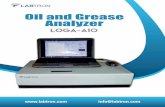

Oil and Grease

Transcript of Oil and Grease

Without calibration transfer

Added(ppm) Found (ppm) %*

5.83 4.77 81.811.7 9.18 78.517.5 14.9 85.1

5.83 4.89 83.911.7 9.41 80.417.5 14.0 80.0

5.83 4.84 83.011.7 9.41 80.417.5 13.7 78.3

UHQ water samples

River water samples

Tap water samples

Sig

nal (

E+

06)

m/z84 124

0

40

80

120

Signals: gasoline in water samples

Error analysis

SEP 1.238

r 0.997

Slope 0.915

Intercept 0.242

Error analysis

SEP 1.330

r 0.993

Slope 0.935

Intercept 0.109

5 15 25

5

15

25

5

0 10 200

10

20

5

Fou

nd (

ppm

)

Added (ppm)

Fou

nd (

ppm

)

Added (ppm)

PLS Prediction (tap water samples)

PLS Prediction (river water samples)

PLS Calibration (UHQ water samples)

5 15 25

5

15

25

5

Fou

nd (

ppm

)

Added (ppm)

84 124

0

20

40

60

80

44 84 124

0

20

40

60

80

44

Sig

nal(E

+06

)

m/z

Calibration samples

Universidad de Salamanca

GERSTEL ChemSensor 4440(Headspace-Mass Spectrometer)

Different analytical procedures have been proposed for the determination of the conventional pollutant oil and

grease, related with hydrocarbons, vegetable oils, animal fats, waxes, soaps, greases and related matter in

waters. As a result of the complexity of the samples the definition of oil and grease is based on the procedure

used, which can alter the amount and composition of the material extracted.

Standard protocols in polluted waters propose gravimetric or infrared spectrometric procedures, with previous

liquid-liquid extraction or solid-phase extraction.

In this work we propose the use of Headspace-Mass Spectrometry, which has a series of advantages because

the sample preparation steps are eliminated and no solvent is needed.

A three component synthetic oil (n-hexadecane, isooctane and benzene) has been used as the calibration

standard.

Introduction

A method based on Headspace-Mass Spectrometry has been developed for the determination of oil and grease in water, involving minimum sample treatment.The analytical signals were the sum of the intensities of the ions measured at m/z: 57, 71, 78, 85 and 99. A Box Behnken design for screening/optimising thesignificant variables was applied.A multivariate PLS calibration model built in UHQ water was used to predict oil in tap and river waters with satisfactory results. Additionally, samples spiked withthree different spike levels of gasoline were analysed using the three component synthetic oil mixture as the calibration standard and the oil content wascorrectly predicted.

Conclusions

DETERMINATION OF OIL AND GREASE IN WATER BYHEADSPACE-MASS SPECTROMETRY

María Esther Fernández Laespada, Yolanda González Martín, José Luis PérezPavón, Carmelo García Pinto and Bernardo Moreno Cordero

Departamento de Química Analítica, Nutrición y Bromatología; Universidad de Salamanca. 37008 Salamanca. ESPAÑA.

HEADSPACE SAMPLER

Temperatures Oven 80 ºC

Loop 120 ºC

Transfer line 130 ºC

Time Head space generation 40 min

Injection 1 min

MASS SPECTROMETER

Data acquisition time 1.0 min

Mass range 49-150 da

Experimental conditions

Statistical Packagesü The Unscrambler® v7.6 SR-1

ü Pirouette v 3.0

Box-Behnken experimental design

Variable Level

Low High

HS generation time (min) (A) 10 40

HS generation temp. (ºC) (B) 50 80

Salt content (g/L NaCl) (C) 2 30

Experiment* Var. A Var. B Var. C

1 10 50 162 40 50 163 25 50 24 25 50 305 10 80 166 40 80 167 25 80 308 25 80 29 10 65 30

10 10 65 211 40 65 212 40 65 30

Centre 25 65 16

* All experiments were made in triplicate

Experimental plan Regression coefficients and P-values

Term m/z=57 m/z=78

Coefficient P-value Coefficient P-value

Intercept 7.78e+6 0.000* 2.93e+6 0.000*A 1.87e+4 0.024* 1.87e+4 0.000*B 7.02e+4 0.000* 1.52e+4 0.000*C 9.51e+3 0.268 2.04e+3 0.342

A x B 1.57e+5 0.147 4.88e+4 0.074A x C -4.67e+4 0.661 -1.96e+4 0.464B x C 1.70e+4 0.873 7.52e+3 0.778A x A -1.17e+4 0.934 -5.03e+4 0.160B x B -1.71e+5 0.230 -6.49e+4 0.073C x C -3.73e+5 0.012* -1.34e+5 0.001*

m/z Lack of fit

57 0.58471 0.23678 0.83285 0.21699 0.608

* Most significant variables and interaction effects (P-value <0.05)

Quantification: Oil and grease in water by PLS

Quantification: Gasoline in water by PLS

With calibration transfer

Added(ppm) Found (ppm) %*

5.83 5.43 93.111.7 9.89 84.517.5 15.7 89.7

5.83 5.18 88.811.7 9.85 84.217.5 14.7 84.0

5.83 5.14 88.211.7 9.80 83.817.5 14.3 81.7

UHQ water samples

River water samples

Tap water samples

Recovery in gasoline spiked water samples

*Results obtained as a mean of three determinations

Future Research

Determination of different types of oils

Diesel fuel, KeroseneCrude oil, Engine oil

5065

80

10

25

40

Res

pons

e

Time (m

in) Temperature (ºC)

m/z = 57

50

65

80

10

25

40

Res

pons

e

Time (m

in) Temperature (ºC)

m/z = 78

Response surfaces

Determination in different water matrices

Sea waterWaste water

Study of other calibration standard mixtures

n-Hexadecane, isooctane and chlorobenzenen-Hexadecane, pristane and toluenen-Hexadecane and stearic acid

Samples spiked with the synthetic oil mixture

The prediction of the gasoline spiked samples was carried out with the model built with the synthetic oil mixture

Signals obtained

Error analysis

SEC 0.648 SEV 0.767

rCal 0.997 rVal 0.995

®