan 2” line

KillWing Valve @ WellHead

12 20.04.23 Classification: Internal

Events each batch

• Mixing chemicals at CCB, Ågotnes outside Bergen.

• 15-20 % wt. solution mixed in Fresh Water.

• Mixed max 800 m³ of solution due to regulations by the government.

• Scandi Flora transported and pumped the chemicals into A-35.

• Start injection 17.09.

• 100 m³ KCl preflush and postflush, rate: 1 000 m³/d in the 2 first batches.

• Injected 150 - 800 m³ solution with chemicals at rate: 1 000 - 2000 m³/d.

• Density of the liquid was 1.23. Viscosity around 3.5 cP. PH around 13.

• End injection 06.11.

• Restrictions on wave height. Maximum 3 m due to hook up between vessel and platform.

13 20.04.23 Classification: Internal

Batch 1

Before 1st Batch treatment DHP for inj. rate 2000 sm3/d was 296bara, after treatment DHP

stabilized around 280bara. This effect was interpreted as stimulation of the well.

14 20.04.23 Classification: Internal

Pressure details batch 1

Start chemical injection

End chemical injection

Start KCl postflush

Start KCl preflush

Stop KCl

preflush

Start SW injection

15 Classification: Internal 2011-09-19

Well shut in

Start chemical injection

Drop due to density

Start SW injection

Increase due to density

Pressure 4th batch (part 1)

16 20.04.23 Classification: Internal

SW inj. pressure after each batchDevelopment of DHP in A-35 after Injection of WJSTP-A Batches

265.0

267.5

270.0

272.5

275.0

277.5

280.0

282.5

285.0

287.5

290.0

292.5

295.0

297.5

300.0

302.5

00:00 01:30 03:00 04:30 06:00 07:30 09:00 10:30 12:00

Hours from start of SW injection after each batch

DH

P, b

ara

Batch1, 2150sm3/d Batch2, 2000sm3/d Batch3, 1920sm3/d Batch4p1, 1750sm3/d Batch4cont, 1920sm3/d

Batch5p1, 1900sm3/d Batch5p2, 1880sm3/d Batch6, 1880sm3/d Batch7, 1890sm3/d Batch8, 1920sm3/d

Summary

• Successful operation but used some more time than planned due to weather conditions.

• It is to early to see any IOR in the producers, so we do not know the answer on the questions!

• We expect increased oil production in the producers after around 1 year.

• Have technical problems in one of the wells per today and the well are therefore shut in. This may worsen the interpretation of the pilot.

• First multi well diverging project in the North Sea. If success it may give a lot of increased oil for more fields than only Gullfaks.

17 - Classification: Internal

18 - Classification: Internal

Presentation title

Presenters name

Presenters title

E-mail address, tel: +00 00 00 00

www.statoil.com

Thank you