Original Hydrosele USA Issue 3

-

Upload

rohitasthana -

Category

Documents

-

view

22 -

download

0

Transcript of Original Hydrosele USA Issue 3

®

High Performance Sealing Technology

Innovative rotary sealing cartridge systems that offer

! Greatly reduced turbine downtime

! Minimal leakage

! Major cost savings

®HydroSele total sealing systems for Water Turbine Shafts

®

Registered Office: Lion House, Oriental Road, Woking, Surrey GU22 8AP, UK. Reg No. 2432592 © James Walker 2008

England

CERTIFICATE No. FM 01269BS EN ISO 9001:2000

BP 4302 508/2mCPN000083831

Health warning: If PTFE or fluoroelastomer (eg, FKM, FFKM, FEPM) products are heated to elevated temperatures, fumes will be produced which may give unpleasant effects, if inhaled. Whilst some fumes are emitted below 250°C from fluoroelastomers or below 300°C from PTFE, the effect at these temperatures is negligible. Care should be taken to avoid contaminating tobacco with particles of PTFE or fluoroelastomer, or with PTFE dispersion, which may remain on hands or clothing. Material Safety Data Sheets (MSDS) are available on request.

Information in this publication and otherwise supplied to users is based on our general experience and is given in good faith, but because of factors which are outside our knowledge and control and affect the use of products, no warranty is given or is to be implied with respect to such information. Specifications are subject to change without notice. Statements of operating limits quoted in this publication are not an indication that these values can be applied simultaneously.

James Walker & Co LtdPower Generation Industry Support Team1 Millennium Gate, Westmere DriveCrewe, Cheshire CW1 6AY, UKTel: +44 (0)1270 536000Fax: +44 (0)1270 536100Email: [email protected]

James Walker & CoTel: +44(0)1270 536000Fax: +44(0)1270 536100Email: [email protected]

James Walker AustraliaTel: +61 (0)2 9644 9755Fax: +61 (0)2 9645 2009Email: [email protected]

James Walker Benelux(Belgium)Tel: +32 3 820 7900Fax: +32 3 828 5484Email: [email protected](Netherlands)Tel: +31 (0)186 633111Fax: +31 (0)186 633110Email: [email protected]

James Walker ChinaTel: +86 21 5117 5802Fax: +86 21 5116 6899Email: [email protected]

James Walker DeutschlandTel: +49 (0)40 386 0810Fax: +49 (0)40 389 3230Email: [email protected]

James Walker FranceTel: +33 (0)437 497 480 Fax: +33 (0)437 497 483Email: [email protected]

James Walker IbericaTel: +34 94 447 0099Fax: +34 94 447 1077Email: [email protected]

James Walker IrelandTel: +353 (0)21 432 3626Fax: +353 (0)21 432 3623Email: [email protected]

James Walker ItalianaTel: +39 02 257 8308Fax: +39 02 263 00487Email: [email protected]

James Walker Mfg (USA)Tel: +1 708 754 4020Fax: +1 708 754 4058Email: [email protected]

James Walker New ZealandTel: +64 (0)9 272 1599Fax: +64 (0)9 272 3061Email: [email protected]

James Walker NorgeTel: +47 22 706800Fax: +47 22 706801Email: [email protected]

James Walker Oil & Gas (USA)Tel: +1 281 875 0002Fax: +1 281 875 0188Email: [email protected]

James Walker SingaporeTel: +65 6777 9896Fax: +65 6777 6102Email: [email protected]

James Walker South AfricaTel: +27 (0)31 205 6251/2/3Fax: +27 (0)31 205 6266Email: [email protected]

James Walker companies worldwide

High Performance Sealing Technology

Issue 3

Innovative rotary sealing cartridge systems that offer

● Greatly reduced turbine downtime

● Minimal leakage

● Major cost savings

● Full system compatibility

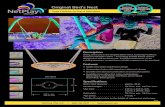

HydroSele® total sealing systems forWater Turbine Shafts

To order or for further details, please call your local contact shown on back cover or listed at www.jameswalker.biz2 To order or for further details, please call your local contact shown on back cover or listed at www.jameswalker.biz2

What is HydroSele ?®

® The innovative HydroSele S

®HydroSele is James Walker's family of

innovative cartridge seals for the shafts

of water turbines. It is the result of over

12 years of design, development and

operational experience on Francis and

Kaplan equipment working under a

wide variety of conditions.

Our sole objective has been to produce

cartridge seals of superior reliability that

greatly improve a turbine's

! Cost efficiency, and

! Operational performance.

Swift payback on investment®

Our innovative HydroSele S offers

significant cost savings by being

retrofitted and fully operational in half the

time of a traditional mechanical seal.

In less than two years, it should have

paid for itself in terms of maintenance

costs, turbine downtime and power

absorption.

At four years, your total investment in

cash and downtime could be just one-

quarter of that for an equivalent

mechanical seal.

Long & reliable service

HydroSele S prototypes are still running

trouble-free after 12 years of operation.

This outstanding reliability enables you to

schedule your maintenance with absolute

confidence.

Simple to install & adjustment-free

HydroSele S is one of the easiest sealing

arrangements to fit on a turbine shaft.

With our technical expertise, your

downtime is cut to a minimum — and the

cartridge sealing unit is totally adjustment-

free once installed.

Economical refurbishment

It takes just hours rather than days to

refurbish our innovative HydroSele. You

no longer need to hold expensive standby

sealing units in stock.

High efficiency sealing

HydroSele's unique method of operation

gives a very low and controlled level of

leakage. This greatly reduces the risk of

flood damage to plant caused by

uncontrolled leakage past sealing faces.

Low power consumption

HydroSele S has an exceptionally low

torque requirement compared to

traditional mechanical seals.

Worldwide technical support

Every HydroSele installation is fully

supported by James Walker's global

network of specialists in high performance

sealing technology.

Field trials, backed by commercial

operations since 2006, show that our

HydroSele systems offer the best long-

term value for money of any shaft sealing

arrangement for many Francis and Kaplan

turbines.

Our HydroSele offer

We will:

! Custom-manufacture the seal from

modular components to suit your

specific application.

! Install the seal on site for you.

! Fully support your HydroSele system

with worldwide technical advice and

refurbishment services.

® Why fit HydroSele S?

®HydroSele S offers many unique financial and

operational benefits over other sealing systems

used on Francis and Kaplan turbines

2. 3.

We are constantly developing our ®HydroSele family to provide a total shaft-

sealing service to OEMs and operators of

water turbines. Current family includes:®HydroSele S — the innovative rotary

cartridge seal for turbine shafts (p3-7).®HydroSele MS — S type plus

maintenance seal (p8).®HydroSele RS — S type with reversed

inner element (p8).®HydroSele W — cartridge containing a

®single Walkersele radial lip seal (p9).®HydroSele WT — cartridge with two

Walkersele lip seals in tandem (p9).®HydroSele WB — cartridge with two

Walkerseles back-to-back (p9). ®HydroSele Total Service — ancillary

equipment and services (p10).

Other variants and combinations of

HydroSele can be custom-designed,

including 'floating' versions to cater for

higher levels of shaft eccentricity.

Extended familyWhat is HydroSele® ? Extended familyHydroSele® is James Walker's family ofinnovative cartridge seals for the shaftsof water turbines. It is the result of over12 years of design, development andoperational experience on Francis andKaplan equipment working under awide variety of conditions.

Our sole objective has been to producecartridge seals of superior reliability thatgreatly improve a turbine's•Costefficiency,and•Operationalperformance.

We are constantly developing ourHydroSele® family to provide a total shaftsealing service to OEMs and operatorsofwaterturbines. Currentfamilyincludes:HydroSele® S — the innovative rotarycartridgesealforturbineshafts(p3-7).HydroSele® MS — S type plusmaintenanceseal(p8).HydroSele® RS — S type with reversedinnerelement(p8).HydroSele® W — cartridge containing asingle Walkersele®radiallipseal(p9).HydroSele® WT — cartridge with twoWalkerselelipsealsintandem(p9).HydroSele® WB — cartridge with twoWalkerselesback-to-back(p9).HydroSele® Total Service — ancillaryequipmentandservices(p10).

Other variants and combinations ofHydroSelecanbecustom-designed,including 'floating' versions to cater forhigherlevelsofshafteccentricity.

Fieldtrials,backedbycommercialoperationssince2006,showthatourHydroSele systems offer the best long-term value for money of any shaft sealing arrangement for many Francis and Kaplan turbines.

Our HydroSele offerWewill:•Custom-manufacturethesealfrom

modular components to suit your specificapplication.

•Supporttheinstallationofthesealonsitewithyou.

•FullysupportyourHydroSelesystemwith worldwide technical advice and refurbishmentservices.

3To order or for further details, please call your local contact shown on back cover or listed at www.jameswalker.biz 3

What is HydroSele ?®

® The innovative HydroSele S

®HydroSele is James Walker's family of

innovative cartridge seals for the shafts

of water turbines. It is the result of over

12 years of design, development and

operational experience on Francis and

Kaplan equipment working under a

wide variety of conditions.

Our sole objective has been to produce

cartridge seals of superior reliability that

greatly improve a turbine's

! Cost efficiency, and

! Operational performance.

Swift payback on investment®

Our innovative HydroSele S offers

significant cost savings by being

retrofitted and fully operational in half the

time of a traditional mechanical seal.

In less than two years, it should have

paid for itself in terms of maintenance

costs, turbine downtime and power

absorption.

At four years, your total investment in

cash and downtime could be just one-

quarter of that for an equivalent

mechanical seal.

Long & reliable service

HydroSele S prototypes are still running

trouble-free after 12 years of operation.

This outstanding reliability enables you to

schedule your maintenance with absolute

confidence.

Simple to install & adjustment-free

HydroSele S is one of the easiest sealing

arrangements to fit on a turbine shaft.

With our technical expertise, your

downtime is cut to a minimum — and the

cartridge sealing unit is totally adjustment-

free once installed.

Economical refurbishment

It takes just hours rather than days to

refurbish our innovative HydroSele. You

no longer need to hold expensive standby

sealing units in stock.

High efficiency sealing

HydroSele's unique method of operation

gives a very low and controlled level of

leakage. This greatly reduces the risk of

flood damage to plant caused by

uncontrolled leakage past sealing faces.

Low power consumption

HydroSele S has an exceptionally low

torque requirement compared to

traditional mechanical seals.

Worldwide technical support

Every HydroSele installation is fully

supported by James Walker's global

network of specialists in high performance

sealing technology.

Field trials, backed by commercial

operations since 2006, show that our

HydroSele systems offer the best long-

term value for money of any shaft sealing

arrangement for many Francis and Kaplan

turbines.

Our HydroSele offer

We will:

! Custom-manufacture the seal from

modular components to suit your

specific application.

! Install the seal on site for you.

! Fully support your HydroSele system

with worldwide technical advice and

refurbishment services.

® Why fit HydroSele S?

®HydroSele S offers many unique financial and

operational benefits over other sealing systems

used on Francis and Kaplan turbines

2. 3.

We are constantly developing our ®HydroSele family to provide a total shaft-

sealing service to OEMs and operators of

water turbines. Current family includes:®HydroSele S — the innovative rotary

cartridge seal for turbine shafts (p3-7).®HydroSele MS — S type plus

maintenance seal (p8).®HydroSele RS — S type with reversed

inner element (p8).®HydroSele W — cartridge containing a

®single Walkersele radial lip seal (p9).®HydroSele WT — cartridge with two

Walkersele lip seals in tandem (p9).®HydroSele WB — cartridge with two

Walkerseles back-to-back (p9). ®HydroSele Total Service — ancillary

equipment and services (p10).

Other variants and combinations of

HydroSele can be custom-designed,

including 'floating' versions to cater for

higher levels of shaft eccentricity.

Extended family Why fit HydroSele® S?Swift payback on investmentOur innovative HydroSele® S offerssignificantcostsavingsbybeingretrofittedandfullyoperationalinhalfthetimeofatraditionalmechanicalseal.

In less than two years, it should havepaid for itself in terms of maintenancecosts,turbinedowntimeandpowerabsorption.

At four years, your total investment incash and downtime could be just one-quarter of that for an equivalentmechanicalseal.

Long & reliable serviceHydroSele S prototypes are still runningtrouble-freeafter12yearsofoperation.This outstanding reliability enables you toschedule your maintenance with absoluteconfidence.

Low power consumptionHydroSele S has an exceptionally lowtorque requirement compared totraditionalmechanicalseals.

Worldwide technical supportEvery HydroSele installation is fullysupported by James Walker's globalnetwork of specialists in high performancesealingtechnology.

Simple to install & adjustment-freeHydroSele S is one of the easiest sealingarrangementstofitonaturbineshaft.Withourtechnicalexpertise,yourdowntime is cut to a minimum — and thecartridge sealing unit is totally adjustment-freeonceinstalled.

Economical refurbishmentIt takes just hours rather than days torefurbishourinnovativeHydroSele.Youno longer need to hold expensive standbysealingunitsinstock.

High efficiency sealingHydroSele's unique method of operationgives a very low and controlled level ofleakage.Thisgreatlyreducestheriskofflood damage to plant caused byuncontrolledleakagepastsealingfaces.

The innovative HydroSele® S

HydroSele® S offers many unique financial and

operational benefits over other sealing systems

used on Francis and Kaplan turbines

HydroSele® S in operationShaft diameter

Surface finish:

Surface hardness:

Diameter tolerance:

Maximum permissible shaft runout:

Inlet flush requirements

Pressure:

Filtration:

Equipment surface or adapter plate

Surface finish:

Flatness:

Cartridge outside diameter

0.4 to 0.8µm Ra (CLA 16 to 32µin)

33 HRC minimum

ISO 286-2/BS EN 20286-2 h8

Please consult James Walker.

To be maintained at a minimum of 2bar (29psi) above maximum system pressure.A through-flow flush system is generally recommended.

100µm (0.004in) or better

0.4 to 0.8µm Ra (CLA 16 to 32µin)

Within 0.05mm (0.002in)

Cartridge to be located in a counter-bored recess 5.00mm (0.197in) deep with a fit based on ISO 286-2/BS EN 20286-2;

®HydroSele S operating capabilities

Shaft diameters: 250 - 1000mm(9.84 - 39.37in)

Please consult James Walker if your shaft diameter exceeds 1000mm (39.37in).

Maximum pressure at gland: 10bar* gauge(145psi* gauge)

Maximum shaft speed: 20m/s*(3937fpm*)

Maximum temperature: 50°C (122°F) at seal/flush water interface

Flush water pressure: 2bar (29psi) above system pressure.

(*These values will be size dependent and may not necessarily be applied simultaneously)

®HydroSele S is a fully split cartridge assembly, containing two

sealing elements working back-to-back with flush water

introduced between them Simple in concept yet ingenious

®in operation, HydroSele S

relies on engineering

excellence for its outstanding

sealing performance

4.

Compact cartridge®HydroSele S is a compact bolt-

on sealing unit that can readily

be installed where housing

space is limited.

® Standard sizes for SHydroSele

5.

®HydroSele S

M16 bolts equi-spaced on E PCD

Dynamic sealing elements

Adapter plate

Shaft sleeve

ØC (location position) Tol: H9

ØA Tol: h9

Shaft (A)Equal toor above

Below Numberof bolts

BoltingPCD (E)

Threaddepth (F)

Locationdiameter

(C)

Overalldepth

(B)

Bolting details Flush pipe fitting (G)DIN ISO 228 Parallel

A+5.512A+6.299A+7.097

81216

A+3.819G3/8

G3/4

1.1811.575

3.4654.7444.843

19.68527.55939.370

9.84319.68527.559

Inch sizes

Tolerances ± 0.004 except where shown

A+140A+160A+180

Shaft (A)Equal toor above

Below Numberof bolts

BoltingPCD (E)

Threaddepth (F)

Locationdiameter

(C)

Overalldepth

(B)

Bolting details Flush pipe fitting (G)DIN ISO 228 Parallel

81216

A+97G3/8

G3/4

3040

88.0120.5123.0

500700

1000

250500700

Metric sizes in mm (apart from G in inches)

Tolerances ± 0.1 except where shown

To order or for further details, please call your local contact shown on back cover or listed at www.jameswalker.biz4

HydroSele® S in operationShaft diameter

Surfacefinish:

Surfacehardness:

Diametertolerance:

Maximumpermissibleshaftrunout:

Inlet flush requirements

Pressure:

Filtration:

Equipment surface or adapter plate

Surfacefinish:

Flatness:

Cartridge outside diameter

HydroSele® S operating capabilities

Shaftdiameters: 250-1000mm (9.84-39.37in)

Please consult James Walker if your shaftdiameterexceeds1000mm(39.37in).

Maximumpressureatgland:10bar*gauge (145psi*gauge)

Maximumshaftspeed: 20m/s* (3937fpm*)

Maximumtemperature: 50°C(122°F)at seal/flushwater interface

Flushwaterpressure: 2bar(29psi) above system pressure.

(*Thesevalueswillbesizedependentandmaynot necessarily be applied simultaneously)

0.4to0.8μmRa(CLA16to32μin)

33HRCminimum

ISO286-2/BSEN20286-2h8

PleaseconsultJamesWalker.

To be maintained at a minimum of 2bar(29psi)abovemaximumsystempressure.Athrough-flowflushsystemisgenerallyrecommended.

100μm(0.004in)orbetter

0.4to0.8μmRa(CLA16to32μin)

Within0.05mm(0.002in)

Cartridgetobelocatedinacounter-boredrecess5.00mm(0.197in)deepwithafitbasedonISO286-2/BSEN20286-2;H9/f8oncartridgeoutsidediameter

HydroSele® S

5To order or for further details, please call your local contact shown on back cover or listed at www.jameswalker.biz 5

Standard sizes for HydroSele® S

Simple in concept yet ingenious

in operation, HydroSele® S

relies on engineering

excellence for its outstanding

sealing performance

Compact cartridge

HydroSele® S is a compact bolt-on sealing unit that can readily be installed

where housing space is limited.

Metric sizes in mm (apart from G in inches)

Shaft (A) Overalldepth

(B)

Locationdiameter

(C)

Bolting detailsFlush pipe fitting (G)DIN ISO 228 ParallelEqual to

or aboveBelow Number

of boltsBoltingPCD (E)

Threaddepth (F)

250 500 88.0 A+140 8

A+97

30G3/8

500 700 120.5 A+160 1240

700 1000 123.0 A+180 16 G3/4

Tolerances±0.1exceptwhereshown

Inch sizes

Shaft (A) Overalldepth

(B)

Locationdiameter

(C)

Bolting detailsFlush pipe fitting (G)DIN ISO 228 ParallelEqual to or

aboveBelow Number

of boltsBoltingPCD (E)

Threaddepth (F)

9.843 19.685 3.465 A+5.512 8

A+3.819

1.181G3/8

19.685 27.559 4.744 A+6.299 121.575

27.559 39.370 4.843 A+7.097 16 G3/4

Tolerances±0.004exceptwhereshown

®HydroSele S is modular in

concept, with each component

designed and precision

manufactured to fit together

perfectly around the turbine

shaft without stripping down the

housing.

Modular concept

1. 3.

2.

4.

5.

6. 7.

® HydroSele relaxed

The ported pressure face (A) allows fluid

to the outside diameter of the housing.

The un-ported atmosphere face (B),

however, forms a static seal that prevents

the fluid from continuing around the back

of the seal to atmosphere.

Because the sealing element is

manufactured to have a small clearance

on the shaft, the fluid can also pass

between the shaft and the running sleeve

of the sealing element.

S If the sleeve were rigid, the pressure

would drop almost linearly along this

route, and leakage would be high. Instead

the pressure distributions on the outside

and inside of the seal produce a turning

moment (M) that tilts the seal to bring the

'atmosphere' edge of the seal sleeve into

close proximity to the shaft, stemming the

leakage.

The under-sleeve pressure then backs-up

to produce a distribution approximating to

that shown — with most of the pressure

drop occurring near the atmosphere edge

of the seal sleeve.

Each of the three metal rings is fully-split

and fitted with locator pins for accurate

realignment. The two sealing elements

and three 'O' rings have single splits.

The unit is installed simply by fitting each

component in sequence around the shaft,

with the bolt holes aligned through the

metal rings.

All modules of the fully assembled

HydroSele are held accurately and firmly

in position by the bolts that fasten the

cartridge to the adapter plate or

equipment surface beneath.

®HydroSele S construction

® How HydroSele S worksHydroSele energised

Loaded contact between the sealing

element and shaft is prevented by the

hydrodynamic pressure generated in the

thin fluid film that is created by shaft

rotation. Equilibrium is therefore set up

between the closing and opening forces

acting on the sealing element.

This results in a seal that is virtually

pressure balanced (providing high

pressure capability) and running on a

hydrodynamic film (providing high speed

capability), with a low level of controlled

leakage.

® S OD pressure

ID pressure

OD pressure

ID pressure

M

A B

To order or for further details, please call your local contact shown on back cover or listed at www.jameswalker.biz6

How HydroSele® S worksHydroSele® S relaxedTheportedpressureface(A)allowsfluidtotheoutsidediameterofthehousing.Theun-portedatmosphereface(B),however,formsastaticsealthatpreventsthe fluid from continuing around the backofthesealtoatmosphere.

Becausethesealingelementismanufactured to have a small clearanceontheshaft,thefluidcanalsopassbetween the shaft and the running sleeveofthesealingelement.

Ifthesleevewererigid,thepressurewould drop almost linearly along thisroute,andleakagewouldbehigh.Insteadthe pressure distributions on the outsideand inside of the seal produce a turningmoment (M) that tilts the seal to bring the'atmosphere' edge of the seal sleeve intocloseproximitytotheshaft,stemmingtheleakage.

The under-sleeve pressure then backs-upto produce a distribution approximating tothat shown — with most of the pressuredrop occurring near the atmosphere edgeofthesealsleeve.

®HydroSele S is modular in

concept, with each component

designed and precision

manufactured to fit together

perfectly around the turbine

shaft without stripping down the

housing.

Modular concept

1. 3.

2.

4.

5.

6. 7.

® HydroSele relaxed

The ported pressure face (A) allows fluid

to the outside diameter of the housing.

The un-ported atmosphere face (B),

however, forms a static seal that prevents

the fluid from continuing around the back

of the seal to atmosphere.

Because the sealing element is

manufactured to have a small clearance

on the shaft, the fluid can also pass

between the shaft and the running sleeve

of the sealing element.

S If the sleeve were rigid, the pressure

would drop almost linearly along this

route, and leakage would be high. Instead

the pressure distributions on the outside

and inside of the seal produce a turning

moment (M) that tilts the seal to bring the

'atmosphere' edge of the seal sleeve into

close proximity to the shaft, stemming the

leakage.

The under-sleeve pressure then backs-up

to produce a distribution approximating to

that shown — with most of the pressure

drop occurring near the atmosphere edge

of the seal sleeve.

Each of the three metal rings is fully-split

and fitted with locator pins for accurate

realignment. The two sealing elements

and three 'O' rings have single splits.

The unit is installed simply by fitting each

component in sequence around the shaft,

with the bolt holes aligned through the

metal rings.

All modules of the fully assembled

HydroSele are held accurately and firmly

in position by the bolts that fasten the

cartridge to the adapter plate or

equipment surface beneath.

®HydroSele S construction

® How HydroSele S worksHydroSele energised

Loaded contact between the sealing

element and shaft is prevented by the

hydrodynamic pressure generated in the

thin fluid film that is created by shaft

rotation. Equilibrium is therefore set up

between the closing and opening forces

acting on the sealing element.

This results in a seal that is virtually

pressure balanced (providing high

pressure capability) and running on a

hydrodynamic film (providing high speed

capability), with a low level of controlled

leakage.

® S OD pressure

ID pressure

OD pressure

ID pressure

M

A B

®HydroSele S is modular in

concept, with each component

designed and precision

manufactured to fit together

perfectly around the turbine

shaft without stripping down the

housing.

Modular concept

1. 3.

2.

4.

5.

6. 7.

® HydroSele relaxed

The ported pressure face (A) allows fluid

to the outside diameter of the housing.

The un-ported atmosphere face (B),

however, forms a static seal that prevents

the fluid from continuing around the back

of the seal to atmosphere.

Because the sealing element is

manufactured to have a small clearance

on the shaft, the fluid can also pass

between the shaft and the running sleeve

of the sealing element.

S If the sleeve were rigid, the pressure

would drop almost linearly along this

route, and leakage would be high. Instead

the pressure distributions on the outside

and inside of the seal produce a turning

moment (M) that tilts the seal to bring the

'atmosphere' edge of the seal sleeve into

close proximity to the shaft, stemming the

leakage.

The under-sleeve pressure then backs-up

to produce a distribution approximating to

that shown — with most of the pressure

drop occurring near the atmosphere edge

of the seal sleeve.

Each of the three metal rings is fully-split

and fitted with locator pins for accurate

realignment. The two sealing elements

and three 'O' rings have single splits.

The unit is installed simply by fitting each

component in sequence around the shaft,

with the bolt holes aligned through the

metal rings.

All modules of the fully assembled

HydroSele are held accurately and firmly

in position by the bolts that fasten the

cartridge to the adapter plate or

equipment surface beneath.

®HydroSele S construction

® How HydroSele S worksHydroSele energised

Loaded contact between the sealing

element and shaft is prevented by the

hydrodynamic pressure generated in the

thin fluid film that is created by shaft

rotation. Equilibrium is therefore set up

between the closing and opening forces

acting on the sealing element.

This results in a seal that is virtually

pressure balanced (providing high

pressure capability) and running on a

hydrodynamic film (providing high speed

capability), with a low level of controlled

leakage.

® S OD pressure

ID pressure

OD pressure

ID pressure

M

A B

7To order or for further details, please call your local contact shown on back cover or listed at www.jameswalker.biz 7

HydroSele® S energizedLoadedcontactbetweenthesealingelement and shaft is prevented by thehydrodynamic pressure generated in thethinfluidfilmthatiscreatedbyshaftrotation.Equilibriumisthereforesetupbetween the closing and opening forcesactingonthesealingelement.

This results in a seal that is virtuallypressure balanced (providing highpressure capability) and running on ahydrodynamicfilm(providinghighspeedcapability),withalowlevelofcontrolledleakage.

®HydroSele S is modular in

concept, with each component

designed and precision

manufactured to fit together

perfectly around the turbine

shaft without stripping down the

housing.

Modular concept

1. 3.

2.

4.

5.

6. 7.

® HydroSele relaxed

The ported pressure face (A) allows fluid

to the outside diameter of the housing.

The un-ported atmosphere face (B),

however, forms a static seal that prevents

the fluid from continuing around the back

of the seal to atmosphere.

Because the sealing element is

manufactured to have a small clearance

on the shaft, the fluid can also pass

between the shaft and the running sleeve

of the sealing element.

S If the sleeve were rigid, the pressure

would drop almost linearly along this

route, and leakage would be high. Instead

the pressure distributions on the outside

and inside of the seal produce a turning

moment (M) that tilts the seal to bring the

'atmosphere' edge of the seal sleeve into

close proximity to the shaft, stemming the

leakage.

The under-sleeve pressure then backs-up

to produce a distribution approximating to

that shown — with most of the pressure

drop occurring near the atmosphere edge

of the seal sleeve.

Each of the three metal rings is fully-split

and fitted with locator pins for accurate

realignment. The two sealing elements

and three 'O' rings have single splits.

The unit is installed simply by fitting each

component in sequence around the shaft,

with the bolt holes aligned through the

metal rings.

All modules of the fully assembled

HydroSele are held accurately and firmly

in position by the bolts that fasten the

cartridge to the adapter plate or

equipment surface beneath.

®HydroSele S construction

® How HydroSele S worksHydroSele energised

Loaded contact between the sealing

element and shaft is prevented by the

hydrodynamic pressure generated in the

thin fluid film that is created by shaft

rotation. Equilibrium is therefore set up

between the closing and opening forces

acting on the sealing element.

This results in a seal that is virtually

pressure balanced (providing high

pressure capability) and running on a

hydrodynamic film (providing high speed

capability), with a low level of controlled

leakage.

® S OD pressure

ID pressure

OD pressure

ID pressure

M

A B

Modular concept

HydroSele® S is modular in

concept, with each component

designed and precision

manufactured to fit together

perfectly around the turbine

shaft without stripping down the

housing.

Each of the three metal rings is fully-splitandfittedwithlocatorpinsforaccuraterealignment.Thetwosealingelementsandthree'O'ringshavesinglesplits.

Theunitisinstalledsimplybyfittingeachcomponentinsequencearoundtheshaft,with the bolt holes aligned through themetalrings.

AllmodulesofthefullyassembledHydroSeleareheldaccuratelyandfirmlyin position by the bolts that fasten thecartridge to the adapter plate orequipmentsurfacebeneath.

HydroSele® S construction

To order or for further details, please call your local contact shown on back cover or listed at www.jameswalker.biz8

HydroSele® MS HydroSele® RSThis enhanced version of HydroSele® Sallows maintenance of the primary sealingelements to be carried out safely andswiftlywiththecartridgeinsitu.

The inner housing ring is adapted toincorporateanexternallyenergizedmaintenance seal that sits well clear of theshaftsleevewhiletheturbineisrunning.During turbine shut-down themaintenancesealisenergizedtomakeintimate contact with the shaft sleeve andprovidehigh-efficiencystaticsealing.

Themaintenancesealisenergizedeitherby automatic diversion of the cartridgeflushwater,orbyseparatepressurizedwaterorairsupplies.

This is designed for situations where awater-lubricated bearing is locatedimmediately inboard of the HydroSele®.

The inner dynamic sealing element isfittedinthereversedirection,andenergizedbypressurizedcleanwaterwithinthebearing.Thesamewaterassupplied to the bearing is also fed to theHydroSele flush ring at lower pressure tolubricateandcoolthesealassembly.

The result is an exceptionally stablesealing system with very low leakage andminimaladditionalpipework.

HydroSele® variants

9To order or for further details, please call your local contact shown on back cover or listed at www.jameswalker.biz 9

HydroSele® W HydroSele® WT HydroSele® WBOur HydroSele® W range comprises splitcartridges that house James Walker'srenowned Walkersele® D7 rotary shaft lipseals.Thisstandardversionhasasinglesealingelementinthecartridge.

Moldedintough,waterresistantelastomers,WalkerseleD7isidealforlowerpressureKaplanturbineduties.

AlthoughHydroSeleWisrecommendedforsmallerturbines,itcanbesuppliedindiametersupto2000mm(78.74in)ifrequired.

The Walkersele is supplied in spilt form foreaseofinstallation.Itisthenjoinedtoform an endless ring using our patentedOSJ®(On-SiteJoining)technique.

This version comprises a fully splitcartridge unit containing two Walkersele®

D7 On-Site Joining lip seals working intandem.BothWalkerselesfacethepressurizedwatertoprovideincreasedsealingintegrity.

The space between the two lip seals isnormally packed with grease duringassembly.Aportisincorporatedtoallowadditional greasing to improve thelubrication of the seal lips and to extendseallife.

Our HydroSele®WBisparticularlysuitablefor protecting bearings in submergedapplicationssuchasbulbturbines.

It uses the same cartridge design asHydroSele®WT,buttheouterWalkersele®

isreversed.

Inoperation,theoutersealactsasaprotective barrier to prevent the ingress ofwaterandexternalcontaminants.

To order or for further details, please call your local contact shown on back cover or listed at www.jameswalker.biz10

®HydroSele case studies

Here are a few examples of the many successes achieved with

®HydroSele S during 12 years of development, testing and

commercial operations.

Case study 1

Application: Two Francis vertical turbines

with 410mm (16.14in) diameter shafts

running at 750rpm and 3bar (43.5psi)

operating pressure.

Previous seal type: Both turbines were

fitted with spring-retained carbon rings.

HydroSele success: In December 1996

the turbine shafts were fitted with

prototypes of the HydroSele S cartridge

unit.

In March 2008 both units were still

working precisely to the customer’s

requirements, with the original

elastomeric sealing elements in place.

Case study 2

Application: Kaplan vertical turbine with

380mm (14.96in) diameter shaft running

at 428rpm and 3bar (43.5psi) operating

pressure.

Previous seal type: The turbine was

originally fitted with a famous brand of

mechanical seal that lasted about two

years, but suffered performance

problems.

HydroSele success: In February 1998, a

prototype HydroSele S was installed.

In July 2007, the total leakage from the

HydroSele S was measured at 2 litre/min

(0.53USgal/min). The original elastomeric

sealing elements were still in operation,

and the unit was continuing to meet the

customer’s specifications.

Case study 3

Application: Two Francis vertical turbines

with 480mm (18.9in) diameter shafts,

running at 375rpm and 2.5bar (36.25psi)

operating pressure.

Previous seal type: Both these turbines

were formerly fitted with conventional

mechanical face seals that leaked heavily.

HydroSele success: In June 2001 each

turbine was fitted with a HydroSele S, with

immediate dramatic reductions in leakage

rates.

In 2008, the leakage rate was measured

at 2 to 4 litre/min (0.53 to 1.06USgal/min),

which was fully acceptable to the

customer.

Our compact skid-mounted FlushPaks are

custom designed to provide the clean,

cool and uninterrupted supply of flush ® water needed for efficient HydroSele

operation.

They contain all the fluid handling and

automatic control systems required to

ensure the minimum of operator

intervention and maintenance.

®An adapter plate enables the HydroSele

unit to be retro-fitted to a turbine casing,

usually via the bolt circle of the previous

sealing system. Sufficient detail is

provided on page 5 to enable a customer

to design and manufacture the plate.

Alternatively, we will custom-design and

supply a precision-machined adapter

plate that provides the perfect base for

optimum HydroSele performance.

®HydroSele FlushPak®HydroSele Adapter

®All HydroSele units are designed to give

a long trouble-free working life, with their

elastomeric sealing elements performing

perfectly for several years before on-site

replacement is needed.

To gauge the operational efficiency of an

installation, we can supply our ®HydroSele Condition Monitoring system.

This monitors major parameters, such as

temperature, pressure and flow rates. It

gives prior warning of changes that affect

the efficiency of a HydroSele unit, thus

enabling on-site maintenance to be

scheduled well in advance.

The system is particularly suitable for use

at plants that are not permanently

manned, and can submit its reports

automatically via email or text messaging,

if required.

®HydroSeleCondition Monitoring

® HydroSeleShaft SleeveWe can provide precision manufactured

split sleeves that protect the turbine shaft

from wear, and present the optimum ®running surface for HydroSele elements.

These are manufactured in corrosion

resistant steel, and will be supplied with

hard surface layers, if required. A taper-

wedge location/locking system ensures

perfect alignment of the split halves.

®HydroSele ServiceWe offer a full service package to support

®all HydroSele installations. Our

applications engineers will assist and

advise on all aspects of turbine sealing.

They are complemented by our site

personnel who are fully safety trained and

available to carry out pre-contract surveys

— plus all levels of on-site work, from

supervision and system installation, to

commissioning and customer training.

Case studies

10. 11.

®HydroSele case studies

Here are a few examples of the many successes achieved with

®HydroSele S during 12 years of development, testing and

commercial operations.

Case study 1

Application: Two Francis vertical turbines

with 410mm (16.14in) diameter shafts

running at 750rpm and 3bar (43.5psi)

operating pressure.

Previous seal type: Both turbines were

fitted with spring-retained carbon rings.

HydroSele success: In December 1996

the turbine shafts were fitted with

prototypes of the HydroSele S cartridge

unit.

In March 2008 both units were still

working precisely to the customer’s

requirements, with the original

elastomeric sealing elements in place.

Case study 2

Application: Kaplan vertical turbine with

380mm (14.96in) diameter shaft running

at 428rpm and 3bar (43.5psi) operating

pressure.

Previous seal type: The turbine was

originally fitted with a famous brand of

mechanical seal that lasted about two

years, but suffered performance

problems.

HydroSele success: In February 1998, a

prototype HydroSele S was installed.

In July 2007, the total leakage from the

HydroSele S was measured at 2 litre/min

(0.53USgal/min). The original elastomeric

sealing elements were still in operation,

and the unit was continuing to meet the

customer’s specifications.

Case study 3

Application: Two Francis vertical turbines

with 480mm (18.9in) diameter shafts,

running at 375rpm and 2.5bar (36.25psi)

operating pressure.

Previous seal type: Both these turbines

were formerly fitted with conventional

mechanical face seals that leaked heavily.

HydroSele success: In June 2001 each

turbine was fitted with a HydroSele S, with

immediate dramatic reductions in leakage

rates.

In 2008, the leakage rate was measured

at 2 to 4 litre/min (0.53 to 1.06USgal/min),

which was fully acceptable to the

customer.

Our compact skid-mounted FlushPaks are

custom designed to provide the clean,

cool and uninterrupted supply of flush ® water needed for efficient HydroSele

operation.

They contain all the fluid handling and

automatic control systems required to

ensure the minimum of operator

intervention and maintenance.

®An adapter plate enables the HydroSele

unit to be retro-fitted to a turbine casing,

usually via the bolt circle of the previous

sealing system. Sufficient detail is

provided on page 5 to enable a customer

to design and manufacture the plate.

Alternatively, we will custom-design and

supply a precision-machined adapter

plate that provides the perfect base for

optimum HydroSele performance.

®HydroSele FlushPak®HydroSele Adapter

®All HydroSele units are designed to give

a long trouble-free working life, with their

elastomeric sealing elements performing

perfectly for several years before on-site

replacement is needed.

To gauge the operational efficiency of an

installation, we can supply our ®HydroSele Condition Monitoring system.

This monitors major parameters, such as

temperature, pressure and flow rates. It

gives prior warning of changes that affect

the efficiency of a HydroSele unit, thus

enabling on-site maintenance to be

scheduled well in advance.

The system is particularly suitable for use

at plants that are not permanently

manned, and can submit its reports

automatically via email or text messaging,

if required.

®HydroSeleCondition Monitoring

® HydroSeleShaft SleeveWe can provide precision manufactured

split sleeves that protect the turbine shaft

from wear, and present the optimum ®running surface for HydroSele elements.

These are manufactured in corrosion

resistant steel, and will be supplied with

hard surface layers, if required. A taper-

wedge location/locking system ensures

perfect alignment of the split halves.

®HydroSele ServiceWe offer a full service package to support

®all HydroSele installations. Our

applications engineers will assist and

advise on all aspects of turbine sealing.

They are complemented by our site

personnel who are fully safety trained and

available to carry out pre-contract surveys

— plus all levels of on-site work, from

supervision and system installation, to

commissioning and customer training.

Case studies

10. 11.

®HydroSele case studies

Here are a few examples of the many successes achieved with

®HydroSele S during 12 years of development, testing and

commercial operations.

Case study 1

Application: Two Francis vertical turbines

with 410mm (16.14in) diameter shafts

running at 750rpm and 3bar (43.5psi)

operating pressure.

Previous seal type: Both turbines were

fitted with spring-retained carbon rings.

HydroSele success: In December 1996

the turbine shafts were fitted with

prototypes of the HydroSele S cartridge

unit.

In March 2008 both units were still

working precisely to the customer’s

requirements, with the original

elastomeric sealing elements in place.

Case study 2

Application: Kaplan vertical turbine with

380mm (14.96in) diameter shaft running

at 428rpm and 3bar (43.5psi) operating

pressure.

Previous seal type: The turbine was

originally fitted with a famous brand of

mechanical seal that lasted about two

years, but suffered performance

problems.

HydroSele success: In February 1998, a

prototype HydroSele S was installed.

In July 2007, the total leakage from the

HydroSele S was measured at 2 litre/min

(0.53USgal/min). The original elastomeric

sealing elements were still in operation,

and the unit was continuing to meet the

customer’s specifications.

Case study 3

Application: Two Francis vertical turbines

with 480mm (18.9in) diameter shafts,

running at 375rpm and 2.5bar (36.25psi)

operating pressure.

Previous seal type: Both these turbines

were formerly fitted with conventional

mechanical face seals that leaked heavily.

HydroSele success: In June 2001 each

turbine was fitted with a HydroSele S, with

immediate dramatic reductions in leakage

rates.

In 2008, the leakage rate was measured

at 2 to 4 litre/min (0.53 to 1.06USgal/min),

which was fully acceptable to the

customer.

Our compact skid-mounted FlushPaks are

custom designed to provide the clean,

cool and uninterrupted supply of flush ® water needed for efficient HydroSele

operation.

They contain all the fluid handling and

automatic control systems required to

ensure the minimum of operator

intervention and maintenance.

®An adapter plate enables the HydroSele

unit to be retro-fitted to a turbine casing,

usually via the bolt circle of the previous

sealing system. Sufficient detail is

provided on page 5 to enable a customer

to design and manufacture the plate.

Alternatively, we will custom-design and

supply a precision-machined adapter

plate that provides the perfect base for

optimum HydroSele performance.

®HydroSele FlushPak®HydroSele Adapter

®All HydroSele units are designed to give

a long trouble-free working life, with their

elastomeric sealing elements performing

perfectly for several years before on-site

replacement is needed.

To gauge the operational efficiency of an

installation, we can supply our ®HydroSele Condition Monitoring system.

This monitors major parameters, such as

temperature, pressure and flow rates. It

gives prior warning of changes that affect

the efficiency of a HydroSele unit, thus

enabling on-site maintenance to be

scheduled well in advance.

The system is particularly suitable for use

at plants that are not permanently

manned, and can submit its reports

automatically via email or text messaging,

if required.

®HydroSeleCondition Monitoring

® HydroSeleShaft SleeveWe can provide precision manufactured

split sleeves that protect the turbine shaft

from wear, and present the optimum ®running surface for HydroSele elements.

These are manufactured in corrosion

resistant steel, and will be supplied with

hard surface layers, if required. A taper-

wedge location/locking system ensures

perfect alignment of the split halves.

®HydroSele ServiceWe offer a full service package to support

®all HydroSele installations. Our

applications engineers will assist and

advise on all aspects of turbine sealing.

They are complemented by our site

personnel who are fully safety trained and

available to carry out pre-contract surveys

— plus all levels of on-site work, from

supervision and system installation, to

commissioning and customer training.

Case studies

10. 11.

HydroSele® Service

We offer a full service package to supportall HydroSele® installations.Ourapplications engineers will assist andadviseonallaspectsofturbinesealing.

They are complemented by our sitepersonnel who are fully safety trained andavailable to carry out pre-contract surveys—plusalllevelsofon-sitework,fromsupervisionandsysteminstallation,tocommissioningandcustomertraining.

HydroSele® Adapter

AnadapterplateenablestheHydroSele®

unittoberetro-fittedtoaturbinecasing,usually via the bolt circle of the previoussealingsystem.Sufficientdetailisprovidedonpage5toenableacustomertodesignandmanufacturetheplate.

Alternatively,wewillcustom-designandsupply a precision-machined adapterplate that provides the perfect base foroptimumHydroSeleperformance.

HydroSele®

Condition Monitoring

AllHydroSele® units are designed to givealongtrouble-freeworkinglife,withtheirelastomeric sealing elements performingperfectly for several years before on-sitereplacementisneeded.

Togaugetheoperationalefficiencyofaninstallation,wecansupplyourHydroSele®ConditionMonitoringsystem.

Thismonitorsmajorparameters,suchastemperature,pressureandflowrates.Itgives prior warning of changes that affecttheefficiencyofaHydroSeleunit,thusenabling on-site maintenance to bescheduledwellinadvance.

The system is particularly suitable for useat plants that are not permanentlymanned,andcansubmititsreportsautomaticallyviaemailortextmessaging,ifrequired.

HydroSele®

Shaft Sleeve

We can provide precision manufacturedsplit sleeves that protect the turbine shaftfromwear,andpresenttheoptimumrunning surface for HydroSele®elements.

These are manufactured in corrosionresistantsteel,andwillbesuppliedwithhardsurfacelayers,ifrequired.Ataper-wedgelocation/lockingsystemensuresperfectalignmentofthesplithalves.

HydroSele® FlushPak

Our compact skid-mounted FlushPaks arecustomdesignedtoprovidetheclean,cool and uninterrupted supply of flushwaterneededforefficientHydroSele®

operation.

They contain all the fluid handling andautomatic control systems required toensure the minimum of operatorinterventionandmaintenance.

Case studies

11To order or for further details, please call your local contact shown on back cover or listed at www.jameswalker.biz 11

®HydroSele case studies

Here are a few examples of the many successes achieved with

®HydroSele S during 12 years of development, testing and

commercial operations.

Case study 1

Application: Two Francis vertical turbines

with 410mm (16.14in) diameter shafts

running at 750rpm and 3bar (43.5psi)

operating pressure.

Previous seal type: Both turbines were

fitted with spring-retained carbon rings.

HydroSele success: In December 1996

the turbine shafts were fitted with

prototypes of the HydroSele S cartridge

unit.

In March 2008 both units were still

working precisely to the customer’s

requirements, with the original

elastomeric sealing elements in place.

Case study 2

Application: Kaplan vertical turbine with

380mm (14.96in) diameter shaft running

at 428rpm and 3bar (43.5psi) operating

pressure.

Previous seal type: The turbine was

originally fitted with a famous brand of

mechanical seal that lasted about two

years, but suffered performance

problems.

HydroSele success: In February 1998, a

prototype HydroSele S was installed.

In July 2007, the total leakage from the

HydroSele S was measured at 2 litre/min

(0.53USgal/min). The original elastomeric

sealing elements were still in operation,

and the unit was continuing to meet the

customer’s specifications.

Case study 3

Application: Two Francis vertical turbines

with 480mm (18.9in) diameter shafts,

running at 375rpm and 2.5bar (36.25psi)

operating pressure.

Previous seal type: Both these turbines

were formerly fitted with conventional

mechanical face seals that leaked heavily.

HydroSele success: In June 2001 each

turbine was fitted with a HydroSele S, with

immediate dramatic reductions in leakage

rates.

In 2008, the leakage rate was measured

at 2 to 4 litre/min (0.53 to 1.06USgal/min),

which was fully acceptable to the

customer.

Our compact skid-mounted FlushPaks are

custom designed to provide the clean,

cool and uninterrupted supply of flush ® water needed for efficient HydroSele

operation.

They contain all the fluid handling and

automatic control systems required to

ensure the minimum of operator

intervention and maintenance.

®An adapter plate enables the HydroSele

unit to be retro-fitted to a turbine casing,

usually via the bolt circle of the previous

sealing system. Sufficient detail is

provided on page 5 to enable a customer

to design and manufacture the plate.

Alternatively, we will custom-design and

supply a precision-machined adapter

plate that provides the perfect base for

optimum HydroSele performance.

®HydroSele FlushPak®HydroSele Adapter

®All HydroSele units are designed to give

a long trouble-free working life, with their

elastomeric sealing elements performing

perfectly for several years before on-site

replacement is needed.

To gauge the operational efficiency of an

installation, we can supply our ®HydroSele Condition Monitoring system.

This monitors major parameters, such as

temperature, pressure and flow rates. It

gives prior warning of changes that affect

the efficiency of a HydroSele unit, thus

enabling on-site maintenance to be

scheduled well in advance.

The system is particularly suitable for use

at plants that are not permanently

manned, and can submit its reports

automatically via email or text messaging,

if required.

®HydroSeleCondition Monitoring

® HydroSeleShaft SleeveWe can provide precision manufactured

split sleeves that protect the turbine shaft

from wear, and present the optimum ®running surface for HydroSele elements.

These are manufactured in corrosion

resistant steel, and will be supplied with

hard surface layers, if required. A taper-

wedge location/locking system ensures

perfect alignment of the split halves.

®HydroSele ServiceWe offer a full service package to support

®all HydroSele installations. Our

applications engineers will assist and

advise on all aspects of turbine sealing.

They are complemented by our site

personnel who are fully safety trained and

available to carry out pre-contract surveys

— plus all levels of on-site work, from

supervision and system installation, to

commissioning and customer training.

Case studies

10. 11.

®HydroSele case studies

Here are a few examples of the many successes achieved with

®HydroSele S during 12 years of development, testing and

commercial operations.

Case study 1

Application: Two Francis vertical turbines

with 410mm (16.14in) diameter shafts

running at 750rpm and 3bar (43.5psi)

operating pressure.

Previous seal type: Both turbines were

fitted with spring-retained carbon rings.

HydroSele success: In December 1996

the turbine shafts were fitted with

prototypes of the HydroSele S cartridge

unit.

In March 2008 both units were still

working precisely to the customer’s

requirements, with the original

elastomeric sealing elements in place.

Case study 2

Application: Kaplan vertical turbine with

380mm (14.96in) diameter shaft running

at 428rpm and 3bar (43.5psi) operating

pressure.

Previous seal type: The turbine was

originally fitted with a famous brand of

mechanical seal that lasted about two

years, but suffered performance

problems.

HydroSele success: In February 1998, a

prototype HydroSele S was installed.

In July 2007, the total leakage from the

HydroSele S was measured at 2 litre/min

(0.53USgal/min). The original elastomeric

sealing elements were still in operation,

and the unit was continuing to meet the

customer’s specifications.

Case study 3

Application: Two Francis vertical turbines

with 480mm (18.9in) diameter shafts,

running at 375rpm and 2.5bar (36.25psi)

operating pressure.

Previous seal type: Both these turbines

were formerly fitted with conventional

mechanical face seals that leaked heavily.

HydroSele success: In June 2001 each

turbine was fitted with a HydroSele S, with

immediate dramatic reductions in leakage

rates.

In 2008, the leakage rate was measured

at 2 to 4 litre/min (0.53 to 1.06USgal/min),

which was fully acceptable to the

customer.

Our compact skid-mounted FlushPaks are

custom designed to provide the clean,

cool and uninterrupted supply of flush ® water needed for efficient HydroSele

operation.

They contain all the fluid handling and

automatic control systems required to

ensure the minimum of operator

intervention and maintenance.

®An adapter plate enables the HydroSele

unit to be retro-fitted to a turbine casing,

usually via the bolt circle of the previous

sealing system. Sufficient detail is

provided on page 5 to enable a customer

to design and manufacture the plate.

Alternatively, we will custom-design and

supply a precision-machined adapter

plate that provides the perfect base for

optimum HydroSele performance.

®HydroSele FlushPak®HydroSele Adapter

®All HydroSele units are designed to give

a long trouble-free working life, with their

elastomeric sealing elements performing

perfectly for several years before on-site

replacement is needed.

To gauge the operational efficiency of an

installation, we can supply our ®HydroSele Condition Monitoring system.

This monitors major parameters, such as

temperature, pressure and flow rates. It

gives prior warning of changes that affect

the efficiency of a HydroSele unit, thus

enabling on-site maintenance to be

scheduled well in advance.

The system is particularly suitable for use

at plants that are not permanently

manned, and can submit its reports

automatically via email or text messaging,

if required.

®HydroSeleCondition Monitoring

® HydroSeleShaft SleeveWe can provide precision manufactured

split sleeves that protect the turbine shaft

from wear, and present the optimum ®running surface for HydroSele elements.

These are manufactured in corrosion

resistant steel, and will be supplied with

hard surface layers, if required. A taper-

wedge location/locking system ensures

perfect alignment of the split halves.

®HydroSele ServiceWe offer a full service package to support

®all HydroSele installations. Our

applications engineers will assist and

advise on all aspects of turbine sealing.

They are complemented by our site

personnel who are fully safety trained and

available to carry out pre-contract surveys

— plus all levels of on-site work, from

supervision and system installation, to

commissioning and customer training.

Case studies

10. 11.

®HydroSele case studies

Here are a few examples of the many successes achieved with

®HydroSele S during 12 years of development, testing and

commercial operations.

Case study 1

Application: Two Francis vertical turbines

with 410mm (16.14in) diameter shafts

running at 750rpm and 3bar (43.5psi)

operating pressure.

Previous seal type: Both turbines were

fitted with spring-retained carbon rings.

HydroSele success: In December 1996

the turbine shafts were fitted with

prototypes of the HydroSele S cartridge

unit.

In March 2008 both units were still

working precisely to the customer’s

requirements, with the original

elastomeric sealing elements in place.

Case study 2

Application: Kaplan vertical turbine with

380mm (14.96in) diameter shaft running

at 428rpm and 3bar (43.5psi) operating

pressure.

Previous seal type: The turbine was

originally fitted with a famous brand of

mechanical seal that lasted about two

years, but suffered performance

problems.

HydroSele success: In February 1998, a

prototype HydroSele S was installed.

In July 2007, the total leakage from the

HydroSele S was measured at 2 litre/min

(0.53USgal/min). The original elastomeric

sealing elements were still in operation,

and the unit was continuing to meet the

customer’s specifications.

Case study 3

Application: Two Francis vertical turbines

with 480mm (18.9in) diameter shafts,

running at 375rpm and 2.5bar (36.25psi)

operating pressure.

Previous seal type: Both these turbines

were formerly fitted with conventional

mechanical face seals that leaked heavily.

HydroSele success: In June 2001 each

turbine was fitted with a HydroSele S, with

immediate dramatic reductions in leakage

rates.

In 2008, the leakage rate was measured

at 2 to 4 litre/min (0.53 to 1.06USgal/min),

which was fully acceptable to the

customer.

Our compact skid-mounted FlushPaks are

custom designed to provide the clean,

cool and uninterrupted supply of flush ® water needed for efficient HydroSele

operation.

They contain all the fluid handling and

automatic control systems required to

ensure the minimum of operator

intervention and maintenance.

®An adapter plate enables the HydroSele

unit to be retro-fitted to a turbine casing,

usually via the bolt circle of the previous

sealing system. Sufficient detail is

provided on page 5 to enable a customer

to design and manufacture the plate.

Alternatively, we will custom-design and

supply a precision-machined adapter

plate that provides the perfect base for

optimum HydroSele performance.

®HydroSele FlushPak®HydroSele Adapter

®All HydroSele units are designed to give

a long trouble-free working life, with their

elastomeric sealing elements performing

perfectly for several years before on-site

replacement is needed.

To gauge the operational efficiency of an

installation, we can supply our ®HydroSele Condition Monitoring system.

This monitors major parameters, such as

temperature, pressure and flow rates. It

gives prior warning of changes that affect

the efficiency of a HydroSele unit, thus

enabling on-site maintenance to be

scheduled well in advance.

The system is particularly suitable for use

at plants that are not permanently

manned, and can submit its reports

automatically via email or text messaging,

if required.

®HydroSeleCondition Monitoring

® HydroSeleShaft SleeveWe can provide precision manufactured

split sleeves that protect the turbine shaft

from wear, and present the optimum ®running surface for HydroSele elements.

These are manufactured in corrosion

resistant steel, and will be supplied with

hard surface layers, if required. A taper-

wedge location/locking system ensures

perfect alignment of the split halves.

®HydroSele ServiceWe offer a full service package to support

®all HydroSele installations. Our

applications engineers will assist and

advise on all aspects of turbine sealing.

They are complemented by our site

personnel who are fully safety trained and

available to carry out pre-contract surveys

— plus all levels of on-site work, from

supervision and system installation, to

commissioning and customer training.

Case studies

10. 11.

Case study 1

Application: Two Francis vertical turbines

with410mm(16.14in)diametershafts

runningat750rpmand3bar(43.5psi)

operatingpressure.

Previous seal type:Bothturbineswere

fittedwithspring-retainedcarbonrings.

HydroSele success: In December 1996

theturbineshaftswerefittedwith

prototypes of the HydroSele S cartridge

unit.

In March 2008 both units were still

working precisely to the customer’s

requirements,withtheoriginal

elastomericsealingelementsinplace.

Case study 2

Application: Kaplan vertical turbine with

380mm(14.96in)diametershaftrunning

at428rpmand3bar(43.5psi)operating

pressure.

Previous seal type: The turbine was

originallyfittedwithafamousbrandof

mechanical seal that lasted about two

years,butsufferedperformance

problems.

HydroSele success: InFebruary1998,a

prototypeHydroSeleSwasinstalled.

InJuly2007,thetotalleakagefromthe

HydroSeleSwasmeasuredat2litre/min

(0.53USgal/min).Theoriginalelastomeric

sealingelementswerestillinoperation,

and the unit was continuing to meet the

customer’sspecifications.

Case study 3

Application: Two Francis vertical turbines

with480mm(18.9in)diametershafts,

runningat375rpmand2.5bar(36.25psi)

operatingpressure.

Previous seal type:Boththeseturbines

wereformerlyfittedwithconventional

mechanicalfacesealsthatleakedheavily.

HydroSele success: In June 2001 each

turbinewasfittedwithaHydroSeleS,with

immediate dramatic reductions in leakage

rates.

In2008,theleakageratewasmeasured

at2to4litre/min(0.53to1.06USgal/min),

which was fully acceptable to the

customer.

HydroSele® case studies

Here are a few examples of the many successes achieved

with HydroSele®Sduringdevelopment,testingand

commercialoperations.

© James Walker 2010BP4302USA 0910/1m

James Walker Mfg. Co.511West195thStreetGlenwood,IL,60425USATel:+17087544020Fax: +1 708 754 4058Email:[email protected]

Certified Quality System

James Walker & Co (UK)Tel: +44(0)1270536000Fax: +44 (0)1270 536100Email:[email protected]

James Walker AustraliaTel: +61(0)297219500Fax: +61 (0)2 9721 9580Email:[email protected]

James Walker Benelux(Belgium)Tel: +3238207900Fax: +32 3 828 5484Email:[email protected](Netherlands)Tel: +31(0)186633111Fax: +31 (0)186 633110Email:[email protected]

James Walker BrasilTel: +552122202152Fax: +55 21 253 11704Email:[email protected]

James Walker ChinaTel: +862168769351Fax: +86 21 6876 9352Email:[email protected]

James Walker DeutschlandTel: +49(0)403860810Fax: +49 (0)40 389 3230Email:[email protected]

James Walker FranceTel: +33(0)437497480Fax: +33 (0)437 497 483Email:[email protected]

James Walker IbericaTel: +34944470099Fax: +34 94 447 1077Email:[email protected]

James Walker IrelandTel: +353(0)214323626Fax: +353 (0)21 432 3623Email:[email protected]

James Walker ItalianaTel: +39022578308Fax: +39 02 263 00487Email:[email protected]

James Walker Mfg Co (USA)Tel: +17087544020Fax: +1 708 754 4058Email:[email protected]

James Walker New ZealandTel: +64(0)92721599Fax: +64 (0)9 272 3061Email:[email protected]

James Walker NorgeTel: +4722706800Fax: +47 22 706801Email:[email protected]

James Walker Oil & Gas (USA)Tel: +12818750002Fax: +1 281 875 0188Email:[email protected]

James Walker SingaporeTel: +6567779896Fax: +65 6777 6102Email:[email protected]

James Walker South AfricaTel: +27(0)312056251/2/3Fax: +27 (0)31 205 6266Email:[email protected]

James Walker worldwide support and distribution

Information in this publication and otherwise supplied to users is based on our general experience and is given in good faith, but because of factors which are outside our knowledge and control and affect the use of products, no warranty is given or is to be implied with respect to such information. Unless governed by type approval or contract, specifications are subject to change without notice. Statements of operating limits quoted in this publication are not an indication that these values can be applied simultaneously.

To ensure you are working with the very latest product specifications, please consult the relevant section of the James Walker website: www.jameswalker.biz.