OSI OSI VOL. 7 ISSUE 4 | 2014 Jack-Up Barge · Jack-Up Barge is a worldwide well known supplier...

Transcript of OSI OSI VOL. 7 ISSUE 4 | 2014 Jack-Up Barge · Jack-Up Barge is a worldwide well known supplier...

Jack-Up Barge B.V.,Krausstraat 14-16 • 3364 AD Sliedrecht, The Netherlands • T +31 (0)184 420 091 • F +31 (0)184 419 596

[email protected] • www.jackupbarge.com

member of the Van Es Holding Group

Jack-Up Barge is a worldwide well known supplier when it comes to Jack-Up Barges and is specialized in the manufacturing, sales and rental of monohull and modular self elevating platforms. Additionally sister companies World Wide Equipment, PVE Cranes and Dieseko Group offer a wide range of floating and foundation equipment like crane barges, flat top barges, tug boats, anchors, winches, piling templates, hydraulic and diesel pile driving hammers, vibrators, crawler cranes and pile driving rigs. With a large network of offices worldwide, Jack-Up Barge enables you to perform successfully anywhere in the world.

Jack-Up Barge The Cl imbing Dutchman

Jackup platform JB118 in action at Borwin Alpha in the German Bight.

Jackup barge ad 2014.indd 1 27-02-14 14:26

OS

I 20

14

| VO

LU

ME

7 | IS

SU

E 4

O

NS

20

14

O

FF

SH

OR

E-IN

DU

ST

RY

.EU

Gemini CEO Speaks Out a gIaNT LEap FOR DUTcH OFFSHORE wIND

Whole in OnecOMpLETE pLaTFORM T&I

subsea norwayLONgER, DEEpER, cOLDER

i n d u s t r y

OSI VOL. 7 ISSUE 4 | 2014

Germany’s Helwin Bèta

36 | OSI 2014 | Vo lume 7 | I ssue 4 www.o f fshore- indus t r y.eu

FABR ICAT ION & ENGINEER ING

WSMU Functions

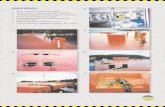

As well as sharing the dimensions of the DCV Aegir’s original RJ workstation, the final design of the WSMU at Scotland-based PTL also has the same functions enabling sequential welding and coating cycles.

External line up tool

Pipe hang offmodule under rotatingwelding floor

Control cabin for the RJ workstation coordinator

FABRICAT ION & ENGINEER ING

www.o f fshore- indus t r y.eu OSI 2014 | Vo lume 7 | I ssue 4 | 37

OnShORe TeSTing BenefiTS OffShORe OPeRaTiOnS

Mock-Up MissionTeSTing PiPe-Lay PROcedUReS and TRaining

OffShORe cReW in an OnShORe LOcaTiOn in

ScOTLand iS SafeR Than On-The-JOB LeaRning

aT Sea in PLaceS Like angOLa – and iT SaveS

valuable vessel time. completed on time and on

budget, kenc Oil & gas’ Workstation Mock-Up

(WSMU) is a custom-built facility that allows

heerema Marine contractors (hMc) to assess

equipment and staff prior to stepping aboard their

dcv aegir. The project’s three key players – from

kenc Oil & gas, Managing director eric Buining and

Project Manager cor hilbrink, and from hMc,

Pipeline Production coordinator arthur van Opstal

– tell the story.

Specific TestingServing as a testing platform for equipment and working procedures, kenc’s WSMU is a functional copy of dcv aegir’s pipe-lay workstation. The WSMU will bring numerous advantages: the crew will be trained, equipment tested and safety issues addressed, says Mr van Opstal from hMc’s Pipeline Production department (PPd). “Previous complex pipe-lay projects have proven that having a full scale testing environment in which we can identify new problem areas upfront is essential for the success of

operations offshore.” With exactly the same dimensions, positions and functions of movement as dcv aegir’s workstation, the WSMU will help the PPd ensure that offshore pipeline installation activities and equipment are ready for action. Mr van Opstal goes on to explain that the purpose of the WSMU is to train on- and offshore crew, simulate offshore production equipment operations, improve maintenance of the production equipment and identify and mitigate safety issues. “The main reason for creating a WSMU is to be >>

Tool manipulator

From left to right: KENC’s Cor Hilbrink and Eric Buining and Arthur van Opstal from HMC.

FABRICAT ION & ENGINEER ING

www.o f fshore- indus t r y.eu OSI 2014 | Vo lume 7 | I ssue 4 | 39

able to test specific pipeline production processes before the work is executed on board dcv aegir, thus minimising on-the-job lessons and any vessel time this may require.”

Tight Scheduleafter discussing various design options, hMc decided to build a WSMU that maintained the overall functions and dimensions as the original workstation on board dcv aegir. This is where kenc Oil & gas joined the team: the dutch engineering company were commissioned to design, manufacture and install the WSMU at Pipeline Technique Limited’s (PTL) facility in huntly, Scotland. in order to accommodate the WSMU, PTL’s premises had to undergo significant modifications: The roof had to be raised to make room for the external line up tool (eLUT) and a 3m deep pit had to be excavated to house the pipe hang off module (hOM).“due to the size of the project, we divided it into several parts,” informs Mr hilbrink. “This enabled streamlined production, assembly and installation.” kenc and PTL carefully coordinated the planning to ensure fast but safe and responsible installation. “We started production of the first components in december last year. The schedule was tight as the mock-up had to be operational in June.”after manufacture, assembly and electrical connection in the netherlands, kenc transported the whole project to Scotland, continues Mr hilbrink. after installation and load testing, the first instructors received their training. “These people will, in turn, train the operators. it’s good to hear from them that the WSMU is a very good representation of conditions on board. This has been a successful project for hMc and kenc.”

Full Automated Movement“The WSMU is suitable for working with pipe diameters from 6 to 28” at pipe-laying angles of between 90 to 50 degrees,” informs Mr Buining. “Two vertical pipe ends are aligned, welded and then inspected.” There is also an option to coat the pipes. in order to save material, the WSMU works with so-called PUPs. “These are short pieces of pipe that are used to test all work procedures and equipment.” The WSMU includes a manipulator for handling of

pipeline production equipment weighing up to 4,000kg. Under the rotating welding floor, the hOM aligns the lower half of the pipe with an accuracy of less than 0.1mm.kenc have realised the function of aegir’s pipe-lay tower with the so-called eLUT. “The eLUT positions pipe pieces below the desired angle of between 50 and 90 degrees in the firing line,” continues Mr Buining. “This represents a complete newly developed control system that allows fully automated movement of all equipment.” although the WSMU is functionally equivalent to the tower of the aegir station, each of the sub-systems described had been completely redesigned, he says. “This was necessary because the product it handles – PUPs – differ from the long pipe pieces on board.” different conditions apply in an onshore testing facility; for example, very high tensile forces are directed to the concrete floor. “despite the differences, the operation of the system is a reflection of the actual situation on board.”

High Level Project Executionkenc undertook all aspects of the WSMU project from design and manufacturing to

installation and training. They will also carry out any future maintenance of the set up. “We have shown that we are technically capable of executing such a high level project,” concludes Mr Buining. Smoothly completed on time and on budget, “this project highlights the growth that kenc has made in recent years. The development of the WSMU has been a key project for us.”

i. www.kenc.nli. www.heerema.com

Low-Down on the Aegir

heerema Marine contractors’ (hMc) dcv aegir’s primary task is the installation of flowlines and riser systems on the seabed at depths of up to 3,500m by means of the J-lay method. The vessel can also install pipelines with the R-lay method, using transportable reels lifted on board the vessel. apart from pipe-lay systems, the 210m vessel also has sufficient lifting capacity to install fixed platforms in relatively shallow waters and can perform non-pipeline related offshore installation and removal tasks.

The WSMU tool manipulator can handle pipe production equipment weighing up to 4,000 kg.