O&MManualClassic

-

Upload

tony-munguia-enriquez -

Category

Documents

-

view

339 -

download

3

Transcript of O&MManualClassic

Operation & Maintenance Instructions

ElJay Rollercone Classic Owner/Operator ManualForm 21280 LJ0190100

A Terex Company

21280 (3/97)

Operation & Maintenance Manual

A Terex Company

Introduction

To the Owner & Operator: We have tried to provide information which will give you a clear understanding of equipment construction, function, capabilities and requirements. This information is based on the knowledge and experience of highly qualified people at our company and in our field organization. Proper use of this information will promote high efficiency, maximum service life and low maintenance costs. We strongly recommend that all persons directly involved with this equipment be familiar with this manual. The information contained in this manual should not be considered all-inclusive for every application. Questions about specific uses of this equipment should be directed to Cedarapids Inc. Anyone who uses this equipment for any purposes other than its intended use assumes the risk of any danger in doing so. Respectfully, Cedarapids Inc.

Important Notice! Federal, state and local safety regulations must be complied with to prevent possible danger to person(s) or property from accidents or harmful exposure. This equipment must be used in accordance with all operation and maintenance instructions. (1) Read all warning, caution and instruction signs. Know what guards and protective devices are included and see that each is used. Additional guards and protective devices that may be required due to proximity to related equipment must be installed by the user (owner) before operating. Never lubricate or adjust equipment when it is operating! Securely lock out the involved power source before doing maintenance, cleaning, adjusting or repair. Secure the power source lockout to prevent start-up by other persons. Wear a protective mask whenever harmful air pollution exists. Use ear plugs whenever noise level is above established limits.

(2) (3)

(4) (5)

16885 (7/91)

Operation & Maintenance Manual

A Terex Company

Section 1 Introduction This book is an operation manual for the new owner/ operator of a Rollercone Crusher manufactured by Cedarapids Inc. Old hands may find it useful, too. We strongly recommend that anyone operating or maintaining the Rollercone Crusher become familiar with this manual. This manual can help you understand how your crusher works, how to get the most production from it, and how to perform regular maintenance and replace wear parts. Experience has shown that it is to your advantage to have a copy of this manual on site at the crusher where operators can consult it as needed ... and to have a copy on file in your office so that shift leaders or supervisors can conveniently refer to it. Additional copies can be ordered through your Cedarapids Distributor Representative. Cedarapids is proud to manufacture this superior product for your use and profit. The precisely engineered Rollercone is a highly functional, heavy duty machine designed to provide years of excellent service in producing crushed rock to customer specifications. Cedarapids takes pride in the quality of its service and replacement parts. Ongoing improvement of product design may result in future changes to some parts. When ordering replacement parts, please be as exact as possible in describing the part. Use part numbers, model numbers and serial numbers to communicate with your Cedarapids Distributor Representative. When you have a question about your crusher or the operation manual, please consult your Cedarapids Distributor Representative.

21280 (3/97)

Page 1.1

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 1 Introduction Table of Contents Section 1 Introduction ................................................ 1.1 Table of Contents ........................................ 1.2 Section 2 - Safety Hints and Rules Personal Safety Hints.................................. 2.1 Work Area Safety Hints .............................. 2.2 Equipment and Tools Safety Hints ............. 2.2 Section 3 - Rollercone Description How It Works .............................................. 3.1 Tramp Iron Relief System .......................... 3.1 Differences Between Fine Head and Standard Head Cone Crushers .................... 3.3 Anti-Spin Brake .......................................... 3.5 Section 4 - Rollercone Capacities Characteristics of Rock ............................... 4.1 Rock Abrasion ............................................ 4.1 Rock Compressive Strength ....................... 4.1 Controlling Wear......................................... 4.1 Getting Better Production ........................... 4.2 Preventing Bowl Float ................................ 4.3 What You Should Know about the Rollercone Bearings ................................... 4.4 Section 5 - Lubrication Importance of Oil Flow Pattern in the Rollercone ................................................... 5.1 Proper Oil Types ......................................... 5.3 Oil Properties at Operating Temperature .... 5.3 Acceptable Lubricants ................................ 5.3 Oil Analysis: When to Change Oil ............. 5.3 Lubricating Oil Capacities .......................... 5.4 Section 6 - Transport and Travel Block the Cone Head .................................. 6.1 Setting Up On Site ...................................... 6.2 Section 7 - Installation Clearance and Mounting Directions ........... 7.1 RC66 Installation Drawings ....................... 7.2 RC60 Installation Drawings ....................... 7.4 RC54 Installation Drawings ....................... 7.6 RC45 Installation Drawings ....................... 7.8 RC36 Installation Drawings ..................... 7.10 Feed Speed ................................................ 7.12 Electrical Control System ......................... 7.13 Electrical Control For External Lubrication ................................. 7.13 Cold Weather Oil Circulation Kit ............. 7.13 Flow Switch and Alarm ............................ 7.14 Oil Heater ................................................. 7.17 Weights and Lifting Procedures................ 7.17 Rollercone Component Weights ............... 7.17 Power and Speed Requirements Chart ..... 7.18 Section 8 - Daily Startup and Maintenance Daily Start Up ............................................. 8.1 Cold Weather Start Up ................................ 8.1 Hot Weather Start Up .................................. 8.1 Daily Maintenance ...................................... 8.1 Rollercone Daily Inspection Form ............. 8.3 Section 9 - Changing Closed Side Settings

21280 (3/97)

Page 1.2

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 1 Introduction Description of the Rollercone Hydraulic Setting Adjustment System......................... 9.1 Rollercones with Hydraulic Adjust............. 9.2 Rollercones with Remote Auto Adjust ....... 9.2 Minimum and Maximum Closed Side Settings ................................... 9.6 Capacity Calculation .................................. 9.6 RC66 Manganese Options .......................... 9.8 RC66 Setting Options ................................. 9.9 RC60 Manganese Options ........................ 9.10 RC60 Setting Options ............................... 9.11 RC54 Manganese Options ........................ 9.12 RC54 Setting Options ............................... 9.13 RC45 Manganese Options ........................ 9.14 RC45 Setting Options ............................... 9.15 RC36 Manganese Options ........................ 9.16 RC36 Setting Options ............................... 9.17 Gradation Chart ........................................ 9.18 Section 10 - Maintenance The Right Way To Check Oil Level In The Crusher ................................ 10.1 Change Lubricating Oil ............................ 10.1 Change Lube Oil Filter Element ............... 10.1 Hydraulic Fluid & Nitrogen Gas Pressures in the Relief System ................. 10.2 Schematic Description of the HydroPneumatic Tramp Iron Relief System ....... 10.3 Relief Accumulator Positions ................... 10.5 Checking Relief System Pressure: 2 Methods ................................................ 10.5 First Method ............................................. 10.6 Alternate Method of Checking Relief System Fluid Pressure .................... 10.7 Checking Nitrogen Gas Precharge Pressure .................................... 10.8 Charging the Tramp Iron Relief System ............................................ 10.9 Bonnet Support ....................................... 10.11 Rotation Stops ........................................ 10.11 Hard-Facing and Wear Components ....... 10.12 Adjusting V-Belt Tension........................ 10.12 Standard Bolt and Nut Torque Specifications ............................. 10.12 Section 11 - Changing Manganese Removing the Upper Assembly ................ 11.1 Removing Upper Assembly by Method A: Adjusting Bolts Remain with Upper Assembly .................. 11.3 Removing Upper Assembly by Method B: Adjusting Bolts Remain with Lower Assembly ................. 11.4 Changing Manganese Bowl Liners on RC36, RC45, and RC54 Models ........ 11.4 Installing Bowl Liners on Models RC36, RC45, RC54 ............................................. 11.5 Changing Bowl Liner on RC66 and RC60 Models .................................... 11.6 Installing Bowl Liner in RC66 & RC60 .......................................... 11.8 Changing Cone Mantle on Standard Head Crushers ......................... 11.10 Changing Cone Mantle On the RC66, RC60, and RC54 Fine Head ........ 11.12 Changing Cone Mantle on RC45, RC36 Fine Head .......................... 11.14 Plastic Backing Quantity Chart .............. 11.16 Installing the Upper Assembly ............... 11.16 Method A: Installing the Upper Assembly with the Adjusting Bolts in the Upper Assembly .................. 11.16 Method B: Installing the Upper Assembly with the AdjustingLJ0190100-1

21280 (3/97)

Page 1.3

Operation & Maintenance Manual

A Terex Company

Section 1 Introduction Bolts in the Lower Assembly .................. 11.17 Adjusting Clamp Cylinder Travel ........... 11.18 Converting RC60 from Standard to Fine Head or Fine Head to Standard ............................ 11.20 Section 12 - Troubleshooting Vibrating Too Much .................................. 12.1 Running Too Hot ...................................... 12.1 Bowl Floating ........................................... 12.1 Possible Causes of Bowl Float ................. 12.1 Section 13 - Glossary Commonly Used Words in Processing Rock with the Rollercone ....... 13.1

21280 (3/97)

Page 1.4

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 2 Safety Hints and Rules Personal Safety Hints Cedarapids equipment is designed with the safety of all personnel in mind. Do not attempt to change, modify, or eliminate accident prevention devices installed at factory. Make sure all personnel who regularly work or who might do work in area of the equipment are familiar with safety precautions. Guards, covers, and shields are installed around moving parts at factory whenever necessary to prevent accidental injury to operators and others working on or near the equipment. Do not remove . Warning: Hazards or unsafe practices which COULD result in death, system loss, severe personal injury, severe occupational illness or severe or major system or environmental damage. Caution: Hazards or unsafe practices which COULD result in minor personal injury, minor occupational illness, or minor system or environmental damage. Cedarapids recommends the following basic safety practices: 1) Read all warning, caution, and instruction signs. 2) Never lubricate equipment when it is in motion. 3) Do not remove any guards, covers, or shields when equipment is running. 4) Replace any guards, covers, or shields after adjustment or maintenance. 5) Always establish a positive lockout of the involved power source before performing maintenance, cleaning, adjusting, or repair. Secure the power source lockout to prevent start-up by other persons. 6) Block parts as necessary to prevent unexpected motion while performing maintenance, adjustments, or repair. 7) Do not attempt to remove jammed product or other blockage from running equipment. Power must be shut off and locked out while doing so.21280 (3/97)

8) Always completely depressurize accumulators before attempting any repair or maintenance to them. Malfunctioning valves or poor maintenance practices can result in build up of extremely high hydraulic and/or pneumatic pressures inside the accumulator, which is a pressure-containment vessel. Allow only qualified, experienced personnel with extensive knowledge of hydraulic systems to attempt maintenance or repair of accumulators. 9) Use adequate hearing protection devices whenever noise level is above acceptable limits. 10) Wear an adequate protective breathing mask when dust and fumes are above acceptable limits. 11) Wear adequate eye protection goggles or safety glasses with side shields to prevent flying particles from entering eyes. 12) Hard hats are a good idea in all work sites and required at most. Wear yours. 13) Dressing appropriately for job. Do not wear loose sleeves, flowing hair, long coat tails, wrist watches or bracelets, or pockets full of tools, which could get caught in moving machinery. Thin-soled shoes without tread could cause unexpected falls or foot injury. Wear safe shoes. 14) Always look around equipment before startup to make sure no one is near moving parts, making adjustments, or performing maintenance. Keep alert to where your coworkers are. 15) Report defective machinery and unsafe conditions to your supervisor. 16) Save your back. If load is more than 40 lbs (18kg), get help or use proper lifting procedures. Use leg muscles, not back, for lifting. Keep loads close to body. Avoid twisting motions and overextensions when moving loads.

Page 2.1

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 2 Safety Hints and Rules 17) Most of all, know your equipment. Understand the machine and the conditions under which it operates. Dont limit playing it safe to only these few general rules. Think and act safely for your specific work environment and your particular equipment. Work Area Safety Hints 1) Keep the work area neat and clean. 2) Keep all warning and caution signs clear and up-to-date. 3) Make certain that all electrical equipment is properly grounded. Wet spots near electric current are dangerous. 4) Store hazardous materials in restricted access areas and mark them clearly. Federal regulations require special labeling of certain materials. 5) Make certain enough ventilation is present to safely run engines. Do not start an engine in an enclosed space without properly vented exhaust. Exhaust fumes from gasoline or diesel can kill! 6) Do not smoke or allow smoking near flammable fuels or solvents. Use nonflammable solvents when possible for cleaning parts and equipment. 7) Avoid electrical and static sparks and any open flame when handling, moving or pouring fuels, battery electrolytes, hydraulic fluids, or coolants. 8) Check for leaks in tanks or tubing with flashlights or other proper equipment. Never use an open flame to check for leaks. 9) Know where fire extinguishers and other fire suppression equipment are located. Learn to use them. 10) Be alert and wary around any pressurized system: hydraulic or air. High pressure gases and oils can be very dangerous. Know your equipment and operate it properly. Equipment and Tools Safety Hints 1) Clean and properly labeled tools are safer tools. Keep your equipment and tools in order. 2) Always use hoisting equipment for heavy loads. Regularly check hooks, cables, shackles, and chains for stretch and wear. Never overload the lifting capacity of hoists, cranes, and lifting devices. 3) Keep V-belts and sheaves in good condition. Frayed belts or cracked sheaves can be dangerous and cause downtime. 4) Keep equipment clean and free of dirt and grease so it can be checked for loose, cracked, or broken parts. Replace defective parts as soon as discovered.

21280 (3/97)

Page 2.2

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 3 Rollercone Description How It Works The Rollercone crushes by compressing rock in a continuous action between a moving cone-shaped surface and a stationary, inverted bowl-shaped surface in the crushing chamber. The outer surface of the lower cone shape crushes rock against the inner surface of the bowl shape above it. The Rollercone is engineered to move the special alloy crushing surfaces within controlled distances of each other by the oscillating action of a rotating wedge. See Figure 3-1, a descriptive cutaway of a typical Rollercone. The upper portion of the crusher contains the tramp iron relief system. This system is highly pressurized but designed to yield if uncrushable material, like tramp iron, finds its way into the feed. Without any damage to the crusher the upper assembly quickly lifts to pass the tramp iron through the crushing chamber, then returns to the original position, to go on crushing as before. A combined force of pressurized hydraulic fluid and compressed gas pushes steadily downward during normal crushing to keep the bonnet, part of the upper assembly, in place. The bowl liner mounts to the bonnet. The bonnet rests on the bonnet support. Rock to be crushed is fed through the hopper and into the crushing chamber, an area lined with cast manganese alloy. The upper crushing surface is the bowl liner; the lower is the mantle. The mantle rests on the cone, which in turn mounts on the wedge plate. The rotating wedge plate moves under the cone like a cam with an upward thrust to make the oscillating movement of the cone and mantle. As a point on the mantle comes nearer and nearer to the bowl liner, the force that can be generated grows rapidly. The gear-driven wedge plate rotates on large, lowfriction roller bearings. The movement between the mantle and the stationary bowl liner can be thought of as opening and closing the crushing surfaces, but it takes place in a circular area around a conical shape. The closed side setting (css) is the nearest the two crushing surfaces come to each other. 180 across the cone from the closed side, the oscillating movement makes an open side where the rock falls lower in the crushing chamber until it is discharges in a steady flow at the lower edge of the mantle. Under normal choke feed conditions the rock will be caught three to eight times in the crushing action. After passing through the crushing chamber the rock falls out through the base to be removed at a rate at least equal to the feed rate. Very great crushing forces are created which mostly bear on the upper and lower thrust bearings. Proper lubrication of thrust and radial bearings is very important in the Rollercone. A pump, gear-driven directly off the pinion shaft, forces oil through the lubrication system when the pinion shaft is rotating in the proper direction. An electric pre-lube pump, mounted externally, pumps oil to the bearings at switchable intervals. During normal operation a flow-sensing device meters and monitors oil flow. Tramp Iron Relief System Cedarapids Rollercones use a patented HydroPneumatic Tramp Iron Relief System that provides more protection to a crusher than any other known system in use today. If properly maintained, the relief system holds the bonnet down with great force. It also allows a great deal of bonnet travel for passing tramp iron without crusher damage or stoppage.

21280 (3/97)

Page 3.1

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 3 Rollercone Description

"crushing chamber"

bonnet and bowl liner

relief system manifold tubes

hopper relief cylinder

accumulator

hold down bolt bonnet support adjusting bolt assembly external prelube oil pump

cone with mantle shim stack shim guard clamp ring

oil filter

upper and lower radial bearings

wedge plate

upper and lower thrust bearings

internal oil pump

oil heater

oil fill pipe

pinion shaft

Figure 3-1 General Description

21280 (3/97)

Page 3.2

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 3 Rollercone Description The system includes hydraulic cylinders mounted in individual support beams. The beams mount over the bonnet support with hold-down bolts to form a pressure ring. Push rods extend from sockets in each piston to sockets in the bonnet. The hydraulic cylinders vent or relieve pressure off to accumulators if uncrushable items enter the crushing chamber. The accumulator bladders are filled with nitrogen gas at 1800 to 2100 pounds per square inch (psi) at 70 Fahrenheit (F). Metric equivalents are 12411 to 14480 kilopascals (kPa) at 21 Centigrade (C). Hydraulic oil is then pumped into the system to compress the nitrogen bladders to 2600 psi (17927kPa). This provides reserve oil in the accumulators to keep the manifold and cylinder under continuous pressure. The accumulator has enough capacity to hold this reserve oil plus the oil that must be displaced through the manifold from the cylinders when tramp iron passes through the crusher. Caution: This system does not tolerate hydraulic or nitrogen gas leaks. Any leaks will soon empty the small reserve of oil in the accumulator. Note that oil leaks can be seen and are easier to detect than gas leaks. Nitrogen leaks arent obvious and are normally found only by periodic gas pressure checks. Caution: If you allow pressure to bleed off from the Tramp Iron Relief System, bowl float will occur. Bowl float voids your warranty. Bowl float is defined as the periodic separation of the bonnet from the bonnet support. See the Glossary and Troubleshooting sections of this manual. See Checking Relief System Pressure in Section 10 of this manual. Differences Between Fine Head and Standard Head Cone Crushers Until recently Cedarapids Rollercones were built in two main model lines, the Standard Head and the Fine Head. This refers to the shapes of the cone heads and corresponding manganese liners. With the introduction of the RC60, a specially designed, convertible cone allows you to switch from standard to fine head configuration (and back) with a simple, bolt-on conversion (Figure 3-2). The Fine Head Rollercone is used to crush finer specification product. Its size reduction ratio is about 4 to 1. The Standard Head crushes a wider range product, including heavier gradations. Its size reduction ratio is about 6 to 1. To get an idea of the percent of product passing certain screen sizes after crushing with your Rollercone, consult the Nominal Product Gradation charts in Section 9 of this manual. Together with the capacity charts, these graphs provide a basis for estimating production rates in either Fine Head or Standard Head crushers at various typical closed side settings. Each type, either Standard or Fine Head, has manganese liners of differing shapes which fit it best for certain crushing jobs. Many operators have found that production problems were solved or greatly reduced by installing liners which were more appropriate for a particular job. The most common manganese liners currently in use are shown in drawings at the end of the section of this manual called Changing Closed Side Settings. Your Cedarapids Distributor or factory representative will be glad to discuss your specific crushing needs.

21280 (3/97)

Page 3.3

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 3 Rollercone Descriptionmantle nut cap bolt o-ring mantle nut cap mantle hold down nut mantle hold down bolt standard cone mantle hold down washer sponge rubber manganese mantle convertible cone standard cone adapter

plastic backing mantle hold down bolt

standard head cone

RC60 "convertible" cone in the standard configuration

sponge rubber ring fine head cone

distributor plate o-ring

distributor plate bolt mantle hold down nut manganese mantle mantle bolt

distributor plate convertible cone

plastic backing

fine head cone

RC60 "convertible" cone in the fine head configurationFigure 3-2 Differences Between Fine and Standard Head Rollercones

21280 (3/97)

Page 3.4

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 3 Rollercone Description Anti-Spin Brake The anti-spin brake (Figure 3-3), prevents the cone head from spinning when the crusher runs empty. During crushing, the brake allows the cone head to rotate slowly to the right (clockwise), but not to the left (counterclockwise). It provides smoother operation, and eliminates unnecessary manganese wear. A torque bar bolts and is dowelled to the underside of the cone head. The torque bar slips inside the floating plate. A cone brake shaft engages the underside slot in the floating plate and is keyed to the brake shaft. The brake shaft projects down through the base frame spindle into an overrunning clutch, which is attached to a guide ring with bolts. The bolts are intended to shear off before any damage occurs to the shaft or clutch. Rollercones should not be run empty for extended periods of time. If sump oil is warm enough to flow freely, no further warmup is necessary. As soon as the drive sheave is up to speed, crushing can begin. If the cone head turns left (counterclockwise) at start-up, consult a Rollercone Service Manual or qualified Cedarapids Service person for repair procedures.

cone stem

floating plate

torque bar upper key brake bar

brake shaft clutch (one way overrunning) clutch guide ring w/ 5/16" Allen head cap screws grade five shear bolts 5/16" x 3/4"

brake cover plate Figure 3-3 Anti-Spin Brake

21280 (3/97)

Page 3.5

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 4 Rollercone Capabilities Characteristics of Rock In any rock crushing operation the physical characteristics of the raw material affect the output product you can achieve. The characteristics of rock of most interest in the rock processing industry are abrasion, compressive strength, toughness, and specific gravity. Cedarapids Inc uses several material tests to quantify or compare rocks on the basis of these characteristics. These tests follow American Standards Testing Methods (ASTM) standard procedures. Rock Abrasion Tests for chemicals with known abrasive compounds can determine the abrasion characteristics of specific rocks. Silica dioxide (SiO2), iron oxide (FeO) and aluminum oxide (Al2O3) are commonly found abrasive compounds in rock. Magnesium carbonate (MgCO3) and calcium carbonate (CaCO2) are also associated with abrasive effects. Abrasive test data are needed more for considering impact or grinder crushing, but abrasion is a factor in the wear life of Rollercone manganese. A high abrasive content causes more liner wear. Rock samples can be sent for chemical analysis to Cedarapids Inc through your Cedarapids Distributor. Such samples should weigh only one to two pounds (0.45 to 0.9kg) and must be representative of the quarry to provide reliable information. Check with your Distributor to get details of the sampling process. Rock Compressive Strength Generally rock with compressive strength up to 50,000 psi (344750 kPa) with acceptable hardness and toughness value is considered suitable for reduction in Rollercones. Before attempting to crush rock with greater than 50,000 psi compressive strength, consult the factory. A scale roughly corresponding to that given in more detail in ASTM C170 is shown below for your convenience: 5,000 to 10,000 psi (34475 to 68950kPa) .......................................Soft 10,000 to 20,000 psi (68950 to 137900kPa) .............................. Medium 20,000 to 30,000 psi (137900 to 206850kPa) ................................. Hard 30,000 to 45,000 psi (206850 to 310275kPa) ........................ Very Hard over 45,000 psi (310275kPa)..................................Extremely Hard Some practical testing of hardness you can do in the field is based on the Mohs Scale of Hardness. Talc has a Mohs hardness value of 1 and diamond the value 10. talc gypsum calcite fluorite apatite =1 =2 =3 =4 =5 orthoclase quartz topaz corundum diamond =6 =7 =8 =9 = 10

With this scale a rock that can be scratched with: your fingernail = about 2 copper coin pocket knife window glass steel file = about 3 = over 5 = 5-1/2 = 6-1/2

For more extensive information about types and characteristics of rock, consult your Cedarapids Distributor and the Cedarapids Pocket Reference Guide. Controlling Wear The manganese wear parts in a Rollercone crusher are designed to wear well in the hammering, compressive action created by the oscillation of the mantle against the bowl liner. Manganese wears faster in highly abrasive conditions.

21280 (3/97)

Page 4.1

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 4 Rollercone Capabilities The strategy for controlling wear is to reduce chances for abrasive action and increase chances for compressive action wherever possible. Here are five ways to effect this strategy: Make sure the crushing chamber is choke fed as often and as much as possible. Provide efficient screening prior to crushing to prevent as much abrasive sand and fines as possible from entering the crushing chamber. Eliminate as much water as possible from entering the crushing chamber. Water mixed with the infeed increases the abrasive characteristics of the rock. Crush across as much surface area of the mantle as possible. Try to make the mantle surface work (and wear) fully from top to bottom, not just at the parallel zone. Use the appropriate manganese configuration for the type of rock and the desired size reduction. A coarse bowl liner is less appropriate for rock crushed to finer grades. Getting Better Production At any equivalent crusher setting and screen opening, Rollercones yield a higher percentage of product than competitive cone crushers. For you this means greater net capacity. To get the most production, it is best to set your Rollercone no tighter than the minimum necessary to get the product size you want. The unique low angle of fall in the crushing chamber and the virtual zero clearance at the bearings allow settings that are very close to the finished product size. Make sure the feed has only a minimum of rock already to size. Minimum closed side setting is just above the point where the bowl will float under maximum allowable pressure on the tramp iron relief system. This setting can vary widely depending on the condition of material being crushed. For example, if a Rollercone is in a closed circuit making 5/8" (16 mm) minus, the screen should have enough capacity so that very few 5/8" or smaller rocks return to the crusher. Too much rock that is near size can cause bowl float, an unacceptable condition that can damage your crusher. With an open circuit many operators find that setting about 1/8" (3mm) tighter will yield a higher percent product passing the sizing screen. It is a good practice to test the efficiency of your closed side setting by sampling the product as it comes out of your under crusher chute. You will need to know what your acceptable recirculating load is. Recirculating loads in the 15% to 20% range are commonly acceptable. Under some conditions, when the setting is too close, pancakes form and the bowl will float. If this condition exists, increase the setting until bowl float stops. See bowl float in the Trouble Shooting section of this manual. To get the most production it is also very important to choke feed your crusher. Uniform choke feeding not only increases the volume going through your crusher but makes a better quality product. Product is more uniformly broken to grade specifications and is more cubical in shape when the crusher is choke fed. Cubical fractures (broken edges with nearly 90 angles; see Glossary) are best for most crushed rock applications because the right angles compact more efficiently and with more stability. Choke feeding helps eliminate any tendency to produce elongated rock particles. Rock pieces that are long and narrow can pass through the crusher without being further reduced in size. This type of rock does not compact as well as cubical rock pieces. Although it is best to choke feed the Rollercone, sometimes providing a high enough feed rate to choke feed it is difficult. In these conditions, build a surge pile or surge bin and run the crusher only when enough material is on hand to choke feed it. AnotherLJ0190100-1

21280 (3/97)

Page 4.2

Operation & Maintenance Manual

A Terex Company

Section 4 Rollercone Capabilities possible action, when the crusher can't be choke fed, is to slow the incoming feed speed with a batter board or other means. See Section 7. If the incoming rock has too much velocity, it could pass so quickly through the crushing chamber that it would not be crushed properly. When the Rollercone is used as a secondary crusher, some operators run the primary crusher for an extra shift so a continuous supply of rock is available to choke feed the Rollercone. Capacity and gradation charts are included in the section on Changing Closed Side Settings. These charts show the average capacity of Rollercones crushing igneous rocks (granite, trap, basalt, etc.) Gradation charts show the average product grades of widely separated tests in open circuit when choke fed. The gradation and capacity charts are offered only to show what is possible with the Rollercone. Your product grades and capacities may differ because different rock content results in different crushing performance. Also, how you operate your crusher will determine its performance. Please carefully study the capacity and gradation charts to make best use of your Rollercone. Your Cedarapids Distributor will be glad to discuss gradations and capacities appropriate to your crushing needs. The feed openings in the charts are based on new manganese and ideal screening conditions. Cedarapids cone mantles and bowl liners are wear parts. Their design gives the best wear-to-production ratio. As each rock is crushed, it gets more cutting edges as it passes through the crushing chamber. The cutting and scraping of the rock wear away the manganese surfaces, causing the closed side setting to gradually increase. The rate of wear depends on the amounts of rock being crushed, the hardness of the rock, the condition and cross-sectional shape of the manganese, moisture content, and other factors. The parallel zone wears down fastest. Adjust the closed side setting as needed to compensate for manganese wear. Authorized Cedarapids cone mantles and bowl liners maintain acceptable feed opening while wearing. Operators commonly find that properly selected Cedarapids mantles and bowl liners that are matched to the work wear out completely and still have adequate feed opening. Usually, you will find a point where you can get better production by changing the manganese instead of continuing to crush with the old. Sometimes a wear pattern called hooking develops in the manganese. When this happens, the manganese needs to be changed. Sooner or later it will be time to change to new manganese. To install the new cone mantle and bowl liner, see Changing Manganese in this manual. Preventing Bowl Float Bowl float is the periodic separation of the bonnet from the bonnet support. See also the Glossary. Caution: Bowl float causes excessive wear and premature failure of some components. Allowing bowl float voids the warranty. Check the crusher for bowl float after making any change in setting, feed material, or feed rate. Bowl float causes pitting, metal transfer, and general wearing away of the bonnet and bonnet support seats. If it goes on too long, bowl float will cause the relief cylinder seals to leak. The end result will be costly repairs and downtime. Bowl float may not be visible without careful observation. You can detect it by looking for movement between the bonnet and bonnet support or between the rotation stop blocks. Even a small but continual movement can develop serious problems. A number of factors can contribute, separately or in combination, to bowl float. See the Trouble Shooting Section of this manual for a discussion of preventing bowl float.LJ0190100-1

21280 (3/97)

Page 4.3

Operation & Maintenance Manual

A Terex Company

Section 4 Rollercone Capabilities What You Should Know about the Rollercone Bearings Besides the prime importance of constant, clean oil flow over the bearings, a few other things are important to know about the Rollercone bearing design. The smooth running, low-vibration Rollercone is sensitive to weight imbalances. Listening to and watching carefully for unusual vibrations can give you an early indication of need for maintenance. One source of imbalance is wear to the counterweights, especially the leading counterweight. Dirt or mud buildup in the crusher or motor sheaves can also cause unbalanced running. Check the condition of the counterweights and drive sheave daily and whenever vibration is detected. Normally, with plenty of clean oil and smooth, lowvibration running, the roller bearings will last a long time and help you produce profitable margins. Other factors can reduce the Rollercones performance. The Trouble Shooting Section may help if you are getting lower product rates than expected. See Transport and Travel, Section 6, of this manual for important notes about blocking the cone head to protect the roller bearings. Why Does the Rollercone Use Rollertype Bearings? The roller bearing design of the Rollercone allows no significant variation in the length of the oscillating stroke of the Rollercone cone head, whether running empty or loaded. This virtual zero clearance makes the Rollercone able, under normal conditions, to work at very close settings and at effective ratios of reduction. The Standard Head Rollercone typically crushes at a 6:1 rock size reduction ratio. The Fine Head commonly has a 4:1 rock size reduction ratio. This means balanced, vibration-free running and better sizing. The only things that affect a Rollercones setting are wear of manganese and bowl float or bonnet float. Manganese wear can be controlled and monitored (especially with the Remote Auto-Adjust system available on some Rollercones). Bowl float should never be allowed. See Bowl Float in the Trouble Shooting Section of this manual.

21280 (3/97)

Page 4.4

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 5 Lubrication Importance of Oil Flow Pattern in the Rollercone The heart of the Rollercone is the roller bearing system, which the lubrication system must protect from friction and contaminant damage. The lubricating oil not only prevents detrimental metalto-metal contact of internal bearing components, it also acts as a coolant to carry bearing-generated heat to oil sump, where it can be safely radiated out of the machine. Note the flow pattern in Figure 5-1.

Figure 5-1 Flow of Lubricating Oil21280 (3/97) Page 5.1 LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 5 Lubrication The bearings can be severely damaged if any of the following oil characteristics are inadequate: viscosity (grade) quantity (flow) cleanliness toughness of lubricant film (Timken load rating) oil pump cast aluminum heater pre-lube pump filter flow monitoring system internal and external lines and passages oil sump The oil heater is specially designed to keep oil flowing freely in cold weather. The large aluminum fins transfer heat to a larger surface area of the oil without burning it. The pre-lube pump circulates oil to the bearings before rotating the cone and can be used together with the oil heater for cold weather conditions. See the Cold Weather Startup section of this manual. The flow monitoring system includes : a flow meter a flow switch a warning horn If a breakdown in oil flow occurs, the flow monitoring system instantly alerts the operator that a malfunction needs to be corrected. As an added safeguard, also wire the switch to shut down the feed to the crusher if the oil flow is interrupted. Caution: Continued operation of the crusher with insufficient oil flow will severely damage the bearings. We urge you to use the flow monitoring system to its full advantage to prevent costly repairs and downtime resulting from insufficient oil flow. The flow monitoring system must be interlocked properly to protect the crusher or the warranty will be voided. To further ensure that only clean oil flows over the roller bearings, each currently manufactured Rollercone is equipped with an external oil filter. The filter is rated to have a high dirt capacity and to filter harmful particles out of the lubricating oil. The filter has a replaceable element. Change the element when the indicator shows a change is needed. It is important to use the proper replacement element in the filter. An element that is too fine plugs quickly. One that is too coarse allows too many particles to pass. Caution: Take precautions to prevent water from getting in oil. Store oil barrels where condensation and rain cannot get in.Page 5.2 LJ0190100-1

The lubrication system consists of:

These features help ensure that a proper amount of clean oil constantly bathes the roller bearings.oil sample port warning horn oil guard filter indicator

pump

flow switch & meter

adaptor

pump motor

cannister for filter element

Figure 5-2 Typical External Lube System

21280 (3/97)

Operation & Maintenance Manual

A Terex Company

Section 5 Lubrication Proper Oil Types Rollercones are filled with filtered ISO 150 oil at the factory when they are tested. This oil will protect the gears and bearings to an operating temperature of 185F (85C). This oil minimizes cold weather start-up problems and still supplies adequate viscosity for bearing lubrication. The lubrication specifications follow. Oil Properties at Operating Temperature Minimum Viscosity: 100 SUS (Saybolt Universal Seconds) Minimum Timken OK Load: 55 lbs Minimum Viscosity Index: 90 All oils should have extreme pressure (EP) additives. Cedarapids feels that the Chevron Borate EP additive is superior to the conventional sulfur-phosphorus additive used in other brands and could prolong bearing life. The following oils can be used as long as the above listed specifications are met.Oil Company Chevron Amoco Exxon Gulf Mobil Shell Texaco Brand Name/Grade Ultra Gear 80W-90 Amogear EP 150 Spartan EP 150 Gulf EP HD 150 Mobilgear 629 Omala 150 Meropa 150

Acceptable Lubricants Cedarapids has found that, for conditions above 0F (-18C) with no wind chill, internal bearing temperature is independent of the outside (ambient) temperature and can reach 180F (82C) in any size crusher. If the oil temperature in your crusher exceeds 185F (85C) with the ISO 150 grade of oil, we recommend installation of ISO 220 or equivalent. This will not make the crusher run any cooler, but the oil will be able to maintain an adequate oil film thickness at the higher operating temperatures. Cedarapids installs the ISO 150 oil in all new Rollercones. Cold weather operation with this grade of oil may necessitate the use of oil heaters to keep the oil fluid and prevent damage to the main lubrication pump. Continuous operation in subzero temperatures may allow use of lighter oils. For example, ISO 68 oil may be used in subzero climates to maintain fluid liquidity as long as oil temperature does not exceed 150F (65C). Above 150F (65C) the ISO 68 thins out below the minimum viscosity of 100 SUS. At this point it should be replaced with heavier oil. However, even the lighter weight oils may require heaters for cold weather start-ups. Before starting the crusher in cold climates, be sure that the oil in the sump and external lines is fluid. Oil Analysis : When to Change Oil Cedarapids recommends that oil be periodically sampled and analyzed in a qualified lab. The data from a proper analysis indicate: the condition of the oil what contaminants are in the oil when it should be changed. Rollercones built in 1989 and after have an oil sampling valve fitted conveniently near the filter. Usually, oil should be changed every 1000 operating hours. You may get longer service from your oil. The best indicator of the oil condition is the Total

21280 (3/97)

Page 5.3

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 5 Lubrication Acid Number, the TAN. It is a measurement of how much the oil has degraded. The TAN rises as the oil degrades. Generally, a 100% increase in TAN indicates that you should change lubricating oil. As the TAN continues to increase, the oil carries more contaminants and the viscosity increases, decreasing the lubricant effectiveness. A good lab analysis shows concentrations of wear metal elements in parts-per-million. The typical concentrations and limits are shown below:Wear Metal Aluminum Copper Nickel Chrome Lead Iron Silicon (dirt) Typical Concentration 0 - 10 0 - 15 0-5 0-5 0 - 20 30 - 50 10 - 30 Upper Limit 50 10 10 50 150 75

Additive Sodium Boron Zinc Phosphorus

Normal Concentration 90 3900 400 300

Minimum Concentration 45 1950 200 180

Lubricating Oil CapacitiesCrusher Model RC66 RC60 RC54 RC45 RC36 U.S. Gallons 35 30 22 18 9 Liters 132.5 113.6 83.3 68.1 34.1

A good oil sample report should show a viscosity number. For example, if you are using an oil with a rating of 140 SUS at 40C (104F) for SAE 80W-90 when it is clean and fresh, a report might show 168 SUS at 40C (104F) for SAE 80W-90. 168 SUS is an increase of 20% in the oils base viscosity level at the same temperature and SAE rating. In this case the report tells you its time to change the oil. Another indication that it is time to change oil is when any of the additives are reduced by 50%. The factory-installed, borate-based oil in the crusher will show the following additives in parts-per-million:

Note: Variations in foundry processes cause the capacity of the oil sump in those Rollercones with cast steel bases to differ among Rollercones of the same model number. Oil capacities shown in the accompanying chart are guidelines only, based on averages. The lubricating oil capacity of your Rollercone may differ from that stated in the chart.

21280 (3/97)

Page 5.4

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 6 Transport and Travel Block the Cone Head The low profile, light weight, and self-contained lubrication system of the Rollercone make it a highly desirable crusher for operations that frequently move from site to site. Transport is so smooth that breakdown, move, and set up can sometimes be done in the same day. One vital step in preparing to move the Rollercone must be emphasized. The cone head must be prevented from lifting or bouncing during travel. When rock is being crushed, the cone head rides smoothly on its roller bearings. When rock is not being crushed, no downward force, except gravity, keeps the cone in contact with the roller bearings. So, a rough road or any other bouncing action (even from the suspension system of the transport vehicle) can lift the cone off the bearings and the cones own weight can beat downward on the bearings. The bearings and races are designed to withstand very heavy rolling forces, but will not withstand this type hammering action. The force of even slight vertical movements of the cone can result in very powerful hammering action. A bounce of the cone in a RC54 of less than 1/16" (1.6mm) is about equal to the force of a ten pound (4.5kg) hammer dropping five feet (1524mm) that would fall directly on the bearings and races. Caution: Always block the cone head before transporting your Rollercone to prevent the cone from bouncing during travel. Serious damage to the vital roller bearings could result if the cone head is not blocked properly. To block the cone head: 1) Lower the shim guard. 2) Using the electric hydraulic adjusting pump, attach line A (top hose) to the clamp cylinder relief valve quick coupler. See the hydraulic adjustment setup in Figure 9-3. Hook up line B (bottom hose) to the adjusting jack manifold quick coupler.21280 (3/97) Page 6.1

3) Close the one gallon accumulator relief valve. 4) Open the clamp cylinder relief valve. With the 3-way control valve of the adjusting pump in the B position, pump the adjusting jack system to 10,000 psi (68950kPa). This will raise the upper assembly off the shim stacks. 5) Cut two wedge-shaped wooden blocks. A 12" to 18" (300 to 450 mm) long piece of 4 x 4 (100 x 100 mm) sawed diagonally works (Figure 61). Place these wedge blocks together in the widest part of the opening between the cone mantle and the bowl liner. Then slide them apart until they are about 30 apart. Tap the wedges tight with a hammer.

30

Figure 6-1

Warning: The next step will let the upper assembly down onto the shim stacks. Make sure people are clear. 6) Make sure everyone is clear of the crusher. Move the 3-way control valve on the adjusting pump to the A position. As the upper assembly comes down it will compress the blocks.LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 6 Transport and Travel 7) With the control valve on the adjusting pump still in the A position, recharge the clamp cylinder system to 1600 psi (11 032kPa). Open the relief valve on the one gallon accumulator. If the pressure does not stay at 1600 psi, continue to charge the clamp cylinder system until it reaches 1600 psi and stays there. 8) Close the clamp cylinder relief valve. Using a small pry bar, raise any one of the adjusting jack rams at least 2" (50mm). This allows for any thermal expansion in the system. Disconnect the hydraulic hoses from the quick couplers. Replace the dust covers on the couplers. Raise and secure shim guard in place. Setting Up On Site If your Rollercone is not mounted on a plant, make sure the support structure is heavy enough to carry the working load of the crusher. Your Rollercone is well-balanced and will run smoothly, with very little vibration. It is the weight of the crusher plus the live, moving load of rock that must be supported. See the Installation Drawings included in this manual. If you have doubts or questions about the stability of your support structure, call the Cedarapids, Inc. Engineering Department or your area Cedarapids Distributor. If you are constructing your own under crusher hopper or chute, an access area under the crusher will make the daily check for obstructions and material buildup in the crusher easier. Set the under crusher collecting chutes all the way out to the inside diameter of the crusher base. This way the discharge speed will not be slowed by the collecting chutes being too small. Any restriction to the discharge will reduce the capacity of your crusher. If your crusher is mounted on a portable plant, make sure the plant is level in all directions and properly cribbed before starting your crusher. Support the trailer frame adequately with wheels off the ground and/or wheels removed. If the tires are in contact21280 (3/97)

with the ground, the vibration of the equipment running may damage the wheel bearings and/or axle assembly. Its a good idea to wrap the brake drums to protect them from dirt and dust. When wiring the crusher starter during installation, the normally open contacts on the flow switch (See the typical crusher wiring schematic, Figure 7-9) are connected to the start/stop circuit for the device feeding the crusher. This interlocks the feed device so it cannot be turned on unless the crusher is running. The pre-lubrication pump timed-relay (TR1 in Figure 7-9) is wired into the crusher start/stop circuit so the crusher cannot be started until the pre-lube pump cycle is completed. It is reset when the crusher stop button is pushed. Caution: It is important that the following items be checked before operating the crusher at start up. Failure to do so may result in damage to the machine. Check that the motor rotation direction on the crusher drive and pre-lubrication pump is correct. Make sure the transportation wedge blocks are removed from the crushing chamber before start up. It is a good idea to store the wedge blocks for use next time you transport your crusher. Make sure the feed to the crusher is interlocked with the lubrication oil flow monitor system. Refer to the Lubrication Section of this manual. Caution: Be sure that the drive pulley on the crusher is turning in the direction indicated by the arrow on the base frame above the pinion shaft. The oil pump will not pump oil to the bearings if the rotation is wrong! After the first shift of operation check the V-belt tension and adjust to V-belt manufacturers specifications. Refer to the Adjusting V-belt section of this manual.

Page 6.2

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 Installation Clearance and Mounting Directions Refer to the Installation Drawings for illustrations and dimensions. Mount the Rollercone level. This is very important and should be checked carefully in both the eastwest and north-south directions. Caution: Operating the crusher out-of-level could reduce its life and operating effectiveness. Install the Rollercone with enough clearance to allow easy daily service, adjustment, visual inspection, and routine maintenance. Minimum clearance dimensions for maintenance and replacement of major components are shown in the Installation Drawings. Caution: It is absolutely essential that enough overhead clearance be provided to allow for the maximum travel of the feed hopper for tramp iron relief when the crusher is set at its maximum discharge opening.

21280 (3/97)

Page 7.1

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 InstallationRC66 installationinstallation information: total weight: 62,700 lbs (28 441kg) recommended drive motor: 300 hp (224kw) belt drive (factory design)1200 rpm motor shaft center to center: 41.9" (1064mm) pinion: 693 rpm crusher sheave: 8-8V-30.0 1800 rpm motor shaft center to center: 45.8" (1163mm) pinion: 722 rpm crusher sheave: 10-8V-30.0 oil capacity: approx. 35 gallons (132 liters) 36" (914mm) 59-1/2" (1511mm) 15" (381mm) 46-1/2" (1181mm) keep this area clear for access to auxilary pump motor and oil filter assembly 15" (381mm)

18" (457mm)

this clearance required to remove pinion assembly.

45-7/8" (1165mm) 51" (1295mm) 60-3/8" (1533mm)

top viewfine head adjustable feed control (removable)

vertical envelope for removal of upper assembly 136" (3454mm)

31" (787mm)

keep this area around circumference of crusher clear for access to shim shim stacks, allowing for crusher adjustment.

20" (508mm)

18" (457mm) 46-13/16" (1189mm) 7-1/2" (191mm) 5-1/2" (140mm)

124-3/16" (3154mm) with hopper extension

10" (254mm) 9-7/8" (251mm) 5-1/2" (140mm) 9-1/2" (241mm) 12-7/8" (327mm) 27-1/2" (699mm)

side view

Figure 7-1 RC66, Four Views for Installation

21280 (3/97)

Page 7.2

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 InstallationRC66 installation (continued)oil drain plugs 88" (2235mm) diameter discharge area 13" (330mm)

13-15/16" (354mm) 5" (127mm) 31" (787mm) 12" (305mm) 4-1/2" (114mm) 1" (25,4mm) x 9-1/2" (241mm) keyway

12-1/2" (318mm) 46" (1168mm) 5" (127mm)

69" (1753mm) square pattern

bottom viewWarning:Tramp iron may cause hopper and bonnet to lift as much as 7-1/2" (191mm) at outside edge. Allow clearance at all times when crusher is in operation.

7-1/2" (191mm)

upper assembly 23,500 lbs (10 660kg)

94-1/2" (2400mm) fine head & standard w/o hopper extension

pinion rotation lower assembly 42,500 lbs (19 278kg). includes cone & wedge plate assemblies. 91-3/4" (2330mm) 102" (2591mm) 26-1/4" (667mm)

Caution:Do not allow obstructions in discharge area. Material must not be allowed to build up inside crusher lower assembly. Possible damage to crusher may result.

keep area around external oil system clear of obstructions.

front view

21280 (3/97)

Page 7.3

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 Installation RC60 installationinstallation information: total weight: 53,000 lbs (24 041kg) recommended drive motor: 250 hp (186kw) belt drive (factory design)1200 rpm motor shaft center to center: 38-1/2" (978mm) pinion: 698 rpm crusher sheave: 8-8V-24.8 1800 rpm motor shaft center to center: 40" (1016mm) pinion: 684 rpm crusher sheave: 8-8V-35.5 oil capacity: approx. 30 gallons (114 liters) 12" (305mm) 55-1/8" (1400mm) 46-1/2" (1181mm) clearance

19" (483mm) on circumference

46-1/2" (1181mm) clearance

32" (813mm) diameter hopper feed opening

24" (610mm) diameter fine head removable feed control opening (fine head only)

top viewfine head adjustable feed control (removable)

141-3/8" (3591mm) fine head adjustable feed control (removable) at maximum crusher opening

66" (1676mm) 42-3/4" (1086mm)anc anc

rotated in this view. this area around circumference of crusher to be kept clear for access to shim stacks to allow for crusher adjustment.

126-1/8" (3204mm) at maximum crusher opening with hopper extension 41-1/4" (1048mm)

27-3/4" (705mm) 14" (356mm) 14-13/16" (376mm) 24-3/8" (619mm) 9-3/4" (248mm)

18" (457mm) min. 32" (813mm)

4" (102mm) 7-1/16" (179mm) 11" (279mm)

side view

this clearance required to remove pinion assembly.

Figure 7-2 RC60, Four Views for Installation

21280 (3/97)

Page 7.4

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 Installation RC60 installation (continued)15-1/8" (384mm) from mounting hole to oil plug 10-1/8" (257mm) from mounting hole to heater magnetic oil plug 4-1/4" (108mm) 57-5/8" (1464mm) (4) 1-7/8" (47,6mm) dia. mounting holes 4" (102mm) C L C L C L

1/8" (3mm) from mounting hole to heater

oil heater

64" (1626mm)

detail view4-1/2" (114mm) diameter 1" (25,4mm) x 1/2" (12,7mm) keyway

75-1/4" (1911mm) discharge opening

64" (1626mm)

25-5/8" (651mm)

Warning:Tramp iron may cause hopper and bonnet to lift as much as 7-1/2" (191mm) at outside edge. Allow clearance at all times when crusher is in operation.

bottom view7-1/2" (191mm) C L

upper assembly weight 18,630 lbs (8450kg)

130-1/4" (3308mm) required clearance for removal of upper assembly when changing manganese 95" (2413mm) maximum shim setting without hopper extension 35-3/16" (894mm)

lower assembly 34,370 lbs (15 590kg). includes cone & wedge plate assemblies.

pinion rotation

Caution:Do not allow obstructions in discharge area. Material must not be allowed to build up inside crusher lower assembly. Possible damage to crusher may result.

8-1/4" (210mm) 4-1/2" (114mm)

27-1/2" (699mm) 85-3/4" (2178mm) 90" (2286)

keep area around external oil system clear of obstructions.

front view

21280 (3/97)

Page 7.5

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 Installation RC54 installationinstallation information: total weight: 41,250 lbs (18 711kg) recommended drive motor: 200 hp (149kw) belt drive (factory design)1200 rpm motor shaft center to center: 38-1/2" (978mm) pinion: 698 rpm crusher sheave: 8-8V-24.8 1800 rpm motor shaft center to center: 40" (1016mm) pinion: 684 rpm crusher sheave: 8-8V-35.5 oil capacity: approx. 22 gallons (83 liters) 52-1/4" (1327mm) this clearance required to remove pinion assembly. 15" (381mm) F.H. only 66" (1676mm)l ce clearance cl l l l l l l l

26" (660mm) on base frame circumference

41" (1041mm) nominal

41" (1041mm) nominal 12" (305mm) 79" (2007mm)

30" (762mm)

28" (711mm) 51-1/8" (1299mm)ance clearance a a a a a a a

top view

fine head adjustable feed control (removable)

optional hopper extension 25" (635mm) maximum 110-1/4" (2800mm) vertical clearance required to remove upper assembly when changing manganese.

18" (457mm) keep this area around circumference of crusher clear for access to shim stacks, allowing for crusher adjustment.d clearance nee

20" (508mm) 16" (406mm) 33-1/2" (851mm)n n n a ed clearance nee e e

18" (457mm)

22" (559mm)c c c c

4" (102mm)clearance need

5-1/4" (133mm)

13-1/2" (343mm)

23-3/8" (594mm)

detail16" (406mm) 6" (152mm)

side view4-1/2" (114mm)

Figure 7-3 RC54, Four Views for Installation

21280 (3/97)

Page 7.6

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 Installation

RC54 installation (continued)66" (1676mm) diameter discharge area 1-7/8" (47,6mm) diameter 4 places 9-3/4" (248mm) nominal

59" (127mm)

21-1/2" (546mm) nominal

3-1/2" (89mm) diameter 7/8" (22,2mm) x 7/16" (11,1mm) keyway allow access to oil drain plug

42-1/2" (1080mm) 59" (1499mm)

Warning:Tramp iron may cause hopper and bonnet to lift as much as 7-1/2" (191mm) at outside edge. Allow clearance at all times when crusher is in operation.

bottom view

7-1/2" (191mm)18-1/2" (4699mm)upper assembly 14,500 lbs (6 577kg)

lower assembly weight 26,750 lbs (12 134kg). includes cone & wedge plate assemblies.clearance cle

81-3/4" (2076mm) std. 80-3/4" (2051mm) F.H. maximum crusher height at maximum discharge setting

36" (914mm)

2-1/4" (57mm) nominal

1" (25,4mm) 4" (102mm) 78" (1981mm) 82" (2083mm)

keep area around external oil system clear of obstructions.

Caution:Do not allow obstructions in discharge area. Material must not be allowed to build up inside crusher lower assembly. Possible damage to crusher may result.

front view

21280 (3/97)

Page 7.7

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 Installation

RC45 installationinstallation information: total weight: 27,300 lbs (12 383kg) recommended drive motor: 125 hp (93kw) belt drive (factory design)1200 rpm motor shaft center to center: 42-3/4" (1086mm) pinion: 745 rpm crusher sheave: 4-8V-24.8 1800 rpm motor shaft center to center: 45.8" (1163mm) pinion: 722 rpm crusher sheave: 4-8V-30.0 oil capacity: approx. 18 gallons (68 liters)

43-3/4" (1111mm)

41" (1041mm) nominal typical

keep area clear for oil filter/ flow switch access. 41" (1041mm) nominal typical

69" (1753mm)

22" (556mm) 24-1/2" (622mm) on F.H.

27" (686mm)

this clearance required to remove pinion assembly. 13-3/4" (349mm)

42" (1067mm) 14-1/2" (368mm) 7-1/4" (184mm) keep this area clear for access to auxiliary pump/ motor assembly.

top viewfine head adjustable feed control (removable).

98" (2489mm) F.H. adjustable feed control (removable)

rotated in this view 48" (1219mm) 29-1/2" (749mm) keep this area around circumference of crusher clear for access to shim stacks when adjusting crusher opening.

91-5/8" (2327mm) at maximum crusher opening with hopper extension.

24" (610mm)

33-3/4" (857mm)

18" (457mm)

12" (305mm) 9-3/4" (248mm) 4-3/4" (121mm)

side view

13-1/4" (337mm)

Figure 7-4 RC45, Four Views for Installation

21280 (3/97)

Page 7.8

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 InstallationRC45 installation (continued)65" (1651mm) diameter discharge area

oil drain plug

2-15/16" (74,6mm) diameter with 3/4" (19mm) x 3/8" (9,5mm) keyway 68" (1727mm)

2" (51mm) 25-1/2" (648mm)

52" (1321mm) square pattern

bottom viewWarning:Tramp iron may cause hopper and bonnet to lift as much as 5-3/4" (146mm) at outside edge. Allow clearance at all times when crusher is in operation. 5-3/4" (146mm)

5" (127mm)

10-1/2" (267mm) 11-1/2" (292mm) on F.H. upper assembly 11,000 lbs (4990kg)

76-5/8" (1946mm) maximum crusher height at maximum discharge setting

Caution:lower assembly 16,300 lbs (7394kg) includes cone & wedge plate assemblies Do not allow obstructions in discharge area. Material must not be allowed to build up inside crusher lower assembly. Possible damage to crusher may result.

front view

keep area around external oil system clear of obstructions.

21280 (3/97)

Page 7.9

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 Installation RC36 installation38" (965mm) installation information: total weight: 16,500 lbs (7484kg) recommended drive motor: 75 hp (56kw) belt drive (factory design)1200 rpm motor shaft center to center: 52-1/4" (1327mm) 60" pinion: 738 rpm (1524mm) crusher sheave: 5D22 1800 rpm motor shaft center to center: 46-1/4" (1175mm) pinion: 729 rpm crusher sheave: 6C24 oil capacity: approx. 9 gallons (34 liters) 32" (813mm) 32" (813mm)

23-1/4" (591mm) clearance necessary to remove pinion shaft assembly

9-1/4" (235mm) diameter FH. only

40" (1016mm)

top view

16-3/4" (425mm) maximum

fine head crusher adjustable feed control (removable) rotated in this view. keep this area around circumference of crusher clear for access to shim c c nce shim stacks, allowing nce nce for crusher adjustment.nce nce nce

79-7/8" (2029mm) vertical clearance required to remove upper assembly when changing manganese

18" (457mm)

18" (457mm) 22-1/4" (565mm) 15-3/4" (400mm)

2-5/8" (67mm) 6-7/8" (175mm)

side view

Figure 7-5 RC36, Four Views for Installation

21280 (3/97)

Page 7.10

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 Installation RC36 installation (continued)56-1/2" (1435mm) diameter discharge area

oil drain plug

58-1/2" (1486mm)

2-11/16" (68,3mm) with 5/8" (15,9mm) x 5/16" (7,9mm) keyway 22-1/16" (560mm)

(4) 1-5/8" (41mm) diameter mounting holes

47" (1194mm) square pattern

bottom view

Warning:Tramp iron may cause hopper and bonnet to lift as much as 5" (127mm) at outside edge. Allow clearance at all times when crusher is in operation. 5" (127mm) 4" (102mm) 12-1/2" c (318mm)c c c

upper assembly 6,700 lbs (3039kg)

62" (1575mm) maximum crusher height (at maximum discharge setting)

Caution:lower assembly 9,400 lbs (4264kg) Do not allow obstructions in discharge area. Material must not be allowed to build up inside crusher lower assembly. Possible damage to crusher may result. allow clearance for external oil system.

front view

21280 (3/97)

Page 7.11

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 Installation Feed Speed Controlling the speed (velocity) of rock feed entering the Rollercone is as important as maintaining clearance for inspection and service. The Rollercone is designed to work while being choke fed. This means that the volume of rock material should be great enough that it backs up into the hopper. The feed hopper should be at least one-third full continuously during crushing. If rock enters the crushing chamber too fast, two undesirable effects can result: 1) Velocity (speed) of the larger rocks, due to excessive drop distance into the crushing chamber when the crusher is not being continuously choke fed, can be so great that impact on the mantle cap can damage it. This is especially true for Standard cones and Fine Head cones with coarse manganese. Either of these configurations are often fed larger size rock. For example, a 12 inch (305mm) round rock falling ten feet (3048mm) will be moving at a speed of over 25 feet per second (7.625m/ sec). At this velocity that rock can strike the mantle cap with over 2600 lbs (11564N) of force. Repeated strikes of this or greater force will eventually damage or destroy the mantle cap, which could lead to even greater damage to the Rollercone. 2) At this velocity rock can pass entirely through the open side of the crushing chamber without being adequately crushed. Under normal crushing conditions rock is caught three to eight times in the crushing action, if the cone is choke fed. Achieving proper gradation of rock product depends in part upon maintaining a high volume of rock mass through the Rollercone while keeping a slower velocity of individual rock pieces. Minimizing feed velocity while keeping feed volumes high generally maximizes product gradation. To help prevent damage to your crusher and to help maintain spec product, it is important to break the fall of rock into the crushing chamber and limit the height of fall to 36 inches (914 mm) or less. A rock box or other flow diversion device mounted above the feed hopper will help reduce the possibility of impact damage to the mantle and help get product that consistently meets your specifications. See Figures 7-6 and 7-7 for examples of designs for controlling feed speeds.

Figure 7-6

21280 (3/97)

Page 7.12

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 Installation Electrical Control For External Lubrication The electrical control shown in the Typical Crusher Wiring Schematic is required for any installation. The electrical controls must be connected in this manner for the proper interlocks and sequence of operation. Note: Failure to have the system interlocked as shown will void the warranty. The electrical control shown in the schematic is available in an optional pre-lube/heater/oil flow control panel mounted in a weather-resistant box which includes: circuit breaker fuses pre-lube pump start/stop push button transformer (440 volt to 115 volt) relay timer relay

Cold Weather Oil Circulation KitFigure 7-7

Electrical Control System Standard voltage for Rollercone crusher components is 115v (volt), 60hz (hertz). Optional 220v, 60hz, or 220v, 50hz systems can be supplied upon request. All components are wired to the junction box (sometimes called j-box) mounted on the crusher. The junction box also contains a convenient electrical power tool outlet matched to the same voltage as the control circuit. Wires from the flow monitor switch, warning horn, oil heater, thermostat, and prelubrication pump all terminate at the terminal strip in the junction box. A typical crusher wiring schematic is provided in this manual (Figure 7-8). Study it carefully to better understand how your crusher operates.

Another optional control panel is available that contains an additional timer and relay to cycle the pre-lube pump every 15-30 minutes when the crusher is not running. This option is valuable for cold weather operation. After oil has been heated in the sump the pre-lube pump circulates the oil up through the crusher bearings and forces the cold oil back into the sump to be heated. The optional pre-lubrication control circuit has a timer relay. See TR1 on the electrical schematic (Figure 7-8). The timer relay is a variable, 2-180 seconds, relay, set for 45 seconds. When the prelube pump is started, it activates the timed relay. This relay activates relay R2. Contact R2 is normally open. The pre-lube pump motor, M2, runs until TR1 times out, at which time contact R2 is opened again and the pre-lube pump is turned off. When TR1 times out, it closes another set of contacts. This allows the crusher to be started. The crusher cannot start until the pre-lube pump operating

21280 (3/97)

Page 7.13

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 Installation sequence is completed. Contact R1 stays closed until either the pre-lube pump STOP button or the crusher STOP button is pushed. Either one will also stop the crusher. Crusher Drive The crusher drive circuit is designed to start only after the pre-lube pump has completed its cycle. Line seven , shown in the typical crusher wiring schematic, is connected both to a timed-to-close contact and to the crusher start switch. The pre-lube pump is timed to run 45 seconds while delaying completion of the starting circuit for the crusher drive. The crusher cannot be started during this time.X1

Another timer, (TR2 in Figures 7-8 and 7-9), is shown for the reduced current starting circuit of a partially wound motor. When you push the crusher start button, one starter coil is pulled into the circuit and the timer starts. After a two-second delay, the other starter coil pulls the remaining windings on the crusher motor into the circuit. Flow Switch and Alarm The flow monitor switch, shown in the electrical schematic (Figure 7-10) is a safety device to protect the crusher in the event of lubrication system failure. It is set to trip when the oil flow decreases. The setting for the flow monitor depends on the size of crusher.

Crusher stop 1 2

Lube pump start 3 R1 3 R1 Crusher start 2 T.C. 18 TR1 TR1 3 T.O. TR1 8 1M1 2 seconds 2-180 seconds

X2

Lube pump 2 stop 5 2 5

TR1

4 4

R2

10 10

TR2

10

To flow monitor switch 1M1

8

8 TR2

T.C. 9

2M1

10

6 6

R2

14

14

M2

Lube pump

14

Red X2

Figure 7-821280 (3/97) Page 7.14 LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 InstallationL1 L2 L3 Main breaker Not provided by ElJay

Circuit breaker

Crusher breaker

M1 M1 M1 M2 M2 M2 Transformer X1 F1 F2 F3 F4 X2

Outlet 20 (12 gauge) Crusher stop 1 2 Lube pump stop 2 5 R1 3 T.C. Crusher start 18 T.O. TR1 8 1M1 TR1 2 seconds 10 R2 Lube pump start 3 R1 3 2-180 seconds

TR1

2

TR2

10

8 1M1 18 N.C. 19 Stop

8

T.C.

9

2M1

10

TR2 Start

Horn

Flow switch N.O. 21 18

Not provided by ElJay

Equipment feeding crusher

6

2M1

11

R1

12 R3

Circulation kit on/off 01 14 13 TR3

Green

TR3 23

Optional cold weather oil circulation kit

R3

6

R2

14

(12 gauge)

14

M2

Lube pump

14 15 16 (12 gauge) 16

Red Heater

R4

All wire sizes 16 gauge except where noted otherwise 1 1 T

16

Amber

Figure 7-9 Typical Crusher Wiring Schematic

17

R4 X2

21280 (3/97)

Page 7.15

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 InstallationCrusher start 2 TR1 T.C. 18

18

N.C.

19 Start

Horn

Flow switch Stop N.O. 21 18

Crusher feedFigure 7-10

X2

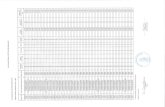

Rollercone RC36 RC45 RC54 RC60 RC66

US Gallons per Minute 1.25 gpm 2.00 gpm 4.00 gpm 6.00 gpm 6.00 gpm

The normally-open switch is wired to the start/stop circuit for the crusher feed device. When the lubrication oil flow starts, this switch closes allowing the feed device to be started. If the oil flow falls below the preset rate, the switch will open and the feed device will be turned off. When this circuit is connected through the auxiliary contact, 1M1, on a part-wound motor starter, the warning horn will sound as the crusher is started up. When the oil flow reaches the switch set point, the horn will stop. This lets the operator know that the system is working correctly. If the auxiliary contact is not used the horn will blow continuously from the time power is turned on until the crusher is started.

The flow monitor switch has two contacts, one that is normally open and one that is normally closed. The normally-closed switch (labeled N.C. on the wiring diagram) controls the warning horn mounted on the crusher. It opens when oil flows through the system and closes, sounding the horn, if the oil flow falls below the preset rate.X1 Fuse 15 R4

Not supplied by ElJay 16 16 Heater

Fuse 1 1Figure 7-1121280 (3/97) Page 7.16

16

Amber

T

17

R4 X2

LJ0190100-1

Operation & Maintenance Manual

A Terex Company

Section 7 Installation Oil Heater All crushers are provided with an oil heater to keep the lubricating oil warm in cold weather. (Wiring Schematic, Figure 7-11). The heater and thermostat are mounted in the bottom of the oil reservoir. The heater requires an external relay, R4, which is actuated by the thermostat. This relay is required because the thermostat will not take the high current required by the heater. The thermostat will turn the heater on when the oil temperature falls below 60F (16C). Weights and Lifting Procedures Refer to the Rollercone Component Weights chart to figure the needed capacity of rigging and lifting equipment. Minimum rigging used for safe lifting should be steel wire rope in good condition, having a break strength of four times the weight to be lifted.Crusher Model RC36STD RC36FH RC45STD RC45FH RC54STD RC54FH RC60STD RC60FH RC66STD RC66FH RC66FH Remote Adjust Upper Assembly 7,000 7,000 11,000 10,250 14,500 12,500 18,630 18,630 23,500 20,750 23,000 Lower Assembly 6,000 6,000 8,500 8,500 13,500 13,500 34,370 34,370 20,000 20,000 20,000

Warning: When the sling is at any angle but vertical, the allowable load which may be safely supported per rope is reduced. Examples: Each rope of a sling at 60 from the horizontal must be reduced to 85% of its safe vertical lifting capacity. At 45 it must be reduced to 70%. At 30 it must be reduced to 50% of the safe vertical lifting capacity. Remove the feed hopper before attempting to lift the crusher. Lift Rollercone crushers as a unit with the lifting eyes provided on the bonnet. When lifting the entire unit, be sure your hoist has enough capacity. Check the weight of your crusher. If a hoist with marginal capacity is to be used to lift the crusher, remove the upper assembly. See the Changing Manganese part of the Maintenance Section of this manual.

Cone Assembly 2,500 2,500 4,300 4,250 7,500 7,500 10,500 10,250 12,500 12,500 12,500

Wedge Plate Assembly 2,500 2,250 3,500 3,500 5,750 5,750 7,900 7,900 10,000 10,000 10,000

Hydraulic Power Unit 2,250

Figure 7-12 Rollercone Component Weights in Pounds

21280 (3/97)

Page 7.17

LJ0190100-1

Operation & Maintenance Manual

A Terex Company