Operation Manual - service-engine.com.ua MIGHTY … · 1. DENSO PRODUCTS LIST 1-1. Vehicle...

Transcript of Operation Manual - service-engine.com.ua MIGHTY … · 1. DENSO PRODUCTS LIST 1-1. Vehicle...

00400075E

Injection Pump

HYUNDAI MIGHTY W Engine

COMMON RAIL SYSTEM (CRS)Operation Manual

June 2004

© 2009 DENSO CORPORATIONAll Rights Reserved. This book may not be reproducedor copied, in whole or in part, without the written permission of the publisher.

TABLE OF CONTENTS

1. DENSO PRODUCTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. SYSTEM OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3. COMPONENTS DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. DESCRIPTION OF CONTROL SYSTEM COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5. CONTROL TYPES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6. DIAGNOSTIC TROUBLE CODES (DTC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

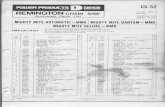

1. DENSO PRODUCTS LIST1-1. Vehicle Specifications

1-2. Part Numbers

Name Engine Type Engine Displacement Reference

MIGHTY W 3.9 L Compact trucks: 2 ton, 2.5 ton, 3 ton

Part Name DENSO Part Number Customer Part Number Reference

Supply Pump 294000-0290 33100-45700 HP-3 type

Injector 095000-5550 33800-45700

Rail 095440-0600 31440-45700

Engine ECU 275800-3142 39100-45700

NE Sensor 029600-0570 39340-45700 Magnetic induction type

TDC Sensor (G Sensor) 949979-1450 39350-45700 Magneto resistance element

type

Accelerator Pedal Position

Sensor

- - Non-DENSO product

Coolant Temperature Sensor - - Non-DENSO product

Manifold Absolute Pressure

(MAP) Sensor

- - Non-DENSO product

Intake Air Temperature Sensor - - Non-DENSO product

2. SYSTEM OUTLINEFocused on complying with exhaust gas regulations for diesel engines, the CRS was developed to achieve the following: 1)

a further reduction in fuel consumption, 2) improved quietness, and 3) higher output.

2-1. System CharacteristicsThe CRS uses a pressure accumulation chamber called a "rail" to store high-pressure fuel. This high-pressure fuel is

then injected into each engine cylinder from solenoid controlled injectors. Since the engine ECU controls the injection

system (injection pressure, injection rate, and injection timing), the CRS achieves independent control uninfluenced by

engine rotational speed or load. Therefore, stable injection pressures can be maintained, specifically in the engine low

rotational speed region. As a result, the black smoke inherent to diesel engines during take-off and acceleration is sup-

pressed, exhaust gas is cleaner and reduced in quantity, and higher output is achieved.

A. Injection pressure control• High-pressure injection from the engine low rotational speed region.

• Optimal control to minimize particulate, and NOx exhaust gas.

B. Injection timing control• More precise, optimal control suited to driving conditions.

C. Injection rate control• Pilot injection that delivers a very small injection prior to the main injection.

2-2. OUTLINE OF CONSTRUCTION AND OPERATIONA. Configuration

The primary CRS consists of a supply pump, rail, injectors, and engine ECU.

B. Operationa. Supply pump

The supply pump draws in fuel from the fuel tank, and delivers high-pressure fuel to the rail. The rail internal pressure is

controlled by the quantity of fuel discharged from the supply pump. The aforementioned control is performed by the Suc-

tion Control Valve (SCV) inside the supply pump based on signals from the engine ECU.

b. Rail

The rail is positioned between the supply pump and injectors to store high-pressure fuel.

c. Injectors

In place of the conventional injector nozzle, the injectors equipped with the CRS use signals from the engine ECU to

achieve optimal injection. The quantity, rate, and timing for the fuel discharged from the injectors is determined by signals

from the engine ECU. These signals control the length of time that the injectors are energized, as well as the timing for

injector energization.

d. Engine ECU

The engine ECU calculates data detected from each sensor to provide overall control of items such as the following: fuel

injection quantity, fuel injection timing, injection pressure, and Exhaust Gas Recirculation (EGR.)

2-3. Fuel System and Control SystemA. Fuel system

The fuel system starts from the fuel filter, and continues through the supply pump, and rail until the the diesel fuel is dis-

charged from the injectors. The fuel system also includes the return path to the fuel tank via the overflow pipe.

B. Control systemIn the control system, the engine ECU regulates fuel injection based on signals from each system sensor. The control

system can be divided by component type into three categories: 1) sensors, 2) the engine ECU, and 3) actuators.

a. Sensors

Sensors convert engine and driving status into detectable electric signals.

b. Engine ECU

The engine ECU performs calculations based on the electric signals from each sensor, then sends signals to each ac-

tuator to achieve the optimal system conditions.

c. Actuators

The actuators operate based on electric signals received from the engine ECU. The fuel injection system controls the

actuators electrically. The injection quantity and injection timing are determined by how long the injector Two Way Valve

(TWV) is energized, while injection pressure is determined by controlling the Suction Control Valve (SCV) for the supply

pump.

3. COMPONENTS DESCRIPTION3-1. Supply Pump (HP-3)A. Outline• The HP3 supply pump primarily consists of the pump body (eccentric cam, ring cam, and plungers), SCV, fuel tempera-

ture sensor, and fuel pump.

• Two plungers are mounted in vertical opposition on the outside of the ring cam, creating a compact assembly.

• The supply pump is actuated in a 1:1 ratio in relation to the engine. The feed pump (trochoid type) is built into the supply

pump to draw fuel up from the fuel tank for delivery to the plunger chamber.

• Fuel delivered to the plunger chamber is placed under high pressure by the two plungers (driven by the internal cam-

shaft), then sent to the rail. The quantity and timing for the fuel supplied to the rail is controlled by SCV operation via

signals from the engine ECU. The SCV described herein is a normally open type (when not energized, the SCV is open.)

*1: Expanded View (Reference)

B. Fuel flow inside the supply pumpFuel drawn from the fuel tank is sent to the rail from inside the supply pump through the path shown in the figure below.

C. Supply pump construction• An eccentric cam is attached to the supply pump drive shaft.

In turn, the eccentric cam fits into the ring cam.

• When the drive shaft rotates, the eccentric cam turns "eccentrically". As a result, the ring cam moves up and down while rotating.

• Plungers and suction valves are attached to the top of the ring cam. The feed pump is then attached to the end of the drive shaft.

D. Supply pump operationAs shown in the figure below, the ring cam and plunger A are pushed upward by eccentric cam rotation. Conversely,

plunger B is pulled in the opposite direction of plunger A due to spring force. As a result, plunger B draws in fuel, while

plunger A sends fuel to the rail.

3-2. Explanation of Supply Pump ComponentsA. Feed pump

The feed pump is a trochoid type pump built into the supply pump. The feed pump draws fuel from the fuel tank, and

sends the fuel to the two plungers via the SCV. The feed pump is operated by the drive shaft. When the feed pump inner

rotor turns, an amount of fuel is drawn in from the suction side of the pump that is equivalent to the space (increasing or

decreasing in size) created between the outer and inner rotors. This fuel is then sent to the pump chamber from the dis-

charge side of the feed pump.

B. Suction Control Valve (SCV)• The SCV is a linear solenoid type valve. The engine ECU controls the amount of time that the SCV is energized (duty

ratio). In turn, the SCV regulates the fuel flow volume supplied from the high-pressure plungers.

• The SCV reduces the supply pump actuation load by drawing in only the quantity of fuel necessary to meet the target

rail pressure.

• When electric current is sent through the SCV, the internal

needle valve moves in accordance with the duty ratio to con-

trol the fuel flow volume.

• When the SCV is off, the needle valve is pressed down by the

return spring. As a result, the fuel path completely opens,

supplying fuel from the plungers (entire quantity suctioned,

entire quantity discharged.)

• When the SCV is on, the return spring contracts, and the fuel

path closes.

• When the SCV is cycled on and off, fuel is supplied in a quan-

tity corresponding to the SCV open surface area(determined

by the actuation duty ratio). The fuel is then discharged from

the plungers.

a. Short duty on time large valve opening large suction quantity

When: short duty on time large valve opening large suction quantity

b. Long duty on time small valve opening small suction quantity

When: long duty on time small valve opening small suction quantity

c. Relationship between actuation signals and current (magnetomotive force)

Diagram of the Relationship Between Actuation Signals and Current (Magnetomotive Force)

C. Attention points for supply pump removal and attachment (reference)To preserve SCV (attached to the supply pump) performance accuracy, the engine ECU performs idle learning correc-

tions. Be aware that when the supply pump is replaced, work must be done with a vehicle manufacturer tester (at a car

dealer) to match the learning value for the old SCV with the new SCV.

3-3. RailA. Outline

The rail stores high-pressure fuel delivered from the supply pump for distribution to the individual injector for each cylin-

der. A rail pressure sensor and pressure limiter are attached to the rail. The rail pressure sensor detects the pressure of

the fuel inside the rail, and sends a corresponding signal to the engine ECU. The engine ECU controls the supply pump

SCV based on this signal to regulate pressure inside the rail.

B. Rail pressure sensorThe rail pressure sensor detects fuel pressure within the rail, and sends a corresponding signal to the ECU. The rail pres-

sure sensor is a Piezo resistance type semiconductor pressure sensor. The sensor uses the pressure added to a metal

diaphragm, and the accompanying changes in electrical resistance to detect pressure inside the rail.

C. Pressure limiterThe pressure limiter is a valve that opens to release excess pressure when the rail internal pressure reaches an abnor-

mally high value. When rail internal pressure reaches approximately 221 MPa, the pressure limiter opens. When pres-

sure returns to approximately 50 MPa, the pressure limiter closes. Fuel released from the pressure limiter is returned to

the fuel tank.

D. Flow damperThe flow damper mitigates pressure pulsations in the rail, and functions to supply fuel when leaks occur downstream of

the damper. When pressure pulsations occur in the rail, the flow damper piston acts as a damper to mitigate the pulsa-

tions with spring drag and orifice flow resistance. When a fuel leak occurs in an injection pipe or injector, the balance

between the following three forces is disturbed: 1) the pressure of the fuel being supplied via the orifice downstream of

the flow damper, 2) spring drag, and 3) the fuel pressure being applied to the piston surface prior to the orifice. As a

result, the end of the piston closes the fuel supply port to terminate the supply of fuel. When rail internal pressure reaches

approximately 1 MPa (10 kg/cm2), the fuel damper recovers.

3-4. InjectorsA. Outline

The CRS uses compact, energy efficient, TWV electromagnetic control type injectors.

B. Construction

C. OperationThe TWV regulates control chamber internal pressure, and starts and stops injection by opening and closing the outlet

orifice path.

a. Non-injection

When no current is supplied to the solenoid, the TWV is pushed downward by the spring, and the outlet orifice closes.

Therefore, the control chamber pressure pushing down on the command piston becomes equal to the pressure pushing

the nozzle needle up. The nozzle needle closes due to nozzle spring force, and the difference in areas to which pressure

is being applied, and as a result, fuel is not injected.

b. Injection

When current is initially applied to the solenoid, the attraction of the solenoid pulls the TWV up, opening the outlet orifice

and allowing fuel to flow out of the control chamber. As the fuel flows out, control chamber pressure decreases, pulling

the command piston up. As a result, the nozzle needle rises, and injection begins.

c. Injection complete

When current continues to be applied to the solenoid, the nozzle is lifted fully, and the maximum injection rate is

achieved. When current to the solenoid is turned off, the TWV falls and closes the orifice. Fuel then flows into the control

chamber via the inlet orifice, increasing the pressure. As a result, the nozzle needle rapidly closes, and injection stops.

D. Injectors with QR codesa. QR codes

• QR Code Location

• Correction Points Using QR Codes

b. Service instructions

When replacing the injectors or the engine ECU, it is necessary to record the ID codes in the ECU using a diagnostic tool

(available from the vehicle manufacturer.)

<Attention>(Failing to correctly register the ID codes for the installed injectors may lead to engine malfunction such as rough idling

and/or abnormal noise.)

• Injector Replacement

• Engine ECU Replacement

4. DESCRIPTION OF CONTROL SYSTEM COMPONENTS4-1. Engine Control System Block Diagram

4-2. Sensors and RelaysA. NE sensor

The NE sensor is a Magnetic Pick Up (MPU) type sensor.

When a signal pulsar attached to the flywheel passes over

the sensor, the magnetic field of a coil within the sensor

changes, generating AC voltage. A signal pulsar is positioned

every 6° on the flywheel with the exception of four missing

teeth, bringing the total number of signal pulsars to 56.

Therefore, 112 pulses are outputted for every two revolutions

of the engine. These signals are used to detect engine rota-

tional speed, and the crank angle every 6°.

B. Top Dead Center (TDC) sensor (cylinder recognition sensor)The TDC sensor is an Magneto Resistive Element (MRE)

type sensor. When a signal pulsar attached to the flywheel

passes over the sensor, the magnetic resistance changes.

The resultant change in current is converted into a rectangu-

lar wave by an internal IC circuit, and is outputted to the en-

gine ECU as a signal. A cylinder recognition pulsar is

attached to the engine camshaft gear to output the cylinder

recognition signal.

There are four pulsars every 90° on the camshaft, plus one

additional pulsar. Therefore, for every revolution of the pump

(or two engine revolutions), five pulses are outputted. Cylin-

der recognition is referenced by combining the NE signal with

the TDC signal. Additionally, the irregular pulsar is used to

distinguish cylinder #1.

TDC for cylinder # 1 occurs after the irregular pulse, located 96°CA after the No. 1 TDC reference signal. The interval

between each cylinder is the same number of degrees (refer to the chart below.)

C. Fuel temperature sensor (THL)The fuel temperature sensor is mounted on the supply pump to detect fuel temperature, and to send a corresponding

signal to the engine ECU. The detection portion of the sensor utilizes a thermistor in which the internal resistance chang-

es according to the temperature. The engine ECU applies voltage to the thermistor, and detects the resulting voltage

change from variations in the engine ECU internal resistance value, and the thermistor resistance value. This voltage

change is then detected as a change in temperature. The resistance value of the sensor at 20°C is 2.45kW, and 1.15kW

at 40°C.

D. Atmospheric pressure sensor (built into the engine ECU)The atmospheric pressure sensor converts atmospheric pressure into an electrical signal. This signal is inputted into the

engine ECU to correct the maximum injection quantity data programmed into the ECU.

4-3. Engine ECUA. Outline

The engine ECU is the command center that controls the fuel injection system, and overall engine operation.

B. External wiring diagram

C. Terminal layout

D. Terminal symbol explanation• Terminals 1-34

• Terminals 35-69

No. Terminal Name Signal Name No. Terminal Name Signal Name

1 (GND) Signal Ground (Auxiliary) 18 (CASE GND) Case Earth (Auxiliary)

2 (GND) Signal Ground (Auxiliary) 19 KWP2000 KWP2000 K Line

3 IN3 Auxiliary 20 IN1 -

4 ÅiIN3-) Auxiliary 21 AD1 Accelerator Pedal Position Sensor 1

5 +B Power 22 AD2 Accelerator Pedal Position Sensor 2

6 +B Power 23 AD10 PTO Accelerator Position Sensor

7 +B Power 24 AD12 Auxiliary

8 TAC1 Tachometer Signal (SOURCE) 25 AD19 Auxiliary

9 TAC2 Tachometer Signal (SINK) 26 AD20 Auxiliary

10 POUT1 Auxiliary 27 VS1 Vehicle Speed Sensor

11 POUT2 Auxiliary 28 CASE GND Case Ground

12 POUT3 Auxiliary 29 IN2 -

13 POUT4 Auxiliary 30 AD14 Idle Volume

14 PIN1 Auxiliary 31 AD15 Auxiliary

15 PIN2 Auxiliary 32 AD16 Intake Air Temperature Sensor

16 33 AD17 Auxiliary

17 34 AD18 Auxiliary

No. Terminal Name Signal Name No. Terminal Name Signal Name

35 +BF +BF (Flyback +B) 53 SW7 Brake Switch

36 OUT5 Exhaust Brake Solenoid Valve 54 A-GND4 Sensor Ground 4

37 OUT6 Auxiliary 55 A-GND5 Sensor Ground 5

38 OUT7 Auxiliary 56 SW1 Key Switch

39 NE-SLD Engine Rotational Speed Shield Earth 57 A-VCC4 Sensor Power Supply 4

40 NE+ Engine Rotational Speed + 58 SW8 Idle Switch (Accelerator Switch)

41 NE- Engine Rotational Speed - 59 SW10 Auxiliary

42 OUT1 Auxiliary 60 SW12 Auxiliary

43 OUT2 Overheat Warning Light 61 SW17 Auxiliary

44 OUT3 Exhaust Brake Light 62 AD21 Auxiliary

45 OUT4 Glow Light 63 AD22 Auxiliary

46 SW1 Key Switch 64

47 OUT8 Auxiliary 65 A-VCC5 Sensor Power Supply 5

48 SW2 Starter Switch 66 SW9 Neutral Switch

49 SW3 Exhaust Brake Switch 67 SW11 Auxiliary

50 SW4 Engine Stop Switch 68 SW16 Diagnosis Switch

51 SW5 Idle Up Switch 69 SW18 Auxiliary

52 SW6 Auxiliary

• Terminals 70-101

• Terminals 102-136

No. Terminal Name Signal Name No. Terminal Name Signal Name

70 OUT19 Glow Relay 86 SW31 Auxiliary

71 OUT20 Glow Relay 87 SW31 Auxiliary

72 GND Signal Ground 88 SW20 Idle Down Switch

73 GND Signal Ground 89 SW21 Power Take Off (PTO) Switch

74 OUT17 Main Relay 90 SW25 Auxiliary

75 OUT18 Main Relay 91 SW26 Auxiliary

76 +BF +BF (Flyback +B) 92 SW13 Auxiliary

77 SW27 Clutch Switch 93 SW28 Auxiliary

78 SW19 Auxiliary 94 SW29 Auxiliary

79 SW14 Auxiliary 95 CAN2H CAN2 High

80 SW15 Auxiliary 96 CAN2L CAN2 Low

81 SW24 A/C Idle Up Switch 97 SW32 Auxiliary

82 S-OUT1 Malfunction Indicator Lamp (MIL) 1 98 SW22 QT CUT Switch

83 S-OUT2 Auxiliary 99 SW23 Auxiliary

84 S-OUT3 Auxiliary 100 SW30 Auxiliary

85 S-OUT4 Auxiliary 101 CAN2-SLD CAN2 Shield Earth

No. Terminal Name Signal Name No. Terminal Name Signal Name

102 P-GND Power Ground 120 G Cam Angle Signal

103 TWV1 Injector Actuation Signal 1 121 AD4 Rail Pressure Sensor 1

104 TWV3 Injector Actuation Signal 3 122 AD11 Auxiliary

105 TWV5 Injector Actuation Signal 5 123 A-VCC3 Sensor Power Supply 3

106 COMMON1 Injector Actuation Signal 1 124 NE-VCC Auxiliary

107 COMMON1 Injector Actuation Signal 1 125 A-VCC2 Sensor Power Supply 2

108 OUT9 Auxiliary 126 A-VCC1 Sensor Power Supply 1

109 OUT10 Auxiliary 127 AD13 Auxiliary

110 OUT11 Auxiliary 128 AD3 MAP Sensor

111 OUT12 Auxiliary 129 (GND) Signal Ground (Auxiliary)

112 OUT13 Auxiliary 130 (GND) Signal Ground (Auxiliary)

113 OUT14 Auxiliary 131 G-GND Cam Angle Ground

114 OUT15 Auxiliary 132 AD5 Rail Pressure Sensor 2

115 OUT16 Auxiliary 133 G-VCC Cam Angle VCC (5 V)

116 134 A-GND1 Sensor Ground 1

117 135 A-GND2 Sensor Ground 2

118 GND Sensor Ground 6 136 A-GND3 Sensor Ground 3

119 NE (MRE) -

• Terminals 137-167

No. Terminal Name Signal Name No. Terminal Name Signal Name

137 TWV2 Injector Actuation Signal 2 153 PCV1 Auxiliary

138 TWV4 Injector Actuation Signal 4 154 AD6 Auxiliary

139 TWV6 Injector Actuation Signal 6 155 AD7 Coolant Temperature Sensor

140 P-GND Power Ground 156

141 P-GND Power Ground 157 CAN1H CAN1 High

142 COMMON2 Injector Actuation Power Supply 2 158 CAN1L CAN2 Low

143 COMMON2 Injector Actuation Power Supply 2 159

144 SCVLO HP3, 4 Lo 160

145 SCVLO HP3, 4 Lo 161 (CASE GND) Case Earth (Auxiliary)

146 SCVHI HP3, 4 Hi 162 AD8 Auxiliary

147 SCVHI HP3, 4 Hi 163 AD9 Fuel Temperature Sensor 2

148 164

149 165 CAN1-SLD Auxiliary

150 PCV2 Auxiliary 166

151 PCV2 Auxiliary 167 (CASE GND) Case Earth (Auxiliary)

152 PCV1 Auxiliary

5. CONTROL TYPESThe CRS provides more appropriate control of the fuel injection quantity and injection timing than the mechanical gover-

nor and timer used in the conventional injection pump. In system control, the engine ECU performs the necessary cal-

culations based on signals received from the sensors located on the engine and the vehicle. The ECU then controls the

timing and duration of the current that is applied to the injectors in order to obtain optimal injection timing and injection

quantity.

5-1. Control FunctionsA. Fuel injection rate control function

When the specified conditions are satisfied, fuel injection rate control performs a pilot injection to deliver a very small

injection quantity prior to the main injection. The purpose of this function is to improve engine startability.

B. Fuel injection quantity control functionThe fuel injection quantity control function replaces the function of the governor in the conventional injection pump. The

optimal injection quantity is achieved by regulating fuel injection based on engine rotational speed and accelerator pedal

position signals.

C. Fuel injection timing control functionThe fuel injection timing control function replaces the conventional timer function. The optimal injection timing is achieved

by performing control based on engine speed and injection quantity.

D. Fuel injection pressure control function (rail pressure control function)The fuel injection pressure control function controls the pump discharge quantity by measuring the fuel pressure with the

rail pressure sensor. Fuel pressure information is then fed back to the engine ECU. Pressure feedback control is per-

formed so that the discharge quantity matches the optimal (command) value set in accordance with the engine rotational

speed and the injection quantity.

5-2. Fuel Injection Rate ControlA. Main injection

As shown in the figure below, main injection begins just prior to engine TDC, and is directly related to engine output.

Depending on engine running conditions, injections other than the main injection may or may not be performed, or may

be regulated in quantity or duration.

B. Pre-injectionPre-injection is a very small injection that is performed prior to the main injection (refer to the graph on the previous page).

While the injection rate increases due to the use of high-pressure fuel injection, the ignition lag (the delay from the start

of injection to the beginning of combustion) cannot be shortened to less than a set value. As a result, the quantity of fuel

injected before ignition increases, and explosive combustion occurs at the time of ignition, increasing both NOx and

noise. To counteract these conditions, a pre-injection is provided to keep the initial injection at the minimum required rate.

As a result, the primary explosive combustion is dampened, reducing NOx and noise.

C. Pilot injectionThe pilot injection is a small injection performed prior to the

main injection to increase startability when engine rotational

speed is low at engine start (pre-heating effect.)

5-3. Fuel Injection Quantity ControlA. Starting injection quantity

The injection quantity when the engine is started is deter-

mined by engine rotational speed and coolant temperature.

As the coolant temperature decreases, the injection quantity

increases. When engine rotational speed reaches a specified

value, the injection quantity decreases.

B. Injection quantity increase delay correction during accelerationIf there is a large change in the accelerator pedal position

when accelerating, the injection quantity increase is delayed

in order to prevent black smoke emissions.

C. Basic injection quantityThe basic injection quantity is determined by the engine rota-

tional speed (NE) and the accelerator pedal position. The in-

jection quantity increases if the accelerator opening

increases when the engine speed is fixed.

D. Injection quantity for the maximum rotational speed settingThe injection quantity for the maximum rotational speed set-

ting is determined by the engine rotational speed. The injec-

tion quantity is restricted to prevent an excessive rise in

engine speed (overrun.)

E. Maximum injection quantityThe maximum injection quantity is determined by the engine

rotational speed, and is corrected according to the engine

coolant temperature. The correction quantity increases as

the engine coolant temperature decreases.

F. Manifold Absolute Pressure (MAP) correctionWhen MAP is low, the boost pressure correction restricts the

maximum injection quantity in accordance with the boost

pressure to reduce black smoke emission.

G. Atmospheric pressure correctionAs shown to the right, the atmospheric pressure correction

adjusts the maximum injection quantity correction line in ac-

cordance with the atmospheric pressure sensor signals.

H. Idle Speed Control (ISC)ISC controls idle speed by regulating the injection quantity such that the actual rotational speed matches the target ro-

tational speed (primarily determined by the engine coolant temperature) calculated by the engine ECU.

a. Automatic control

Automatic control determines the target idle rotational speed

in accordance with the engine coolant temperature.

b. Manual control

Manual control enables the rotational speed to be raised or

lowered using the idle rotational speed adjustment volume at-

tached to the driver's seat.

c. A/C idle up

When the conditions shown in the figure to the right are sat-

isfied, the idling rotational speed is set to a constant value.

d. Auto cruise correction

Under auto cruise correction, the engine ECU receives signals from the cruise computer to adjust the injection quantity

such that the actual vehicle speed matches the target vehicle speed.

5-4. Fuel Injection Timing ControlFuel injection timing characteristics differ according to whether the injection is the main injection, or the pilot injection. To

control the injection timing, the NE sensor uses the target for normal injection timing control. The TDC sensor then uses

this information as a reference signal.

A. Main injection timing controlThe main injection timing is determined by the basic injection

timing in the ECU memory. The basic injection timing is cal-

culated based on the final injection quantity, engine rotational

speed, and the coolant temperature. When the engine is

started, only the coolant temperature and engine rotational

speed are used for the calculation.

B. Pilot injection timing control (pilot interval)The pilot injection timing is controlled by adding a pilot inter-

val to the main injection timing. The pilot interval is calculated

based on the final injection quantity, engine rotational speed,

coolant temperature, atmospheric temperature, and atmo-

spheric pressure (corrected using the engine ECU MAP da-

ta). When the engine is started, only coolant temperature and

engine rotational speed are used for the calculation. For de-

tails on the pilot interval, refer to "Pilot injection", under "Fuel

Injection Rate Control" in this manual.

5-5. Fuel Injection Pressure ControlA. Fuel injection pressure

The fuel injection pressure is calculated by the engine ECU

using the final injection quantity and engine rotational speed.

When the engine is started, the value determined by the en-

gine ECU is calculated based on the coolant temperature and

engine rotational speed.

6. DIAGNOSTIC TROUBLE CODES (DTC)

DTC Malfunctioning Part Malfunction Details

P0122 Accelerator Pedal Position Sensor

No. 1

Signal for accelerator pedal position sensor no. 1 is too low

P0123 Signal for accelerator pedal position sensor no. 1 is too high

P0222 Accelerator Pedal Position Sensor

No. 2

Signal for accelerator pedal position sensor no. 2 is too low

P0223 Signal for accelerator pedal position sensor no. 2 is too high

P0121 Accelerator Pedal Position Sensor

No. 1

Accelerator pedal position sensor no. 1 has not reached idle output

P0221 Accelerator Pedal Position Sensor

No. 2

Accelerator pedal position sensor no. 2 has not reached idle output

P0120 Accelerator Pedal Position Sensor

No. 1

Accelerator pedal position sensor no. 1 has not reached non-idle output

P0220 Accelerator Pedal Position Sensor

No. 2

Accelerator pedal position sensor no. 2 has not reached non-idle output

P1120 Accelerator Pedal Position Sensor Accelerator pedal position sensor bi-directional signal is invalid

P0226 Idle Switch Idle switch is stuck open

P0225 Idle switch is stuck closed

P0238 Manifold Absolute Pressure (MAP)

Sensor

MAP sensor signal is too high

P0237 MAP sensor signal is too low

P0236 MAP sensor signal is invalid

P0193 Rail Pressure Sensor Rail pressure sensor signal is too high

P0192 Rail pressure sensor signal is too low

P0194 Rail pressure sensor signal is stuck at the intermediate value

P0563 VB High Vehicle system voltage is too high

P0562 VB Low Vehicle system voltage is too low

P0118 Engine Coolant Temperature

Sensor

Engine coolant temperature sensor signal is too high

P0117 Engine coolant temperature sensor signal is too low

P0183 Fuel Temperature Sensor

(Attached to Pump)

Fuel temperature sensor (attached to the pump) signal is too high

P0182 Fuel temperature sensor (attached to the pump) signal is too low

P0113 Intake Air Temperature Sensor Intake air temperature sensor signal is too high

P0112 Intake air temperature sensor signal is too low

P0108 Atmospheric Pressure Sensor Atmospheric pressure sensor signal is too high

P0107 Atmospheric pressure sensor signal is too low

P0615 Starter Switch Starter switch is shorting to the battery

P0335 NE Sensor No NE sensor signal

P0340 TDC Sensor No TDC sensor signal

P0385 NE and TDC Sensor No signal from either the NE sensor or TDC sensor

P0503 Vehicle Speed Sensor Vehicle speed sensor frequency is too high

P0502 Open or short in the vehicle speed sensor

P0501 Vehicle speed sensor signal is invalid

P1231 Exhaust Brake Open or ground short in the exhaust brake MV1 output

P1232 Battery short in the exhaust brake MV1 output

P2148 Injector COM1 Battery short in the COM1 output, or battery short in TWV1 or 3 output

P2147 Ground short in the COM1 output, or ground short in TWV1 or 3 output

P2146 Open in the COM1 output, or open in both TWV1 and TWV3

P2151 Injector COM2 Battery short in the COM2 output, or battery short in TWV2 or 4 output

P2150 Ground short in the COM2 output, or ground short in TWV2 or 4 output

P2149 Open in the COM2 output, or open in both TWV2 and TWV4

P0201 Injector No. 1 Open in TWV1 output, or open in injector coil

P0202 Injector No. 2 Open in TWV2 output, or open in injector coil

P0203 Injector No. 3 Open in TWV3 output, or open in injector coil

P0204 Injector No. 4 Open in TWV4 output, or open in injector coil

P2503 Charging Circuit (Inside ECU) Capacitor charging circuit malfunction (insufficient charging)

P2504 Capacitor charging circuit malfunction (over-charging)

P0088 Rail Pressure Sensor Rail pressure sensor has exceeded the upper limit

P0089 Rail pressure sensor has exceeded the high upper limit

P0629 Suction Control Valve (SCV)

(Pump)

Battery short in the SCV (+) output

P0627 Open or ground short in the SCV (+) output

Open or ground short in the SCV (-) output

Open in the SCV coil; short in the SCV coil

Battery short in the SCV (-) output

P1190 SCV seizure

P0301 Injector (FCCB) # 1 cylinder injection system malfunction

P0302 # 2 cylinder injection system malfunction

P0303 # 3 cylinder injection system malfunction

P0304 # 4 cylinder injection system malfunction

P0219 Engine Overspeed Engine overspeed

P1384 Glow Plug Open or ground short in the glow relay output

P1383 Open or battery short in the glow relay output

P0217 Engine Coolant Temperature

Sensor

Engine coolant temperature has exceeded the upper limit

P0704 MT Clutch Switch Clutch switch circuit malfunction (MT vehicles only)

P0850 Neutral Switch Neutral switch circuit malfunction (MT vehicles only)

P0093 Fuel Leak Pressure sensor output invalid (including fuel leaks)

P2293 Pressure Limiter Pressure limiter operation

P1217 Supply Pump Supply pump protection

P1218 Supply pump replacement

P1219 Supply pump malfunction (insufficient feed)

DTC Malfunctioning Part Malfunction Details

P0091 Flow Damper #1 cylinder flow damper operation (fuel leak other than from the flow

damper)

P0092 #2 cylinder flow damper operation (fuel leak other than from the flow

damper)

P0093 #3 cylinder flow damper operation (fuel leak other than from the flow

damper)

P0094 #4 cylinder flow damper operation (fuel leak other than from the flow

damper)

P1616 Main Relay Main relay seizure

P0602 QR Code (Injector Compensation) QR data not written

P0611 QR D data error

P0612 QR definition error (definition for QR correction not correct)

P0607 CPU Malfunction CPU malfunction, watchdog IC malfunction

P0606 CPU malfunction, main CPU malfunction

P0601 Checksum error - flash range

DTC Malfunctioning Part Malfunction Details

Published: June 2004

[DTP]

Duplication prohibited without permissionEdited and published by:

Service Department, DENSO Corporation

1-1 Showa-cho, Kariya, Aichi Prefecture, Japan