Overview of Common Aerospace Aluminum Alloys - 2024,...

Transcript of Overview of Common Aerospace Aluminum Alloys - 2024,...

Page 1 of 19

Sean Caetano

2.821: Structural Materials

April 1, 2017

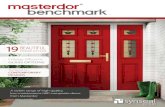

Overview of Common Aerospace Aluminum Alloys:

2024, 6061, and 7075

1. Introduction

Since the birth of the aerospace industry, aluminum has played a vital role in its

advancement. In 1903 with the Wright brothers cast their airplane’s engine block out of

a high copper composition aluminum alloy. From there, aluminum’s unique properties,

particularly as an alloy, have allowed aluminum to remain as the primary material for

aircraft manufacture.

Aluminum has many useful properties, including: ease of fabrication and

machining, corrosion resistance due to a tightly held and rapidly forming oxide layer,

good thermal and heat conductivity, non-‐ferromagnetic, non-‐pyrophoric, non-‐toxic, and

a relatively low density weighing in at only 2.7g/cm3, compared to 7.8g/cm3 for steel. [1]

The purpose of this research paper is to give an overview of the three most

common aluminum alloys found in aerospace namely 2024, 6061, and 7075. However,

for completeness, we begin by examining the general numerical designation system for

aluminum alloys. During this investigation we will explore important characteristics and

forming processes that govern aluminum alloys along with direct examples pertaining to

Page 2 of 19

2024, 6061, and 7075. With a firm understanding from our investigation we finish with

an overview of 2024, 6061, and 7075.

2. Aluminum Designation System

Aluminum alloys and their intrinsic alloying elements combined with the forming

process result in a microstructure with physical, mechanical, and chemical properties

very different from the original raw aluminum. [1] In the United States the most

common aluminum alloy designation system is that of the Aluminum Association (AA)

who is responsible for the database and registration of aluminum alloys. AA primarily

designates aluminum alloys by their means of manufacture by dividing them into two

fundamental groups: wrought and cast. Wrought alloys are those that are formed by

mechanical work such as rolling or hammering and have a 4-‐digit designation (XXXX).

Cast alloys on the other hand are those that are formed by pouring molten alloy into a

die or mold to form the desired shape and have a 3-‐digit and one decimal place

designation (XXX.X). [2] In 1954 AA had 75 active registered compositions of aluminum

alloys while in 2015 that number reached 530 and continues to grow. [3] Cast aluminum

alloys are relatively rare in aerospace applications and are unusually limited to non-‐

structural applications; as such this research paper will focus on wrought aluminum

alloys.

Page 3 of 19

2.1. Wrought Aluminum Alloy Series Designation

The first number in the wrought designation system describes the series of the alloy and

is specified based on the principle-‐alloying element other than aluminum. Table 1

outlines the principal alloying element for each wrought aluminum series.

Table 1: Wrought Aluminum Series Designation [2]

Alloy Series Principal Alloying Element

1XXX 99.000% Minimum aluminum content

2XXX Copper

3XXX Manganese

4XXX Silicon

5XXX Magnesium

6XXX Magnesium and Silicon

7XXX Zinc

8XXX Other Elements

The last two designation numbers of each series two through seven (2XXX –

7XXX) are simple numerical identifiers and identify the alloy within each series. Note: for

series one (1XXX) the last two digits signify the aluminum purity above the 99%

minimum requirement.

The second number in each series designates the modification from the original

alloy (X0XX). Consequently, if the second number in the designation is a zero then that

Page 4 of 19

specific alloy was the original alloy specified in that series with the unique identification

of the last two digits. For example, 2024 is the original alloy 24 specified in the 2000

aluminum series. Beyond series designation, Al alloys are further specified based on

tempering which we will discuss in the next section.

2.2. Wrought Aluminum Alloy Tempering Designation

There are five different temper designations allocated to aluminum alloys and

are summarized in Table 2 below.

Table 2: Wrought aluminum alloy tempering designation [2]

Temper Letter Designation

F As-‐Fabricated – No thermal or strain hardening employed

O Annealed – Material is in purely annealed state

H Strain Hardened – Material is cold worked and can be

followed by post thermal treatment to moderate hardening

W Solution Heat Treated – Unstable Al alloys that spontaneously

hardens after solution heat treatment

T Thermally Treated – Uses heating and quenching to harden

alloy, potentially with supplemental cold working.

Page 5 of 19

The two most common techniques to harden an alloy are heat treatment (T) or

strain hardening (H). Each aluminum alloy series lends itself to a certain hardening

process.

2.2.1 Thermally Treated: Series 2XXX, some 4XXX, 6XXX, and 7XXX aluminum alloys

Can be heat treated to increase the strength of the material and therefore will have the

“T” designation. Heat treatment of an Al alloy typically requires three stages:

1. Solution heat treatment: The alloy is subjected to elevated temperatures for a

long enough period to dissolve all hardening elements into the solid aluminum

alloy solution

2. Quenching: Cooling the alloy (usually rapidly with water) to produce a

supersaturated solution from the solid alloy solution formed during solution heat

treatment.

3. Age hardening: Depending on the alloy’s composition, aging further increases

the alloy’s strength by allowing the hardening elements to precipitate in a

controlled fashion, creating an ordered array of atoms in the aluminum alloy

matrix and less susceptible to dislocation movement and hence increased

strength. There are generally two types of aging: natural and artificial. [1] [2] [4]

3.1. Natural Aging: Allowing the alloy to sit at room temperature for a given

period of time. Figure 1 demonstrates how the tensile yield strength of

three solution heat treated Al alloys (2024, 6061, and 7075) increases as

they are naturally aged over time.

Page 6 of 19

Figure 1: Natural aging curves for 2024-‐T4, 6061-‐T4, and 7075-‐W [1]

3.2. Artificial Aging (Precipitation Heat Treating): This increases the rate of

aging by elevating the alloy to a modest temperature (325F – 400F).

However, holding the alloy at the elevated temperature for too long causes

the precipitate particles to continue to grow and convert to the equilibrium

phases as the material transforms to the annealed condition. Figure 2

demonstrates the effect of temperature and time has on the artificial age

hardening process on 6061. [1]

Page 7 of 19

Figure 2: Artificial aging curves for solution heat treated 6061 alloy [1]

The thermally treated “T” designation is also paired with a numerical digit that specifies

the specific heat treatment process. There could also be a supplemental “51” or “52”

indicating stress relieving by stretching or compressing respectively. The specific heat

treatment processes drives the hardness properties of the aluminum alloy and are

summarized in Table 3 overleaf. [2]

Page 8 of 19

Table 3: Wrought aluminum alloy heat treatment temper designation [1]

T Temper Heat Treat Process

T1 Cooled and naturally aged after elevated temperature forming

T2 Cold worked after cooling from elevated temperature forming

and naturally aged

T3 Solution heat treated, cold worked, and naturally aged

T4 Solution heat treated and naturally aged

T5 Artificially aged after cooling from elevated temperature

shaping process

T6 Solution heat treated and artificially aged

T7 Solution heat treated and over-‐aged

T8 Solution heat treated, cold worked, and artificially aged

T9 Solution heat treated, artificially aged, and cold worked

T10 Cold worked after cooling from elevated temperature shaping

process and then artificially aged

TX51 or TXX51 Stress relieved by stretching

TX52 or TXX52 Stress relieved by compressing

Referring to Table 3 above, 2024-‐T651 is a solution heat-‐treated aluminum alloy

that is artificially aged and stress relived by stretching.

Page 9 of 19

2.2.2 Strain Hardened: Series 1XXX, 3XXX, some 4XXX, and 5XXX aluminum alloys

These aluminum alloys are not heat-‐treated but are instead hardened purely by

plastically deformation through a process called cold working (strain hardening) and are

addressed with the temper specification “H”. [5] Similarly to T temper, H temper is

always followed by digits. The first digit specifies the basic operation of strain hardening

and the second digit specified the degree to which the alloy was strain hardened, see

Table 4 below.

Table 4: Wrought aluminum alloy strain hardening temper designation [2]

H Temper Meaning

H1 Strain hardened

H2 Strain hardened and partially annealed

H3 Strain hardened and over-‐aged

H4 Strain hardened and lacquered or painted

HX2 Quarter hard

HX4 Half hard

HX6 Three-‐quarters hard

HX8 Full hard

HX9 Extra hard

Now that we have an understanding of the designation system the final important

characteristic to discuss before the common aerospace grade alloys is “Alclading”.

Page 10 of 19

3. Alclading

Aluminum and most aluminum alloys have excellent corrosion resistance due to the

tightly held aluminum oxide layer. However, aluminum alloys with moderate to high

copper content (greater than 1% w%), such as 2XXX and some 7XXX series, are more

susceptible to corrosion. To mitigate this issue, cathodic protection can be applied

through a process called alclading. Here the susceptible alloy is sandwiched between

two sacrificial sheets of very thin and near pure aluminum, see Figure 3 for an example

of 2024-‐T3 alloy. The alclading serves as an anode and is metallurgically bonded to the

alloy core. The electrode potential between the alloy core and the alclad is typically

between 80 to 100 mV. This cathodic protection drives the corrosion out radially from a

break in the alclad. Consequently the perforation corrosion resistance of thin parts such

as sheet metal and tubing greatly increases. [1]

Figure 3: Alclad alloy cross section

The thickness of alclad depends primarily on the thickness of the underlying

alloy. Using 2024 as an example, the alclad thickness is 5% on gauges less than 0.062”

while only 2.5% on gauges greater than 0.062”. [1] [6]

2024-‐T3 Alloy Alclad (high purity aluminum – 1230 alloy)

Page 11 of 19

4. Common Aerospace Grade Aluminum Alloys

Three of the most common aerospace grade aluminum alloys are 2024, 6061, and 7075.

In aerospace application the most important properties other than density are corrosion

susceptibility, stiffness, strength, and resistance to fatigue. Each of these physical,

mechanical, and chemical properties will be discussed in the following paragraphs.

4.1 2024 Overview

Principle Alloying Element: Copper

2024 was first introduced by Alcoa in 1931 and progressively overturned 2017-‐T4 as the

predominant 2XXX series alloy in the aerospace industry. [6] The first iteration of the

alloy was in alclad due to its susceptibility to corrosion from its high copper content;

refer to Appendix 1 for an overview of the composition of 2024. Overtime 2024 became

arguably the most popular aerospace grade material for aircraft structural applications

where stiffness, good strength and fatigue performance is required, such as aircraft

fuselages, wing tension members, and fasteners. [6] The high copper content of 2024

increases the thermal conductivity of the aluminum alloy and consequently reduces the

alloys applicability to welding. Thus, most aerospace parts made from 2024 are in the

form of folded sheet metal (anodized or alclad) or machined. The mechanical properties

of 2024, with respect to different tempers, are outlined in Appendix 2. Appendix 3 is an

exhaustive list of 2024 tempers, both with and without alclad.

Page 12 of 19

4.2 6061 Overview

Principle Alloying Element: Magnesium and Silicon

While not matching the strength or fatigue performance of 2024, 6061 is still a very

popular aluminum alloy in the aerospace industry, particularly in light aircraft, due to its

superior workability (welding, machining, and fabrication) and corrosion resistance. The

principal alloying elements of 6061 are Silicon and Magnesium while housing a very low

copper content (refer to Appendix 1 for 6061 composition) resulting in high natural

corrosion resistance. Furthermore, the low copper content also makes this alloy a good

candidate for welding. The T-‐tempers of 6061 are strong enough for most general-‐

purpose applications. The most common 6061 alloy used in the aerospace industry is

6061-‐T6 where components are usually in the form of machined extrusions and a

mixture of structural and non-‐structural fabricated and machined parts. [1]

4.3 7075 Overview

Principle Alloying Element: Zinc

One of the strongest aluminum alloys, 7075, is the most popular aluminum alloy for

critical structural applications where high strength is required. Introduced in 1943 with

T6 temper, 7075-‐T6 quickly became the aluminum alloy of choice for high strength

applications. An even higher strength 7XXX series alloy (7178-‐T6) was introduced in

1951, however, unlike the success seen by 2024 overturning 2017, 7075-‐T6 has

remained the predominant critical structural aluminum alloy to this day partly due to its

superior fracture toughness. Apart from its strength, 7075 has the addition of chromium

Page 13 of 19

that serves to resist stress corrosion cracking and hence good corrosion resistance. [7]

Refer to Appendix 1 for an overview of 7075-‐T6’s superior strength properties while

maintaining moderate fatigue resistance.

5. Summary

2024, 6061, and 7075 are arguably the most popular aerospace grade aluminum alloys

used in the industry. This paper’s investigation began with understanding the 4 digit

(XXXX) numerical designation system of wrought aluminum alloys. The first, second, and

last two alloy digits signify the principal alloying element, alloy version, and series alloy

identifier respectively. Each alloy can be tempered to alter the mechanical properties.

The tempering process depends on the alloys metallurgy where all 2024, 6061, and 7075

alloys are thermally treated and given a letter designators “T” and a corresponding digit

depending on the specific thermal treatment process.

2024 has a relatively high copper content and as a consequence is susceptible to

corrosion. A cathodic protection method called Alclading is a common technique used

to protect thin parts made from 2024. Alclad is also available for 6061 and 7075 in sheet

metal and plate forms.

2024 is the most common aerospace grade material used on commercial aircraft

and is often a designer’s material of choice that requires good strength and fatigue

resistance. While the high copper content makes 2024 susceptible to corrosion it also

increases the alloys thermal conductivity and not suitable for welding.

Page 14 of 19

6061 has superior workability (welding, machining, and fabrication). While not

having the strength of 2024, it is still very common in aerospace, particularly in light

aircraft for non-‐structural applications. 6061-‐T6 is the most common 6061 alloy and is

often the material of choice for machined extrusions.

7075 is one of the strongest aluminum alloys with strengths similar to mild steels

and is a very popular material choice for high strength aircraft structural applications.

Understanding the properties and common applications of 2024, 6061, and

7075, an aerospace design engineer will be able to achieve the vast majority of their

part design requirements.

Page 15 of 19

6. Bibliography

[1] Joseph R. Davis, "Aluminum and Aluminum Alloys," in Metals Handbook, 2nd, Ed.

OH: ASM International.

[2] ESAB knowledge center. (2014, March) ESAB. [Online].

http://www.esabna.com/us/en/education/blog/understanding-‐the-‐aluminum-‐alloy-‐

designation-‐system.cfm [Accessed: Feb. 28, 2017]

[3] The Aluminum Association. (2017) The Aluminum Association. [Online].

http://aluminum.org/aluminum-‐advantage/infographic-‐gallery/aluminum-‐alloys-‐101

[Accessed: Feb. 28, 2017]

[4] Total Materia. (2002, April) Total Materia. [Online].

http://www.totalmateria.com/Article39.htm [Accessed: Mar. 5, 2017]

[5] E. Paul Degarmo, J T. Black, and Ronald A. Kosher, Materials and Processes in

Manufacturing , 9th ed. New York: Wiley, 2003.

[6] Alcoa, "Alloy 2024 Sheet and Plate," Alcoa Mill Products, Inc., Specification.

[7] Alcoa, "Alloy 7075 Plate and Sheet," Alcoa Mill Products, Specification.

Page 16 of 19

Appendices

Appendix 1: Composition limits for wrought aluminum alloys [1]

Composition w%

AA No. Si Fe Cu Mn Mg Cr Zn Ti Supplier and purchaser specified other

elements

2024 0.5 0.5 3.8-‐4.9 0.3-‐0.9 1.2-‐1.8 0.1 0.25 0.15 Zr + Ti limit of 0.20% max for extruded and

forgings only

6061 0.4-‐0.8 0.7 0.15-‐0.4 0.15 0.8-‐1.2 0.04-‐0.35 0.25 0.15

7075 0.4 0.5 1.2-‐2.0 0.3 2.1-‐2.9 0.18-‐0.28 5.1-‐6.1 0.2 Zr + Ti limit of 0.25% max for extruded and

forgings only

Page 17 of 19

Appendix 2: Typical Mechanical Properties of 2024, 6061 and 7075 [1]

Ultimate Tensile

Strength Tensile Yield Strength

Hardness,

HB (a)

Ultimate Shearing

Strength

Fatigue Endurance

limits (b)

Modulus of Elasticity

(c)

Alloy and Temper MPa ksi MPa ksi MPa ksi MPa ksi GPa 106 psi

2024-‐O 185 27 75 11 20 22 47 125 18 73 10.6

2024-‐T3 485 70 345 50 18 -‐ 120 285 41 73 10.6

2024-‐T4, T351 470 68 325 47 20 19 120 285 41 73 10.6

6061-‐O 125 18 55 8 30 85 12 60 9 69 10.0

6061-‐T4, T451 240 35 145 21 65 165 24 95 14 69 10.0

6061-‐T6, T651 310 45 275 40 95 205 30 95 14 69 10.0

7075-‐O 230 33 105 15 60 150 22 -‐ -‐ 72 10.4

7075-‐T6, T651 570 83 505 73 150 330 48 160 23 72 10.4

(a) 500 kg load and 10mm ball.

(b) Based on 500,000,000 cycles of completely reversed stress using the R.R. Moore type machine and specimen.

(c) Average of tension and compression moduli. Compression modulus is about 2% greater than tension modulus.

NOTE: Alclad alloy products have slightly lower mechanical performance due to a part’s cross-‐section including the soft alclad layers.

Page 18 of 19

Appendix 3: 2024, 6061, and 7075 Wrought Alloy Tempers [1]

Tube Forgings and

Forgings

Stock Alloy Sheet Plate Drawn Extruded Pipe

Structural

Profiles Extruded Rod Bar Wire Rivets

2024

O, T3, T361,

T4, T72,

T81, T861

O, T351,

T361, T851,

T861

O, T3 O, T3,

T3510,

T3511, T81,

T8510,

T8511

O, T3,

T3510,

T3511, T81,

T8510,

T8511

O, H13,

T351, T4,

T6, T851

O, T351, T4,

T6, T851

O, H13,

T36, T4, T6

T4

2024 Alclad

O, T3, T361,

T4, T81,

T861

O, T351,

T361, T851,

T861

2024 Alclad

(one side)

O, T3, T361,

T81, T861

O, T351,

T361, T851,

T861

2024 1.5%

Alclad

O, T3, T361,

T81, T861

O, T351,

T361, T751,

T861

2024 1.5%

Alclad (one

side)

O, T3, T361,

T81, T861

O, T351,

T361, T851,

T861

Page 19 of 19

6061

O, T4, T6 O, T451,

T651

O, T4, T6 O, T1, T4,

T4510,

T4511, T51,

T6, T6510,

T6511

T6 T6 O, T1, T4,

T4510,

T4511, T51,

T6, T6510,

T6511

O, H13, T4,

T451, T6,

T651

O, T4, T451,

T6, T651

O, H13, T4,

T6, T89,

T913, T94

T6 F, T6, T652

6061 Alclad O, T4, T6 O, T451,

T651

7075

T6, T73, T76

T6511,T73,

0, T651,

T7351,

T7651

O, T6, T73 O, T6,

T6510,

T6511, T73,

T73510,

T73511

O, T6,

T6510,

T6511, T73,

T73510,

T73511,

T76,

T76510,

T76511

O, H13, T6,

T651, T73,

T7351

O, T6, T651,

T73, T735

O, H13, T6,

T73

T6, T73 F, T6, T652,

T73, T7352

7075 Alclad

O, T6, T73,

T76

O, T651,

T7351,

T7651

![Untitled Document [eagar.mit.edu]eagar.mit.edu/handouts/H-3371-17.pdf · Title: Untitled Document Created Date: 9/12/2002 8:20:24 PM](https://static.fdocuments.net/doc/165x107/5c8f435009d3f2ec738c56b0/untitled-document-eagarmitedueagarmiteduhandoutsh-3371-17pdf-title.jpg)