Operation,SizingandInstallationManual - HVACQuickthe CAF/AH. This will minimize thermal siphoning in...

Transcript of Operation,SizingandInstallationManual - HVACQuickthe CAF/AH. This will minimize thermal siphoning in...

69-CAF0912

Hydronic Models with Built-inHeat Recovery Ventilator (HRV)

MANUFACTUREDWITH

AIRCOM ELECTRONICS

Operation, Sizing and Installation Manual

Models

CAF-U-S4A-24-P16 (E16)CAF-D-S4A-24-P16 (E16)CAF-H-S4A-24-P16 (E16)CAF-U-L4A-36-P16 (E16)CAF-D-L4A-36-P16 (E16)CAF-H-L4A-36-P16 (E16)CAF-U-L2A-48-P16 (E16)CAF-U-00-24-P16 (E16)CAF-U-00-36-P16 (E16)CAF-U-00-48-P16 (E16)

IntroductionOverview of the Clean Air Furnace ..................................3Description and PurposeOperation Heating/Cooling...............................................4

The Recovery Core ...........................................................5

Combo System Basic Principles .......................................6

Plumbing......................................................................7-14

Installation .................................................................15-17

Pitot Tube Air Flow Balancing ..................................18-19

Function and Controls ...............................................20-21Optional DehumidistatOptional Timers ..............................................................22

Wiring the Controls.........................................................23

Aircom Relays ................................................................24

Start-up Procedure ..........................................................25

Service and Maintenance ................................................26

Troubleshooting ..............................................................27Controlling your HRVHow the Dehumidistat Works .........................................28

Model Number Nomenclature Breakdown.....................29

Specifications ............................................................30-39

System Commissioning ..................................................40

Work Sheets...............................................................41-42

Wiring Diagrams .......................................................43-44

Never install an HRV/ERV in a situationwhere its normal operation, lack of operationor partial failure may result in thebackdrafting or improper functioning ofvented combustion equipment!

CAUTION

Assess how the operation of an HRV/ERVmay interact with already installed ventedcombustion equipment (ie. Gas Furnaces,Oil Furnaces, Wood Stoves, etc.).

CAUTION Table of Contents

2

The Clean Air Furnace hydronic coil is not tobe used for chilled water applications wherecondensation is expected.

ATTENTION

Air Condition coil freezing can damage thehydronic coil of the Clean Air Furnace.Install a Freeze Thermostat Kit to your airconditioning coil to prevent coil freeze up.Check with your air conditioner distributor toobtain a Freeze Thermostat Kit.

ATTENTION

Do not apply electrical power to the unit untilinstallation has been fully completed (includinglow voltage control wiring).

Installing Contractor

Telephone / Contact

Serial Number

Installation Date Model

TO BE COMPLETED BY CONTRACTOR AFTER INSTALLATION

Register for your warranty at www.lifebreath.com

Airia will require the Model and Serial Number to register the unit.

You will notice that the heated air in your home feels morecomfortable than air heated by a conventional furnace. Onereason for this is that LIFEBREATH's hydronically heatedair is uniform and temperate... no short blasts of hot air orhot and cold temperature spikes. The air flowing from yourhot air vents will not feel as hot to the touch as air from aconventional furnace.With a high efficiency, adequately sized natural gas,propane or oil hot water heater/boiler, you will always haveplenty of hot water for showers and baths, washing dishesand clothes, and all other normal domestic hot water needs.If there is an unusually high demand for hot water, such asfilling a large hot tub, then all you need to do is allow moretime for the task so the water heater/boiler can keep up toits job of providing hot water for the heating system as wellas other household uses.

Once it is correctly installed, safety will never be an issuewith your LIFEBREATH furnace. No flames, fumes or fluegases to be concerned about. Your domestic hot waterheater/boiler now provides the heat source for your furnace.This Operation and Installation Guide will help you learnabout your LIFEBREATH Clean Air Furnace quickly andeasily. The table of contents will show you where to findinformation on every feature of this unit along with easy tounderstand operating instructions. If, however, you doencounter a question that is not covered in this Guide youshould call the LIFEBREATH dealer who installed yourfurnace. Chances are that he will be able to give you asatisfactory answer but if he is unable to do so then weinvite you to contact us directly.

Airia Brands Inc.

Introduction

Overview of the Clean Air Furnace

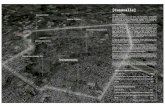

Hydronic Coil and PumpCompartment

Recovery Coreand VentilationCompartment

Aircom Electronicsand FanCompartment

3

IMPORTANT NOTEThe purpose of this manual is to act as an installation guideonly for the LIFEBREATH Clean Air Furnace.Manufacturers' instructions for other components, such asthe water-heater/boiler, must be followed.All national and local code requirements must be met wheninstalling a LIFEBREATH Clean Air Furnace. Be sure toconsult the proper authorities.Note: Temperatures greater than 130°F (54°C) pose a seri-

ous risk of scalding individuals running domestichot water for potable use.

This appliance complies with IAS Canada Inc. RequirementCR95-003, Additional Requirements for Fan Coil Units foruse with Potable Water Heaters.All piping and components connected to this appliance shallbe suitable for use with potable water.Toxic chemicals, such as used for boiler treatment, shall notbe introduced into the potable water heater system.When using this system and the hot water for space heatingis set to a higher temperature than for other uses, an anti-scald valve shall be used to ensure water for common use isreduced in temperature to minimize a scalding hazard.

Combining two or more end uses such as space heating andthe heating of domestic hot water in a single system has thepotential to increase efficiency and reduce overall capitalcosts. However, the proper design, installation, and com-missioning of these systems are critical if these advantagesare to be realized.This manual provides a guideline of good engineering prac-tice in the design, installation and commissioning ofIntegrated Combo Systems. The guidelines in the manualare designed for residential forced warm air IntegratedCombo Systems which utilize domestic water heaters orboilers and the LIFEBREATH furnace. Heating and coolingloads shall be calculated in accordance with recognizedResidential Heat Loss and Heat Gain Calculation methods.Duct design shall comply with recognized Residential AirSystem Design methods. This manual provides worksheetsto be used for the purpose of sizing residential water heatersand the combo furnace.The LIFEBREATH Clean Air Furnace is a volume ventila-tion system. Use the optional Lifebreath Bathroom ExhaustSystem Kit (Part 99-CAF-BESKIT) if you wish to exhaustfrom specific locations such as bathrooms.

Description and Purpose

Operation Heating/Cooling

When the room thermostat calls for heat, it activates a cir-culation pump located inside the Clean Air Furnace. Thispump delivers hot water from the water heater, through thefurnace coil and back to the water tank. Simultaneously, thefurnace blower switches on to high speed and will start cir-culating air across the coil, which picks up heat and deliversit to the rest of your home.Once the thermostat's temperature is reached the pump willshut off, and the blower will return to its pre-set speed oroff.Note: When the furnace blower is left running on lowspeed the air in the home circulates continuously. Whenthe heat is called for the blower will automatically switchto a higher speed. After the required hot air has beendelivered the blower will switch back to low speed.When the thermostat calls for cooling (evaporator coil andcondensing unit required), the furnace blower activates tohigh speed and the outdoor condenser unit is energized.After the thermostat temperature is reached, the condensingunit will shut off and the blower will return to its presetspeed or off.

VentilationThe heat recovery ventilation (HRV) portion of the CleanAir Furnace, is automatic. Once set, a desired amount offresh air will be drawn into the home while the furnaceblower is activated.To reduce humidity, increased ventilation may be requiredduring heating season. An optional remote dehumidistat canbe installed. The dehumidistat will increase the speed of thefurnace blower to high and will return to its original settingwhen humidity levels decrease. Your dehumidistat must beswitched off during warmer months. A quality humidifiershould be added if you wish to increase winter humiditylevelsTypically the air flow for ventilation will be set to 50 -70cfm, for low speed furnace operation, and100 - 150cfm at high speed. The pleated furnace filtershould be checked regularly and replaced as needed. TheHRV filter should be washed twice a year or more often ifneeded.

Off Season Circulation TimerAll models are equipped with a circulation timer. It is nor-mal operation for these models to automatically run thecirculation pump intermittently for a short period of time.

4

HRV - Aluminum CoreA Heat Recovery Ventilator (HRV) is designed to providefresh air into a building while exhausting an equal amountof stale air. During the winter months, the incoming coldfresh air is warmed by utilizing the heat recovered from thestale air before it is exhausted to the outdoors. During sum-mer months when the indoor space is air conditioned, theHeat Recovery Ventilator will help in cooling the incomingfresh air with the stale air that is being exhausted.

ERV - Enthalpic Paper CoreAn Energy Recovery Ventilator (ERV) is designed to pro-vide fresh air into a building while exhausting an equalamount of stale air. An ERV is designed for use in warmhumid areas with heavy air conditioning use. The ERV willtransfer both sensible and latent heat from the incomingfresh air to the outgoing stale air thereby reducing the load(due to ventilation) on the air conditioning system.

The Recovery Core

Stale Air from Building

Stale Air to Outside

FreshOutdoor Air

Fresh Airto Building

The ERV - Enthalpic Core is not suitable forclimates where the outdoor temperaturedrops below -4°C (25°F).

ATTENTION

5

WATER HEATER

DOMESTIC HOT WATER

SUPPLY AIR

BLOWER

HEATING COIL

HRV/ERV CORE

CHECKVALVE

RETURN AIR

COLD WATER INLET

ANTI-SCALD VALVE(WHEN REQUIRED)

VALVE(shut off)

VALVE(shut off)

VALVE(shut off)

VALVE(balancing)

COOLING COIL(OPTIONAL)

DRAINVALVE

EXPANSION TANK(WHEN REQUIRED)

CHECKVALVE

Closed Loop SystemA system becomes closed when a Check Valve or a back-flow prevention valve is installed in the cold water pipingupstream of the water heater.A check valve will prevent water being relieved into thecold water system due to pressure created when water isheated in the water heater.

Combo System Basic Principles

Open and Closed SystemsOpen and Closed systems both deliver hot water and spaceheating.Water systems that incorporate a pressure tank (i.e. wellsystems) are normally Open Systems and most municipalwater systems are Closed Systems.

Drain ValveA drain valve is required to allow the heating loop to bedrained for service or repair and to remove air from theheating loop when commissioning a system. The drainvalve should be near the low point of the return piping sys-tem to be near the water heater. Ball, Globe or Gate Valvesare suitable for drain valves.

ATTENTIONCheck valves should always be installed in avertical rise with the flow of water shown.

IMPORTANT

Refer to local codes, local bylaws and installationmanuals supplied with water heater before startingany installation work.

ConventionalCooling(Not availablethrough Airia)

This Check Valve minimizesThermo-Siphoning. ThermoSiphoning is the cold waterbackflowing through theheating loop when domestichot water is called for.

6

Plumbing

In order to improve serviceability of our products, thecheck valve is included with our manual kit for field instal-lation between the air-handler and hot water source.The check valve should be installed in a vertical run ofpipe with the flow of water in an upward direction.An arrow on the check valve indicates its correct orienta-tion and must match the direction of water flow.This will allow for ease of service to remove any installa-tion debris or service required due to extended hard waterconditions.

Note: Take care during soldering to avoid debris orsolder from lodging in the check valve.Note: It is critical to follow the piping configurationshown. Maintain a minimum distance of 12” abovethe CAF/AH. This will minimize thermal siphoning inthe combo system.

* It should be noted that problems have been observed when using the sidetappings on certain water heaters; therefore, it is strongly recommended to use the topwater tappings as indicated in Figure 1 to minimize thermal-siphoning and relatedissues.

WaterHeater

CheckValve

ToHouse

CAForAH

Min. 12" (305 mm)abovetop of CAF / AH

12"

WaterHeater

CAForAH

CheckValve

Min. 12" (305 mm) above top of CAF / AH

ToHouse

12"

Figure 1

Figure 2

7

8

Expansion TanksExpansion tanks are required in addition to a Check Valvefor Closed Systems because pressure is created when wateris heated in the water heater.The expansion tank has an air bladder which will contract torelieve pressure in the system. The tank should always beconnected to the cold water piping between the water heatershut off valve and the cold water inlet to the water heater.

Anti-Scald ValveAn anti-scald valve is required when the water heater ther-mostat is set above 140°F (60°C). Also, an anti-scald valvemay be required for all installations by the “authority hav-ing jurisdiction”. The valve is placed in the hot water supplypiping from the water heater downstream of the heatingloop connection and upstream of any domestic hot waterconnection.The purpose of the valve is to limit the maximum tempera-ture available for domestic hot water by mixing hot waterfrom the water heater with cold water from the municipalsupply.The Anti-Scald valve must be thermostatically controlledand approved to the ASSE standard No. 1016 and 1017 foruse as an anti-scald device.

Plumbing

WATER HEATER

DOMESTIC HOT WATER

SUPPLY AIR

BLOWER

HEATING COIL

HRV/ERV CORE

CHECKVALVE

RETURN AIR

COLD WATER INLET

ANTI-SCALD VALVE(WHEN REQUIRED)

VALVE(shut off)

VALVE(shut off)

VALVE(shut off)

VALVE(balancing)

COOLING COIL(OPTIONAL)

DRAINVALVE

EXPANSION TANK(WHEN REQUIRED)

CHECKVALVE

Closed Loop System

Time to Scald(1st degree burns)

Temperature Time

120°F 8 min.

130°F 20 sec.

140°F 3 sec.

160°F <1 sec.

ConventionalCooling(Not availablethrough Airia)

Valves(a) Located on the cold water side of the Heater.

This valve has the ability to isolate the hot water(domestic and space heating) from the household coldwater supply. Every water heater requires this valveregardless of space heating use.

(b) Located on the hot water supply side of the heatingloop, downstream of its connection to the domesticwater.

(c) Located on the return side of the heating loop upstreamof its connection to the domestic cold water.

9

(a)

H C

(b)

(c)

Supply

Return

Plumbing

Ball Valve

The Ball Valve can be used as a shut off or drain valve.When in the open position, a full bore ball valve has verylittle resistance to flow, and these valves tend to be both theleast expensive and the least susceptible to seizing overtime. Do not use reduced bore ball valves as they are veryrestrictive to water flow.

Gate Valve

The Gate Valve can be used as a shut off or drain valve.When in the open position, there is very little resistance toflow. Gate valves tend to be less expensive than other typesof valves but are susceptible to chatter (noise) and malfunc-tion with age.

Globe Valve

The Globe valve can be used as a shut off, drain or throt-tling valve. Even in the open position, the valve is fairlyrestrictive to flow. It has a much greater equivalent length(resistance.) than the other types of valves.

Balancing (Throttling) Valve

The Balancing (Throttling) Valve is used to reduce thewater flow rate and thereby increase the water temperaturedrop. This is done to ensure proper activation of the waterheater thermostat.A Globe Valve could also be used for Balancing (Throttling)but has more resistance than the Balancing Valve.

These twovalves isolatethe heatingloop forservice orrepair.

Call for Space HeatingThere are two thermostats controlling every combo system,the water heater thermostat (controlling the hot water tem-perature) and the room thermostat (controlling the room airtemperature).

When the room thermostat calls for heat, the circulationpump is activated. Hot water is then drawn from the top ofthe water heater through the air handler, and then returnedto the water heater.

Plumbing

WATER HEATER

DOMESTIC HOT WATER

SUPPLY AIR

BLOWER

CHECKVALVE

RETURN AIR

COLD WATER INLET

ANTI-SCALD VALVE(WHEN REQUIRED)

VALVE(shut off)

VALVE(shut off)

VALVE(shut off)

VALVE(balancing)

COOLING COIL(OPTIONAL)

DRAINVALVE

HEATING COIL

HRV/ERV CORE

Open Loop System

HotWater Temperature DropThe water heater thermostat will initiate the water heater asrequired as long as there is a 20°F (11°C) temperature dropbetween the hot water supplied to the air handler and thereturning water.A temperature drop less than 20°F (11°C) can cause thewater heater thermostat not to initiate. This will result in alower hot water supply temperature or poor space heatingperformance with fluctuating domestic water temperatures.

Call for Domestic HotWater and Space HeatingWhen both return water from the space heating loop andnew cold water (replacing domestic water being used)enters the water heater, the mixed entering water is coolenough to activate the thermostat quickly. In this situation,the water heater must be capable of satisfying the combinedneed for domestic hot water and space heating at the sametime.

Plumbing components and systemconfiguration may vary from diagramsportrayed.

ATTENTIONChemicals (such as boiler system additives)cannot be added to a domestic hot water system.

ATTENTION

ConventionalCooling(Not availablethrough Airia)

10

11

The pre-assembled, Quick Connect Kit shortens theinstallation time. It provides an instant, easy assembly of themajor plumbing fittings required for a proper CAF/AHinstallation.

The Quick Connect Kit includes the WATER IN andWATER OUT assemblies. Kits are available in 1/2” and3/4”sizes. Refer to the CAF/AH specification sheet locatedin the Operation and Installation Manual to obtain the correctsize of water connections for the unit being installed.

Push-fit Fittings instantly make plumbing connectionsthereby eliminating the need for solder. Be sure to read thePush-fit Fitting Installation Instructions (included with theQuick Connect Fitting Kit) before making any connections.

PART #99-CAF-PKit1/2The 1/2” assembled kit.

PART #99-CAF-PKit3/4The 3/4” assembled kit.

Quick Connect Kit: PART# 99-CAF-PKit 1/2 or 3/4

WATER HEATER

SUPPLY AIR

RETURN AIR

BalancingValve

VALVE(shut off)

WATER OUTAssembly

EXPANSION TANK(WHEN REQUIRED)

CHECKVALVE

WATER INAssembly

KIT CONTENTS

WATER IN Assembly

WATER OUT Assembly

Plumbing

Air SystemA circulation fan draws cool house air at approx. 70°F(21°C) from the return ductwork, forces it through the watercoil where it is heated, and then distributes it to the variousrooms of the house through the supply ductwork.

Water System PressuresWithin the water system of an Integrated Combo system, adesigner/installer must understand the following terms:1. Hot water supply temperature (EWT)2. Hot water flow rate (GPM)3. Air handler return temperature4. Air handler flow rate (CFM)

Head PressureHead pressure is the pressure created by the circulationpump to push water through the piping system. It is thispressure which is used to overcome the resistance to waterflow (friction) caused by the water pipe and fittings. It issimilar in concept to the external static pressure in an airduct system. Head pressure is measured in feet of water(millimeters of water).

Water Flow RateWater flow rate is the amount of water flowing in the sys-tem. It is directly related to the head pressure and theresistance to flow. Flow rate is measured in gallons perminute (liters per minute).

The circulation pump is factory installed within the air han-dler. The water flow rate will vary depending on the pumpsperformance and the head pressure (resistance) of the com-plete heating loop system.The piping and fittings used to connect the water heater andair handler must be sized to handle the volume of hot waterrequired by the air handler within the pressure limitations ofthe circulation pump. All piping, fittings solders, and fluxesmust be acceptable for use with domestic hot water.

Pressure Drop (PD)Pressure drop (PD) is the reduction in total pressure causedby components added to a piping system such as coils,valves, and fittings. The measurement of pressure drop isthe difference in pressure on the inlet side of the componentand the outlet side. Pressure drop is measured in feet ofwater (millimeters of water).When connecting the water lines for heating loop (air han-dler) to the domestic water system, the pipes should beconnected with a “tee” to the side of a vertical domesticwater pipe or the bottom of a horizontal domestic waterpipe. This is to help prevent air from entering the heatingloop. The connections should be as near as practical to thewater heater.

Water Pump Performance Specifications

NOTE

The vertical height of the heating loop does notimpact on the head pressure as the pressurerequired to push the water up the vertical height isoffset by the weight of the water in the vertical dropon the other side of the heating loop.

16

14

12

10

8

6

4

2

0

Capacity on U.S. gpm

S2 and S4 Models

1 2 4 6 8 10 12

Tota

lHea

din

Fee

t

L2 and L4 Models

1 2 4 6 8 10 12 14 16 18 20

16

14

12

10

8

6

4

2

0

Capacity on U.S. gpm

Tota

lHea

din

Fee

t

12

13

Air Handler Output CapacityThere are four factors that will significantly affect theheating output of the air handler.They are:• Hot water supply temperature (EWT)• Hot water flow rate (GPM)• Air Handler return air temperature• Air Handler air flow rate (CFM)

HotWater Supply TemperatureThe hot water supply temperature is controlled by the waterheater thermostat. This is set by the installing contractor toprovide the required temperature at the hot water outlet ofthe water heater.The hot water supply temperature is typically 140°F (60°C).If this temperature must be increased to achieve higheroutputs from the furnace an anti-scald valve must be used toprevent domestic hot water temperatures above 140°F(60°C). The manufacturer of the Hot water Tank should beconsulted for temperatures higher than 140°F.It is important that a warning label be placed near the waterheater thermostat telling the homeowner not to change thethermostat setting. The label is included with the furnace.

HotWater Flow RateThe hot water entering the water coil is the source of heat tothe air handler. The effect of changing the amount of waterentering the coil is the same as changing the watertemperature. As water flow is reduced, the output of the airhandler and the air temperature rise will both be lowered.

Air Handler Return Air TemperatureThe return air temperature entering the air handler isapprox. 60°F (33°C) below the hot water inlet temperature.If the return air temperature entering the air handler isreduced, more heat transfer will occur and the output of theair handler will increase.

Air Handler Air Flow RateThe air entering the air handler can only be warmed by thetemperature difference between the hot water and the coolair. As the volume (CFM (L/s)) of air is reduced, the amountof heat which can be transferred is also reduced.

Air Handler Temperature RiseIn a fuel fired furnace, the combustion gases can be 1000°F(538°C) above the return air temperature. These unitstypically have a temperature rise from 50°F (10°C) to 90°F(32°C) and therefore delivers air at the diffuser at 120°F(49°C) to 160°F (71°C).With an Integrated Combo System, the hot watertemperature is approx. 130°F (54°C) which is 60°F(15.5°C) above the return air temperature. These unitstypically have a temperature rise of 35°F (2°C) to 40°F(4°C) and therefore would deliver air at the diffuser atapproximately 105°F (40.5°C) to 110°F (43°C).

RoomThermostatThe room thermostat controls both the watercirculation pump and the air circulation fan. It should be ona centrally located, inside wall away from any source ofheat such as diffusers, appliances and direct sunlight.

Energy Saving RoomThermostatA set back thermostat or “smart stat” can be used with acombo system, but care must be taken in the timing of thetemperature changes. The timing of morning warm upshould be early enough that the desired air temperature hasbeen reached before the people begin to use domestic hotwater. The highest demand for space heating is during themorning warm up and the highest demand for domestic hotwater is during morning showers. Even if the water heateris properly sized, it may not be able to meet this combinedload. Therefore, large set backs should be avoided.

Design vs. Field ConditionsThe factors discussed between design parameters and actualfield conditions can impact greatly on output capacity.Therefore, it is important to do a thorough and completecommissioning of the integrated combo system to ensurethe design parameters are met.

Plumbing

NOTE

Although the water in the combo system is

pressurized by the domestic water system, thepump is required to create water flow in the heatingloop. The domestic water system applies the samepressure to the supply and return sides of the

heating loop.

14

Plumbing

Drain LineThe ventilation portion of the Clean Air Furnace has twodrain pans for removing condensation, which may occur onthe heat recovery core during cold weather.

PipingThe hot water piping between the hot water tank and theClean Air Furnace should be new copper type, and shouldnot be treated with chemicals, sealant or anything else, thatwill interfere with the purity of the potable water. Only non-lead, low temperature solder is permitted for sealing copperjoints.Where possible the length of pipe should not exceed 200'total equivalent length. Any piping running through uncon-ditioned space must be insulated to prevent heat loss, andpossible freezing of the line.

Look inside the furnace and locate the pump. Attach the"Hot Water In" (Supply) to the pipe running to the pump.Attach the "Hot Water Out" (Return) to the pipe running tothe coil. Do not reverse these lines, as this will cause theunit to malfunction.For piping conventional water heaters, connections to andfrom the Clean Air Furnace to the water tank should bemade at the point where the pipes leave the tank vertically.A "T" fitting used in each vertical line, with the Clean AirFurnace piping connected to the horizontal side of this fit-ting, will work best in avoiding air locks in the circulationpump of the furnace.*Note: Remove shipping block from underneath pump anddiscard.

DRAINSPOUT

TAPE

THROUGH KNOCKOUTTO DRAIN

TEECONNECTOR

DRAINSPOUT

2” (50 mm)

KNOCKOUT KNOCKOUT

HRV Drain Line Diagram

This manual gives the contractor guidelines for installingthe LIFEBREATH Clean Air Furnace. All national andlocal codes relating to this type of equipment must befollowed.

Locating The UnitThe Clean Air Furnace is designed to be installedvertically, (unless it is designated as a Horizontal unit”H”), in a conditioned space, where the surroundingtemperature does not fall below 50°F (10°C). Atticinstallations are not recommended. Typically the unit isinstalled in a mechanical area of the basement, or otherpartitioned mechanical room, elsewhere in the home.A location close to an outside wall is recommended, as theventilation supply and exhaust portion will need to beducted to the outside air. Sufficient clearance around theunit is required for service of the filter, heat recovery coreand components. As a rule this unit should be installedadjacent to the hot water heater. If this is not possible, or ifthe piping layout is complex, the total head pressure on thepump should be calculated.

Duct ConnectionsTo accommodate various installations, the Clean AirFurnace has knockouts for the return air plenum andventilation ducts, on both sides of the cabinet. Special careand attention should be given to determining whichknockouts are to be removed.Slide Heat Recovery Core out to remove ventilationknockouts. Never install ductwork directly to the cabinetthat is smaller than the opening provided.Penetrations from sheet metal screws used to fasten theductwork to the cabinet of the unit should only be placedinto the duct flange provided. This is to avoid contact anddamage of the heating/air conditioning coils and internalwiring.

15

Option 1 - Upflow Models

NOTE: Return plenum opening can be on either side of cabinet and is not dependent on which side the ventilation ports are on.

Ventilation Ports Off Left Ventilation Ports Off Right

Remove circular metal knockout

Remove styrofoamknockout

Remove circular metal knockout

Remove styrofoamknockout

Installation

Do not remove circular knockout wheninstalling the optional Bathroom ExhaustSystem (Part 99-CAF-BESKIT). Refer toinstructions with kit.

ATTENTION

DuctingThe duct sizing for the furnace section can be determinedusing HRAI Residential Air System Design Manual,SMACNA, or any other industry-recognized manuals.Note: "Combo units" normally deliver air at approx.110°F (43°C), and therefore may require larger thannormal ductwork. When installing the Clean Air Furnaceas a replacement unit on a retrofit application, alwayscalculate the size of duct that is there.Any ductwork running through unconditioned space mustbe sealed properly and insulated to prevent heat loss. Alllocal codes must be followed in determining the amount ofinsulation needed.

The ventilation section consists of two 6" (15.2cm) roundports located on the side of the cabinet, which vent to theoutside. Insulated ducting with a vapor barrier such as flex-ducting, or ridged pipe wrapped in pipe sleeve, is requiredto prevent condensation from occurring on the pipe. Alsothe airflow in these lines is designed to bebalanced. (See "Balancing Airflows" in this manual, fordamper location and procedure).

16

Option 2 - Downflow Models

Remove circular metal knockout

Ventilation Ports Off Left Ventilation Ports Off Right

Installation

A Backdraft Damper is required in the exhaust air duct to prevent cold air from entering the unit when the Clean Air Furnace is not running.

WARNING

The 99-CAF-BESKIT is not compatiblewith horizontal models.

ATTENTION

Remove styrofoamknockout

Remove styrofoamknockout

R

Remove styrofoamknockout

Remove styrofoamknockout

Do not remove lower styrofoam knockout wheninstalling the optional Bathroom Exhaust System(Part 99-CAF-BESKIT). Refer to instructions with kit.

ATTENTION

Option 3 - Horizontal Models

Locating IntakeWeatherhoodThe intake weatherhood should be located as follows:• 4 - 6' from ventilation exhaust hood, and upstream ofprevailing winds, if possible.

• At least 6' from a dryer vent, oil fill pipes, combustionoutlets, gas meters, garbage containers or anything else,which may contaminate the air.

• Do not locate fresh air intake in garages, crawl spaces orattics.

• Install 18" (45.72 cm) above grade, or above expectedsnow accumulation.

Locating the ExhaustWeatherhoodsThe Exhaust Weatherhood should be located as follows:• At least 4-6' from the supply inlet• At least 18" (45.72 cm) above grade or expected snowaccumulation

• At least 3' from gas meters, combustion vents, or dryervents

• Do not install in garages, crawl spaces or atticsOutside Ducting theWeatherhoodsThe ventilation portion of the Clean Air Furnace can bevented off either side of the unit by removing knockoutsprovided. Once the knockouts in are removed, a bead ofsilicone can be placed on the plastic thermo-collars(provided), to form a seal between the collars and the

cabinet. The collars can then be fastened into place withscrews. Note the exhaust outlet is always the port on thebottom, and the supply inlet is always the port on the top,both ports should be labeled from the factory as such.The ductwork from the outside weatherhoods to the unit, isusually flexible ducting, although rigid pipe may be neededif the runs are greater than 10 feet. In either case the pipes(both exhaust and supply and the added fittings) must beinsulated, with a complete vapor barrier.To minimize restriction in airflows the ducting should beshort, with as few bends as possible. See diagram belowfor recommended connection of insulated ducting tooutside weatherhoods.It is necessary to have balanced air flows in an HRV. Thevolume of air brought in from the outside must equal thevolume of air exhausted by the unit. If the air flows are notproperly balanced then:• The HRV may not operate at itsmaximum efficiency

• A negative or positive air pressure may occurin the house

• The unit may not defrost properly• Failure to balance the HRV may void warranty

17

1. Thermal Collar slides over galvanizedsleeve of Weatherhood.

2. Fasten Thermal Collar to Belt.3. Slide the Insulated Flexible Ducting over the Weatherhood's galvanized sleeve and fasten it to the Thermal Collar.4. Hood is hinged to allow for easy access for cleaning of bird screen.

WEATHERHOOD INSTALLATION

T

1/4" (6 mm) SCREEN(front view)

EXTERIORWALL

SCREEN(side view)

COLLAR IS SUPPLIED TOENSURE VAPOUR BARRIER

IS 100% SEALED TOWALL PLATE

12" galvanizedpipe supplied

LocatingWeatherhood

Installation

Design and install the fresh air intake in anarea where the hoods will gather thefreshest air.

ATTENTION

Prior to balancing, ensure that:1. All sealing of the ductwork system has beencompleted.

2. All of the HRV's components are in place andfunctioning properly.

3. Balancing dampers are fully open.4. Unit is on high speed.5. After taking readings of both the stale air to the HRVduct and fresh air to the house duct, the duct with thelower CFM ([L/s] velocity) reading should be left alone,while the duct with the higher reading should bedampered back to match the lower reading.

6. Return unit to appropriate fan speed for normaloperation.

Balancing ProcedureThe following is a method of field balancing an HRV usinga Pitot tube, advantageous in situations when flow stationsare not installed in the ductwork. Procedure should be per-formed with the HRV on high speed.Choose the straightest section of duct between the HRVand the weatherhoods. This will be used for both thesupply and return ducts.Drill a small hole in the duct (about 3/16"), three feetdownstream of any elbows or bends, and one foot upstreamof any elbows or bends. These are recommended distancesbut the actual installation may limit the amount of straightduct.The Pitot tube should be connected to a magnehelic gaugeor other manometer capable of reading from 0 to 0.25 in.(0 - 62 Pa) of water, preferably to 3 digits of resolution.The tube coming out of the top of the Pitot is connected tothe high pressure side of the gauge. The tube coming out ofthe side of the Pitot is connected to the low pressure orreference side of the gauge.

Insert the Pitot tube into the duct, pointing the tip into theairflow.For general balancing it is sufficient to move the Pitot tubearound in the duct and take an average or typical reading.Repeat this procedure in the other (supply or return) duct.Determine which duct has the highest airflow (highestreading on the gauge). Then damper that airflow back tomatch the lower reading from the duct. The flows shouldnow be balanced.Actual airflow can be determined from the gauge reading.The value read on the gauge is called velocity pressure.The Pitot tube comes with a chart that will give the air flowvelocity based on the velocity pressure indicated by thegauge. This velocity will be either feet per minute ormeters per second. To determine the actual airflow, thevelocity is multiplied by the cross sectional area of the ductbeing measured.

This is an example for determining the airflow in a 6" duct.The Pitot tube reading was 0.025inches of water. From thechart, this is 640 feet per minute.The 6" (15.2 cm) duct has a cross sectional area of:

= [3.14 x (6"÷12)2]÷4= 0.2 square feet

The airflow is then:640 ft./min. x 0.2 square feet = 128 cfm

For your convenience, the cross sectional area of somecommon round duct is listed below:DUCT DIAM. (inches) CROSS SECTION AREA (sq. ft.)

5.0 (125 mm) .146.0 (150 mm) .207.0 (175 mm) .27

18

Note: For best results keep Pitot tube well away from dampers.

Pitot Tube

Figure A

Pitot Tube and Gauge

Figure B

Placement of the Pitot Tube

Pitot Tube Air Flow Balancing

The accuracy of the airflow reading will be affected by howclose to any elbows or bends the readings are taken.Accuracy can be increased by taking an average of multiplereadings as outlined in the literature supplied with the Pitottube.

19

BUILT-IN BALANCING

DAMPERS

BACK DRAFTDAMPER

OUTSIDE

INSULATED PIPEWITH VAPOUR

BARRIER

Figure C

Push and turn with slottedscrewdriver. Damperautomatically locks whenpressure is released.

When connecting ductworkto the collar, take note wherescrews are located. Screwsshould be located no furtherthan 1/2” (12.70 mm) from out-side edge of collar, so as not toimpede operation of the damper.

1/2” (12 mm)

Insulated flexibleducting

Balancing Collar Instructions

Figure D

Pitot Tube Air Flow Balancing

A Backdraft Damper is required in the exhaust air duct to prevent cold air from entering the unit when the Clean Air Furnace is not running.

WARNING

Back Draft DamperThe back draft damper (not included) can be located any-where in a vertical rise of the exhaust duct.

20

R W Y G

A/C Unit

Thermostat

To “Y”

To “C”

T30

SW1

T29T28REDOGYWRCT25

T17

K3 K4 K5

COM

N.O.

K6

COM

N.O.

COM

N.O.

COM

N.O.

T18 T19

T20

RELAYFEED

T43

SPARE

T26 T27 GRNYEL

P2 P3

R 24Vac12Vac Com Thermostat DETC

Defrost

Freeze

Fan Hi Fan Med Fan Low

ON

P1

C4 C3

K7 K1 K2K8

8 7 6 5 4 3 2 1

C2 C1

T31

T32

T33

T34

T35

T36

T37

T38

T39

T40

T41

T42

Contact 1

N.0. COM N.C. N.0. COM N.C. N.0. COM N.C. N.0 . COM

Contact 2 Contact 3 Contact 4

Digital Controls

DIP SWITCHES TO BEADJUSTED BY QUALIFIEDTECHNICIANS ONLY. N.C

SEUL UN TECHNICIENQUALIFIÉ PEUT AJUSTÉ LESCOMMUTATEURS DIP.

CHASSIST44

T21 T22 T23 T24

AUX 1 AUX 2

T3 T4 T5 T6

Line/Ligne

T1 T2 T13 T14 T15 T16

Neutral/NeutreT11 T12

2 AMPS

Standard 24 VoltThermostatConnection(Thermostats are not avail-able through Airia)

Thermostat Heat Anticipator SettingsMechanical Thermostats - start at .5 amp and may need tobe increased depending upon the residual heat left in thehydronic coil and duct work.Electronic Thermostats - to be set on electric style heat.Off Season Circulation Timer

Water is periodically circulated through the space heatingloop during the summer and other periods of infrequent use.The concern is that water which remains stationary in theheating loop during the summer may be less than desirableas domestic hot water when it is returned to the water heaterat system startup in the fall.

Basic FunctionsC - CommonR - 24 volt SupplyW - Medium or High Fan Relay with Circulation Pump

(The speed depends on Dip Switch # 6 setting)Y&G- Medium or High Fan Relay

(The speed depends on Dip Switch # 7 setting)G - Low Speed Fan RelayO - High Speed Fan Relay with Circulation Pump

Function and Controls Standard Motor

Standard Motor DIP Switch Settings(DIP #1-8 OFF is Factory Setting)

ON

87

65

43

21

DIP #2 to ON will disable theOff Season Circulation Timer

DIP #6 to ON will selectMedium Speed for heating(Factory setting is OFF for HighSpeed)

DIP #7 to ON will selectMedium Speed for coolingswitch (Factory setting is OFFfor High Speed)

Do not adjust any other DIP switches thanindicated above.

WARNING

Do not energize the CAF until the plumbing is connected and commissioned. Failure to do sowill damage the pump.

WARNING

Switch Setting

Adjust Switches

Both OFF

5 0N - 6 OFF

5 OFF - 6 ON

5 ON - 6 ON

Heat

Normal

Increase 15%

Decrease 15%

Normal

Cool

Normal

Increase 15%

Decrease 15%

Normal

Fan Speeds

Switch Setting

Heat Switches

Both OFF

3 0N - 4 OFF

3 OFF - 4 ON

3 ON - 4 ON

Fan Speeds

Heat

High

Med High

Med Low

Low

Switch Setting

Cool Switches

Both OFF

1 0N - 2 OFF

1 OFF - 2 ON

1 ON - 2 ON

Fan Speeds

Cool

High

Med High

Med Low

Low

Delay Switches are for future use - no function at this time

Note: Refer to individual specification pages for AirflowPerformance specifications. Above settings correspond

to DIP switch settings on the ECM circuit board only.Do not adjust DIP switches on MAIN Circuit Board.

T31

Co

N.0. CDigital Controls

R W Y GA/C Unit

Thermostat

To “Y”

To “C”

T30T29T28REDOGYWRCT25

T17

K3

COM

K6

COM

N.O.

T26 T27 GRNYEL

P2 P3

R 24Vac12Vac Com Thermostat DETC

Defrost

Freeze

Fan

P1

C4 C3

K8

T31

Co

N.0.Digital Controls

DIP SWITCHES TO BEADJUSTED BY QUALIFIEDTECHNICIANS ONLY.

SEUL UN TECHNICIENQUALIFIÉ PEUT AJUSTÉ LESCOMMUTATEURS DIP.

CHASSIS

T44

T3 T4 T5 T6

Line/Ligne

T1 T2 T13 T14 T15 T16

Neutral/NeutreT11 T12

2 AMPS

SW1

ON

8 7 6 5 4 3 2 1

T21 T22 T23 T24

AUX 1 AUX 2

Standard 24 VoltThermostatConnection(Thermostats are not avail-able through Airia)

Basic Functions• Thermostat fan switch will control low speed fanoperation

• Call for heating - high speed• Call for cooling - high speed

Function and Controls ECM Motor

ECM Motor DIP Switch Settings

Do not energize the CAF until the plumbing is connected and commissioned. Failure to do so will damage the pump.

WARNING

DIP switches #6 & #7 must be ON for theECM motor to function (factory setting).

ATTENTION

ECM Motor DIP Switch Settings(DIP 6&7 ON is Factory Setting)

ON

87

65

43

21 DIP #2 to ON will disable the

Off Season Circulation Timer

Factory Setting

Do not adjust any other DIP switches thanindicated above.

WARNING

COOL

1 2 3 4 5 6 7 8

HEAT ADJUST DELAY

COOL HEAT ADJUST DELAY

SW

1

off

on

T2

T1

Thermostat Heat Anticipator SettingsMechanical Thermostats - start at .5 amp and may need to beincreased depending upon the residual heat left in thehydronic coil and duct work.Electronic Thermostats - to be set on electric style heat.

21

Key Features• The Dehumidistat measures the indoor humidity level and willinitiate high speed ventilation when the moisture level in thebuilding exceeds the set point on the control.

• Once the humidity in the building is reduced, the unit will revert toits previous setting.

• The Dehumidistat should be set to OFF for all season except theheating season.

• Connect to 3 wire 20 gauge low voltage wire.

Humidity ControlYour HRV will produce a dehumidifying effect when outdoor humiditylevels are lower than indoor humidity levels. Never use thedehumidistat feature when outdoor temperatures are above 59 F (15 C).Note: The indoor humidity level is measured at the control.

Setting the DehumidistatPress and release the DEHUMIDISTAT button until theDEHUMIDISTAT LIGHT is at the desired setting. After 5 seconds thedehumidistat light will either flash or be on continuous.A flashing light indicates the humidity level is higher than the settingand the unit is operating on high speed ventilation. A continuous lightindicates the humidity level is lower than the setting. Connect to 3 wire20 gauge low voltage wire. Mounts in a standard 2” x 4” electrical box.Note - Only 1 dehumidistat should be active on a system.

Optional Dehumidistat - Part #99-DH-01

%

80

20

Instruction card

Dehumidistat IndicatorLEDsSet to the desired humiditylevel. High speed ventilationwill initiate when the indoormoisture level exceeds the setpoint on the control.

DehumidistatAdjust button

Lifestyle 20/40/60 Minute TimerPart # 99-DET01Initiates high speed ventilation for 20, 40 or 60 minutes. The 20/40/60Minute Status Lights indicate high speed operation.Lockout Mode is useful if you wish to disable the timer. Set lockout byholding the Select Button for 5 seconds. Unlock by holding for5 seconds.Connect to 3 wire 20 gauge low voltage wire. Mounts in a standard2" x 4" electrical box.

Lifestyle 20 Minute TimerPart # 99-20M01Initiates high speed ventilation for 20 minutes. The 20 Minute StatusLight indicates high speed operation.Lockout Mode is useful if you wish to disable the timer. Set lockout byholding the select button for 5 seconds. Unlock by holding for5 seconds.Connect to 3 wire 20 gauge low voltage wire. Mounts in a standard2" x 4" electrical box.

Optional Timers

Select Button

Select Button

20/40/60 MinuteStatus Lights

20 MinuteStatus Lights

The timer will override the Operational Mode (regardless of thesettings) and initiate high speed ventilation. Upon completion of thetimer cycle, the HRV will return to your selected Operational Modeand speed setting.

22

Wiring the Controls

%

80

20

T30

SW

1

T29T28

RE

DO

GY

WR

CT25

T17

K3

K4

K5

CO

M

N.O

.

K6

CO

M

N.O

.

CO

M

N.O

.

CO

M

N.O

.

T18T19

T20

RE

LAYFE

ED

T43

SPA

RE

T26T27

GR

NY

EL

P2

P3

R24Vac

12VacC

omTherm

ostatD

ET

CDefrost

Freeze

FanH

iFan

Med

FanLow

ON

P1

C4

C3

K7K1

K2K8

87

65

43

21

C2

C1

T31

T32

T33

T34

T35

T36

T37

T38

T39

T40

T41 T42

Contact1

N.0.

CO

MN

.C.

N.0.

CO

MN

.C.

N.0.

CO

MN

.C.

N.0

.CO

M

Contact2

Contact3

Contact4

Dig

italCo

ntro

ls

DIP

SW

ITC

HE

STO

BE

AD

JUS

TE

DB

YQ

UA

LIF

IED

TE

CH

NIC

IAN

SO

NLY.

N.C

SE

UL

UN

TE

CH

NIC

IEN

QU

AL

IFIÉ

PE

UT

AJU

ST

ÉL

ES

CO

MM

UTA

TE

UR

SD

IP.

CH

AS

SIS

T44

T21T22

T23T24

AU

X1

AU

X2

T3T4

T5T6

Line/Ligne

T1T2

T13T14

T15T16

Neutral/N

eutreT11

T12

2A

MP

S

Optional Dehumidistat

Connect to Yellow, Red & Green

Optional Timers

Connect to Yellow, Red& Green

23

Aircom Relays

The Aircom circuit board has three available “dry contact”relays. Contact 3 is not available.Maximum 115V 10 amp resistive load.

Contact 1This relay is a dry contact (no power supplied from board).The relay switches states upon a call for heat.This relay can be used to switch the heat demand signal forboiler operation.Power (if required) must be supplied to common from anexternal source.Max. voltage - 120 voltsMax. Amperage - 10 amps

T30T29T28

T43

SPARE

P2 P3

F2 MAX 2 amp

R 24Vac

Defrost

Freeze

K7 K1 K2K8

T31

T32

T33

T34

T35

T36

T37

T38

T39

T40

T41

T42

Contact 1

N.0. COM N.C. N.0. COM N.C. N.0. COM N.C. N.0 . COM

Contact 2 Contact 3 Contact 4

N.C

BoilerContact

T30T29T28

T43

SPARE

P3

MAX 2 amp

R 24Vac

Defrost

K7 K1 K2K8

T31

T32

T33

T34

T35

T36

T37

T38

T39

T40

T41

T42

Contact 1

N.0. COM N.C. N.0. COM N.C. N.0. COM N.C. N.0 . COM

Contact 2 Contact 3 Contact 4

N.C

HumidifierContact

Contact 2This relay is a dry contact (no power supplied from board).The relay switches states when the CAF blower motor is inoperation.This relay can be used to interlock humidifiers, AirCleaning Equipment, etc.Power (if required) must be supplied to common from anexternal source.Max. voltage - 120 voltsMax. Amperage - 10 amps

24

In order for any appliance to work properly it must be setup and tested by a knowledgeable technician.

The following conditions must be met prior tostart-up:1. Ensure that connecting water lines are purged and free ofdebris.Caution: solder or other debris may cause the furnacepump or check valve to malfunction.

2. Blower wheel rotates freely inside its housing.3. Wiring connections are tight.4. Water is sitting in the "P" trap below the HRV core.5. All duct and pipe connections are sealed.6. Check that styrene block is removed from under pump.7. Front access door is on tight.8. Fan speed selection:a) Heating/Cooling - factory setting is at high speed andcan be changed in the electrical box to medium-high ormedium if required.b) Ventilation - low speed is controlled by theThermostat Fan switch.

Once all of the necessary connections have beenmade, the Clean Air Furnace Start-Up Procedure isas follows:1. Close shut-off valves separating the Clean Air Furnacefrom the water heater.

2. Set up water heater according to manufacturer'sinstructions.

3. Purge air from unit. To do so, open the supply shut-offvalve to the furnace. Attach a garden hose to drain valve,and drain water until you get a continuous flow. Closethe drain valve and purge the pump. To purge the airfrom the pump, turn the large screw on the face of thepump counter-clockwise until water leaks out, thentighten. Open the supply shut-off valve.

4. Turn on power supply to Clean Air Furnace.5. Switch the room thermostat to heat. The thermostatshould be set higher than the current room temperature inorder to energize the pump and commence the heatingcycle. (If the pump does not start, or the Clean AirFurnace is not producing heat, refer to theTroubleshooting Section in this manual.

6. Set room thermostat at desired temperature setting.

Start-Up Procedure

25

A dedicated maintenance program will prolong the life ofthe equipment, and maintain its optimum performance.We recommend at least two (2) full inspections andcleanings per year under normal operating conditions, andmore if circumstances warrant it (i.e. situations of heavysmoke may require servicing every one to two months).

Service should include:• Cleaning of screens protecting outside hoods.• Cleaning of the HRV (aluminum) core.• Inspect filters and replace as necessary.• Wipe down drain pans and inside of cabinet, using a milddisinfectant.

• Ensure condensate drain has free flow of moisture.• Inspect operation of blowers and electrical panel.• Confirm operation.

Clean Core Twice aYeara) Open access door.b) Carefully grip ends of core, and pull evenly outward.Core may be snug, but will slide out of the "H" channel.

c) Once removed from the cabinet, remove the foam filters.d) Wash the core in warm soapy water (do not use dish-washer).

e) Install the clean filtersf) Install the clean core.

Service/Maintenance

Ultra-e�cientheating coil

Tempered fresh airto heating coil

Fresh air intakes to HRV

Heated fresh airto registers

Stale air to outside

Hot watercirculation pump

Hot waterreturn

Heat recoveryventilator heatexchanger

PSC type hi-e�ciencymotor

Return airfrom house

Hot watersupply

Note: This illustration may vary fromthe actual model installed.

26

Lack of heat1. Check that the room thermostat is set to the desiredtemperature.

2. Confirm the units have power and the shut-off valves areopen.

3. Ensure there is power to the unit and that the pump isworking. If the pump is not working properly it may bestuck. Disconnect power and remove screw in center faceof the pump. Using a screwdriver, turn the pump shaftseveral times to free it from sticking. Replace center-screw and re-connect power. If pump still fails to start, itmay require replacement.

4. Confirm that the hot water heater is working and that hotwater is entering the Clean Air Furnace.

5. Verify that the airflow in and out of the system matchesdesigned specs. If airflow is low, check for blockage inthe filter or some other obstruction.

6. Make sure your water heater is sized large enough forheat load of house and for domestic hot water use.

7. Air may still be in the water lines. If so, re-purge thesystem according to the start up procedure.

8. Confirm that the inlet and outlet pipe connections are notreversed.

9. Ensure that there are no other restrictions in the waterlines, such as faulty valves, or debris.

Pump is noisyPumps can become noisy when air remaining in the linesinterfere with their operation. If this occurs re-purge thesystem as indicated in the Start-Up Procedure.

HRV core freezes up1. Make sure that the supply and exhaust lines are balancedaccording to the "Balancing Procedure" in this manual.

2. If out of balance, ensure that the balancing dampers havenot been moved and that there are no obstructions in theoutside hoods.

During cooling cycle, hot water circulates throughthe coilIf the check valve inside the cabinet is stuck in the openposition, hot water may infiltrate the heating coil. Thisoccurs when the hot pipes are not capped-off duringinstallation or service and foreign debris enters the piping.This debris can settle under the check valve seat and permithot water to flow into the coil. The problem can be correct-ed by repeatedly flushing the heating loop until it is clean.

Water sits in drain pipes1. Check drain pans or lines for plugs.2. Confirm that the HRV core is installed according tomanufactures recommendations.

3. Check the drain line for kinks.4. Make sure that the O-ring in the drain nozzles sit flat.5. Ensure the drain line has enough "fall" to it.

Condensation/ice forming inside ventilation ductsA rip in the vapor barrier or poorly sealed joints may causecondensation or ice to form on the ducting. If this occurs,replace the entire line.

Troubleshooting

27

Today's modern, tight homes require fresh outdoor air tomaintain a healthy indoor air environment. The amount ofventilation you require in your home will depend upon:• the number of occupants and their activity levels,• the way your home was built.• your personal preferences for fresh air,The HRV introduces fresh air to your home whilerecovering energy from the air it exhausts. Specifically, anHRV that is properly installed, operated and maintainedwill:• exhaust stale, contaminated air• recover the majority of the energy from the exhaustedstale air

• use the recovered energy to preheat or precool outside airthat is drawn into the house

• distribute the fresh air throughout the house

HOW MUCHVENTILATION DO I NEED?During seasons when your windows and doors are closed(winter, and summer if air conditioned), the HRV should beset to operate continuously on low speed with the option ofgoing to high speed as the need arises. For example: if youare entertaining and there is a large number of peoplepresent, the unit should be switched temporarily to highspeed.You may wish to use an intermittent operational mode ifyour home is unoccupied (20 minutes ON / 40 minutesOFF).

Controlling your HRV

High indoor humidity levels are apparent from the visiblecondensation on windows. The amount of condensation onthe windows will increase as outdoor temperatures drop.Your HRV will reduce indoor humidity levels when outdoorair is drier than indoor air. This usually occurs during theheating season when outdoor temperatures are less than15°C (59°F).The Optional Dehumidistat (99-DH01) can be set to achievea further dehumidification effect from your HRV. Highspeed ventilation will be initiated upon exceeding thedehumidistat set point regardless of the mode and speed ofoperation. Once the humidity in the house is reduced, theHRV will revert back to its previous setting.We suggest operating the unit for the first few days withoutuse of the dehumidistat function to observe if a furtherdehumidification effect will be required. The dehumidistatoperates in % of RH (relative humidity) with 80 being highand 20 being low. Set the Dehumidistat to 80% to disable.If, after a few days, further dehumidification is required (thehouse is still too humid), set the humidity level to a loweramount.

The average person is comfortable between 30-50% RH.The dehumidistat should be set to OFF for all seasonsexcept the heating season. OFF is achieved by setting thedehumidistat to 80.

How the DehumidistatWorks

28

29

ConfigurationU - Upflow - Return Air off Left or Right sideD - Downflow - Return Air off Left side, Right side or Top

(not available for L2A or 00 Coils)H - Horizontal - Return on left side only

(not available for L2A or 00 Coils)

Hydronic Coil Size

S4A - Small Coil - 4 Row CoilL2A - Large Coil - 2 Row Coil (available in upflow only)L4A - Large Coil - 4 Row Coil00 - No Hydronics - No Heating Coil, No Pump (available in upflow only)

24 - 2 tons30 - 2.5 tons36 - 3.0 tons48 - 4.0 tons*Cooling coils not available from Airia

Motor ConfigurationP16 - Standard PSC Motor 120V/60HzE16 - Upgrade ECM Motor 120V/60Hz

Example Model Number CAF - U - S2A - 24 - P16

* CFM (High Speed)Cooling Capacity

Model ConfigurationCAF - Clean Air Furnace (Built-in HRV)Refer to AH (Air Handler) specifications ifa built-in HRV is not required.

Available Clean AirFurnace Models

CAF-U-S4A-24-P16(E16)CAF-D-S4A-24-P16(E16)CAF-H-S4A-24-P16(E16)CAF-U-L4A-36-P16(E16)CAF-D-L4A-36-P16(E16)CAF-H-L4A-36-P16(E16)CAF-U-L2A-48-P16(E16)CAF-U-00-24-P16(E16)CAF-U-00-36-P16(E16)CAF-U-00-48-P16(E16)

Refer to individual specifications pages forHydronic Coil and Blower outputs andconfigurations.

Model Number Nomenclature Breakdown

Refer to individual specification pages forHydronic Coil and Blower outputs andconfigurations.

ATTENTION

30

Core Ventilation system has patented aluminum heat recovery core (standard) or an enthalpic energy recovery core (optional) forenergy-efficient ventilation. Enthalpic cores are recommended for regions where the temperature does not dropbelow 25°F (-4°C).

Filters Washable air filters in exhaust and supply air streams of ventilation section, 1" (25 mm) pleated in return plenum side.

Case Pre-painted galvanized steel for superior corrosion resistance.

Date: ___________________________________________

Tag: _____________________Qty:___________________

Project: _________________________________________

Engineer: _______________________________________

Contractor: ______________________________________

Supplier: ________________________________________

Quote#: _________________________________________

Submitted by: ____________________________________

Options99-186 Weatherhoods, Two - 6" (150 mm) c/w 1/4" (6 mm) meshscreen

99-RSK6 6” (150 mm) back draft damper

99-DH-01 Lifestyle Dehumidistat - Initiates high speedventilation for 20, 40, or 60 minutes (3 wire) 20 gauge wire(minimum) 100 ft. length

OPTIONALTIMERS

99-DET01 Lifestyle 20/40/60 Minute Timer - Initiates high speedventilation for 20, 40, 60 minutes. (3 wire) 20 gauge wire(minimum) 100 ft. length

99- 20M01 Lifestyle 20 Minute Timer - Initiates high speedventilation for 20 minutes. (3 wire) 20 gauge wire (minimum)100 ft. length.

WarrantyUnits carry a lifetime warranty on the heat recovery (aluminum) core, a five year warranty on the energy recovery (enthalpic) core and afive year replacement parts warranty on all other components.

Model CAF-U-S4A-24-P16

Voltage 120 VAC 60 Hz

Hp 1/3

Amps (total) 8

Water 1/2" (12 mm) CopperConnections Soldered Connection

Airflow (High).25 in wg 1030 CFM.5 in. wg 890 CFM

Ventilation 100 - 140 CFMAirflow

Effectiveness 70%(Aluminum Core)

Total Efficiency 50%(Enthalpic Core)

Net Weight 150 lbs.

Shipping Weight 165 lbs.

Top

Front

29.5”(749 mm)

29.5"(749 mm)

19"(483 mm)

47.5"(1207 mm)

6"

14"(356 mm)

12"(305 mm)

4”(100 mm)19”

(483 mm)

22.4”(567 mm)

Supply Air17.25”(438 mm)

VentilationSupply AirInlet

VentilationExhaust AirOutlet

22”(559 mm)

Return Air Blower Section

(SERVICE CLEARANCE 1') (SERVICE CLEARANCE 3')

Side

Latches

(150 mm)

6"(150 mm)

Dimensions & Clearances

Note: Ventilation ports and return plenumopening available off either side of cabinet. Allunits conform to CSA and UL Standards.

Model CAF-U-S4A-24-P16

31

Options99-186 Weatherhoods, Two - 6" (150 mm) c/w 1/4" (6 mm) meshscreen

99-RSK6 6” (150 mm) back draft damper

99-DH-01 Lifestyle Dehumidistat - Initiates high speedventilation for 20, 40, or 60 minutes (3 wire) 20 gauge wire(minimum) 100 ft. length

OPTIONALTIMERS

99-DET01 Lifestyle 20/40/60 Minute Timer - Initiates high speedventilation for 20, 40, 60 minutes. (3 wire) 20 gauge wire(minimum) 100 ft. length

99- 20M01 Lifestyle 20 Minute Timer - Initiates high speedventilation for 20 minutes. (3 wire) 20 gauge wire (minimum)100 ft. length.

WarrantyUnits carry a lifetime warranty on the heat recovery (aluminum) core, a five year warranty on the energy recovery (enthalpic)core and a five year replacement parts warranty on all other components.

Core Ventilation system has patented aluminum heat recovery core (standard) or an enthalpic energy recovery core (optional) for ener-gy-efficient ventilation. Enthalpic cores are recommended for regions where the temperature does not drop below 25°F (-4°C).

Filters Washable air filters in exhaust and supply air streams of ventilation section, 1" (25 mm) pleated in return plenum side

Case Pre-painted galvanized steel for superior corrosion resistance.

SideFront

29.5"(749 mm)

19"(483 mm)

47.5"(1207 mm)

6”(150 mm)

12"(305 mm)

4"(100 mm)

Top

29.5"(749 mm)

22"(559 mm)

19"(483 mm)

14"(356 mm)

Bottom

29.5”(749 mm)

19"(483 mm)

16"(406 mm)

Supply Air

Return Air

17.25"(438 mm)

Ventilation Supply Air Inlet

Ventilation Exhaust Air Outlet

22"(559 mm)

Return Air

Latches

Blower Section

(SERVICE CLEARANCE 1') (SERVICE CLEARANCE 3')

14”(356 mm)

6”(150 mm)

Dimensions & Clearances Model CAF-D-S4A-24-P16

Voltage 120 VAC 60 Hz

Hp 1/3

Amps (total) 8

Water 1/2" (12 mm) CopperConnections Soldered Connection

Airflow (High).25 in wg 1030 CFM.5 in. wg 890 CFM

Ventilation 100 - 140 CFMAirflow

Effectiveness 70%(Aluminum Core)

Total Efficiency 50%(Enthalpic Core)

Net Weight 150 lbs.

Shipping Weight 165 lbs.Note: Ventilation ports and return plenum opening available off either side of cabinet.All units conform to CSA and UL Standards.

Date: ___________________________________________

Tag: _____________________Qty:___________________

Project: _________________________________________

Engineer: _______________________________________

Contractor: ______________________________________

Supplier: ________________________________________

Quote#: _________________________________________

Submitted by: ____________________________________

Model CAF-D-S4A-24-P16

32

Core Ventilation system has patented aluminum heat recovery core (standard) or an enthalpic energy recovery core (optional) for ener-gy-efficient ventilation. Enthalpic cores are recommended for regions where the temperature does not drop below 25°F (-4°C).

Filters Washable air filters in exhaust and supply air streams of ventilation section, 1" (25 mm) pleated in return plenum side.

Case Pre-painted galvanized steel for superior corrosion resistance. Service drain 1/2” (12 mm) or 3/4” (19 mm) NPT.

Front

19"(483 mm)

47.5"(1207 mm)

Latches

Blower Section

(SERVICE CLEARANCE 10")

Top

29.5"(749 mm)

14"(356 mm)

12"(305 mm)

4"(100 mm)

VentilationSupplyAir Inlet

VentilationExhaustAir Outlet

22"(559 mm)

Return Air

29.5"(749 mm)

22"(559 mm)

19"(483 mm)

14"(356 mm) Return Air

ReturnAir End

16"(406 mm)

Supply Air17.25"

(438 mm)

Supply Air End

ServiceDrain

6”(150 mm)

6”(150 mm)

19"(483 mm)

29.5"(749 mm)

Note: All units conform to CSA and UL Standards.

Model CAF-H-S4A-24-P16

Voltage 120 VAC 60 Hz

Hp 1/3

Amps (total) 8

Water 1/2" (12 mm) CopperConnections Soldered Connection

Airflow (High).25 in wg 1030 CFM.5 in. wg 890 CFM

Ventilation 100 - 140 CFMAirflow

Effectiveness 70%(Aluminum Core)

Total Efficiency 50%(Enthalpic Core)

Net Weight 150 lbs.

Shipping Weight 165 lbs.

OPTIONS99-186 Weatherhoods, Two - 6" (150 mm) c/w 1/4" (6 mm) mesh

screen

99-RSK6 6” (150 mm) back draft damper99-DH-01 Lifestyle Dehumidistat - Initiates high speed ventila-tion for 20, 40, or 60 minutes (3 wire) 20 gauge wire (minimum)100 ft. length

OPTIONALTIMERS

99-DET01 Lifestyle 20/40/60 Minute Timer - Initiates high speedventilation for 20, 40, 60 minutes. (3 wire) 20 gauge wire(minimum) 100 ft. length

99- 20M01 Lifestyle 20 Minute Timer - Initiates high speedventilation for 20 minutes. (3 wire) 20 gauge wire (minimum)100 ft. length.

WarrantyUnits carry a lifetime warranty on the heat recovery (aluminum) core, a five year warranty on the energy recovery (enthalpic)core and a five year replacement parts warranty on all other components.Date: ___________________________________________

Tag: _____________________Qty:___________________

Project: _________________________________________

Engineer: _______________________________________

Contractor: ______________________________________

Supplier: ________________________________________

Quote#: _________________________________________

Submitted by: ____________________________________

Model CAF-H-S4A-24-P16

Dimensions & Clearances

Core Ventilation system has patented aluminum heat recovery core (standard) or an enthalpic energy recovery core (optional) for ener-gy-efficient ventilation. Enthalpic cores are recommended for regions where the temperature does not drop below 25°F (-4°C).

Filters Washable air filters in exhaust and supply air streams of ventilation section, 1" (25 mm) pleated in return plenum side

Case Pre-painted galvanized steel for superior corrosion resistance.

Top

Side

22.25"(565 mm)

Supply Air

VentilationSupply AirInlet

VentilationExhaust AirOutlet

Return AirBlower Section

(SERVICE CLEARANCE 1') (SERVICE CLEARANCE 3')

Front

Latches

29.5"(749 mm)

19"(483 mm)

47.5"(1207 mm)

6"

14"(356 mm)

12"(305 mm)

4”(100 mm)

19”(483 mm)

17.25”(438 mm)

22”(559 mm)

(150 mm)

6"(150 mm)

29.5"(749 mm)

Dimensions & ClearancesModel CAF-U-L4A-36-P16Voltage 120 VAC 60 Hz

Hp 1/2

Amps (total) 10.6

Water 3/4" (19 mm) CopperConnections Soldered Connection

Airflow (High).25 in wg 1350 CFM.5 in. wg 1180 CFM

Ventilation 100 - 140 CFMAirflow

Effectiveness 70%(Aluminum Core)

Total Efficiency 50%(Enthalpic Core)

Net Weight 150 lbs.

Shipping Weight 165 lbs.

Note: Ventilation ports and return plenumopening available off either side of cabinet.All units conform to CSA and UL Standards.

Options99-186 Weatherhoods, Two - 6" (150 mm) c/w 1/4" (6 mm) meshscreen

99-RSK6 6” (150 mm) back draft damper

99-DH-01 Lifestyle Dehumidistat - Initiates high speed ventila-tion for 20, 40, or 60 minutes (3 wire) 20 gauge wire (minimum)100 ft. length

OPTIONALTIMERS

99-DET01 Lifestyle 20/40/60 Minute Timer - Initiates high speedventilation for 20, 40, 60 minutes. (3 wire) 20 gauge wire(minimum) 100 ft. length

99- 20M01 Lifestyle 20 Minute Timer - Initiates high speedventilation for 20 minutes. (3 wire) 20 gauge wire (minimum)100 ft. length.

WarrantyUnits carry a lifetime warranty on the heat recovery (aluminum) core, a five year warranty on the energy recovery (enthalpic)core and a five year replacement parts warranty on all other components.Date: ___________________________________________

Tag: _____________________Qty:___________________

Project: _________________________________________

Engineer: _______________________________________

Contractor: ______________________________________

Supplier: ________________________________________

Quote#: _________________________________________

Submitted by: ____________________________________

Model CAF-U-L4A-36-P16

33

34

Options99-186 Weatherhoods, Two - 6" (150 mm)

c/w 1/4" (6 mm) mesh screen

99-RSK6 6” (150 mm) back draft damper99-DH-01 Lifestyle Dehumidistat - Initiates high speed ventila-tion for 20, 40, or 60 minutes (3 wire) 20 gauge wire (minimum)100 ft. length

OPTIONALTIMERS

99-DET01 Lifestyle 20/40/60 Minute Timer - Initiates high speedventilation for 20, 40, 60 minutes. (3 wire) 20 gauge wire(minimum) 100 ft. length

99- 20M01 Lifestyle 20 Minute Timer - Initiates high speedventilation for 20 minutes. (3 wire) 20 gauge wire (minimum)100 ft. length.

SideFront

29.5"(749 mm)

19"(483 mm)

47.5"(1207 mm)

6"

14"(356 mm)

12"(305 mm)

4"(100 mm)

Top

29.5"(749 mm)

22"(559 mm)

19"(483 mm)

14"(356 mm)

Bottom22.25"

(565 mm)

Supply Air

Return Air

17.25"(438 mm)

Ventilation Supply Air Inlet

Ventilation Exhaust Air Outlet

22"(559 mm)

Return Air

Latches

Blower Section

(SERVICE CLEARANCE 1') (SERVICE CLEARANCE 3')

19"(483 mm)

29.5"(749 mm)

(150 mm)

6"(150 mm)

Note: Ventilation ports and return plenum opening available off either side of cabinet.All units conform to CSA and UL Standards.

Dimensions & ClearancesModel CAF-D-L4A-36-P16

Voltage 120 VAC 60 Hz

Hp 1/2

Amps (total) 10.6

Water 3/4" (19 mm) CopperConnections Soldered Connection

Airflow (High).25 in wg 1350 CFM.5 in. wg 1180 CFM

Ventilation 100 - 140 CFMAirflow

Effectiveness 70%(Aluminum Core)

Total Efficiency 50%(Enthalpic Core)

Net Weight 150 lbs.

Shipping Weight 165 lbs.

WarrantyUnits carry a lifetime warranty on the heat recovery (aluminum) core, a five year warranty on the energy recovery (enthalpic)core and a five year replacement parts warranty on all other components.

Core Ventilation system has patented aluminum heat recovery core (standard) or an enthalpic energy recovery core (optional) for ener-gy-efficient ventilation. Enthalpic cores are recommended for regions where the temperature does not drop below 25°F (-4°C).

Filters Washable air filters in exhaust and supply air streams of ventilation section, 1" (25 mm) pleated in return plenum side

Case Pre-painted galvanized steel for superior corrosion resistance.

Date: ___________________________________________

Tag: _____________________Qty:___________________

Project: _________________________________________

Engineer: _______________________________________

Contractor: ______________________________________

Supplier: ________________________________________

Quote#: _________________________________________

Submitted by: ____________________________________

Model CAF-D-L4A-36-P16

35

OPTIONS99-186 Weatherhoods, Two - 6" (150 mm) c/w 1/4" (6 mm) mesh

screen

99-RSK6 6” (150 mm) back draft damper

99-DH-01 Lifestyle Dehumidistat - Initiates high speed ventila-tion for 20, 40, or 60 minutes (3 wire) 20 gauge wire (minimum)100 ft. length

OPTIONALTIMERS

99-DET01 Lifestyle 20/40/60 Minute Timer - Initiates high speedventilation for 20, 40, 60 minutes. (3 wire) 20 gauge wire(minimum) 100 ft. length

99- 20M01 Lifestyle 20 Minute Timer - Initiates high speedventilation for 20 minutes. (3 wire) 20 gauge wire (minimum)100 ft. length.

Core Ventilation system has patented aluminum heat recovery core (standard) or an enthalpic energy recovery core (optional) for ener-gy-efficient ventilation. Enthalpic cores are recommended for regions where the temperature does not drop below 25°F (-4°C).

Filters Washable air filters in exhaust and supply air streams of ventilation section, 1" (25 mm) pleated in return plenum side.

Case Pre-painted galvanized steel for superior corrosion resistance. Service drain 1/2” (12 mm) or 3/4” (19 mm) NPT.

WarrantyUnits carry a lifetime warranty on the heat recovery (aluminum) core, a five year warranty on the energy recovery (enthalpic)core and a five year replacement parts warranty on all other components.

Date: ___________________________________________

Tag: _____________________Qty:___________________

Project: _________________________________________

Engineer: _______________________________________

Contractor: ______________________________________

Supplier: ________________________________________

Quote#: _________________________________________

Submitted by: ____________________________________

Dimensions & Clearances Model CAF-H-L4A-36-P16

Voltage 120 VAC 60 Hz

Hp 1/2

Amps (total) 10.6

Water 3/4" ( 19 mm) CopperConnections Soldered Connection

Airflow (High).25 in wg 1350 CFM.5 in. wg 1180 CFM

Ventilation 100 - 140 CFMAirflow

Effectiveness 70%(Aluminum Core)

Total Efficiency 50%(Enthalpic Core)

Net Weight 150 lbs.

Shipping Weight 165 lbs.

Front

47.5"(1207 mm)

Latches

Blower Section

(SERVICE CLEARANCE 10")

Side

29.5"(749 mm)

6"(150 mm)

14"(356 mm)

12"(305 mm)

4"(100 mm)

VentilationSupplyAir Inlet

VentilationExhaustAir Outlet

22"(559 mm)

Return Air

ReturnAir End

29.5"(749 mm)

19"(483 mm)

Supply Air17.25"(438 mm)

Supply Air End

Service Drain

14"(356 mm) Return Air

6"(150 mm)

22"(559 mm)

19"(483 mm)

19"(483 mm)

22"(559 mm)

29.5"(749 mm)

Note: All units conform to CSA and UL Standards.

Model CAF-H-L4A-36-P16

Core Ventilation system has patented aluminum heat recovery core (standard) or an enthalpic energy recovery core (optional) for ener-gy-efficient ventilation. Enthalpic cores are recommended for regions where the temperature does not drop below 25°F (-4°C).

Filters Washable air filters in exhaust and supply air streams of ventilation section, 1" (25 mm) pleated in return plenum side.

Case Pre-painted galvanized steel for superior corrosion resistance.

Date: ___________________________________________

Tag: _____________________Qty:___________________

Project: _________________________________________

Engineer: _______________________________________