On Site Installation Check List 5 0

-

Upload

minoj-sarasan -

Category

Documents

-

view

18 -

download

6

description

Transcript of On Site Installation Check List 5 0

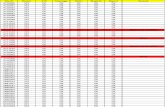

ON-SITE INSTALLATION CHECK LIST (SUPERVISOR & COOPERATORS)

Date: Site Name/Logistic Code:

Cooperator:

Telephone Supervisor: Huawei's PM:

1-Pre-Check (Supervisor) PASS FAIL N/A1-1 Engineering documentation available at site1-2 Site survey document available at site

1-3

1-4

1-5 Installation equipment (Site master, power meter etc) present at site

2-GENERAL (Supervisor & Cooperator) PASS FAIL N/A2-1 The cabinet is placed as per engineering documents

2-2

2-3 The antistatic wrist-strap is inside the cabinet and connected to the ESD port

2-4

2-5

2-6

2-7

2-8 The cabinet is fully isolated from the floor

2-9

Address:

Supervisor:

Site made ready (SMR) for installation from Customer, as per Site survey recommendationsSite equipment received, checked and report made (if missing any) for Huawei's PM

The cabinet is mounted properly on the concrete base. After the installation, the cabinet is leveled and stands firmly on the ground.

The horizontal error of the cabinet is less than 3 mm and the vertical error is not more than 3 mm

All screws are securely fastened. The spring washers are installed on the flat washers

The surface of the cabinet is clean and tidy. All the labels on the surface are correct, readable, and intact

The front door of the cabinet is easy to open and close and the paint job of the cabinet is not damaged (while opening/closing the door)

The cabinet is fully sealed (water tight) and seal adhesives are applied on the holes/outlets of the cabinet

2-10

2-11 The internal cabling and board configuration are as per engineering documents

2-12

2-13

2-14

3-TRANSMISION (Supervisor & Cooperator) PASS FAIL N/A3-1 E1 trunk cables fixed to cable trays and ladders

3-2 Good cable route from transmission equipment to BTS (with cable ties)

3-3 E1 trunk cable cut with suggested redundancy length3-4 E1 pair connectors (towards DDF) are made professionally3-5 E1 trunk cable properly identified (towards BTS)3-6 E1 pair cable properly identified (towards DDF)3-7 E1 pairs connected to DDF3-8 E1 trunk cables connected to BTS professionally3-9 DDF Box fixed to the wall

3-10 Cable connectors are professionally done and cover with heat shrink

3-11 The DCSU board DIP switch is in the correct position (75ohm or 120ohm)

3-12 The E1 is labeled on both sides (both ends)

4-ALARMS (Supervisor & Cooperator) PASS FAIL N/A4-1 Alarm Box fixed to wall as per engineering documents

4-2 Alarm Box cables fixed to cable trays and ladders as per engineering documents

4-3 Alarm cables terminal connectors are made professionally

4-4 Alarm cables interconnection done professionally as per engineering documents

4-5 Alarm cables connected to BTS side.4-6 Alarm cables connected to Alarm Box 4-7 The alarm cables are well identified in the Alarm Box.4-8 Alarm cables connected to DEMU board and well identified

4-9 Alarm cables connected to the alarm sensors as per engineering documents

The site environment is cleaned (after BTS installation) from any waste and left-over material

The side power equipment is well secured to the floor and is located on the side of the BTS cabinet (for indoor only)

After completion of Site installation, Pending items list (snag list) prepared (if any)

The SUPERVISOR to paste/put the Customer’s inventory label/sticker (called SIR) on each board/cabinet, installed at each site and make an inventory list of all the SIR label numbers corresponding to Huawei’s labels numbers

5-POWER (Supervisor & Cooperator) PASS FAIL N/A

5-1

5-2 Cable color code is according to the standard5-3 DC cables fixed to cable trays and ladders5-4 DC terminal connectors (to BTS side) are completed

5-5 DC terminal connectors (to side power) side are completed (for indoor only)

5-6 DC terminal connectors (to rectifier/PDF side) are completed5-7 DC cable connected to BTS side5-8 DC cable connected to side power side (for indoor only)5-9 DC cable connected to rectifier side

5-10 DC cables identified towards BTS5-11 DC cables identified towards side power5-12 DC cables identified towards rectifier side5-13 All the terminals are well covered with heat shrink

6-GND SYSTEM (Supervisor & Cooperator) PASS FAIL N/A6-1 GND cable fixed to cable trays and ladders6-2 GND terminal connector (to BTS side) completed

6-3 GND terminal connector to grounding bar (MGB) side completed

6-4 GND terminal connector to Side Power side completed (for indoor only)

6-5 GND cable connected & identified to BTS

6-6 GND cable connected to bar (MGB) or crimped to ring.6-7 GND cable connected to Side Power (for indoor only)

6-8 GND cable between Main and Slave cabinet completed and connected

6-9 GND cables identified (to grounding bar side)6-10 GND cable are run through a protective pipe (PVC)6-11 All the terminals are well covered with heat shrink6-12 The DDF grounding cable are installed professionally6-13 The grounding resistance (<5 Ohms)

6-14

The Side Power is installed properly, all the PSU and connections are done professionally and the equipment is working as per requirements (for indoor only)

Cables and connectors to AGB bars is done professionally, where applicable as per Customer instructions

7-SYSTEM ANTENNA AND RF (Supervisor & Cooperator) PASS FAIL N/A

7-1 BTS boards cabling interconnection done as per engineering documents

7-2 RF jumper connector (towards RF feeder) completed7-3 RF jumper connectors (towards BTS port on DDPU) completed7-4 RF jumper identified towards BTS cabinet

7-5 RF jumper identified towards RF feeder (towards feeder cable side)

7-6 RF jumper fixed to trays and ladders7-7 Support for RF antenna fixed on tower/steel pole

7-8

7-9

7-10 RF jumper (Antenna side) identified and fixed7-11 RF Feeder connectors completed

7-12 RF Feeder fixed along tower/steel pole

7-13 RF Feeder identified at the bottom (towards BTS) and top (towards antenna)

7-14

7-15 Grounding clips connected at the middle (for more than 60m tower).

7-16 Grounding clips attached to feeder are made waterproof7-17 Distance between feeder clamps is 1.5m to 2m7-18 Each RF path is well connected and identified

7-19

7-20

7-21 The Omni antenna should be vertical with error less than ± 2 degrees.

7-22

7-23 The Paint for the cable feeders and the jumpers are done professionally

7-24

Waterproofing and sealing for all outdoor jumpers and feeder cables are as per "antenna system installation" guide

Feeder cables don't cross each other and the degrees of bending are same for all feeders

RF Feeder grounding clips connected at top, bottom and before the BTS to the MGB (for less than 60m tower).

Antennas placement should be in the 45-degree protected area of the lightning rod

The azimuth and tilt angle of the installed antenna should be as per engineering design specifications and should not be more than ± 5 degrees. The tilt angle error should not be more than ± 0.5 degrees

The VSWR test result is as per requirement (1.2db or less) and the test results ready to be provided to Huawei's PM

The SUPERVISOR will check the Support/Mounting for the GSM antenna (If required for a site). In case the GSM antenna cannot be installed with the CDMA existing antenna (due to space constrain), a new mounting (as defined by Customer) will be installed by the COOPERATOR

7-25

8- Testing & Commissioning (Supervisor) PASS FAIL N/A8-1 Commissioning guide and tools available at Site

8-2

8-3 Follow the acceptance protocol/procedure provided by Huawei PM

8-4 Verify the communication between the BTS (Site) and the associated BSC8-5 Put Site in service

9-Documentation (Supervisor & Cooperator) PASS FAIL N/A

9-1

9-2

9-3 Cargo Problems Feedback Form9-4 Installation environment check list9-5 Antenna VSWR and TRX power test record table

9-6 Equipment Installation Report (GSM BTS)9-7 Preliminary Acceptance Test (PAT)9-8 Pictures of all Installation work and equipment, as per SOW

9-9

9-10

__________________________________ _____________________________________SIGNATURE FOR Cooperator SIGNATURE FOR Huawei (Supervisor)

__________________________________ _____________________________________(Cooperator's Representative Name) (Huawei's Representative Name)

__________________________________ ____________________________________Date Date

The SUPERVISOR will make sure that the original orientation (angle, height, direction and azimuth) of the CDMA antenna remains unchanged, after new mounting installation

After completion of installation (BTS powered up, Cards internal test completed & TX connected), test and commission the BTS as per Huawei’s Commissioning guide/instructions

Cooperator performs a self check and complete the Site quality check list (this document)

Supervisor completes the FINAL Site quality check list (this document) and get it signed by the Cooperator to be submitted to Huawei’s PM

Send to Huawei the Installation Report including all the required inventory information

Inventory list of all the SIR label numbers corresponding to Huawei’s labels numbers to be submitted to Huawei's PM

ON-SITE INSTALLATION CHECK LIST (SUPERVISOR & COOPERATORS)

Huawei's PM:

OBSERVATIONS (Please provide comments, in any)

OBSERVATIONS (Please provide comments, in any)

Address:

Supervisor:

OBSERVATIONS (Please provide comments, in any)

OBSERVATIONS (Please provide comments, in any)

OBSERVATIONS (Please provide comments, in any)

OBSERVATIONS (Please provide comments, in any)

OBSERVATIONS (Please provide comments, in any)

OBSERVATIONS (Please provide comments, in any)

OBSERVATIONS (Please provide comments, in any)

SIGNATURE FOR Cooperator SIGNATURE FOR Huawei (Supervisor)