OPTIMA · specifically for medium to large data center installations. OPTIMA units combine precise...

Transcript of OPTIMA · specifically for medium to large data center installations. OPTIMA units combine precise...

2020 Full Product Booklet

OPTIMAPrecision Air Conditioners for Critical ApplicationsCooling capacity: 80kW (Minimum cooling capacity 20kW)

Cooling Solutions for the Information,Communication and Technology Industries

www.airsysnorthamerica.com

2

ABOUT USAIRSYS Cooling Technologies Inc., is a global cooling solution provider with products and engineering services designed to

provide a wide variety of solutions for schools, data centers, mobile shelters and outdoor telecom cabinets. Whether the

products are used for sensible cooling telecommunication environments, or for human comfort, the AIRSYS team of highly

trained technicians can assist their client’s through every step of the deployment process from design through maintenance.

25TH ANNIVERSARYAIRSYS has reached an exciting milestone in 2020

with the company’s 25th anniversary as an award-

winning supplier of the world’s most energy efficient

cooling solutions.

MANUFACTURING FACILITY

Located in the manufacturing belt of the Carolinas in

Spartanburg County, AIRSYS operates out of a 60,000 square

foot manufacturing facility and corporate headquarters. Our

teams of highly trained technical, sales and field services staff

are veteran HVAC industry insiders who all work together to

provide 24/7 customer assistance for their clients.

RESEARCH AND DEVELOPMENT

As a global manufacturer of high-performance air-

conditioning equipment, AIRSYS is committed to providing

highly reliable and energy efficient cooling solutions

for critical environments. At AIRSYS we are focused on

progressive technologies for the HVAC industry. Through

our large research and development division, we proudly

develop new equipment that utilizes inverter driven

technologies, coupled with precise controls to maximize the

designed load calculations for a given space.

3

GLOBAL FOOTPRINT

AIRSYS Group has multiple branches in 7 countries around the world. The two manufacturing centers are

located in China and the United States. We have served more than 45 countries around the world.

AIRSYS (UK) Ltd.

AIRSYS Brasil Ltda.

AIRSYS Deutschland GmbH

AIRSYS Klima Sanayi ve Ticaret A.Ş.AIRSYS North America.

AIRSYS HQ

AIRSYS Factory

AIRSYS Service Center

AIRSYS Hongkong Co,.

AIRSYS Singapore Pte. Ltd.

APACChinaKoreaIndiaSingaporeMalaysiaPhilippinesIndonesiaAustraliaPakistanBangladeshKazakhstanNepalOmanCambodia

EuropeUKGermanyItalySpainRomaniaSerbiaFrancePolandTurkeyRussia

LATAMBrazilArgentinaPeruEcuadorColombia

AfricaSouthAfricaKenyaNigeria

NORAMUSACanada

4

CORE COMPETITIVENESS

Best value in Capital Expenditures (CAPEX) and lowest in Operational

Expenditures (OPEX)

Leading Edge Technologies

Energy efficiency, Intelligent Control, High

Reliability.

Responsiveness Strong R&D capability Global Footprint providing turn-key service

Best in class manufacturing facility

Lowest Total Cost of Ownership (TCO)

5

SERVICE

Consultation

Design

Products

Engineering

Service

6

At AIRSYS we believe in the quality of the product throughout

it’s entire life cycle, including research and design, pilot

testing, manufacturing, sales, and service. Therefore, we feel it

is necessary to ensure quality control at all points throughout

the product’s life cycle. We oversee the whole process and

have full participation in total quality management, so that

quality standards continue to be met (or exceeded) and that

customer satisfaction with our product is always ensured. We

proudly engineer the following ten technologies into each of

our products.

To Balance the Enviornment and forge ahead as a leading

manufacturer of high performance HVAC products, these ten

technologies are necessary to give our clients the highest

quality products that reduce overall energy consumption,

and provide high reliability for years to come.

TECHNOLOGIES

10 CUTTING EDGE TECHNOLOGIESUSED IN AIRSYS PRODUCTS

AIR FILTER PROTECTION DEVICES (AFPD)

SUPPLY CONDITIONCONTROL

INTELLIGENT CONTROLS

DC POWERED COOLING

ELECTRONICALLY COMMUTATED FANS

IoT COMPATIBALE SOFTWARE

SMART OPTIMIZATION FOR REFRIGERATION SYSTEMS

FREE COOLING

ADIABATIC COOLINGHIGH EFFICIENCY

EASY SERVICEABILITY

INTELLIGENT CONTROL

HIGH RELIABILITY

ECO-FRIENDLY

HIGH PRECISION

INVERTER TECHNOLOGY

7

PRODUCT OVERVIEWThe OPTIMA product family from AIRSYS is designed

specifically for medium to large data center installations.

OPTIMA units combine precise temperature and humidity

control with outstanding reliability and energy efficiency,

throughout 24*7 operation. The OPTIMA range of precision

air conditioners offers various heat-rejection options to meet

the needs of any installation.

The OPTIMA-INV series includes an energy efficient inverter

compressor. Other energy-saving technologies incorporated

into the OPTIMA series include options for EC fans, free

cooling and dual cooling sources.

8

MODEL NUMBER NOMENCLATURE

01 OPTIMA-INV Product TypeOPTIMA-INV: OPTIMA-INV precision air conditioner with inverter compressor, abbr. as OPTV

02 · Separator Character "."

03FCDC

DFC

FC—Indirect free cooling /DC—Dual cooling sources /DFC—Direct free coolingNone—Without free cooling or dual cooling sources

04 · Separator Character "."

05 OVER UNDER

Air Supply SchemeOVER – Up flow, abbr. as "O"/UNDER – Down flow, abbr. as "U"

06 · Separator Character "."

07 DXA Heat-Rejection DXA—Direct expansion with air cooled condenser

08 80 Nominal Cooling Capacity: kW

09 V2 Compressor Type and Number V2- OPTIMA-INV, 2 compressors

10 A4 Cabinet Size Codev: A4

11 R410 RefrigerantR410=R410A

12 · Separator Character "."

13 460/3/60 Power sourceVoltage/Phase/Frequency

14 · Separator Character "."

15 XXX Code for Custom Design

01 02 03 04 05 06 07 08 09 10 11 12 13 14 15

OPTIMA-INV .FCDC

DFC. OVER

UNDER . DXA 80 V2 A4 R410 . 460/3/60460/3/60 .. XXXXXX

STANDS FOR: OPTIMA-INV Precision Air Conditioner with direct free cooling; air supply scheme is down flow; heat rejection

via direct expansion with air cooled condenser; cooling capacity is 80kW; equipped with two compressors; cabinet size is A4;

R410A refrigerant; the input power supply is 460V/3Ph/60Hz; supply fan is EC centrifugal fan; outdoor unit is AMAE series.

FOR EXAMPLE: OPTV-DFC.U.DXA80V2A4R410.460/3/60

Note: 1ton = 3.517kW

9

HEAT REJECTION OPTIONS

• Air cooled direct expansion system (DXA) includes throttle, evaporator coil,

scroll compressor and refrigeration piping configuration.

• Heat from the indoor air is transferred to the refrigerant at the evaporator coil

and rejected to the outside air via the air-cooled condenser.

• Indoor unit: OPTIMA-INV.(DFC.)DXA

• Outdoor unit: AMAE series air-cooled condenser

• The FC.DXA unit is a dual-circuit system combining DXA heat-rejection with

indirect free cooling (FC). The circuits are independent.

• When there is a call for cooling, and the difference between indoor and

ambient temperatures is acceptable, the FC unit will run to provide indirect

free cooling through rejecting heat via a dry cooler. Only when free cooling

capacity is insufficient to meet the cooling demand will the DXA unit start up

mechanical cooling. Reduced run hours of the DXA system through the use of

the FC unit saves energy.

• Indoor unit: OPTIMA-INV-FC.DXA

• Outdoor unit: AMAE air cooled condenser, CMEH dry cooler,PUG pump kit.

• The DC.DXA unit is a dual-circuit system offering both DXA (air cooled)

mechanical cooling and chilled water cooling (CW). It contains two independent

cooling circuits with different heat-rejection methods for redundancy.

• Indoor unit: OPTIMA-INV-DC.DXA

• Outdoor unit: AMAE air cooled condenser,PUG pump kit, user supplied chilled

water source.

AIR COOLED DIRECT EXPANSION SYSTEM (DXA)

AIR COOLED DIRECT EXPANSION WITH INDIRECT FREE COOLING (FC.DXA)

AIR COOLED DIRECT EXPANSION WITH DOUBLE COOLING SOURCE (DC.DXA)

10

OPERATING RANGE AND CONTROL ACCURACY

APPLICATIONS

DXA

Operating Range

Outdoor Temperature:

-40~+131°F(-40~+55°C) (special options are available for extreme temperature conditions)

Piping Length:

Total length of 100ft.(30m) of gas and liquid refrigeration piping loop (consult AIRSYS sales representative for specific

installation arrangement)

Piping Vertical Distance:

Condenser above indoor unit: max 66ft.(20m)

Condenser below indoor unit: max 16ft.(5m)

(consult AIRSYS sales representative for specific installation arrangement)

Control Accuracy

Temperature Range and Accuracy:

Range: 59~95 °F(15~35°C), Accuracy: ±1.8 °F(1°C)

Humidity Range and Accuracy:

Range: 35~80%, Accuracy: ±5%

No. Applications1 Computer Rooms and Data Centers.

2 Telecom Equipment Rooms and Shelters.

3 Other Electronic Equipment Rooms.

4 Healthcare Equipment Rooms.

5 Laboratories with precise environmental requirements Precise Environmental Requirements.

6 Manufacturing facilities requiring precise environmentsFacilities Requiring Precise Environments.

7 StorageFacilities Requiring Precise Environments such as Museums and Wine Cellars.

11

The control accuracy for temperature is ±1.8°F(±1°C) and for

Relative humidity is ±5%.

Heat-Rejection arrangements include DX air cooled, DX air

cooled with direct free cooling (DFC), DX air cooled with

indirect free cooling (FC) and double cooling sources (DC).

Options are available to suit all installation requirements.

Supply air arrangements include top discharge (up flow)

and bottom discharge (down flow). Return air arrangements,

include top return, bottom return, front return and rear return

to meet all varied requirements of ICT sites.

The unit framework is provided with corrosion protection

treatment. The treatment is sufficient to provide protection

for a 15 year life cycle for inland installation.

If necessary, the treatment for sea air environment can be

supplied as an option.

The technical compartment housing the compressor,

humidifier, control and safety devices is separates from the air

flow, enabling ordinary service and preventive maintenance

to occur during operation.

Highly efficient EC fans are supplied with OPTIMA products.

OPTIMA-INV units are equipped with s scroll inverter

compressor which can vary speed continuously according to

the cooling demand.

A washable, easy maintainable and durable G4 class air

filter is a standard configuration for the OPTIMA range. With

optional air pressure switch, a clogged filter alarm can be

triggered when the filter is dirty.

The unit is installed with a pressure sensor which is used

for the fan speed control of the outdoor unit, therefore

maintaining refrigeration system pressure within a suitable

range and ensuring the stable operation of the system.

When compared to On/Off condensing control, the OPTIMA

system increases the energy saving significantly and extends

the working life of the compressor. It also enables the unit to

startup and work at low ambient temperatures (to -40 °F(-40

°C) or lower).

1 Precise Control

2 Various Heat Rejection Arrangements

3 Various Supply Air Arrangements

4 Corrosion-proof

5 Easy Maintenance

6 EC Fan

7 Scroll Compressor

8 Air Filter

9 Continuous Control System for Condensing Pressure

ENGINEERED FEATURES

12

The dehumidification process occurs through decreasing the evaporator coil surface temperature or reducing the air flow

across the coil. These features enable faster dehumidification, increased energy savings and more precise humidity control.

An electrode humidifier, controlled by a microprocessor, monitors and adjusts the humidifying capacity precisely, while the

water quality monitoring and wash extends the maintenance interval, prolonging the working life of the unit.

The construction of the electric heater element (stainless steel pipe with wrapped fins) allows for a reduced operating

temperature, therefore eliminating ionization, and avoiding unpleasant odors.

All the electrical and control components are installed in an isolated control panel with orderly wiring and clear labeling,

meeting the IEC standards.

All the microprocessor-connected components are continuously monitored and controlled and, in case of malfunction, the

unit is shut down and the fault is shown on the display.

10 Forced Dehumidification System

11 Electrode Humidifier

12 Electric Heater

13 Isolated Control Panel

14 Self-diagnosis

ENGINEERED FEATURES

13

ENERGY SAVING TECHNOLOGIES

OPTIONAL ENERGY SAVING RUNNING MODESOptional Energy Saving Running ModesThe OPTIMA family of products offers two running modes which may be

chosen from the controller display:

Standard running mode: In this mode, the temperature and humidity are controlled within narrower

ranges;

Energy saving mode: In this mode, good energy savings can be achieved through allowing the

temperature and humidity to be controlled within wider ranges.

14

ELECTRONICALLY COMMUTATED (EC) FANS

Energy EfficiencyEC fans have brushless DC motors and integrated control

modules. Motor efficiencies of 85-90% are achievable; 30%

to 50% higher than traditional AC fans.

The difference in energy efficiency between variable speed

EC fan control and traditional on/off fixed speed AC fans can

be seen in the graph; the bars show the power consumption

of fans which are switched in gradually as required while

the blue curve shows the power consumption with infinitely

variable speed control.

Supply air temperature control, as the name suggests, means

driving the operation of the compressor based on the air

temperature at the supply air discharge location; when

cool air is being supplied at the setpoint temperature, the

compressor is stopped until supply air temperature begins to

increase. This control method provides accurate adjustment

of the cooling capacity according to actual demand and can

save a considerable amount of energy.

Supply air temperature control is typically applied to cold

aisle cooling systems. As the cold aisle temperature profile

is uniform (i.e. there is no short-circuiting of air), accurate

reading of the supply air temperature is simple to obtain from

the unit supply air discharge location.

Because the supply air and cold aisle air temperatures are

equal, the cold air is supplied directly to the equipment

requiring cooling and no energy is wasted cooling the rest

of the room. Compared to return air temperature control

systems, supply air control systems can operate at a higher

supply air temperature under the same cooling demand

conditions. As well as this, evaporating temperatures will

typically be higher and therefore more energy efficient.

For down flow units utilizing supply air temperature control,

the differential air pressure can be monitored to ensure the

cool air has been evenly distributed to all the servers.

SUPPLY AIR TEMPERATURE AND PRESSURE CONTROL

An EC fan refers to a centrifugal fan that utilizes an Electronically Commutated motor (or brushless DC motor).

EC fans have numerous benefits including:

AC

EC

EC ACq

v =

pe =

Sound pressure level of AC fans (on/o� operation)

Sound pressure level of EC fans (continuous)

Noise reduction from continuousspeed adjustment

0% 25%

25%

50%

50%

qv

pe

75%

75%

100%

100%

AC

EC

EC ACq

v =

LPA =

0% 25% 50% qv

LPA

dB(A)

75% 100%

-3

-6

-9

-12

-15

-18

-21

EC

EC

0% 25%

25%

50%

50%

qv

pe

75%

75%

100%

100%

qv = Air volume

LPA = Sound pressure level

0% 25% 50% qv

LPA

dB(A)

75% 100%

-3

-6

-9

-12

-15

-18

-21

Benefit of continuous

speed adjustment

Benefit of continuous speed adjustment

Power consumption of AC fans (on/o� operation)

Power consumption of EC fans (continuous)

Saving from continuous speed adjustmentq

v = Air flow

pe = Input power

15

Lower NoiseIn a given installation, switching off half the fans (and halving the air flow) will

typically only reduce the generated noise by approximately 3dB. Compare this

to EC fans, where reducing fan speed to provide half the air flow typically yields

an reduction of approximately 15dB. This is possible as EC fans are able to

operate across an infinitely controllable speed range, which in turn effectively

avoids electromagnetic and rectifier noise (generated by other traditional

motor and speed control devices), thus reducing the overall noise level.

In the graph, the bars indicate the sound pressure level of fans which are

switched in gradually as required and the blue curve shows the sound

pressure level with infinitely variable speed control.

As can be seen from the picture EC fan sound pressure level is 12dB lower

compared to the traditional AC fan.

Compact, Integrated Electronic Control SystemAll EC fans have dedicated speed control modules and filters built into the

motor assembly, making for a compact and self-contained solution. All that

is required is to connect the main power supply and the sensor signals to

the controller for complete speed control of between 10% and 100%. EC fans

provide a simple, convenient solution and can also support group control

and remote monitoring.

Wide Working Voltage • Wide AC input voltage range: 1~200-277VAC or 3~380-480VAC 50&60Hz

• Wide DC input voltage range: 16-28VDC or 36-57VDC

AC

EC

EC ACq

v =

pe =

Sound pressure level of AC fans (on/o� operation)

Sound pressure level of EC fans (continuous)

Noise reduction from continuousspeed adjustment

0% 25%

25%

50%

50%

qv

pe

75%

75%

100%

100%

AC

EC

EC ACq

v =

LPA =

0% 25% 50% qv

LPA

dB(A)

75% 100%

-3

-6

-9

-12

-15

-18

-21

EC

EC

0% 25%

25%

50%

50%

qv

pe

75%

75%

100%

100%

qv = Air volume

LPA = Sound pressure level

0% 25% 50% qv

LPA

dB(A)

75% 100%

-3

-6

-9

-12

-15

-18

-21

Benefit of continuous

speed adjustment

Benefit of continuous speed adjustment

Power consumption of AC fans (on/o� operation)

Power consumption of EC fans (continuous)

Saving from continuous speed adjustmentq

v = Air flow

pe = Input power

16

More Precise Temperature ControlCompared to a fixed-frequency compressor, an inverter compressor can

achieve more precise temperature control through maintaining the room

temperature closer to the setpoint temperature. The control accuracy can be

as close as ± 0.9 °F(±0.5°C), even when the load is constantly changing. The

comparison between fixed-frequency and inverter compressor temperature

control accuracy is shown on the right picture.

High Efficiencies, Lower NoiseCompared to the on/off operation of fixed-speed compressors, inverter

compressors have stepless speed changes which, through intelligent control,

consistently aim to run at the most efficient operating point . This variable

frequency operation can save nearly 30% on operating costs.

Results from an AIRSYS performance test of fixed-frequency vs. inverter

compressors can be seen in the graph; the stark difference between

compressor COPs is easily seen.

Additionally, an inverter compressor starting current is only about 10% of

that of a fixed-frequency compressor, they typically have a higher reliability

and the noise generated at part load is approximately 5-10 dB lower.

INVERTER TECHNOLOGY

OPTIMA-INV inverter series precision air conditioners adopt energy-

efficient DC inverter scroll compressors that can achieve stepless

speed and on-demand cooling capacity adjustment to achieve the

greatest efficiencies. Inverter technology is available with direct

expansion air-cooled (DXA) type units.

The inverter system manages the compressor speed with infinitely

variable control according to the actual cooling demand;. When the

difference between room and setpoint temperatures is high, the

compressor operates at a high speed (and greater cooling capacity).

As the temperature difference reduces, the compressor speed

gradually reduces to more accurately maintain room temperature (a

subsequently conserving energy).

Tem

pera

ture

Tem

pera

ture

Time

Time

Zone temperature Setpoint

Zone temperature Setpoint

Variable speed compressor

Fixed speed compressor

17

OPTIMA-INV Inverter Series precision air conditioners utilize

electronic expansion valves to regulate the refrigerant flow entering

the evaporator and match it to the running speed of the compressor.

Compared to thermal expansion valves, electronic expansion valves

control much more accurately and efficiently. They are also able

to control system evaporation temperature and superheat more

effectively and lead to an overall higher system efficiency.

Data center power consumption is generally divided between four major sources; IT equipment, cooling systems, backup

power and lighting systems. The specific proportions are different in each data centers, however a typical split is presented

here.

As the pie chart show, the energy consumption of the cooling system is second only to the actual IT equipment; i.e. the air

conditioning systems account for a large portion of the total energy consumption of the data center. Therefore, by taking

advantage of free cooling solutions (and hence reducing the run hours of the compressors) large energy savings are potentially

achievable. AIRSYS has developed both direct and indirect free cooling systems, as well as dual heat-rejection mode units

which can significantly reduce the overall energy consumption of a data center. Options are available or configurable to suit

any and all installation requirements.

17

ELECTRONIC EXPANSION VALVE (EEV) TECHNOLOGY

18

INDIRECT FREE COOLING

DUAL COOLING SOURCES

Indirect free cooling refers to heat-rejection through circulating water between an indoor cooling coil and an outdoor dry

cooler or cooling tower; the water absorbs the heat at the indoor coil and then discharges it to the atmosphere via the dry

cooler or cooling tower.

By adding a water coil to the direct-expansion evaporator

coil and completing an indirect free cooling (FC) circuit with

a dry cooler or cooling tower, significant energy savings

can be made through a reduction in the DX compressor run

hours. When there is a call for cooling, and the difference

between indoor and ambient temperatures is acceptable,

the FC system will run to provide indirect free cooling. If the

FC system can not satisfy the total cooling demand, the DX

cooling system will commence operation, however, as the

outdoor ambient temperature decreases, the proportion of

FC capacity will increase. When free cooling capacity reaches

100%, and cooling demand is being met, complete FC mode

is achieved and there is no compressor power consumption

from the DX system.

OPTIMA-INV units can accommodate the indirect free cooling

option. The corresponding series are OPTIMA-INV-FC.DXA.

The schematic diagram showing the principle of operation

for an air cooled direct expansion unit with indirect free

cooling (FC) is as follows:

Air cooled direct expansion unit with indirect free cooling (FC)

42 31

5

6

7

8 9 10

13 14 12

11

1 - Indoor unit

2 - Outdoor unit

3 - Pump group (optional)

4 - Dry cooler (optional)

5 - Compressor

6 - Evaporator

7 - Supply fan

8 - Expansion valve

9 - Sight glass

10- Filter dryer

11 - Liquid receiver

12 - Air cooled condenser

13 - Return air

14 - Supply air

Dual cooling (DC) source units are supplied with two fully

independent cooling circuits; chilled water system cooling

(default) and mechanical (DX) cooling (supplementary).

Where a chilled water system is always available for heat

rejections, the unit will always run in chilled water cooling

mode. Only when chilled water cooling can not meet the

cooling demand will the microprocessor controller switch

from chilled water cooling to DX cooling. Where a chilled

water system is not always available (e.g. seasonal plant

operation), chilled water cooling will only occur when the

system is available.

As heat rejection via chilled water is prioritized, run time for

the DX cooling system is minimized resulting in an extend life

expectancy of the compressor corresponding energy savings.

19

DC units have an inherently higher reliability (due to inbuilt redundancy) and can ensure that cooling is more consistently

available. They also have the intelligence to select the most efficient operation mode depending on the environment, which

can greatly reduce energy consumption.

OPTIMA-INV units can accommodate dual cooling options. The corresponding series names are OPTIMA-INV-DC.DXA.

The schematic diagram showing the principle of operation for an air cooled DX dual cooling system is as follows:

For installations where outdoor temperatures are commonly lower than indoor temperature, fresh air can be introduced

directly into the room to cool the equipment; this is known as direct free cooling (DFC). A well designed and integrated DFC

system can greatly reduce the dependency on other cooling systems and save energy through minimizing their run hours.

DFC systems can be integrated with OPTIMA-INV units, with up flow and down flow configurations. The corresponding series

names are OPTIMA-INV-DFC. The diagram showing the arrangement and principle for direct free cooling options is as follows:

OPTIMA-INV-DFC systems include mechanical (DX) cooling and free cooling modes, together with the intelligence to switch

between the modes to ensure the most efficient operation. When utilizing direct free cooling, the DX system compressor stops,

which has a significant impact on the energy consumption.

In recent years, energy-efficient data centers have attracted greater attention and many data centers are now able to achieve

significant energy savings through both increasing the IT equipment tolerance temperatures and expanding the considered

geographical scope to exploit direct free cooling (which is not only limited to regions of extreme cold).

Air cooled direct expansion unit with dual cooling sources (DC)

42 31

5

6

7

8 9 10

13 14 12

11

1 - Indoor unit

2 - Motorized 2-way valve

3 - Pump group(optional)

4 - Chiller(user supplied)

5 - Compressor

6 - Evaporator

7 - Supply fan

8 - Expansion valve

9 - Sight glass

10 - Filter dryer

11 - Liquid receiver

12 - Air cooled condenser

13 - Return air

14 - Supply air

15 - Chilled water coil

DIRECT FREE COOLING (DFC)

20

Continuous and reliable operation of the air conditioning

systems is critical for the successful operation of data

center equipment. As a result of the high proportion of

power consumed by such air conditioning systems, energy

consumption has been a challenge faced by modern data

centers. AIRSYS precision air conditioners aim to address

this challenge, in part, through effective group control

and rotation functions. Such control philosophies ensure

consistent room temperature and humidity, together with

continuous reliable operation (generally, by the addition of a

spare unit for redundancy) whilst minimizing the total power

required for the air conditioning. Group control and rotation

functions will also typically extend unit life and effectively

save energy by improving the overall management of the

system.

GROUP CONTROLS

AWG20/22 Shield Cable

Main Unit Secondary Unit 1 Secondary Unit 2 Secondary Unit ≤ 7

21

REMOTE CONTROL AND NETWORK MONITORING

Remote control and network monitoringNetworking and Monitoring of air conditioning equipment is typically a

subsystem of a Building Management System (BMS) and provides centralized monitoring and management of all the

air-conditioning equipment.

Thanks to years of experience in the production and application of precision air conditioning equipment, AIRSYS is

able to provide a variety of monitoring systems ranging from simple SMS alarm monitoring to the most sophisticated

TeraCloud based GPRS wireless centralized monitoring system. There is a solution available to suit all sites and

installations.

• 3 kinds of local direct cable connection

• 3 kinds of LAN network connection

• 4 kinds of wireless network connection

N16

N2

N1

RS232 Data Cable

N16

N2

N1

N16

N2

N1

Wireless Connection Types Local Area Network (LAN) Connection Types

Ethernet Network Cable

LAN Connection 1

LAN Connection 2

RS485-RS232 Converter

RS485-RS232 Converter

Direct Connection for Multiple Units

RS485 Bus

RS485 Bus

RS485 BusRS232 Cable

Ethernet Network Cable

RS485-TCP/IP Converter With 16 Ports

Cooling Unit & Comm. Card

Single Port RS485-TCP/IP Converter

Single Unit Direct Connections

GSM Mobile Communication Network

GSM Communication Network

Wireless Connection 1

Mobile Phone

Mobile PhoneGSM Module

GSM Module

Wireless Connection 3

Wireless Connection 4

Direct Connection 1

Direct Connection 2

Direct Connection 3

Direct Connection 4

Wireless Network Communication

RS485-TCP/IP Wireless Router

Wireless Router

RS485 CardModbus Protocol

Wireless Connection 2

RS485 Data Cable

Monitoring Computer Requirements: 1. TCP/IP card2. RS485 card3. RS232 card 4. IntelliVision Plus Software

RS485 Data Line

Ethernet Network Cable

22

UNIT CONFIGURATIONS

OPTIMA-INV-FC/DC units also includes the following standard configurations.

Note: “●”standard configuration, “—” no option available.

OPTIMA FAMILY - STANDARD PRODUCT CONFIGURATIONS

No. Standard Configuration No. Standard Configuration1 Powder coated steel frame 13 Rubber vibration absorber for compressor

2 Powder coated steel panel with inside thermal and acoustic insulation 14 Electric expansion valve

3 EC centrifugal fan 15 Sight glass

4 Copper tube aluminum fin coil 16 Filter dryer

5 Condensing water tray 17 Liquid receiver

6 Class G4 air filter 18 High pressure transducer

7 Temperature and RH sensor at return air inlet 19 Pressure switch for high/low pressure protection

8 Air pressure switch for supply fan protection 20 Continuous control system for condensing pressure

9 Microprocessor control 21 Phase sequence protection relay for power supply

10 Electrical control panel 22 RS485 communication

11 Stainless steel electric heater, various capacity available 23 Clock function

12 Proportional controlled electrode type humidifier, various capacity available 24 Wooden packaging

Standard Configuration OPTIMA-INV-FC OPTIMA-INV-DCCopper tube aluminum fin free cooling coil ● —

Copper tube aluminum fin chilled water cooling coil — ●

Motorized 2-way valve ● ●

23

OPTIONS FOR THE OPTIMA FAMILY PRODUCT

No. Options Configuration No. Options Configuration

1 Air pressure switch for clogged filter alarm 8 Additional floor water detector

2 Motorized no-return damper for up flow unit 9 Colored touch screen graphical user interface.

3 Supply air plenum for up flow unit 10 RS232 communication

4 Supply air plenum for down flow unit 11 pCOWeb communication card

5 Backward air return for up flow unit 12 GSM short message module

6 Installation support stand with adjustable legs 13 Remote display controller

7 Supply air temperature sensor 14 Low temperature operation kit for outdoor temperature below-4°F(-20°C)

OPTIONAL SUPPLY AIR PLENUM DIMENSIONS AND WEIGHT

ELECTRIC HEATER/HUMIDIFIER SELECTION SHEET

Cabinet sizes Units Sizes

Width in(mm) 98(2490)

Depth in(mm) 35(890)

Height in(mm) 18-1/2(470)

Weight Ib(kg) 192(87)

Heat capacity (BTUH) Heat capacity (kW) MOP (A) MCA (A)

Electric

Heater

61200 18 90 83 ●

92200 27 — — ○

Humidification capacity (lb/hr) Humidification capacity (kg/h) MOP (A) MCA (A)

Electric

Humidifier

17.6 8 — — ●

22.0 10 — — ○

28.0 13 — — ○

33.0 15 — — ○

Note: “●”means standard configuration,

“○”means option,

“—”please contact manufacturer for a detailed MOP and MCA.

24

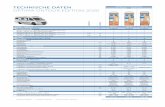

TECHNICAL SPECIFICATIONSOPTIMA-INV(-/FC/DFC).DXAModel Number OPTIMA-INV.DXA80V2A4 OPTIMA-INV-FC.DXA80V2A4 OPTIMA-INV-DFC.DXA80V2A4Unit Type UP/Down Flow UP/Down Flow UP/Down FlowRefrigerant Type R410A R410A R410ACompressorCompressor Type Hermetic scroll Hermetic scroll Hermetic scrollPower(1) kW 20.0 20.0 20.0Current(1) A 28.5 28.5 28.5Supply fanType EC centrifugal fan EC centrifugal fan EC centrifugal fanQty. of fan n. 3 3 3Air volume SCFM (m3/h) 12900 (21900) 12900 (21900) 12900 (21900)Power kW 4.0 5.0 4.0External static in.H2O(Pa). 0.4(100) 0.4(100) 0.4(100)Air filter MERV 8 MERV 8 MERV 8Electric heaterType Stainless steel Stainless steel Stainless steelElectric heater capacity BTUH(kW) 61400(18.0) 61400(18.0) 61400(18.0)Current A 22.6 22.6 22.6HumidifierType Electrode type Electrode type Electrode typeHumidification capacity lb/hr(kg/h) 17.6(8) 17.6(8) 17.6(8)Power kW 5.9 5.9 5.9 Current A 7.4 7.4 7.4 Outdoor CondenserModel*Qty. AMAE15*2 AMAE15*2 AMAE15*2Dry cooler(only available for FC unit) Model*Qty. VMEG55 VMEG55 VMEG55FC unit free cooling coil/DC unit chilled water coil1Water flow SCFM(m3/h) 8.0(13.6) 8.0(13.6) 8.0(13.6)Preesure drop in.H2O (kPa) 272(69.1) 272(69.1) 272(69.1)DFC Return Air Box / / S1+S2Power source (Voltage/Phase/Frequency) 460V/3p/60Hz 460V/3p/60Hz 460V/3p/60HzUnit max. operating power(2) kW 43.2 46.1 43.2 Unit max. operating current(2) A 59.4 66.6 59.4 Unit piping connection(Φ)Humidifier water supply in 1/2″ 1/2″ 1/2″Condensate water drainage in 3/4″ 3/4″ 3/4″Refrigerant discharge (3) in 7/8″ 7/8″ 7/8″Refrigerant liquid(3) in 5/8″ 5/8″ 5/8″Unit dimensions and weightWidth in(mm) 98.0(2490) 98.0(2490) 98.0(2490)Depth in(mm) 35.0(890) 35.0(890) 35.0(890)Height in(mm) 77-3/16(1960) 77-3/16(1960) 77-3/16(1960)Weight lb(kg) 1775(805) 1962(890) 1775(805)

Notes:

(1) The date of the compressor under standard conditions. Evaporation temperature 50°C(10°C), condensation 116.5°C(47°C).

(2) Max. operating power input and current input: as above spec sheet, under the condition of dehumidification plus 100% electric reheat.

(3) Only represents the inner pipe diameter of the unit.

25

VARIABLE SPEED COMPRESSOR OF UNIT CAPACITY DATA

NOMINAL COOLING PERFORMANCE

Note:

All Data given at 85.0(29.4)/ 64.2(17.8) °F(°C) entering indoor Dry-Bulb/ Wet-Bulb temp and 52.0(11.1) °F(°C) return dew-point temperature.

Notes:

(1)All Data given at 85.0(29.4)/ 64.2(17.8) °F(°C) entering indoor Dry-Bulb/ Wet-Bulb temp and 52.0(11.1) °F(°C) return dew-point temperature.

(2)The cooling capacity is provided entirely by direct natural cooling.

(3)This figure does not include exhaust fan power.

ModelOutdoor Ambient

Dry-bulb Temperatu (°F/°C)

Min Total Capacity (BTUH /kW)

Max Total Capacity (BTUH /kW)

Min Sensible Capacity (BTUH /

kW)

Max Sensible Capacity (BTUH

/kW)

OPTIMA-INV.

DXA80V2A4

95/35.0 68200/20.0 307100/90.0 66500/19.5 303700/89.0

80/26.7 71700/21.0 327600/96.0 69900/20.5 313900/92.0

65/18.3 78500/23.0 337800/99.0 76800/22.5 320700/94.0

40/4.4 85300/25.0 348000/102.0 83600/24.5 331000/97.0

OPTIMA-

INV-FC(DC).

DXA80V2A4

95/35.0 68200/20.0 307100/90.0 66500/19.5 303700/89.0

80/26.7 71700/21.0 327600/96.0 69900/20.5 313900/92.0

65/18.3 75100/22.0 337800/99.0 76800/22.5 320700/94.0

40/4.4 68200/20.0 348000/102.0 68200/20.0 331000/97.0

OPTIMA-

INV-DFC.

DXA80V2A4

95/35.0 68200/20.0 307100/90.0 66500/19.5 303700/89.0

80/26.7 71700/21.0 327600/96.0 69900/20.5 313900/92.0

65/18.3 75100/22.0 337800/99.0 76800/22.5 320700/94.0

40/4.4 68200/20.0 348000/102.0 68200/20.0 331000/97.0

ModelOutdoor Ambient

Dry-bulb Temperature (°F/°C)

Total Net Cooling Capacity (BTUH /

kW)(1)

Total Net Sensible Cooling Capacity

(BTUH /kW)(1)

Total Rated Power (kW)(1)

Net Sensible COP (kW/kW)(1)

OPTIMA-INV.

DXA80V2A4

95/35.0 218800(82.6) 279800(82.0) 27.0 3.0

80/26.7 296900 (87.0) 294100(86.2) 23.8 3.6

65/18.3 303700(89.0) 297900(87.3) 22.0 4.0

40/4.4 307100(90.0) 303700(89.0) 20.5 4.3

OPTIMA-

INV-FC(DC).

DXA80V2A4

95/35.0 218800(82.6) 279800(82.0) 28.0 2.9

80/26.7 296900 (87.0) 294100(86.2) 24.8 3.5

65/18.3 303700(89.0) 297900(87.3) 23.0 3.8

40/4.4 307100(90.0) 303700(89.0) 17.0 5.2

OPTIMA-

INV-DFC.

DXA80V2A4

95/35.0 218800(82.6) 279800(82.0) 27.0 3.0

80/26.7 296900 (87.0) 294100(86.2) 23.8 3.6

65/18.3 279800(82.0)(2) 279800(82.0)(2) 4.0(3) 20.5

40/4.4 307100(90.0) 303700(89.0) 4.0(3) 22.3

26

Note: (1)The capacity is rated at entering air temperature 95°F(35°C) and condensing temperature 122°F(50°C) condition.

Model AMAE15Capacity (1) BTUH(kW) 195200(57.2)

Fan

Fan qty. No. 2

Air flow rate SCFM(m3/h) 12950(22000)

Input power kW 1.26

Input current A 5.6

Connection tube size

Gas pipe in 1/2″

Liquid pipe in 3/8″

Unit external dimensions and Weight

Length in(mm) 78-1/8(1985)

Width in(mm) 24-7/16(620)

Height in(mm) 42-1/2(1080)

Weight lb(kg) 306(139)

Wooden packaging dimensions and Weight

Width in(mm) 82-5/8(2100)

Depth in(mm) 29-3/4(755)

Height in(mm) 48-5/8(1235)

Weight lb(kg) 434(197)

NOMINAL COOLING PERFORMANCE

AMAE

Note: All Capacities, EER certified to AHRI 1360 testing standard.

Model Nominal Total Capacity (BTUH/kW)

EER (Standard) (BTU/W)

EER(90% Part Load)(BTU/W)

EER (60% Part Load)(BTU/W)

OPTIMA-INV.DXA80V2A4 218800(82.6) 10.3 10.9 11.6

OPTIMA-INV-FC(DC).DXA80V2A4 218800(82.6) 10.0 10.7 11.0

OPTIMA-INV-DFC.DXA80V2A4 218800(82.6) 10.3 10.9 11.6

27

Unit model PUG15 PUG20Water flow SCFM(m3/h) 8.9(15.2) 11.9(20.2)

Pressure ft(m) 91.9(28) 85.3(26)

Pump Qty. n. 2 2

Input power kW 2.2 3

Input current A 4.9 6.3

Connection tube size

Water inlet pipe in 2″ 2″

Water outlet pipe in 2″ 2″

Unit external dimensions and Weight

Length in(mm) 54-3/8(1390) 54-3/8(1390)

Width in(mm) 29-1/2(750) 29-1/2(750)

Height in(mm) 41-3/8(1050) 41-3/8(1050)

Weight lb(kg) 331(120) 359(150)

PUG PUMP GROUP BOX

Model S1 S2MERV 8 Panel air filter

Size in(mm) 32-1/2*21-1/2*3/8(825*545*10)

28-1/4*21-1/2*3/8(717*545*10)

Qty n. 1 2

MERV 13 Bag air filter

Size in(mm) 32-3/5*21-1/2*1-7/8(828*545*46)

28-1/4*21-7/16*1-7/8(717*545*46)

Qty n. 1 2

Air inlet/outlet

Length in(mm) 28-7/8(732) 51-15/16(1320)

Width in(mm) 16-1/8(410) 16-1/8(410)

Unit external dimensions and Weight

Width in(mm) 34-1/4(870) 58-1/4(1480)

Depth in(mm) 26-3/4(680) 26-3/4(680)

Height in(mm) 57-1/8(1450) 57-1/8(1450)

Weight lb(kg) 198(90) 315(143)

Wooden packaging dimensions and Weight

Width in(mm) 40-1/8(950) 64-3/16(1560)

Depth in(mm) 32-1/4(750) 32-1/4(750)

Height in(mm) 65(1600) 65(1600)

Weight lb(kg) 362(105) 516(165)

DFC FRESH AIR INLET BOX

28

A4 UNIT CABINET DIMENSION DRAWING FOR UP FLOW UNIT

A4 UNIT CABINET DIMENSION DRAWING FOR UNDER FLOW UNIT

UNIT DIMENSIONAL DRAWINGS

70

1

6363

302

2364

2490

1960

890

1

[35in] [98in]

[11-7/8in]

[2-1/2in]

[2-1/2in] [93-1/16in]

[77-3/16in]

Note: (1) Connection pipe: There are differences in connection pipe positions of the units. Please refer to the actual units.

Note: (1) Connection pipe: There are differences in connection pipe positions of the units. Please refer to the actual units.

29

OPTIMA-DFC FRESH AIR INLET BOX DIMENSION DRAWING-S1

OPTIMA-DFC FRESH AIR INLET BOX DIMENSION DRAWING-S2

870 680mm 870mm

730mm

1450

400

730

400

1450mm

870mm

680

[57-1/16in]

[34-1/4in]

[77-3/16in]

[34-1/4in]

[26-3/8in]

[34-1/4in]

[77-3/16in]

[15-3/4in]

[57-1/16in][15-3/4in]

[26-3/8in]

2

1

680

400

400

1450

1480

1330

1480

13301450

680

1480

[58-1/4in]

[52-3/8in]

[58-1/4in]

[26-3/8in]

[58-1/4in]

[52-3/8in]

[26-3/8in]

[57-1/4in]

[15-3/4in]

[15-3/4in]

[57-1/4in]

1

2

1. connected to the outdoor side

2. connected to the unit

1. connected to the outdoor side

2. connected to the unit

30

AMAE15 DIMENSION DRAWING

[78-1/8in]

[73-1/8in]

[42-1/2in]

[24-3/8in]

[22-7/16in]

ADJUSTABLE STAND(OPTIONAL)

300~600mm[11-4/5~23-3/5in]

2444mm [96-1/4in] 835.5mm [32-7/8in]

31

AIR SUPPLY BOX DIMENSION DRAWING(OPTIONAL)

446.4mm

400mm

[296-5/16in]

[15-3/4in]

836.7mm [32-15/16in]

AIR SUPPLY PLENUM DIMENSION DRAWING(OPTIONAL)

[35in]890mm2490mm

[18-

1/2i

n]47

0mm

[98in]

AIRSYS (NORTH AMERICA) SALES AND SERVICE CONTACT:

AIRSYS GLOBAL SUBSIDIARIES CONTACT:

Sales Contact:Email: [email protected] Main: + 1 (855) 874-5380

AIRSYS Refrigeration Engineering Technology (Beijing) Co., Ltd.Add: 10th floor, Hongkun Shengtong building, 19, Ping Guo Yuan Xi Xiao Jie, Shijingshan, Beijing, China 100043

Tel: +86(0)10 68656161

Gu’an Airsys Environment Technology Company Ltd.Add: 25, Dongfang Street, Gu’an Industry Park, Langfang City, Hebei Province, China

Tel: +86(0)10 68656161

Shanghai Airserve HVAC System Service Co., Ltd.Add: #7-2, No.658, Daduhe Rd., Putuo District, Shanghai, China, 200333

Tel: +86(0)21 62452626 Fax: +86 (0)21 62459622

AIRSYS Australia Sales OfficeAdd: PO BOX 1088, Flagstaff Hill, SA, 5159, Australia

Tel: +61 479151080

AIRSYS BRASIL LTDA.Add: Av. Moaci, 395 Conj 35/36 04083-000 – Planalto Paulista SAO PAULO – SPTel: +55 (11) 25976817 / +55 (11) 21585560

AIRSYS Deutschland GmbHAdd: Dahlweg 120, D-48153 Münster GermanyTel: +49 (0) 1757535054 / 251-97307478

AIRSYS Turkey - Klima Sanayi ve Ticaret A.Ş.Add: Barbaros Mahqq. Evren Cad. Erzurumlular Sk. No:23 Ataşehir / Istanbul Turkey

Tel: +90(216) 4706280 Fax: +90(216) 4706290

AIRSYS (North America), LLCICT and Human Comfort Cooling:Add: 7820 Reidville Rd. Greer, SC 29651 , USATel: +1 (855) 874 5380

Web: https://airsysnorthamerica.com/

Medical Cooling:Add: 3127 Independence Dr Livermore, CA 94551, USATel: +1 800 7131543

Web: https://advancedcoolingtech.com/

AIRSYS Singapore Pte. LtdAdd: 12 Lorong Bakar Batu #06-01 Singapore (348745)

Tel: +65 62787188 Fax: +65 68416301

AIRSYS (UK) Ltd.Add: 245 Europa Boulevard, Warrington, UK. WA5 7TN

Tel: +44 (0) 1925 377 272 Call Centre: +44(0)8456099950

www.air-sys.com

Product design and specification subject to change without prior notice.

Email: [email protected] Main: + 1 (855) 874-5380

Service Contact:

WWW.AIRSYSNORTHAMERICA.COM

AIRSYS North America