One-Step Synthesis of Monodisperse and Hierarchically ...

Transcript of One-Step Synthesis of Monodisperse and Hierarchically ...

13556 DOI: 10.1021/la101778z Langmuir 2010, 26(16), 13556–13563Published on Web 07/21/2010

pubs.acs.org/Langmuir

© 2010 American Chemical Society

One-Step Synthesis of Monodisperse and Hierarchically Mesostructured

Silica Particles with a Thin Shell

Hongmin Chen,† Tao Hu,† Xinmeng Zhang,†,§ Kaifu Huo,†,^ Paul K. Chu,*,† and Junhui He*,‡

†Department of Physics and Materials Science, City University of Hong Kong, Tat Chee Avenue, Kowloon,Hong Kong, China, ‡Functional Nanomaterials Laboratory, Technical Institute of Physics and Chemistry,

Chinese Academy of Sciences (CAS), Beijing 100190, China, §State Key Lab of Advanced Welding ProductionTechnology, School ofMaterials Science &Engineering, Harbin Institute of Technology, Harbin 150001, China,and ^College ofMaterials andMetallurgy,WuhanUniversity of Science andTechnology,Wuhan 430081,China

Received May 4, 2010. Revised Manuscript Received July 12, 2010

Monodisperse, uniform, and hierarchicallymesostructured silica particles with a thin shell have been fabricated via one-step synthesis using dodecanethiol (C12-SH) and CTAB as dual templates. A series of hierarchically mesostructured silicaparticles with a morphology similar to that of pomegranate can be obtained by simply adjusting the mass ratio of C12-SHto CTAB.When the mass ratio is increased, a mesophase transformation occurs from an ordered 2D hexagonal structureto a mesostructured cellular foam in the core of the hierarchically mesoporous silica particles. These unique silica particlesare characterized by small-angle X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electronmicroscopy (TEM) and energy dispersive spectroscopy (EDS), Fourier transform infrared spectroscopy (FT-IR), andnitrogen adsorption-desorption measurements. The formation mechanism of the hierarchically mesostructured silicaparticles with a thin shell is proposed according to the experimental results. Synergistic self-assembly of C12-SH andCTABin the solution is believed to play a key role in mediating the formation of these hierarchical silica mesostructures, and thehydrophobic dodecanethiol can act as both the swelling agent for CTAB micelles and coagent for the formation of amicroemulsion with CTABmicelles. This synthesis method is simple, straightforward, and suitable for the preparation ofthe other biomineral nanostructures that are unique scaffolds in biological, medical, and catalytic applications.

1. Introduction

Recently, synthesis of hierarchically silica mesostructures hasattracted much attention due to promising applications1 and thepossibility to elucidate the fundamental mechanisms aboutbiomineralization.2 The important goal and big challenge con-cerning the design and fabrication of silica mesostructures are to

produce hierarchical silica materials with multiple pore sizes,namely micropores, mesopores, and macropores.3-13 In particu-lar, mesostructures with well-defined morphologies are especiallyinteresting and important because they may offer more advan-tages than monomodal mesostructures.5-8,10,12,14 First of all,introduction of hierarchical structures may enhance the function-ality of the pore wall and interactions with various species.Second, hierarchical combinations of multiscale pores allow formass transport pathways within inorganic networks. Third, thecoexistence of multiscale pores may enhance and harmonize thediffusion of foreign molecules of different sizes through theporous matrices. Last but not least, silica materials with hier-archical structures are promising in a myriad of applicationsincluding catalysis, adsorption, separation, biomedicine, andespecially multifunctional carriers in drug delivery.15-18

The composition, internal porous structure, and morpho-logy of silica structures greatly impact their applications. In gene-ral, surfactant-assisted self-assembly is one of most promising

*To whom correspondence should be addressed. E-mail: [email protected] (P.K.C.); [email protected] (J.H.).(1) (a) Davis, M. E. Nature 2002, 417, 813. (b) Trewyn, B. G.; Slowing, I. I.; Giri,

S.; Chen, H.; Lin, V. S.-Y. Acc. Chem. Res. 2007, 40, 846. (c) Piao, Y. Z.; Burns, A.;Kim, J.; Wiesner, U.; Hyeon, T.Adv. Funct.Mater. 2008, 18, 3745. (d) Yang, Z. L.; Lu,Y. F.; Yang, Z. Z. Chem. Commun. 2009, 2270. (e) Joo, S. H.; Park, J. Y.; Tsung,C. K.; Yamada, Y.; Yang, P. D.; Somorjai, G. A. Nature Mater. 2009, 8, 126. (f)Han, Y.; Zhang, D. L.; Chng, L. L.; Sun, J. L.; Zhao, L.; Zou, X. D.; Ying, J. J. NatureChem. 2009, 1, 123.(2) (a) Sanchez, C.; Arribart, H.; Guille, M. M. G. Nature Mater. 2005, 4, 277.

(b) Pouget, E.; Dujardin, E.; Cavalier, A.; Moreac, A.; Valery, C.; Marchi-Artzner, V.;Weiss, T.; Renault, A.; Paternostre, M.; Artzner, F. Nature Mater. 2007, 6, 434. (c)Yang, S.; Zhou, X. F.; Yuan, P.; Yu, M. H.; Xie, S. H.; Zou, J.; Lu, G. Q.; Yu, C. Z.Angew. Chem., Int. Ed. 2007, 46, 8579.(3) Guo, X.; Deng, Y.; Tu, B.; Zhao, D. Langmuir 2010, 26, 702.(4) Chen, Y.; Li, Y.; Chen, Y.; Liu, X.; Zhang, M.; Li, B.; Yang, Y. Chem.

Commun. 2009, 5177.(5) Zhang, H.; Hardy, G. C.; Rosseinsky, M. J.; Cooper, A. I.Adv. Mater. 2003,

15, 78.(6) Karkamkar, A. J.; Kim, S.; Mahanti, S. D.; Pinnavaia, T. J. Adv. Funct.

Mater. 2004, 14, 507.(7) Andersson, J.; Johannessen, E.; Areva, S.; Baccile, N.; Azaı̈s, T.; Lind�e,M. J.

Mater. Chem. 2007, 17, 463.(8) Sel, O.; Sallard, S.; Brezesinski, T.; Rathousk�y, J.; Dunphy, D. R.; Collord,

A.; Smarsly, B. M. Adv. Funct. Mater. 2007, 17, 3241.(9) Zhong, H.; Liu, J.; Wang, P.; Yang, J.; Yang, Q. Microporous Mesoporous

Mater. 2009, 123, 63.(10) Ji, Q.; Acharya, S.; Hill, P. J.; Vinu, A.; Yoon, S. B.; Yu, J.; Sakamoto, K.;

Ariga, K. Adv. Funct. Mater. 2009, 19, 1792.(11) Loiola, A. R.; Silva, L. R. D.; Cubillas, P.; Anderson, M. W. J. Mater.

Chem. 2008, 18, 4985.(12) Li, F.; Wang, Z.; Ergang, N. S.; Fyfe, C. A.; Stein, A. Langmuir 2007, 23,

3996.

(13) (a) Wang, H. N.; Wang, Y. H.; Zhou, X. F.; Zhou, L.; Tang, J. W.; Lei, J.;Yu, C. Z.Adv. Funct. Mater. 2007, 17, 613. (b) Cai, X.; Zhu, G.; Zhang, W.; Zhao, H.;Wang, C.; Qiu, S.; Wei, Y. Eur. J. Inorg. Chem. 2006, 3641.

(14) Ho, W.; Yu, J. C.; Lee, S. Chem. Commun. 2006, 1115.(15) (a) Lim, Y. T.; Kim, J. K.; Noh, Y. W.; Cho, M. Y.; Chung, B. H. Small

2009, 5, 324. (b) Yoon, T. J.; Kim, J. S.; Kim, B. G.; Yu, K. N.; Cho, M. H.; Lee, J. K.Angew. Chem., Int. Ed. 2005, 44, 1068.

(16) (a) Fang, C.; Zhang, M. J. Mater. Chem. 2009, 19, 6258. (b) Lin, Y. S.;Haynes, C. L.Chem.Mater. 2009, 21, 3979. (c)Wang,W.; Gu, B.; Liang, L.; Hamilton,W. A. J. Phys. Chem. B 2004, 108, 17477.

(17) (a) Liong, M.; Angelos, S.; Choi, E.; Patel, K.; Stoddart, J. F.; Zink, J. I. J.Mater. Chem. 2009, 19, 6251. (b) Shiomi, T.; Tsunoda, T.; Kawai, A.; Matsuura, S.;Mizukami, F.; Sakaguchi, K. Small 2009, 5, 67. (c) Chen, H.; He, J.; Tang, H. M.; Yan,C. X. Chem. Mater. 2008, 20, 5894.

(18) (a) Gu, J. L.; Fan, W.; Shimojima, A.; Okubo, T. Small 2007, 3, 1740. (b)Climent, E.; Berardos, A.; Martinez-Manez, R.; Maquieira, A.; Marcos, M. D.; Pastor-Navarro, N.; Puchades, R.; Sancenon, F.; Soto, J.; Amoros, P. J. Am. Chem. Soc. 2009,131, 14075.

DOI: 10.1021/la101778z 13557Langmuir 2010, 26(16), 13556–13563

Chen et al. Article

approaches for the synthesis of silica materials with the designedcomposition, pore structure, function, and morphology.19 Des-pite success in the synthesis of mesoporous silica nanostructures(including spheres, rods, fibers, tubes, films, and foams, etc.) withsingle-size pore by surfactant-assisted assembly, it is not easy tofabricate hierarchical silica mesostructures using only one tem-plate. It is known from the chemistry of surfactants that surfac-tant assemblies with varied morphologies and supermolecularstructures, including micelles, vesicles, liquid crystals, and otherassemblies, can be obtained in mixed surfactant solutions by theinteractions with cotemplates such as hydrogen bonding, van derWaals forces, and electrostatic interaction.20 Hence, a cotemplateapproach has been proposed to produce hierarchical silicastructures. By simple regulation of the ratio of the cosolvents orcosurfactants, silica nanostructures with varied morphologiesand pore structures have been successfully synthesized.21-29

One of the general synthetic route is by electrostatically matchingvarious anionic organalkoxysilanes with the cationic surfactantmicelles in a base-catalyzed condensation reaction of tetraethox-ysilane based on the costructure-directing effect.21-24 Moreover,siliceous nanopods, helical structures, and ordered mesoporouscapsules can be fabricated by simply tuning the ratio of the twosurfactants.25,26 Chiral mesoporous silica fibers, tubes, and bun-dles have also been prepared using dual template27 and silicaspheres with controllable cavities in the shell have recently beensynthesized by using similar techniques.18c,28 Although anionichydrophilic surfactants (carboxylate, sulfate, sulfonate, and soon) have been successfully used as cosurfactants to prepare silicamaterials with well-controlled morphologies and structures,29 tothe best of our knowledge, hydrophobic anionic surfactants

containing the mercapto functional group (-SH) have not beenadopted in the synthesis of hierarchically silica structures.

In this paper,we report a simple and easy synthetic technique toproduce monodisperse and hierarchical mesostructured silicaparticles with a uniform size by using C12-SH and CTAB ascosurfactants. The dual-surfactant-template technique conductedunder optimal conditions and selecting the proper ratio of the twosurfactants enable independent control of structural parameterssuch as the particle diameter (less than 200 nm), shell thickness,pore structures, and morphologies. The formation mechanism ofthe hierarchically mesostructured silica particles is proposed anddiscussed. This technique can be readily extended to synthesizeother mesostructures with specific morphologies and architec-tures by fine-tuning the length of carbon chain of thiol.

2. Experimental Section

2.1. Materials. Cetyltrimethylammonium bromide (CTAB),sodium hydroxide (NaOH), 1-dodecanethiol (named as C12-SH),and tetraethoxysilane (TEOS)werepurchased fromSigma-Aldrich.All the chemicals were analytical grade and used without furtherpurification. Ultrapure water with a resistivity 18.2 MΩ 3 cmobtained from a Millipore Milli-Q purification system wasused throughout the experiments.

2.2. Preparation ofMesoporous Silica Nanospheres.Meso-porous silica nanospheres were prepared in a basic solution usingC12-SH and water as cosolvents and CTAB as the surfactant. In atypical procedure, 0.2 g of CTAB was dissolved in an emulsioncomposed of 96 mL of H2O, 0.7 mL of 2 M NaOH, and theappropriate amounts ofC12-SH.After themixturewas vigorouslystirred for 0.5 h at 80 �C, 1.5mLof TEOSwas quickly added. Theresulting mixture was again vigorously stirred at 80 �C for 2 h. Awhite precipitate was obtained, filtered, washed with pure water,and dried in air at 60 �C for 24 h. The organic and othercomponents in the products were eventually removed by calcina-tion in air at 550 �C for 5 h. The amounts of C12-SH and CTABadded to the reaction solution during the synthesis of the silicasamples with different mass ratios (R) of C12-SH/CTAB areshown in Table 1, and the other experimental parameters werethe same as those aforementioned.

2.3. Characterization. Scanning electronmicroscopy (SEM)was carried out on a JEOL JSM-7001F field emission scanning

Table 1. Summary of the Different Amounts of C12-SH and CTAB

Added with R Values Change in Reaction Solution

sample R C12-SH (mL) CTAB (g) corresponding figure

S1 0.04 0.01 0.2 Figures 1a and 2S2 0.08 0.02 0.2 Figures 1b and 3S3 0.20 0.05 0.2 Figures 1c and 4S4 0.40 0.10 0.2 Figures 1d and 5S5 0.80 0.20 0.2 Figure 6aS6 2.0 0.50 0.2 Figure 6bS7 4.0 1.00 0.2 Figure 6cS0 0 0 0.2 Figure 7

Table 2. Physicochemical Properties of FabricatedMesoporous Silica

Nanospheres

sample d (nm)aBET surfacearea (m2/g)

pore volumeb

(cm3/g)pore size

distributionc (nm)

S1 4.211 763 0.299 <2S2 4.203 707 0.612 2.6S3 1036 0.711 2.7S4 1078 0.751 3.1aEstimated from SA-XRD patterns of samples. bEstimated from the

amounts of N2 adsorbed at a relative pressure (P/P0) of 0.99.cCentral

value of the pore size distribution as calculated from the N2 adsorptionbranch using the BJH method.

(19) (a) Fukao, M.; Sugawara, A.; Shimojima, A.; Fan, W.; Arunagirinathan,M. A.; Tsapatsis, M.; Okubo, T. J. Am. Chem. Soc. 2009, 131, 16344. (b) Blas, H.;Save, M.; Pasetto, P.; Boissoere, C.; Sanchez, C.; Charleux, B. Langmuir 2008, 24,13132. (c) Yu, M. H.; Wang, H. N.; Zhou, X. F.; Yuan, P.; Yu, C. Z. J. Am. Chem. Soc.2007, 129, 14576. (d) Wang, W.; Gu, B.; Liang, L. J. Colloid Interface Sci. 2007, 313,169. (e) He, J.; Chen, H.; Zhang, L. Prog. Chem. 2007, 19, 1488.(20) (a) Holland, P. M.; Rubingh, D. N. Mixed Surfactant Systems; American

Chemical Society: Washington, DC, 1992.(b) Yin, H.; Zhou, Z.; Huang, J.; Zheng, R.;Zhang, Y. Angew. Chem., Int. Ed. 2003, 42, 2188. (c) Discher, D. E.; Eisenberg, A.Science 2002, 297, 967.(21) (a) Che, S.; Liu, Z.; Ohsuna, T.; Sakamoto, K.; Tersaki, O.; Tatsumi, T.

Nature 2004, 429, 281. (b) Che, S.; Garcia-Bennett, A. E.; Yokoi, T.; Sakamoto, K.;Kunieda, H.; Terasaki, O.; Tatsumi, T. Nature Mater. 2003, 2, 801.(22) (a) Wu, X. J.; Xu, D. S. J. Am. Chem. Soc. 2009, 131, 2774. (b) Zhang, L.;

Qiao, S. Z.; Jin, Y. G.; Cheng, L.; Yan, Z. F.; Lu, G. Q. Adv. Funct. Mater. 2008, 18,3834. (c) Rambaud, F.; Valle, K.; Thibaud, S.; Julian-Lopez, B.; Sanchez, C.Adv. Funct.Mater. 2009, 19, 2896.(23) (a)Wang, J.; Xiao, Q.; Zhou, H. J.; Sun, P. C.; Yuan, Z. Y.; Li, B. H.; Ding,

D. T.; Shi, A. C.; Chen, T. H. Adv. Mater. 2006, 18, 3284. (b) Wang, J.; Li, F.; Zhou,H. J.; Sun, P. C.; Ding, D. T.; Chen, T. H.Chem.Mater. 2009, 21, 612. (c) Liu, J.; Yang,Q. H.; Zhang, L.; Jiang, D. M.; Shi, X.; Yang, J.; Zhong, H.; Li, C. Adv. Funct. Mater.2007, 17, 569. (d) Chen, H.; He, J. Chem. Commun. 2008, 4422.(24) (a) Cauda, V.; Schlossbauer, A.; Kecht, J.; Zurner, A.; Bein., T. J. Am.

Chem. Soc. 2009, 131, 11361. (b) Muhlstein, L. A.; Sauer, J.; Bein, T. Adv. Funct.Mater. 2009, 19, 2027. (c) Kobler, J.; Moller, K.; Bein, T. ACS Nano 2008, 2, 791.(25) (a) Li, Y.; Bi, L. F.; Wang, S. B.; Chen, Y. L.; Li, B. Z.; Zhu, X. L.; Yang,

Y. G. Chem. Commun. 2010, 2680. (b) Yang, S.; Zhao, L. Z.; Yu, C. Z.; Zhou,X. F.; Tang, J. W.; Yuan, P.; Chen, D. Y.; Zhao, D. Y. J. Am. Chem. Soc. 2006,128, 10460. (c) Djijiputro, H.; Zhou, X. F.; Qiao, S. Z.; Wang, L. Z.; Yu, C. Z.; Lu, G. Q.J. Am. Chem. Soc. 2006, 128, 6320.(26) (a) Yang, S.; Zhou, X.; Yuan, P.; Yu, M.; Xie, S.; Lu, G. Q.; Yu, C. Z.

Angew. Chem., Int. Ed. 2007, 46, 8579. (b) Yuan, P.; Yang, S.; Wang, H.; Yu, M.; Zhou,X.; Lu, G.; Zou, J.; Yu, C. Z.Langmuir 2008, 24, 5038. (c)Wu, X.; Ruan, J.; Ohsuna, T.;Terasaki, O.; Che, S. Chem. Mater. 2007, 19, 1577.(27) (a) Yang, Y.; Nakazawa, M.; Suzuki, M.; Kimura, M.; Shirai, H.;

Hanabusa, K. Chem. Mater. 2004, 16, 3791. (b) Yang, Y.; Suzuki, M.; Owa, S.;Shirai, H.; Hanabusa, K. Chem. Commun. 2005, 4462. (c) Yang, Y.; Suzuki, M.;Fukui, H.; Shirai, H.; Hanabusa, K. Chem. Mater. 2006, 18, 1324. (d) Yang, Y.;Nakazawa, M.; Suzuki, M.; Shirai, H.; Hanabusa, K. J. Mater. Chem. 2007, 17, 2936.(28) (a) Shiomi, T.; Tsunoda, T.; Kawai, A.; Matsuura, S.; Mizukami, F.;

Sakaguchi, K. Small 2009, 5, 67. (b) Chen, H.; He, J. Dalton Trans. 2009, 6651.(29) (a) Yokoi, T.; Sakamoyo, Y.; Terasaki, O.; Kubota, Y.; Okubo, T.;

Tatsumi, T. J. Am. Chem. Soc. 2006, 128, 13664. (b) Yokoi, T.; Wakabayashi, J.;Otsuka, Y.; Fan,W.; Iwama,M.;Watanabe, R.; Aramaki, K.; Shimojima, A.; Tatsumi, T.;Okubo, T. Chem. Mater. 2009, 21, 3719.

13558 DOI: 10.1021/la101778z Langmuir 2010, 26(16), 13556–13563

Article Chen et al.

electronmicroscope operated at 5 kV. The powder products weredispersed in ethanol by sonication for 10 min, put on a siliconwafer, and dried at 60 �C overnight. The white powders werecoatedwith a layer of gold before SEMobservations. Before trans-mission electronmicroscopy (TEM) and energy dispersive spectro-scopy (EDS) observations, the powder products were dispersedin ethanol by sonication for 10 min and put on carbon-coatedcopper grids. After drying at 60 �C overnight, they were observedin a JEOL JEM-2100F transmission electron microscope at anacceleration voltage of 200 kV. Small-angle X-ray diffraction(SA-XRD) patterns of the prepared products were acquired ona Philips X’Pert-MPD (PW 3040) X-ray diffractometer using CuKR radiation operated at 40 kV and 40 mA. Fourier transforminfrared spectroscopy (FT-IR) was carried on a Perkin-Elmer

spectrum 100 FT-IR spectrometer using KBr pellets. Nitrogenadsorption-desorption measurements were carried out on aQuantachrome NOVA 1200e surface area and pore size analyzerat-196 �Cusing the volumetricmethod. The productswere driedat 200 �C before the analysis. The Brunauer-Emmett-Teller(BET) specific surface areas were calculated by using adsorptiondata according to P/P0 = 0.04-0.20 (six points collected). Thepore size distributions were estimated from the adsorptionbranches of the isotherms using the Barrett, Joyner, and Halenda(BJH) method. The pore volumes were determined from theamounts of adsorbed N2.

3. Results and Discussion

3.1. Effects of the Mass Ratio (R) of C12-SH/CTAB on

theMorphology and Structure of Silica Products.By varyingthemass ratios of C12-SH/CTAB, hierarchical silica particles withvaried pore structures can be readily fabricated. For convenience,the samples synthesized at varied R values are referred as S1, S2,S3, S4, S5, S6, and S7 here. Their morphology and structure aredetermined by SEM and TEM, and the physicochemical proper-ties of S1-S4 are summarized in Table 2.

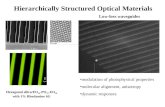

The SEM images in Figure 1 show monodisperse sphericalparticles with a uniform size and smooth surface. The diameter ofthe silica spheres ranges from 100 to 200 nm. These silica sampleshave porous structures as shown by the TEM images. Figures2-7 display the typical TEM images of the samples. S1 (R=0.04)consists of spherical particles of ∼200 nm in size (Figure 2a,b).These spherical particles are hollow (capsules) as revealed by thecontrast between the dark edge and pale center in the spheres(Figure 2).30 The shells of these hollow nanospheres have athickness of about 12 nm (Figure 2a and magnified TEM imagein Figure 2b). Few connecting necks are observed between thehollow spheres fromFigure 2, showing that the hollow spheres arewell monodisperse. The higher magnification image in Figure 2breveal ordered porous structures composed of the 2D hexa-gonal phase in the core,30a and the pore size is about 3.9 nm.

Figure 1. Typical SEM images of mesoporous silica nanospheres of S1 (a), S2 (b), S3 (c), and S4 (d). Scale bar: 1 um.

Figure 2. Typical TEM images of mesoporous silica nanospheresof S1.

(30) (a) Wang, J. G.; Li, F.; Zhou, H. J.; Sun, P. C.; Ding, D.; T.; Chen, T. H.Chem. Mater. 2009, 21, 612. (b) Feng, Z.; Li, Y. S.; Niu, D. C.; Li, L.; Zhao, W. R.;Chen, H. R.; Li, L.; Gao, J. H.; Ruan, M. L.; Shi, J. L. Chem. Commun. 2008, 2629.

DOI: 10.1021/la101778z 13559Langmuir 2010, 26(16), 13556–13563

Chen et al. Article

More accurate pore size information is obtained by SA-XRDandnitrogen sorption analysis, and it will be discussed later. There aretwo different pore images from the same viewing angle accordingto Figure 2b, one corresponding to the ordered hexagonalmesoscopic structures indicated by squares mainly distributedin the center of the spheres and the other associatedwith the fringemesoscopic structures as marked by ovals. The porous structuresmarked by squares and ovals are likely to be 2D hexagonal phasebut viewed from different directions. In other words, there is justone pore structure showing two types of images depending on theorientation.

Increasing the R value does not alter the morphology, but thepore structures are changed from being orderly to less orderly.

As shown inFigures 1b and 3, S2 (R=0.08) has a better sphericalmorphology than S1. The high contrast between the dark edgeand pale center in the spheres observed fromFigure 3 indicates itshollow nature. The magnified TEM image in Figure 3b corrobo-rates the hollow core together with a thin shell 10 nm thick. Mostof the pores show the weakly ordered 2D hexagonal mesophase.

S3 (R=0.20) also consists of spherical nanoparticles∼180 nmin size (Figure 4). All of themhave perfect spherical-like structureswhich are uniform in size and monodisperse. The TEM image inFigure 4bdiscloses awell-defined shell-like structurewith the shellbeing about 9 nm thick. Although a few fringes can be observedfrom the inside of the spherical particles (indicated by ovals inFigure 4b), the pore structures are disordered.

By further increasing theR value to 0.40, the porous core-shellstructures (S4) are retained, but the shell thickness is changed toabout 5 nm. The contract between the core and shell is not well-defined as as shown in the TEM images in Figure 5. The pore sizewhich is larger than that in S1-S3 is about 6 nm. The whole silicastructure is similar to that of the natural product of pomegranate,as shown in Figure 5c.

With the R values equal to or larger than 0.8, special porestructures and connecting necks between the hierarchical porousspheres emerge (Figure 6). As shown in Figure 6a, S5 consists ofspherical particles, and bigger hollow cores can be found insidethe structures. The cavity of the hollow cores is about 50 nm asestimated from the TEM images. Some larger hollow regions arehomogeneously covered bymany smaller ones. In the structure ofS6, some bigger hollow cores exist in a particle at the same time,and many smaller hollow regions are distributed around theselarger hollow cores (Figure 6b). By further increasingR to 4.0, theparticles have bigger hollow cores (Figure 6c) and thinner shellsthan S5 and S6. The TEM results show that all the productsconsist of mesostructured cellular foams.

In contrast, without the addition of C12-SH, monodispersemesoporous silica spheres (30-60 nm) can be obtained.MCM-41mesochannels are observed from the TEM results of the calcinedsample (Figure 7). Notably, compared to the silica samplesobtained in the presence of C12-SH, no thin shell is found on the

Figure 4. Typical TEM images of mesoporous silica nanospheresof S3.

Figure 5. Typical TEM images (a, b) of mesoporous silica nano-spheres of S4. (c) is the graphic of pomegranate.

Figure 3. Typical TEM images of mesoporous silica nanospheresof S2.

13560 DOI: 10.1021/la101778z Langmuir 2010, 26(16), 13556–13563

Article Chen et al.

surface of the silica particles.31 Also, without the addition ofCTAB, the sol-gel process of TEOS did not happen even if thesolution was kept overnight under vigorous stirring as TEOSdisperse into hydrophobic C12-SH emulsion. The results suggestthat C12-SH plays a key role in mediating the formation of themonodisperse hierarchicallymesostructured silica particles with athin shell with assistance from CTAB.

Figure 8 shows the typical SA-XRDpatterns of calcined S1-S4.The calcined silica samples obtained at different R values show anobvious diffraction peak at about 2.1� (2θ) which can be indexed tothe different planes of the p6mm mesostructure. Only one strongcharacteristic diffraction peak is observed for S1, and that can beidentified at (10) diffraction based on the two-dimensional p6mmunit cell. S2has aweakpeak at 2.3� (2θ), and that ismore likely (11)or (20) peaks, and the (10) peak is outside the range according theMCM-41 XRD. The diffraction peaks observed from S1 and S2corresponding to the other planes of p6mmbecome ambiguous andbroader, or disappear, and S3 and S4 show no identifiable diffrac-tion peaks in their XRD results, indicating that these samples haveweak ordered or disordered mesoscopic structures. The broaddiffraction peak was in agreement with the aforementioned TEMobservations. The d spacings calculated from the SA-XRDpeak ofthe (10) diffraction are summarized in Table 2.

The nitrogen adsorption/desorption isotherms obtained fromS1-S4 (Figure 9a) show typical type IV features indicative of thepresence of mesopores.32 A sharp capillary condensation step inthe relative pressure range 0.85-0.95 is observed from every

mesoporous silica sample, suggesting the presence of textural(disordered) porosity.33 Nitrogen isotherms for calcined samplesS1 and S2-S4 are different, and S2-S4 have similar nitrogensorption isotherms, indicating that S2-S4 have similar porestructures. The H2 hysteresis of S2-S4 suggests the formationof large mesopores with narrow windows in contact with adjacentpores.34 The shape of the isotherm and hysteresis loop suggests thatthese materials consist of large cells that are connected to each otheras well as the matrix of the particle by much smaller windows.35

Figure 7. TypicalTEMimages ofmesoporous silica nanospheres obtainedwithout addingC12-SH: (a) lowmagnification; (b) along differentvision: the channel direction (c-axis; b) and perpendicular to it (c).

Figure 6. Typical TEM images of mesoporous silica nanospheres: S5 (a), S6 (b), and S7 (c).

Figure 8. SA-XRD patterns of fabricated mesoporous silica na-nospheres of S1-S4.

(31) (a) Kresge, C. T.; Leonowicz, M. E.; Roth, W. J.; Vartuli, J. C.; Beck, J. S.Nature 1992, 359, 710. (b) Radu, D. R.; Lai, C. Y.; Huang, J. G.; Shu, X.; Lin, V. S.-Y.Chem. Commun. 2005, 1264.(32) (a) Sing, K. S. W.; Everett, D. H.; Haul, R. A. W.; Moscou, L.; Piertti,

R. A.; Rouqu�erol, J.; Siemieniewska, T.Pure Appl. Chem. 1985, 57, 603. (b) Lowell,S.; Shields, J. E. Powder Surface Area and Porosity; Chapman and Hall: New York,1991.

(33) Han, Y.; Ying, J. Y. Angew. Chem., Int. Ed. 2005, 44, 288.(34) (a) Sakamoto, Y.; Kaneda, M.; Terasaki, O.; Zhao, D. Y.; Kim, J. M.;

Stucky, G. D.; Shin, H. J.; Ryoo, R. Nature 2000, 408, 449. (b) Kruk, M.; Jaroniec,M. Chem.Mater. 2001, 13, 3169. (c) Fukuoka, A.; Kikkawa, I.; Sasaki, Y.; Shimojima,A.; Okubo, T. Langmuir 2009, 25, 10992.

(35) (a) Lukens, W. W.; Yang, P.; Stucky, G. D. Chem. Mater. 2001, 13, 28.(b) Djijiputro, H.; Zhou, X. F.; Qiao, S. Z.; Wang, L. Z.; Yu, C. Z.; Lu, G. Q. J. Am.Chem. Soc. 2006, 128, 6320. (c) Tang, B.; Vyas, S. M.; Lehmler, H.; Knutson, B. L.;Rankin, S. E. Adv. Funct. Mater. 2007, 17, 2500.

DOI: 10.1021/la101778z 13561Langmuir 2010, 26(16), 13556–13563

Chen et al. Article

In addition, the pore size distribution curves (Figure 9b) of S1-S4are determined from the adsorption branch of the isotherms. Exceptthat the pore size distribution of S1 is smaller than 2 nm, all the poresize distributionsof S2-S4 exhibit a sharppeak centered at the valueof around 2-4 nm, implying a uniformmesopore size. According toprevious reports, the classical BJH method underestimates the porewidth for MCM-41, when it is smaller than 4 nm.34b In the currentresults, the pore width might have also been underestimated. It maybe estimated more accurately on the basis of condensation pressure.However, largemesopores are not predicted by calculation using theBJH method, and this may result from that small mesopores areusually dominant in hierarchically porous systems.36 In addition,according to the nitrogen adsorption-desorption results (Table 2),addition of C12-SH affects the mesoporosity of the silica particles,including pore size, pore volume, and BET surface area.37 The BETsurface area and pore volume are around 700-1100 m2/g and0.3-0.75 cm3/g, respectively.3.2. Formation Mechanism of the Hierarchical Meso-

structured Silica Particles with a Thin Shell. Based on theexperimental results, amechanismdescribing the formation of the

hierarchical mesostructured silica particles by regulating the massratios of dual templates is postulated. It is believed that theevolution of the morphology of the silica particles should beclosely related to the interactions among C12-SH, CTAB, andsilica oligomers during the aqueous sol-gel process. Hydropho-bic C12-SH molecules can act both as a swelling agent for CTABsurfactants micelles and as a coagent for the formation ofmicroemulsion with CTAB surfactant micelles in addition tothe swelling effect.37 The majority of the formed supermolecularaggregates via electrostatic interaction of C12-S

- and CTAþ

structures are involved in the formation of the silica structures.31b

Various complex architectures are quickly realized due to

Figure 9. Nitrogen adsorption-desorption isotherms (a) and cor-responding pore size distributions (b) obtained from adsorptionbranches of silica nanospheres of S1-S4.

Figure 10. (a) FT-IR spectra of S4 before and after calcinationand CTAB molecules and (b) the related EDS result.

Scheme 1. Schematic Illustration of the Interaction among CTAB,

C12-SH, and Partially Hydrolyzed Products of TEOS Precursor in

the Interface of the Micelles or Microemulsion or Vesicles

(36) (a) Feng, Z.; Li, Y.; Niu, D.; Li, L.; Zhao, W.; Chen, H.; Li, L.; Gao, J.;Ruan, M.; Shi, J. Chem. Commun. 2008, 2629. (b) Sel, O.; Sallard, S.; Brezesinski,T.; Rathousk�y, J.; Dunphy, D. R.; Collord, A.; Smarsly, B. M. Adv. Funct. Mater.2007, 17, 3241.(37) (a) Sayari, A.; Kruk, M.; Jaroniec, M.; Moudrakovski, I. L. Adv. Mater.

1998, 10, 1376. (b) Liu, J.; Yang, Q. H.; Zhang, L.; Jiang, D. M.; Shi, X.; Zhong, H.; Li,C. Adv. Funct. Mater. 2007, 17, 569.

13562 DOI: 10.1021/la101778z Langmuir 2010, 26(16), 13556–13563

Article Chen et al.

self-assembly between silica oligomers and CTAB around theformed C12-SH/CTAB supermolecular aggregates.

As the C12-SH molecules are hydrophobic and function as apore expander or microemulsion with the assistance of CTAB,under strong basic conditions during the synthesis, the formedanionic C12-S

- molecules have strong electrostatic interactionswith the cationic surfactant CTAþ and silica oligomers.31b C12-SHmolecules have weak characteristic peaks of -SH in 2750-2550cm-1 and weak characteristic peaks of C-S in 720-570 cm-1.38 Itis not found the characteristic peaks of-SH in the structure of S4before calcination (Figure 10a), but the weak characteristic peaksof C-S in 720-570 cm-1 could be found. The EDX result inFigure 10b indicates S element exists in its structure. On the basis ofthe FT-IR andEDS results, it is believed that C12-S

- could form inthe basic solution (ca. pH = 11).39 Scheme 1 shows the possiblebinding model of the interaction among C12-S

-, CTAþ, andpartially hydrolyzed products of TEOS precursor in the interfaceof the micelles or microemulsion or vesicles.40

C12-SH can bind to the CTAB micelle via electrostatic inter-action to generate several C12-SH/CTAB aggregates resulting inthe formation of the structures in the cores. At the same times,manymore CTABmolecules are involved in the formation of theC12-SH/CTAB micelle aggregates giving rise to the structures ofthe shells. Finally, cross-linking polymerization of TEOS aroundthe CTAB template simultaneously occurs around several differ-ent C12-SH/CTAB aggregate interfaces, leading to the formationof the hierarchical structures of the particles.

When a relatively small amount ofC12-SH (R<0.04) is added,the C12-SH molecules can insert into the formed CTAB micelles.In fact, hydrophobic C12-SH molecules function as the poreexpander to produce 2D hexagonal phases with larger periodi-cities under the experimental conditions.41 Moreover, anionicC12-S

- molecules exist in the mixture and have electrostaticinteractions with the CTAþ supermolecular aggregates.31b How-ever, small amounts of anionic molecules cannot successfullybreak up the stability of aggregates.Unilamellar vesicles ofCTABwhich surround the above C12-S

- and CTAþ supermolecularaggregates (2D hexagonal phases) are formed in order to preservethe less stability of the whole supermolecular systems. Finally, ahierarchical silica structurewith a thin shell and a hexagonal weakordered mesoporous core is obtained. With further increasingof the R values (0.08< R<0.2), more amounts of C12-S

- areformed to destroy the stability of the interfacial layer of theC12-SH/CTAB aggregates, and then these hydrolyzed TEOSmolecules can further cross-link around the destroyed surfaceof the large C12-SH/CTAB aggregates. This cross-linking con-densation proceeds further with these C12-SH/CTAB micelles asthe template, finally leading to the formation of the hierarchicalmesostructured silica particles with disordered pores. The in-creased electrostatic interactions betweenC12-S

- andCTAþ havethe ability to break up the stability of CTAþ hexagonal phases,making them shorten or converting them to unilamellar vesicles.The increased hydrophobicity rendered by C12-SH may inducethe transformation from the hexagonal phases to unilamellarvesicles.23c Silica foams with a uniform cavity are produced whenR is increased to 0.4, and the morphology is similar to that ofpomegranate (Figure 5c) with a lot of small and uniform hollowspheres in a big hollow sphere. Owing to the fusion of soft vesiclesat highermass ratios, siliceous foams with amultidispersed cavityare synthesized.13a,23a Vesicles fuse to become a big emulsion and

Scheme 2. Schematic Illustration of the Relationship between the Changes in Mesophase Structure and the Mass Ratio of C12-SH/CTAB

(38) Sigma-Aldrich, FT-IR spectra of 1-dodecanethiol: http://www.sigmaaldrich.com/catalog/ProductDetail.do?D7=0&N5=Product%20No.|BRAND_KEY&N4=471364|ALDRICH&N25=0&QS=ON&F=SPEC and http://www.sigmaaldrich.com/spectra/ftir/FTIR007887.PDF, June 10, 2010.(39) (a) Sides, R.; Yarwood, J.; Fox, K.Mikrochim. Acta 1988, II, 93. (b) Munoz,

B.; Ramila, A.; Perez-Pariente, J.; Dıaz, I.; Vallet-Regı, M.Chem.Mater. 2003, 15, 500.(40) (a) Zhang, Z.; Han, Y.; Xiao, F. S.; Qiu, S.; Zhu, L.; Wang, R.; Yu, Y.;

Zhang, Z.; Zou, B.; Wang, Y.; Sun, H.; Zhao, D. Y.; Wei, Y. J. Am. Chem. Soc.2001, 123, 5014. (b) Xiao, F. S.; Wang, L.; Yin, C.; Lin, K.; Di, Y.; Li, J.; Xu, R.; Su,D. S.; Schlgl, R.; Yokoi, T.; Tatsumi, T. Angew. Chem., Int. Ed. 2006, 45, 3090.

(41) (a) Cao, L.; Man, T.; Kruk, M. Chem. Mater. 2009, 21, 1144. (b) Liu, J.; Li,C. M.; Yang, Q. H.; Yang, J.; Li, C. Langmuir 2007, 23, 7255.

DOI: 10.1021/la101778z 13563Langmuir 2010, 26(16), 13556–13563

Chen et al. Article

function as a soft template to form silica capsules.23a Because ofthe electrostatic interactions between CTAþ and C12-S

-, somecompound folds are observed inside the hollow structures.

According to the results, the formation mechanism is illu-strated in Scheme 2. It is concluded that with increasing R valuesthe self-assembled materials produced using the dual C12-SHand CTAB templates undergo transformations from the hexa-gonal mesostructures to the vesicular structures and finally tofoams during the formation of the core structures. Generally,increasing the hydrophobic/hydrophilic volume fractionmay leadto a morphology change from hexagonal mesostructures tovesicles.13a,23a,42 According to the geometric packing model inwhich the organization of surfactant molecules is described by thepacking parameter (g): g=V/al, where V is the effective volumeof the surfactant tail region, a refers to the effective headgrouparea at the micelle surface, and l is the surfactant tail lengthproposed by Israelachvili and co-workers;43 the value of g maydetermine the structure of the self-assembled surfactant aggre-gates as well as surfactant-templated composite materials.43 Theinteractions between C12-S

- and CTAþ may counteract part ofthe cationic charges in theCTAþmolecules, and thus a is reduced.In addition, the C12-S

- molecules may insert into the hydropho-bic part of the mixed micelles (increasing V). However, whenR=0.04, the small amount of C12-S

- may be insignificant to changethe hexagonal packing in the cylindrical micelles. The R-S-

structures mainly play a role in reducing the surface free energyand promoting the formation of the pomegranate-like morpho-logy. When the R value is adjusted to 0.08-0.4, the g value isincreased and the vesicular structure is favored.44 The above

discussion provides an explanation for the structure transforma-tion from the hexagonal to the vesicular structures.A simple inter-pretation is that during the synthesis using variousmass ratios themultilamellar vesicular structures coexist with the hexagonalmesostructures and foam structures.

4. Conclusion

We demonstrate that hydrophobic dodecanethiol can beemployed to fine-tune hierarchical silica mesostructures bysimple regulation of the mass ratio of surfactants in thestarting solution. Weak ordered 2D hexagonal mesophasesand foam structures can be prepared in one-step synthesis,and both of the mesophase structures are enshrouded by thinshells with a morphology similar to that of pomegranate.Dodecanethiol can act as both a swelling agent for the CTABmicelles and a coagent for the formation of the microemul-sion with the CTAB micelles. At a low mass ratio of C12-SH/CTAB, dodecanethiol acts mainly as a swelling agent bypenetrating into the core of the surfactant micelles. At highmass ratios, dodecanethiol can form a microemulsion withCTAB in addition to rendering the swelling effect. Our resultsindicate that the mesostructure (hexagonal or disordered) andshape of the inner cavity (hexagonal or spherical shape) of thesilica structures can be facilely tuned. These hierarchicalmesostructures provide an unique scaffold structure suitablefor biological, medical, and catalytic applications. The app-roach described here can be extended to the synthesis ofhierarchical structures having other compositions. In addi-tion, the results may shed light on the fundamental mecha-nisms of biomineralization.

Acknowledgment. This work was financially supported byCity University of Hong Kong Strategic Research Grant (SRG)7008009 and the National Natural Science Foundation of China-NSAF Grant 10776034.

(42) (a) Antonietti, M.; Forster, S.Adv. Mater. 2003, 15, 1323. (b) Discher, D. E.;Eisenberg, A. Science 2002, 297, 967.(43) Israelachvili, J. N.; Mitchell, D. J.; Niham, B. W. J. Chem. Soc., Faraday

Trans. 2 1976, 72, 1525.(44) (a) Yang, S.; Zhao, L. Z.; Yu, C. Z.; Zhou, X. F.; Tang, J. W.; Yuan, P.;

Chen, D.; Zhao, D. Y. J. Am. Chem. Soc. 2006, 128, 10460. (b) Antonietti, M.;Forster, S. Adv. Mater. 2003, 15, 1323.