Padeye Calculation For Lifting Analysis

Transcript of Padeye Calculation For Lifting Analysis

PROJECT :

SOUTH BELUT DEVELOPMENT PROJECT

Sheet Rev.‐ C

TITLE :Structure Calculation of Chemical Injection

Skid No. 1Prepared by : Date : Document No.Nelson W. Panjaitan 31‐May‐12 F036‐11‐IN‐CAL‐001

PADEYE CALCULATION

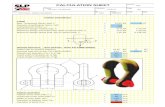

a. Pulling Skid Line. b. Lifting Skid Line.Fig. 1. Pulling and Lifting Skid Line.

DR

R1

t2

t1

R1

Typ.t

H

h tf

tw

Fig. 2. Padeye Detail 1.

DAF = 2

50

b

tFW

L

DAF = 2Maximum lower sling load (S) = 4495.5 kg = 9.91 kipsS x DAF = 8991 kg = 19.82 kips

PADEYE CALCULATION

α‐max = 90 °Sv = S x DAF x sin α = 8991 kg = 19.82 kipsSh = S x DAF x cos α = 8880.31 kg = 19.58 kipsPin Dia. (d) = 25.40 mm = 1.00 inchesHole Dia. (D) = 75.00 mm = 2.95 inchesPin clearence = 49.60 mm = 1.95 inchesPadeye plate thickness (t1) = 25.00 mm = 0.98 inchesCheek plate thickness (t2) = 0.00 mm = 0.00 inchesTotal plate thickness (t) = 25.00 mm = 0.98 inchesPadeye radius (R) = 100.00 mm = 3.93 inchesCheek plate radius (R1) = 0.00 mm 0.00 inchesPadeye plate length (L) = 375.00 mm = 14.74 inchesDistance between top beamand center of pin (H) = 87.00 mm = 3.42 inchesFy = 36 ksiWidth of the beam (b) = 200.00 mm = 7.86 inchesHeight of the beam (h) = 200.00 mm = 7.86 inchesFlange thickness (tf) = 12.00 mm = 0.47 inchesWeb thickness (tw) = 8.00 mm = 0.31 inches

Pin Bearing StressAll bl b i t 0 75 FAllowable bearing stress = 0.75 x Fy

= 27 ksi

Bearing capacity (P‐allow) = 0.75 x Fy x d x t= 26.48 kips

Status :Pallow > Sv (OK)

Tear Out Shear Padeye Plate and Cheek PlateAllowable shear stress = 0.40 x Fy

= 14.4 ksi

Shear Capacity (V‐allow) = [2 x (t1 x (R ‐ D/2)) + 2 x (t2 x (R1 ‐ D/2))]x (0.40 x Fy)

= 69 50 kips= 69.50 kipsStatus :Vallow > Sv (OK)

Tension Padeye PlateAllowable tensile stress acrosspin hole = 0.45 x Fy

= 16.2 ksi= 16.2 ksi

Tensile Capacity (T‐allow) = [2 x (t1 x (R ‐ D/2)) + 2 x (t2 x (R1 ‐ D/2))]x (0.45 x Fy)

PADEYE CALCULATION

= 78.19 kipsStatus :Tallow > Sv (OK)

Combined Axial Tension and Bending StressStress ratio = (fa/Ft) + (fb‐in plane/Fb) + (fb‐out plane/Fb)Where,fa = Sv/(t1 x L) = 1.37 ksifb‐in plane = [(Sv/(1/6.t1)) x (H/L^2)] = 1.91 ksifb‐out plane = (5%.Sv.H)/(1/6.t1^2.L) = 1.43 ksiFb‐in plane = 0.66 x Fy = 23.76 ksiFb‐out plane = 0.75 x Fy = 27.00 ksiFt = 0.60 x Fy = 21.60 ksiSo,Stress ratio = 0.20 < 1.00 (OK)

Fillet Weld (E70XX)Length of fillet weld (LFW) = 2 x b

= 15.72 inches

Thickness of Fillet Weld (tFW) = 6.00 mm0 24 i h= 0.24 inches

Fillet weld capacity (FW‐allow) = LFW x tFW x 0.3 x 0.707 x 70= 55.03 kips

Status :FWallow > Sv (OK)