Outershield 71-CX wire... · Lincoln Electric . Outershield ... from the ingredients listed above....

Transcript of Outershield 71-CX wire... · Lincoln Electric . Outershield ... from the ingredients listed above....

Outershield® 71-CX

www.lincolnelectric.com.au

Lincoln Electric

Outershield® 71-CX

www.lincolnelectric.com.au

Q3.85A (02/08)

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0

2/16 www.lincolnelectric.com.au

Outershield® 71-CX

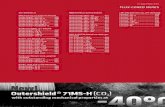

OVERVIEWDesigned and manufactured in Australia, Outershield® 71-CX is an all positional rutile based micro-alloyed wire. Outershield® 71-CX provides an extremely smooth arc transfer, with excellent “ease of use” making good out of position welds with a clean surface finish under 100% CO2 shielding gas.

WELDING POSITIONS

1.2 13.0 936 033602

1.6 13.0 936 033606

Diameter mm (in.)

Spool Weight (kg)

Pallet Weight (kg) Part number

DIAMETERS / PACKAGING

ADVANTAGE LINCOLN®

•ExcellentmechanicalpropertiesandlowHydrogenlevels

•Allposition,singleandmultiplepasswiredesignedtojoinsteelsof490-650MPatensileclass

•Smoth,spraytypearctransferandlowspatterlevelandeasyslagremoval

•Slagsystemprovidesforweldpoolsupport,goodwettingandbeadshapeinallpositions

•Grade3ShippingApprovals(Pending)

MEChANICAL PROPERTIES – ‘As welded’ per AWS A5.20 & AS2203.1

1G 2F 2G

5G

TYPICAL APPLICATIONS•Heavyequipment

•Bridge,ship,bargeoroffshoredrillingrigconstruction

•Machineryfabrication

•Structuralfabrication

•Generalfabrication

CLASSIFICATION:AWSA5.20E71T-1H8E71T-9H8&E71T-12H8

AS2203.1ETP-GCp-W503ACM1H10

3G 4G

DIFFuSIbLE hYDROGEN

Carbon Dioxide 6-7mls / 100gms

Shielding gas Typical results

RequirementsYield Strength MPa

(ksi)Tensile Strength MPa

(ksi)Elongation % Charpy V-notch J(ft-lbs)

AWS E71T-1 400 (58) 480 (70) 2227J @ -18ºC

(20 ft.lb @ -0ºF)

AWS E71T-9 400 (58) 480 (70) 2227J @ -18ºC

(20 ft.lb @ -0ºF)

AWS E71T-12 400 (58) 480 - 620 (70-90) 2227J @ -18ºC

(20 ft.lb @ -0ºF)

AS ETP-GCp-503A. CM1 360 490 - 650 22 47J @ -20ºC

Results Typical with 100% CO2

525 600 27 120J @ -20C

COMPETITOR bRANDSESAB®7100UltraHyundai®Supercored71KOBE®DW100Cigweld®Verti-CorUltra

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0

3/16www.lincolnelectric.com.au

Outershield® 71-CX

DEPOSIT ChEMISTRY (1), (2)

Requirements %C %Mn %P %S %Si %Ni

AWS E71T-1 & T-9 0.18 1.75 0.03 0.03 0.90 0.50

AWS E71T-12 0.15 1.60 0.03 0.03 0.90 0.50

AS ETP-GCp-503A CM1h10 0.20 1.75 0.040 0.030 0.90 0.50

Test Results Typical with 100% CO2

0.02 1.25 0.015 0.015 0.52 0.35

(1)Allweldmetal(2)Singlevaluesaremaximum

TYPICAL OPERATING PROCEDuRES

Wire Polarity ESO mm (inches)

Wire Feed Speed (in./min.)

Voltage (V)

Approx. Current (A)

Deposition Rate (kg/h)

1.2mm DC+ 1 9mm (3/4)

200 22 -25 180 2.0

250 23 - 27 200 2.5

300 24 - 30 230 3.0

350 27 - 31 250 3.6

400 28 - 32 280 4.0

500 28 - 33 350 5.0

1.6mm DC+ 1 9mm (3/4)

125 23 -27 200 2.1

150 23 -27 230 2.5

175 24 -27 250 2.9

200 24 -29 270 3.3

250 25 -30 320 4.4

300 28 -31 350 5.1

350 29 -32 390 6.0

400 30 -34 440 7.1

N.B.Whensettingparametersforwelding,itisrecommendedthatvoltsshouldbesetatthemedianofthevoltagerangeandadjustedtosuiteachapplicationandindividualoperator.

ForexampleIf1.2mmdiameterwireissetat300in/min,thenthestartingvoltageshouldbe27Vandadjustedwithintherangerecommended.

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0

Outershield® 71-CX

4/16 www.lincolnelectric.com.au

AWS A5.20 CLASSIFICATION - FLux-CORED WIRES

Outershield® 71-CX

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0

Outershield® 71-CX

5/16www.lincolnelectric.com.au

MATERIAL SAFETY DATA SHEET For Welding Consumables and Related Products

Page 1 of 3 page(s)

Ref: US-CW364 PK21 Supersedes: New

Trade Name: Outershield 71CX Sizes: All Date: Jan 06 No. 4422000

STATEMENT OF HAZARDOUS NATURE

Hazardous according to criteria of Worksafe Australia.

COMPANY DETAILS

Company: The Lincoln Electric Company (Australia) Pty. Ltd. Address: 35 Bryant Street Padstow, NSW, 2211 Telephone Number: (02) 9772 7222 Emergency Telephone Number (AH): (02) 9772 7251

IDENTIFICATION

Product Name: Outershield 71-CXOther Names: Manufacturer’s Product Code: UN Number: None allocated Dangerous Goods Class and Subsidiary Risk: None allocated Hazchem Code: None allocated Poisons Schedule Number: None allocated Use: Flux cored arc welding electrode.

Physical Description/Properties

Appearance: Grey steel wire Boiling Point/Melting Point: >1300°C Vapour Pressure: N/A ( steel wire) Specific Gravity: N/A. (steel wire) Flashpoint: N/A Flammability Limits: Non flammable Solubility in Water: Insoluble

Ingredients

Chemical Name: CAS Number: Proportion:

Carbon Steel Tube 7439-89-6 85% Core compositionTitanium dioxides (as Ti) 13463-67-7 <5% Iron 7439-89-6 <5% Manganese and/or Mn alloys and compounds (as Mn) 7439-96-5 <5% Magnesium and/or Mg alloys and compounds (as Mg) 7439-95-4 0.5% Aluminium oxide &/or bauxite 1344-28-1 <0.5% Silicon and/or Silicon alloys and compounds (as Si) 7440-21-3 <0.5% Mineral Silicates 1332-58-7 <0.5% Nickel (metal) 7440-02-0 <0.5% Fluorides (as F) 7789-75-5 <0.5%

Outershield® 71-CX

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0

Outershield® 71-CX

6/16 www.lincolnelectric.com.au

MATERIAL SAFETY DATA SHEET For Welding Consumables and Related Products

Page 2 of 3 page(s)

Ref: US-CW364 PK21 Supersedes: New

Trade Name: Outershield 71CX Sizes: All Date: Jan 06 No. 4422000

HEALTH HAZARD INFORMATION

Hazardous Decomposition Products: Welding fumes and gases cannot be classified simply. The composition and quantity of both are dependent upon the metal being welded, the process, procedure and electrodes used.

Other conditions which also influence the composition and quantity of the fumes and gases to which workers may be exposed include: coatings on the metal being welded (such as paint, plating or galvanising), the number of welders and the volume of the worker area, the quality, and amount of ventilation, the position of the welder’s head with respect to the fume plume, as well as the presence of contaminants in the atmosphere (such as chlorinated hydrocarbon vapours from cleaning and degreasing activities).

When the electrode is consumed, the fume and gas decomposition products generated are different in percent and form from the ingredients listed above. Decomposition products of normal operation include those originating from the volatilisation, reaction, or oxidation of the materials shown above, plus those from the base metal and coating, etc. as noted above.

Reasonably expected fume constituents of this product would include: Primarily iron oxide and fluorides; secondarily complex oxides of manganese, potassium, silicon, sodium and titanium.

Maximum fume exposure guidelines and PEL for this product is 5.0 mg/m³.

Gaseous reaction products may include carbon monoxide and carbon dioxide. Ozone and nitrogen oxides may be formed by the radiation from the arc.

Determine the composition and quantity of fumes and gases to which workers are exposed by taking an air sample from inside the welder’s helmet if worn or in the worker’s breathing zone. Improve ventilation if exposures are not below limits. See ANSI/AWS F1.1, F1.2, F1.4, and F1.5, available from the Welding Technology Institute of Australia, PO Box 6165, Silverwater, NSW 2128

Arc Rays can injure eyes and burn skin. Skin cancer has been reported.

Electric shock when not used in accordance with manufacturers recommendations

Health Effects

AcuteSwallowed: Metallic wire. Not a likely source of exposure.

Eye: Arc rays from electric arc welding can injure eyes.

Skin: Not irritating to the skin. Arc rays can cause burns to the skin.

Inhaled: Short-term overexposure to welding fumes may result in discomfort such as metal fume fever, dizziness, nausea, or dryness or irritation of nose, throat, or eyes. May aggravate pre-existing respiratory problems (eg. Asthma, emphysema). Exposure to extremely high levels of fluorides can cause abdominal pain, diarrhoea, muscular weakness and convulsions. In extreme cases can cause loss of consciousness and death. Maximum fume exposure guideline for this product is 5.0 mg/m³

Chronic:Long-term overexposure to welding fumes can lead to siderosis (iron deposits in lung) and may affect pulmonary function. Manganese overexposure can affect the central nervous system, resulting in impaired speech and movement. Bronchitis and some lung fibrosis have been reported. Repeated exposure to fluorides may cause excessive calcification of the bone and calcification of ligaments of the ribs, pelvis and spinal column. May cause skin rash.

First Aid

Outershield® 71-CX

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0

Outershield® 71-CX

7/16www.lincolnelectric.com.au

MATERIAL SAFETY DATA SHEET For Welding Consumables and Related Products

Page 3 of 3 page(s)

Ref: US-CW364 PK21 Supersedes: New

Trade Name: Outershield 71CX Sizes: All Date: Jan 06 No. 4422000

Swallowed: Seek medical aid.

Eye: In the event of severe arc radiation exposure seek immediate medical attention.

Skin: In the event of severe arc radiation exposure seek immediate medical attention.

Inhaled: Remove from fume exposure. If breathing has stopped perform expired air resuscitation E.A.R. and seek immediate medical attention.

Advice to Doctor Treat symptomatically.

PRECAUTIONS FOR USE

Exposure Standards: Maximum welding fume exposure guideline for this product is 5.0 mg/m³

Engineering Controls: When welding use enough ventilation, local exhaust at the arc, or both to keep the fumes and gases from the workers’ breathing zone. Keep exposure as low as possible. Train the welder to keep his head out of the fumes. Keep exposure as low as possible.

Personal Protection: Respiratory Protection: Use respirable fume respirator or air supplied respirator when welding in confined space or general work area when local exhaust or ventilation do not keep exposure below TLV.

Eye Protection: Use flash goggles to avoid accidental arc radiation exposure. Protective Clothing: Wear head, hand and body protection which helps to prevent injury from UV radiation, sparks and electrical shock.

Flammability: This product is not flammable, but welding arc and sparks can ignite combustibles.

SAFE HANDLING INFORMATION

Storage and Transport: Store in original containers in a dry area away from moisture. Not defined as a Dangerous Good as per the Australian Code for the Transport of Dangerous Goods.

Spills and Disposal: No special procedures required. Discard any product, residue, disposable container, or liner as ordinary waste in an environmentally acceptable manner according to Federal, State and Local Regulations unless otherwise noted.

Fire/Explosion Hazard: Non flammable. Welding arcs and sparks can ignite combustibles.

CONTACT POINT

Contact Person Welding Technology and QA Manager (02) 9772 7285

Outershield® 71-CX

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0

Outershield® 71-CX

8/16 www.lincolnelectric.com.au

WELDING PROCEDuRE RECOMMENDATION – SAMPLE ONLYWPS No:71-CX1.22F Rev.:2 Date:18May,2007

Contractor Client

WeldingCode Madeat ProjectNo.

WELDING PROCESS FCAW POSITION WELDERS AND OPERATORS

base material AS3678Gd250 to 3F WTC

Joint type Filter

Plate thickness 10mm

Plate Dimensions 75x300mm

Welding equipment

IdealArc®DC400PowerSource

Interpasstemp

250C max

DH10WirefeederPreheat Ambient min

Reheat Nil

WELDING CONSuMAbLES

Electrode Shielding flux Shielding gas

Electrode Manufacturer Dia. Trade name Lot No. Trade name Lot No. Type – Mix

ALincoln Electric

(AS 2203.1 Class) (AWS A5.20 CLASS)

1.2mmOutershield® 71-CX ETP W503 CM1 H10

E71T-1 H8, E71T-12 H8FRL 09 n/a n/a

Carbon Dioxide

WELDING PARAMETERS

Electrode / shielding flux / gas A

Pass 1

Side 1

Gap mm 0-1

Electrode current / polarity DC+

CTWD mm 15

Voltage Volts 26

Wire Feed Speed ipm 290

Current Amps (approx) 230

Gas flow rate [L/min.] 18

Travel Speed mm/min 200

Heat Input [kJ/mm] 1.8

Fillet size mm 6

JOINT DETAIL

WELD PROFILE AND MACRO ETCh

10mm

10mm

6mm

Name : R.Kuebler - WTC Manager Authority sign/date: 6/2/2006

Signature

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0

Outershield® 71-CX

9/16www.lincolnelectric.com.au

JOINT DETAIL

WELDING PROCEDuRE RECOMMENDATION – SAMPLE ONLYWPS No: 71-CX1.23F Rev.:2 Date:18May,2007

Contractor Client

WeldingCode Madeat ProjectNo.

WELDING PROCESS FCAW POSITION WELDERS AND OPERATORS

base material AS3678Gd250 to 3F WTC

Joint type Filter

Plate thickness 10mm

Plate Dimensions 75x300mm

Welding equipment

IdealArc®DC400PowerSource

Interpasstemp

250C max

DH10WirefeederPreheat Ambient min

Reheat Nil

WELDING CONSuMAbLES

Electrode Shielding flux Shielding gas

Electrode Manufacturer Dia. Trade name Lot No. Trade name Lot No. Type – Mix

ALincoln Electric

(AS 2203.1 Class) (AWS A5.20 CLASS)

1.2mmOutershield® 71-CX ETP W503 CM1 H10

E71T-1 H8, E71T-12 H8FRL 09 n/a n/a

Carbon Dioxide

WELDING PARAMETERS

Electrode / shielding flux / gas A

Pass 1

Side 1

Gap mm 0-1

Electrode current / polarity DC+

CTWD mm 10

Voltage Volts 24

Wire Feed Speed ipm 185

Current Amps (approx) 175

Gas flow rate [L/min.] 18

Travel Speed mm/min 140

Heat Input [kJ/mm] 1.8

Fillet size mm 6

JOINT DETAIL

WELD PROFILE AND MACRO ETCh

10mm

10mm6mm

Name : R.Kuebler - WTC Manager Authority sign/date: 6/2/2006

Signature

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0

Outershield® 71-CX

10/16 www.lincolnelectric.com.au

WELDING PROCEDuRE RECOMMENDATION – SAMPLE ONLYWPS No:71-CX1.62F Rev.:2 Date:18May,2007

Contractor Client

WeldingCode Madeat ProjectNo.

WELDING PROCESS FCAW POSITION WELDERS AND OPERATORS

base material AS3678Gd250 to 3F WTC

Joint type Filter

Plate thickness 10mm

Plate Dimensions 75x300mm

Welding equipment

IdealArc®DC400PowerSource

Interpasstemp

250C max

DH10WirefeederPreheat Ambient min

Reheat Nil

WELDING CONSuMAbLES

Electrode Shielding flux Shielding gas

Electrode Manufacturer Dia. Trade name Lot No. Trade name Lot No. Type – Mix

ALincoln Electric

(AS 2203.1 Class) (AWS A5.20 CLASS)

1.6mmOutershield® 71-CX ETP W503 CM1 H10

E71T-1 H8, E71T-12 H8FRL 08 n/a n/a

Carbon Dioxide

WELDING PARAMETERS

Electrode / shielding flux / gas A

Pass 1

Side 1

Gap mm 0-1

Electrode current / polarity DC+

CTWD mm 20

Voltage Volts 28

Wire Feed Speed ipm 225

Current Amps (approx) 300

Gas flow rate [L/min.] 18

Travel Speed mm/min 200

Heat Input [kJ/mm] 2.5

Fillet size mm 8

10mm

10mm

8mm

JOINT DETAIL

WELD PROFILE AND MACRO ETCh

Name : R.Kuebler - WTC Manager Authority sign/date: 6/2/2006

Signature

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0

Outershield® 71-CX

11/16www.lincolnelectric.com.au

WELDING PROCEDuRE RECOMMENDATION – SAMPLE ONLYWPS No:71CX1.63F Rev.:2 Date:18May,2007

Contractor Client

WeldingCode Madeat ProjectNo.

WELDING PROCESS FCAW POSITION WELDERS AND OPERATORS

base material AS3678Gd250 to 3F WTC

Joint type Filter

Plate thickness 10mm

Plate Dimensions 75x300mm

Welding equipment

IdealArc®DC400PowerSource

Interpasstemp

250C max

DH10Wirefeeder Preheat Ambient min

WELDING CONSuMAbLES

Electrode Shielding flux Shielding gas

Electrode Manufacturer Dia. Trade name Lot No. Trade name Lot No. Type – Mix

ALincoln Electric

(AS 2203.1 Class) (AWS A5.20 CLASS)

1.6mmOutershield® 71-CX ETP W503 CM1 H10

E71T-1 H8, E71T-12 H8FRL 08 n/a n/a

Carbon Dioxide

WELDING PARAMETERS

Electrode / shielding flux / gas A

Pass 1

Side 1

Gap mm 0-1

Electrode current / polarity DC+

CTWD mm 15

Voltage Volts 23

Wire Feed Speed ipm 150

Current Amps (approx) 235

Gas flow rate [L/min.] 18

Travel Speed mm/min 140

Heat Input [kJ/mm] 2.3

Fillet size mm 8

JOINT DETAIL

WELD PROFILE AND MACRO ETCh

Name : R.Kuebler - WTC Manager Authority sign/date: 6/2/2006

Signature

10mm

10mm

8mm

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0

Outershield® 71-CX

12/16 www.lincolnelectric.com.au

TROubLE ShOOTING GuIDE

Problem Possible Cause Corrective Measures

Poor arc start

Poorconnection. Checkground(Earthclamp).

Gasnotturnedon. Checkgascylindervalve.

Wrongpolarity. CheckpolarityforDC+(Electrodemustbe+,thework-).

Faultycontrolcable.Checkcontrolcableconnection.Replacedefectivepartifnecessary.

burn-backs and arc-length fluctuations and general feeding issues

Wirefeedtooslow. Increasewirefeedspeed.

Improperdriverolls. Checkforcorrectsizeandtype.

Insufficientdriverollpressure. Increasepressure.

Contacttipdirty. Replacecontacttip.

Arcingincontacttip. Replacecontacttip.

Powercircuitfluctuations. Checklinevoltage.

Wrongpolarity. CheckpolarityforDC+(Electrodemustbe+,thework-).

Linerdirtyorworn. Replaceliner.

Driverollpressuretootight(flattenedcoredwirewillbindinliner)orbirdsnest.

Decreasepressureondriverolls.

Driverollstooloose.Holdrollofwirewithhand,ifdriverollsslip,tightendriverollpressure.

To Reduce Spatter

Shieldinggasinsufficient.Increasepressure.Protectarcfromdraughts(excesswind).Checkgashosefordamage.

Shieldinggaspressuretoohigh(causingturbulenceinweldpoolarea).

Adjustgaspressuretorecommendedsetting.

Travelangleoftorchtoogreat. Reduceangleoftorch.

Contaminantsonfillerwire(coredwirecanabsorbmoisture).

Preventbystoringwire,covered,inclean,dryarea.Donotopenwirepackageuntilreadyforuse.Keepspoolonweldercovered.Checkwirethathasbeenopenforanylengthoftimeforsurfacecontaminants.Ifanewspoolseemsoxidizedordirty,removetwoorthreeouterlayersanduseremainderonlyifitisclean.

Oily,dirtyliner. Replaceliner.

Hydrocarbon(Water,Oil,rust)contaminationonbasemetal.

Drybasematerialthoroughlycleanwithsolventorgrind.

Driverollslip.Increasepressureonrolls.Changesizeandtypeofrollstosuitwiresize.

Excessivebendingtorchcable.Minimizebendingofcablei.e.straightenguncablewherepossible.

undercut

Weldingspeedtoofast. Decreasetravelspeed.

Arcvoltagetoohigh. Reducevoltagesetting.

Incorrecttorchangle. Decreaseangleoftorchtofaceofmaterial.

Incorrecttechniquewhenweaving Pauselongerateachsideofweave.

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0

Outershield® 71-CX

13/16www.lincolnelectric.com.au

Problem Possible Cause Corrective Measures

Crater cracks Leavingcrateropenatendofweld.

Quicklyreversedirectionoftraveland“seal”thecrater.Speedrateoftravelapproachingendofweld,reducingsizeofweldpoolasarcisbroken.Userunofftabsattheendofweld.

Incomplete penetration / Fusion

Badjointdesign(Buttjoint). Checkrootopening,rootfacedimensions,includedangle.

Weldingspeedtoorapid. Slowtravelspeed.

Weldingcurrent/WFStoolow. Increaseweldingcurrent/WFS.

Arclengthtoolong. Reducevoltageorincreasewirefeedspeed.

Improperweldingangle. Changegunangle.

Incomplete fusion in fillets welds

Weldingspeedtoofast. Slowtravelspeed.

Weldingcurrent/Voltagetoolow. Increaseboth.

Arclengthtoolong. Reducevoltage.

Weldingangletoshallow. Decreasegunangle.

Dirtybasematerial. Grindexcessscalefrommaterial.

Welding cables overheating

Cablestoosmall. Checkcurrentrequirements.Replace.

Cableconnectionsloose. Check,tighten.

Incorrectcables. Checkcurrentcarryingcapacity.

Dirty welds

Shieldinggasinsufficient. (See“porosity”).

Dirtybasematerial. (See“porosity”).

Dirtyfillerwire. (See“porosity”).

Wormholing

Contaminatedbasematerial. Makesurebasemetalisclean,dryandfreefromhydrocarbons.

Shieldinggasinsufficient. Checkgasflowattorch,checkregulatorandconnections.

Wirehashydrocarboncontamination.

Makesurefillerwireisstoredaspermanufacturersrecommendations.

Dirtyliner. CleanlinerorChangeifrequired.

undesirable weld profiles (Vertical Stringer welds)

bead too convex very narrow, and dropping out

Insufficientvoltageorwirefeedspeedtoohigh.

Increasevoltageordecreasewirefeedspeed.

Travelspeedtoofast. Decreasetravelspeed.

Weld bead sagging in Middle

Basemetaltoohot. Waitfortemperaturetoreduce.

Voltagetoohighorwirefeedspeedtoolow.

Decreasevoltageorincreasewirespeedfeed.

Finished profile has “lumpy appearance”

Travelspeedtooslow. Increasetravelspeed.

Incorrecttorchangle. Torchangletostaybetween0ºand10ºtohorizontalplane.

Weld beads has lumpy appearance

Proceduretoohighforplatethickness.

Reducevoltsandwirefeedspeed.

Erratictravelspeed. Keepconstanttravelspeed.

ARC W

ELDIN

G SUPP

LIES

- 07

847

787

0