P Blank Segmented Bowls - Tahoe Turnertahoeturner.com/instructions/pdf/penblankbowl.pdf · A small...

-

Upload

hoangnguyet -

Category

Documents

-

view

217 -

download

3

Transcript of P Blank Segmented Bowls - Tahoe Turnertahoeturner.com/instructions/pdf/penblankbowl.pdf · A small...

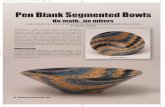

Whenever I make a presentation to a group of woodturners, the pen blank segmented bowl alwaysreceives an enthusiastic response. The ability to create acomplex-looking, segmented turning with no math andwithout even a single miter joint is simply irresistible to mostturners. This project relies on the concept of stackingbandsaw cut rings. The technique is not new nor did Iinvent it. Turners Mike Shuler and Michael Mode have usedthe technique for awhile with great success. Years ago,Dale Nish profiled the technique in his book CreativeWoodturning, having adapted the technique from thesalad bowl industry where its use continues as a means ofconserving wood.

WOOD SELECTIONFor this particular little bowl, I used small (about 11/16"square), resin-impregnated pen blanks (see Fig. 1). Thismaterial is ideally suited because it is quite strong, whichpermits a very thin vessel wall, and is available in manycolors. However, as you will see, any wood type in almostany size may be used.

Pen Blank Segmented BowlsNo math...no miters

by Malcolm Tibbetts◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆

54 ● Woodturning Design Winter 2006

Inside of Bowl

WTD 54-58 10/7/05 9:49 AM Page 54

Woodturning Design Winter 2006 ● 55

Wood: the exact species or colors are your decision, but choose a light-colored and a dark-colored wood to ensure dramatic contrast; if you use small pen blanks, then I recommend the resin-impregnated, stabilized style*

Tools: lathe, bandsaw (or scroll saw), fine-toothed blade, drum sander (or planer), clamps, small faceplate, power-sanding drill with pad and assorted sanding discs, small bowl gouge, shear scraper, wall thickness gauge, compass, steel straight edge

Veneer (optional)Medium density fiberboard (MDF)Waste block and mounting screwsBoth 90-minute and 5-minute epoxyAssorted grits of abrasive paperBuffed lacquer or oil or finish of choiceSmall flashlightDouble-sided tapeWax paperDisposable glovesPencil

*The 11/16" pen blanks used for this particular project were purchased from Arizona Silhouette,

PO Box 11170, Yuma, AZ 85366-9170; phone: 928-329-8039;

website: www.arizonasilhouette.com.

SUPPLIES

DIMENSION THE WOODAs with most wood-working projects,the first step is toaccurately di-mension the wood.For small piecessuch as these, alittle sanding witha disc sanderworks nicely.Next, split theblanks using abandsaw in orderto create addi-tional laminationc o m p o n e n t s(see Fig. 2). Theeasiest method ofsmoothing thebandsaw cuts isto attach thepieces to medi-um density fiber-board (MDF) withd o u b l e - s i d e dtape and then

make light passesthrough a drumsander. Anothermethod is to care-fully sand the sur-faces using a discsander. Regard-less of method,the sur facesshould be smoothand parallel. Tocreate a l itt lemore visual inter-est, I also cut afew pieces ofveneer. When youdesign such a lamination, always try to position light colorsnext to dark colors; avoid putting two similar colors next toeach other. Strive for contrast because similar colors willblend over time and viewers will hardly notice your efforts.

LAMINATIONThe next step is toglue together allthe componentsinto one lamina-tion (see Fig. 3).Because of theresin-impregnatednature of the penblank wood, 90-minute epoxyseems to be thebest glue choice.Be especiallycareful to keepall the layers “inline” (see Fig. 4).Do not allow them to slip during clamping, or you will lose precious thickness. Before proceeding, allow theepoxy to cure for at least a few hours; however, overnightis better.

SPLIT AND SAND THE BLANKThe goal at the start was to create the largest and thickestsquare lamina-tion. To transformthis rectangularlamination into asquare lamina-tion, it must becleaned up andthen split usingthe bandsaw.Take your t imeduring the re-sawing in orderto produce twoequally thickhalves (see Fig. 5).

At this point,

Three resin-impregnated pen blanks.

Fig. 1

Splitting the blanks with a bandsaw.

Fig. 2

All ready to glue.

Be sure to prevent slippage.

Fig. 4

Re-sawing the lamination.

Fig. 5

Fig. 3

WTD 54-58 10/13/05 11:25 AM Page 55

56 ● Woodturning Design Winter 2006

the two halves should have a smooth side and a bandsaw-created, slightly uneven side. Both halves mustnow be dimensioned smooth and to an even thickness.Using double-sided tape and a drum sander is mymethod; however, a thickness planer will also work. Justmake sure you secure the lamination halves to a backingboard (MDF works well) using high-quality double-sidedtape and then surround the pieces with scrap material.Firmly attach the scrap wood to the backing board, andextend the scrap in front and behind the laminations. Thiswill prevent any unwanted snipe from occurring. Makeextremely light passes through the sander or planer.

LAY OUT AND CUT THE RING SECTIONSPlace the two smoothed halves next to each other, andtemporarily secure them with a little tape. Determine thecenter and draw circles using a compass (see Fig. 6). Thecircles should beabout 1/4" apart.If using this tech-nique with thickermaterial, you willneed to spacethe circles furtherapart. The goal isto cut angledrings, which canbe stacked. If therings are cutproperly, the bot-tom diameter ofone ring will besimilar to the topdiameter of the ring below. The beauty of this technique is that very little waste occurs. The bandsaw cuts do, however, man-date the basicshape of thebowl. Dependingupon the thick-ness of yourmaterial, there isonly a l itt leopportunity tomodify the shape.The thicker thewood and thewider the circlesare spaced, themore flexibil itythere will be, butyou will also sacrifice wood and the bowl will be smaller.

Prepare to concentrate! The bandsaw cuts must be very accurate; the entire project will be ruined if youdeviate very far from the lines. Use your smallest, fine-toothed blade, with the table set at 45°, and cut slowly(see Fig. 7). Another method of cutting is to use a scrollsaw with a tilting table.

PREPARE FOR TURNINGFig. 8 shows the half-rings. Use a piece of wax paper

placed on a flat surface as a gluing platform. A small dabof 5-minute epoxy on the seams and a little momentaryfinger pressure easily create full rings (see Fig. 9). Beforegluing the halves together, inspect them by holding themup to a bright light and checking the fit. If needed, touchup the ring endsusing a discsander (or youcan try doing itby hand using asanding block).

Now it is asimple matter ofstacking the ringsinto a bowl form.Start by attach-ing the bottompiece onto awaste block (seeFig. 10). Makesure that yourwaste block is atleast 1" thicker than the penetration of the mountingscrews. This will allow you to “turn” the waste block to create easy access to the lower portion of the bowl.Obviously, the base must be as centered as possible; an easy method is to use the lathe’s tailstock as a clampand centering device.

Bandsaw layout lines.

Fig. 6

Cutting half-rings with the bandsaw.

Fig. 7

Lathe-mounted bottom ring.

Fig. 10

Half-rings ready to be glued.

Fig. 8

Assembled full rings.

Fig. 9

WTD 54-58 10/7/05 12:58 PM Page 56

GLUE-UPBefore gluing on the next ring, decide upon your layout.For this bowl, I created a spiral effect, but other arrange-ments are possible. Dry stack them and explore designpossibilities. To achieve nice tight horizontal glue lines, thesurfaces must be perfectly flat and smooth. It is best toglue the rings one at a time. Create a slightly recessedcenter on the vessel base, leaving about a 1/4" flat rimaround the outside. Hold a straight edge across the bot-tom rim surface, and shine a small flashlight under theedge to check for flatness. Strive for a very flat surfacewith your lathe tools, and then hold a small flat sandingblock against the glue joint for just a few seconds as thelathe spins. Be careful not to round the edges with thesanding block. It is always a good idea to check the surface one more time with the straight edge and flash-light before proceeding.

The next ring in the assembly should already besmooth and flat with the possible exception of the twohalf-ring joints. A tiny touch-up with a disc sander or a fewmanual swirling strokes on a piece of 80-grit sandpapershould eliminate any irregularities on the surface. Fig. 11shows the sec-ond ring as it isglued and clamp-ed to the base.For clampingpressure, just afew heavy face-plates and achuck are used.Again, becauseof the resin in thewood, epoxy isused for all thegluing steps. Exer-cise great careto ensure a cen-tered position. Isuggest wearingdisposable glovesand using yourfingertips aroundthe glue joint todetermine thecorrect position-ing. To achievethe correct rota-tional posit ion,make a few pen-cil marks during adry f it that youcan see duringthe gluing. Therest of the pro-ject simply requires repeating these steps until all the ringsare joined (see Fig. 12).

TURNINGAs layers are added, avoid the temptation of turningaway wall thickness until the assembly is completed. Then

Adding the second ring.

Fig. 11

The last ring has been added.

“Bowl for Sandy”

“Bowls for Cristie and Andy”

“Latin Curves”

Fig. 12

Fig. 13

Fig. 14

Woodturning Design Winter 2006 ● 57

Fig. 15

WTD 54-58 10/7/05 12:59 PM Page 57

the shift in woodturning from utilitarian to artistic. Histurned vessels are classical forms with modern design.He found beauty in imperfection, experimenting withcast off pieces of wood that others would considerscrap. In addition to exotic woods like South Americantulipwood, Cape ebony, and snakewood, flawed andgreen woods, such as spurs from the base of trees, were ripe material for Osolnik’s creations.

Osolnik taught workshops and seminars around theworld and received many awards including theSouthern Highlands Handicraft Guild LifetimeAchievement Award and the Kentucky Governor’sAward for Lifetime Achievement in the Arts. One of hisdesigns, his signature hourglass-shaped candlesticks(shown at left), earned him the Award of Good Designfrom the Furniture Association of America in 1955 andthousands were purchased by major department storesin the 1950s and 60s.

Fuller Craft Museum is located at 455 Oak Street inBrockton, Massachusetts. The museum is open dailyfrom 10:00 AM to 5:00 PM. Admission is $8.00 for adults,$5.00 for seniors and students, and is free for membersand children under 12. For more information, please visitwww.fullercraft.org.

shape the bowl’s outside profile using the available wallthickness. The exact turning technique is your choice. I didmy shaping with a small bowl gouge followed by lightshear scraping. The bowl’s interior should be done last.Because of the strength of the material, you can carefullycreate a very thin finished wall thickness. This particular lit-tle bowl’s wall thickness is about 0.05", and it is still quitesturdy. Sanding the surfaces to at least 600 grit is recom-mended. Avoid aggressive power sanding, and definitelyavoid overheating the surfaces during sanding.

Regarding finish, the choice is yours. The resin-impregnated wood polishes quite nicely without any finish,but you will want to apply at least a couple of coats ofprotection. Either buffed lacquer or oil will work nicely.

This technique is certainly not limited to tiny bowlsmade from pen blanks. Shown on the previous page arejust a few other examples of bowls that range from about7" to 12" in diameter (see Figs. 13, 14, and 15). While it is difficult to detect, “Bowl for Sandy” has five horizontalseams, and it was constructed the exact same way; how-ever, instead of offsetting the arrangement of layers, thelayers were stacked precisely as they originally existed. To achieve the design in “Bowls for Cristie and Andy,” Icreated two identical bowls and then mixed the half-rings.In other words, I glued the half-rings of one assembly tothe opposite half-rings of the other assembly. For the bowl“Latin Curves,” the effect was more complicated. I creat-

Malcolm Tibbetts

Malcolm lives in South Lake Tahoe,California, with his schoolteacherwife, Tere. After a long career inthe ski industry and raising twochildren, he now works as a full-time wood artist. Around 1993,after many years as an amateur

woodworker, Malcolm became “hooked” by the lathe.His turnings have won many awards, and he has piecesin prestigious collections around the world. He is theauthor of The Art of Segmented Woodturning, publishedby Linden Publishing.

Malcolm welcomes your questions and commentsand can be reached by e-mail at [email protected]. View more of Malcolm’s work on his website atwww.tahoeturner.com.

ed the initial lamination differently. Instead of the compo-nents being parallel like in a cutting board, they were alloriented at a 45° angle.

Use your imagination and have fun as you create seg-mented bowls with no math, no miter joints, very littlewaste, and the potential to discover unique designs.

Regarded as the father of contemporary Americanwoodturning, Rude Osolnik gained fame for literallyturning scrap woodinto bowls, vessels,and candlesticks. Over30 of his best knownpieces will be featuredin Rude Osolnik: ALifetime of Turning, onexhibit at Fuller CraftMuseum from October22, 2005 to February19, 2006.

Osolnik (1915-2001) spent 60 yearsturning, teaching, andinspiring a generationof woodturners. Helived most of his life inKentucky and spent 40years teaching in theIndustrial Arts Depart-ment at Berea College. Along with Mel Lindquest, BobStocksdale, and Edward Moulthrop, Osolnik pioneered

58 ● Woodturning Design Winter 2006

Rude Osolnik: A Lifetime of TurningOctober 22, 2005 to February 19, 2006

WTD 54-58 10/7/05 9:50 AM Page 58