Offshore Rig Technology 2014 Brochure

Transcript of Offshore Rig Technology 2014 Brochure

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

TOC

Offshore Rig TechnologyCatalog 2014

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

2

TOCINTRODUCTION 1 of 5

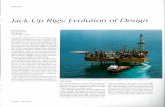

IntroductionSchlumberger is the industry leader in deepwater exploration and development services, with a proven record of success in all environments including deepwater provinces such as the Gulf of Mexico, the North Sea, West Africa, and Brazil, as well as emerging areas including India, Asia, and Australia.

High operation and infrastructure cost in deepwater environments requires an increased level of equipment quality and reliability. Our highly qualified personnel complete the requirement for flawless service provision.

This document highlights Schlumberger offshore rig technology offerings across a broad range of oilfield operational domains.

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

3

TOCINTRODUCTION 2 of 5

Equipping a rig with best-in-class engineered oilfield equipment before it leaves the shipyard provides many advantages. In addition to better in-field service delivery, it ensures the new unit is ready for expected operations and can start up quickly. The receiving location knows what to expect, so can better prepare for the rig’s arrival. Risk of nonproductive time (NPT) is reduced with thorough modeling and testing of equipment, and its effective integration.

Rigs ready for startup

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

4

TOCINTRODUCTION 3 of 5

Better resource usageThe modular oilfield equipment is designed for minimum use of deck space and fast installation and rig-up. In many instances, synergies between equipment and control systems for multiple field applications can mean less need for individual service modules, reduced requirement for personnel on board, and more efficient use of limited operational space.

Efficient logisticsInstalling complex oilfield equipment in remote locations can present logistical challenges, as well as delays, and extra costs in import/export and related regulatory processes. Bringing a fully equipped rig on site to begin operations can overcome these challenges.

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

5

TOCINTRODUCTION 4 of 5

Considering health, safety, and environment (HSE) issues early in the design process allows proper time for analysis and mitigation of risks, and avoids subsequent compromises installing and integrating unplanned modules. Installing the equipment and cabling at the most appropriate time in the building process, and in a well-controlled shipyard environment, avoids risks and hazards inherent in installation in remote ports or at sea.

Rig HSE requirements supported

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

6

TOCINTRODUCTION 5 of 5

Schlumberger has a wealth of experience designing and installing equipment in new-build rigs in shipyards around the world. We have installation teams located in areas of highest new-build activity, and a support organization able to mobilize anywhere in the world. Our teams understand the importance of early engagement in the installation design and execution process.

Worldwide new-build installation experience

Schlumberger offers an unrivalled global footprint of local operations bases, with 24/7 technical support from expert teams strategically located around the world, including Singapore, China, South Korea, UAE, and USA. Schlumberger has extensive experience of integrated operations in remote areas and, in addition to industry-leading individual technologies, can provide complete solutions to complex technical and logistical challenges.

Global operations support infrastructure

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

7

TOC

Contents

Surface and Mud LoggingFLAG* Fluid Loss and Gain Detection Service | CLEAR* Cuttings Loading and Wellbore Stability Surveillance Service |

Combined Services Units | Mud Logging Units

Drilling Tools, Tubulars & InspectionPremium Tubular Products | Rigfloor Sub Packages | Premium Hardbanding | Ezy-Torq Hydraulic Cathead |

Landing Strings | Inspection | Wellbore Cleanup Specialized Tools

Solids Control, Cuttings Management, Fluids Processing and Pressure ControlSolids Control | Cuttings Management | Fluids Processing | Pressure Control

Wireline LoggingFormation Evaluation Equipment

CementingSkid-Mounted Units | Batch Mixers | Liquid Additive Systems | Cement Equipment Package

Well TestingModular Compact Well Test System | Booms and Burners

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

8

TOCCEMENTING: 1 of 38 INTRODUCTION

CementingWhatever the drilling environment and however remote the location, Schlumberger innovative cementing technologies offer a range of solutions to achieve zonal isolation for the life of your well. Schlumberger cementing equipment packages are designed to address overall needs based on our experience and your input. Successful cement jobs

■ deliver slurry consistency ■ control the factors that cause or prevent wet shoes ■ reduce the possibility of fluid contamination points ■ reduce failure rates through operational redundancy.

■ Since 2007, Schlumberger cementing equipment has been installed on more than 65 new-build rigs, including jackups, drillships, and semisubmersibles.

■ Schlumberger engages with customers at the design and execution stages with dedicated installation teams present in all major shipbuilding areas, including

■ South Korea ■ Singapore ■ China ■ UAE ■ USA

■ Schlumberger has equipment and manufacturing support in Singapore, close to new-build activity.

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

9

TOCCEMENTING: 2 of 38 SKID MOUNTED CEMENTING UNITS

Skid-Mounted Cementing UnitsThe performance and versatility of Schlumberger skid-mounted cementing units make them ideal for offshore, high-pressure pumping services. These state-of-the-art units, capable of delivering up to 3,450 hp, can be used as backup or supplemental mud pumps, as well as efficient cementing units. Power to drive the pumps comes from high-performance diesel engines or air-cooled electric motors.

All Schlumberger offshore cementing skids comply fully with the latest European Community (EC) regulations for safety and health protection. An integrated bulkhead on the driver module reduces noise, and remote radiator packages and split designs allow installation of soundproofed walls.

The skids are fitted with sensors for data acquisition and monitoring systems, and an optional remote control system permits operation of the unit from an adjacent control room.

When a Schlumberger Mk-III mixer is used in combination with the skid, cement-mixing rates of more than 20 bbl/min can be achieved.

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

10

TOCCEMENTING: 3 of 38 SKID MOUNTED CEMENTING UNITS: CPS-763 1 of 2

CPS-763 Applications ■ Deepwater cement slurry mixing and pumping ■ High-pressure pumping and testing operations ■ Precision pumping for integrity tests

Benefits ■ Increased mixing rate capability minimizes job time ■ Power-take-off-driven cementing pumps, improved

reliability, and smaller footprint ■ Minimized environmental impact (due to elimination

of diesel tank, radiator, and exhaust pipe requirements)

Features ■ Electrically driven 1,193 kW (1,600 hhp) ■ 3-in high-pressure lines for accurate,

high-rate displacement ■ A high-rate, process-controlled liquid additive

system allows the metering of up to six chemicals into the mix water stream

■ Data acquisition and control is handled by two complete systems for redundancy and reliability of automated mixing, solids fraction monitoring, foam process control, and liquid additive systems

ELECTRIC

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

11

TOC

DescriptionOne of a range of Schlumberger CPS* cement pumping skids, the CPS-763 ultradeepwater cementing package is designed and built for extreme conditions and can be used at working pressures up to 103 MPa (15,000 psi).

The CPS-763 has two electrically driven batch mixers which can be integrated for spacer or pill mixing, isolated from contamination points.

The 1,193-kW (1,600-hhp) unit can pump at a rate of 3.8 m3/min (24.4 bbl/min) and can be optionally equipped with a high-efficiency mixing package of dual SLURRY CHIEF* cement mixing equipment Mark III cement mixers. These mixers have average tank capacity rates of 3.5-m3/min (22-bbl/min) for lead slurries and 2 m3/min for standard tail systems.

CEMENTING: 4 of 38 SKID MOUNTED CEMENTING UNITS: CPS-763 2 of 2

SpecificationsGeneralEngines Two General Electric GE B22A2 Capability (each motor) 860 kW (1,150 bhp), 690 V Transmissions Two Allison SS 6600Cooling systems Marine cooled (air cool optional)Triplex PumpsFront Gardner Denver GD-1250 Plunger diameter 95 mm [3.75 in] Maximum pressure 1,248 bar [18,100 psi] Maximum pump rate 81 m3/h [8.47 bbl/min]Rear Gardner Denver GD-1250 Plunger diameter 127 mm [5 in] Maximum pressure 702 bar [10,186 psi] Maximum pump rate 144 m3/h [15.05 bbl/min]

Slurry Mixing SystemModel Single or dual CBS-393Capacity (single CBS-393) 1-m3 [6-bbl] mixing tub and 3-m3 [18-bbl] averaging

tankMaximum mixing rate (single CBS 393)

1,749 L/min[60 sacks of dry cement per min or 11 bbl/min]

Slurry pumps RA-56Mix-water pumps RA-45Liquid Additive SystemModel Wide range of options, from manual metering types

to fully computerized direct-injection typesOtherArea classification Zone II package Process control and acquisition

Redundant control systems

Remote control mode Optional

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

12

TOCCEMENTING: 5 of 38 SKID MOUNTED CEMENTING UNITS: CPS-977 1 of 2

CPS-977 Applications ■ High-pressure pumping ■ Metering and pumping of mixing and displacement fluids ■ Recirculating cement

Benefits ■ Full system redundancies ■ Direct-driven mixing pumps for improved reliability

and efficiency ■ Minimized environmental impact (due to elimination

of diesel tank, radiator, and exhaust pipe requirements)

Features ■ Nonradioactive densitometer ■ Split skid and bullhead ■ Full selection fluid ends ■ Pressurized packing and lube systems ■ Solid fraction monitoring

ELECTRIC

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

13

TOCCEMENTING: 6 of 38 SKID MOUNTED CEMENTING UNITS: CPS-977 2 of 2

DescriptionThe CPS-977 cement pumping skid is designed for offshore high-pressure pumping services, delivering up to 2,000 hhp. Two 1,150-bhp GE GEB22A3 AC motors power the unit and are cooled using a closed-loop seawater circuit. The skid-mounted cementer is equipped with the Advanced Cement Control (ACC) data acquisition

and monitoring system, which allows precise control of slurry density. The CPS-977 features stainless steel displacement tanks, has an adjustable choke valve, and a temporary replacement for mud pumping. This unit is compliant with Zone 2 hazardous area regulations and is ABS-CDS certified.

SpecificationsGeneralEngines Two General Electric GEB22 motors and one General

Electric GEB20 Capability each 860 kW (1,150 bhp)

Transmissions Allison S8610M with air shift, six speeds Allison S9810M with air shift, seven speeds

Cooling systems Marine cooledTriplex PumpsModel 1 Gardener Denver GD1250 Series with 33⁄4-in fluid end

Capability 18,100 psi or 8.9 bpm (FOPI)Model 2 Gardener Denver HD2250 Series with 5½ in fluid end

Capability 10,000 psi or 19.3 bpm (IOPI)Discharge manifold 15,000 psiDisplacement tanks Two x 20 bbl stainless steel 316

Slurry Mixing SystemModel Twin CBS-393 mixing systems with Mark III mixersMaximum mixing rate 22 bbl/min lead slurry and 15 bbl/min standard

tail slurry (60 sacks per min dry cement per mixer)Volume capacity 6-bbl mixing tub and 18-bbl averaging tank per mixerLiquid Additive SystemModel Four x SUP-511 pumps (Waukesha 015U2)

Capability of SUP-511 0.25−11 galUS/min at 100 psi max discharge pressure

Model Three x SUP-512 pumps (Waukesha 045U2)Capability of SUP-512 1.0–54 galUS/min at 100 psi max discharge pressure

Flowmeters Micro Motion R050S and R100S, accurate to ± 0.5% of rate

OtherArea classification Zone II Package–DNV certifiedProcess control and acquisition

Redundant control systems

Auxiliary equipment Twin 100-bbl batch mixers, electric with independent drives for each centrifuge and agitator

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

14

TOCCEMENTING: 7 of 38 SKID MOUNTED CEMENTING UNITS: CPS-3000 1 of 2

CPS-3000 Applications ■ Mixing and pumping of cement slurries

in deepwater applications ■ High-pressure pumping and testing operations ■ Precision pumping for integrity tests

Benefits ■ Increased mixing rate capability to minimize job time ■ Complete redundancy of systems

Features ■ High hhp to allow for metered displacements

and completion pumping operations ■ The mixing package comprises dual Mark III mixers from

the range of SLURRY CHIEF* cement mixing equipment with tanks capable of 22-bbl/min rates for lead slurries and 15-bbl/min rates for standard tail systems

■ Twin 100-bbl batch mixers can be integrated for spacer pill mixing, isolated from contamination points

■ A high-rate, process-controlled, direct-injection liquid additive system provides the ability to accurately meter up to seven chemicals into the mix water stream

■ Accurate control of slurry density

ELECTRIC

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

15

TOCCEMENTING: 8 of 38 SKID MOUNTED CEMENTING UNITS: CPS-3000 2 of 2

DescriptionThe CPS-3000 is a 3,450-hp unit capable of pumping 26 bbl/min at pressures up to 15,000 psi (18,000 psi with a high-pressure manifold). Two complete process control units handle data acquisition and control for redundancy and reliability of automated cement mixing, solids fraction monitoring, foam process control, and liquid additive system.

SpecificationsGeneralEngines Two General Electric GEB22 motors and one General

Electric GEB20 Capability each 860 kW (1,150 bhp)

Transmissions Allison S8610M with air shift, six speeds Allison S9810M with air shift, seven speeds

Cooling systems Marine cooledTriplex PumpsModel 1 Gardener Denver GD1250 Series with 33⁄4-in fluid end

Capability 18,100 psi or 8.9 bpm (FOPI)Model 2 Gardener Denver HD2250 Series with 5½ in fluid end

Capability 10,000 psi or 19.3 bpm (IOPI)Discharge manifold 15,000 psiDisplacement tanks Two x 20 bbl stainless steel 316

Slurry Mixing SystemModel Twin CBS-393 mixing systems with Mark III mixersMaximum mixing rate 22 bbl/min lead slurry and 15 bbl/min standard

tail slurry (60 sacks per min dry cement per mixer)Volume capacity 6-bbl mixing tub and 18-bbl averaging tank per mixerLiquid Additive SystemModel Four x SUP-511 pumps (Waukesha 015U2)

Capability of SUP-511 0.25−11 galUS/min at 100 psi max discharge pressure

Model Three x SUP-512 pumps (Waukesha 045U2)Capability of SUP-512 1.0–54 galUS/min at 100 psi max discharge pressure

Flowmeters Micro Motion R050S and R100S, accurate to ± 0.5% of rate

OtherArea classification Zone II Package–DNV certifiedProcess control and acquisition

Redundant control systems

Auxiliary equipment Twin 100-bbl batch mixers, electric with independent drives for each centrifuge and agitator

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

16

TOCCEMENTING: 9 of 38 SKID MOUNTED CEMENTING UNITS: CPS-361 1 of 2

CPS-361 Applications ■ Provides high-pressure pumping services ■ Metering and pumping of mixing and displacement fluids ■ Recirculating cement

Benefits ■ Precision control of slurry density

Features ■ Mark III mixer from the range of SLURRY CHIEF* cement

mixing equipment with CBS-393 ■ Nonradioactive densitometer ■ Stainless steel displacement tanks ■ Adjustable choke valve ■ Optional CMK 828 solids fraction monitoring

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

17

TOCCEMENTING: 10 of 38 SKID MOUNTED CEMENTING UNITS: CPS-361 2 of 2

DescriptionThe CPS-361 cement pumping skid delivers high-pressure pumping services (up to 500 hhp) for operations. This split skip with bulkhead has two 340-bhp electronic diesel engines.

The skid is equipped with Advanced Cement Control (ACC) data acquisition and monitoring, allowing the precise control of slurry density. It has a pressurized packing lube system, a full selection of fluid ends, and can be supplied with a marine cooling kit.

SpecificationsGeneralModel Two Caterpillar C9 wet manifolds Capability 254 kW [340 bhp] at 2,100 rpm Transmissions Two Allison 4700-OFSCooling system Two onboard stainless steel radiatorsArea classification Rig-safe (air-starting, air-intake shut-off valves,

spark-arresting muffler, water-cooled exhaust manifold, and turbo)

Triplex PumpsFront Serva TPB-600 Plunger diameter 89 mm [3.5 in] Maximum pressure 689 bar [10,000 psi] Maximum pump rate 75 m3/h [7.9 bbl/min]Rear Serva TPB-600 Plunger diameter 114 mm [4.5 in] Maximum pressure 434 bar [6,300 psi] Maximum pump rate 124 m3/h [13 bbl/min]

Slurry Mixing SystemModel CBS-393 mixing system with SLURRY

CHIEF equipment Mark III mixerVolume capacity 6-bbl mixing tub and 18-bbl averaging tank per mixerMaximum mixing rate 2,560 kg/min [60 sacks dry cement/min]OtherDischarge manifold 1,034-bar [15,000-psi] maximum working pressureDisplacement tanks Two × 1,590–L [2 × 10–bbl] stainless steel 316Emissions compliance EPA Nonroad Tier III/Euro Nonroad Stage IIIA/IMO

Tier 1OptionMarine cooling Two marine coolers to replace standard onboard

radiators Flow rate 2 × 378.5 L [2 × 100 galUS/min] Flow resistance 18.2 kPa/L [10 psi/galUS]

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

18

TOCCEMENTING: 11 of 38 SKID MOUNTED CEMENTING UNITS: CPS-679 1 of 2

CPS-679 Applications ■ Provides high-pressure pumping services ■ Meters and pumps mixing and displacement fluids ■ Recirculating cement mixer

Benefits ■ Full system redundancies ■ Direct-driven mixing pumps for improved reliability

and efficiency

Features ■ Nonradioactive densitometer ■ Split skid with bulkhead ■ Solid fraction monitoring ■ Temporary replacement for mud pump ■ Dual human-machine interface (HMI) system

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

19

TOCCEMENTING: 12 of 38 SKID MOUNTED CEMENTING UNITS: CPS-679 2 of 2

DescriptionThe CPS-679 cement pumping skid was designed for offshore high-pressure pumping services. Two 715-hp Caterpillar® diesel engines power the unit, and it has an adjustable choke valve and stainless steel displacement tanks. The CPS-679 has a full selection of fluid ends, a pressurized packing lube system, and a remote radiator package.

This unit features a split design with bulkhead for installation of a soundproof wall. The remote control system allows local and remote operation. It is Zone 2 hazardous area compliant and ABS-CDS, DNV-OS-E101 certified.

SpecificationsGeneralModel Two Caterpillar C18 engines Capability (each) 715 hp at 2,100 rpmTransmissions Two Allison S6610Cooling system Two remote radiatorsCompliance

Hazardous area Zone 2 compliantCertifications

ABS-CDS, DNV-OS-E101Triplex PumpsFront pump Gardner Denver GD 1250 series Plunger diameter 33/4 in (95 mm) Maximum pressure 18,100 psi [1,248 bar] Maximum pump rate 6.18 bpm [59 m3/hr]Rear pump Gardner Denver GD 1250 series

Plunger diameter 5 in [127 mm] Maximum pressure 10,186 psi [702 bar] Maximum pump rate 10.99 bpm [105 m3/hr]

Slurry Mixing SystemModel Remote controlled CBS-393 mixing system with

remote controlled SLURRY CHIEF* cement mixing equipment Mark III mixer

Maximum mixing rate 2,560 kg/min [60 sacks dry cement/min]Volume capacity 6-bbl mixing tub and 18-bbl averaging tank per mixerBulk SystemModel CUS-122 remote control surge tankCapacity total/usable 80 cuft / 70 cuftPLC Control SystemPLC cabinet One programmable logic controller cabinet located

in the cement control room / electrical switch roomHMI computers Two human–machine interface computers located

in the cement control roomOtherDischarge manifold 1,034-bar [15,000-psi] maximum working pressureDisplacement tanks 2 × 1,590 L [2 × 10 bbl] stainless steel 316

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

20

TOCCEMENTING: 13 of 38 SKID MOUNTED CEMENTING UNITS: CBS-393 1 of 2

CBS-393 Applications ■ Efficient and flexible method of providing homogeneous

cement slurries at their designed density, solids fractions, and pump rates

■ On-the-fly mixing and recirculation of cement slurries or other fluids

Benefits ■ The combination of mixing tub and averaging tub enables

fast response when bulk delivery issues or other discrepancies in slurry quality are observed

■ The quality and volume of the cement slurry in the mixing tub is controlled manually or automatically to ensure a constant density or solids fraction

■ Maintains a large buffer volume of premixed slurry to enable pumping operations at designed downhole rates

Features ■ Recirculating Mark III mixer from the range of SLURRY

CHIEF* cement mixing equipment ■ Bulk blend control valve ■ Quick cement slurry shut-off ■ Six-barrel mixing tub and 18-barrel averaging tank ■ SlurryAirSeparator* mechanical cement slurry defoamer ■ Guided radar level sensors ■ Promass mass flowmeter

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

21

TOCCEMENTING: 14 of 38 SKID MOUNTED CEMENTING UNITS: CBS-393 2 of 2

DescriptionThe CBS-393 slurry mixing system offers mixing rates of up to 11 bpm, depending on the bulk cement delivery rates and cement slurry design. The dry cement blend is delivered to the SLURRY CHIEF equipment Mark III mixer by gravity feed from the CUS-122 surge tank via a metering knife gate. It is mixed directly with the mix water delivered to the mixer from a dedicated 5x6 centrifugal pump.

The cement slurry passes into a six-barrel mixing tub and is continuously recirculated through the Mark III mixer and a Promass mass flowmeter. (Note: the 5x6 centrifugal pump is not included with the CBS-393.) The cement slurry is recirculated and transferred to the cement pump unit using a second centrifugal pump prior to going down hole.

SpecificationsSLURRY CHIEF Equipment Mark III MixerLength diagonal 54 in (1,372 mm)Width 30 in (762 mm)Height 27 in (689 mm)Dry weight (without mixing tub)

297 lbs (135 kg)

Max. mixing capacity 60 sacks dry cement per minute (2,560 kg/min)Density range 11.6 - 22 lb/gal (1.4 to 2.64 sg)Slurry TubCapacity 6-bbl mixing tub + 18-bbl averaging tub (954 + 2,862 L)Length (overall) 9 ft (2,727 mm)

Slurry Tub cont.Width (overall) 6 ft 8 in (2,011 mm)Height (overall) 8 ft 8 in (2,642 mm)Dry weight, excl. mixer 3,300 lbs (1,500 kg)Operating weight, excl. mixer

23,460 lbs (10,641 kg) assuming 20 ppg fluid in both tubs

Slurry Mixing Rate CapabilitiesDensity 22 lb/gal

(2.64 sg)19 lb/gal (2.28 sg)

17 lb/gal (2.04 sg)

Bulk delivery rate 2,328 lb/min (1,056 kg/min)

5,223 lb/min (2,639 kg/min)

5,805 lb/min (2,633 kg/min)

Slurry rate 3 bbl/min 8 bbl/min 11 bbl/min

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

22

TOCCEMENTING: 15 of 38 SKID MOUNTED CEMENTING UNITS: CBS-593 1 of 2

CBS-593 Applications ■ Cementing services ■ High-power pumping services ■ Remedial cementing operations

Benefits ■ The design focuses on reliability, redundancy,

and noise reduction ■ Full redundancy ensures job completion ■ Downtime reduced by reliability of equipment ■ Mixes all slurry types

Features ■ Power to 388 kW (520 hhp) ■ Working pressure rating of 68.95 MPa (10,000 psi) ■ Integrated data acquisition system ■ Mixing capacity of 60 sacks (dry cement) per minute ■ Self-sufficient unit, including treating iron

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

23

TOCCEMENTING: 16 of 38 SKID MOUNTED CEMENTING UNITS: CBS-593 1 of 2

DescriptionThis SLURRY CHIEF* cement mixing equipment Mark III mixer is used in conjunction with a 0.95-m3 (6-bbl) mixing tub which produces superior density control and separates the critical mixing stage from downhole pumping. It is also capable of mixing a maximum of 3.2 m3 (20 bbl) of cement in batch mode for squeeze and plug operations.

A CemCAT* cementing computer-aided treatment system is used to monitor and record treatment parameters and provide a job report. Two triplex pumps equip the unit for simultaneous high-energy mixing and downhole pumping or for parallel downhole pumping.

SpecificationsSLURRY CHIEF Equipment Mark III MixerLength diagonal 54 in (1,372 mm)Width 30 in (762 mm)Height 27 in (689 mm)Dry weight (without mixing tub)

297 lbs (135 kg)

Max. mixing capacity 60 sacks dry cement per minute (2,560 kg/min)Density range 11.6 - 22 lb/gal (1.4 to 2.64 sg)Slurry TubCapacity 6-bbl mixing tub + 18-bbl averaging tub (954 + 2,862 L)Length (overall) 9 ft (2,727 mm)

Slurry Tub (continued)Width (overall) 6 ft 8 in (2,011 mm)Height (overall) 8 ft 8 in (2,642 mm)Dry weight, excl. mixer 3,300 lbs (1,500 kg)Operating weight, excl. mixer

23,460 lbs (10,641 kg) assuming 20 ppg fluid in both tubs

Slurry Mixing Rate CapabilitiesDensity 22 lb/gal

(2.64 sg)19 lb/gal (2.28 sg)

17 lb/gal (2.04 sg)

Bulk delivery rate 2,328 lb/min (1,056 kg/min)

5,223 lb/min (2,639 kg/min)

5,805 lb/min (2,633 kg/min)

Slurry rate 3 bbl/min 8 bbl/min 11 bbl/min

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

24

TOCCEMENTING: 17 of 38 BATCH MIXERS

Batch MixersBatch mixers are available for the mixing of cement slurries and other fluids. The units feature two centrifugal pumps for picking up fluids from remote tanks, recirculating for mixing, and for delivering fluid to high-pressure pumps.

CBS-965

CBS-957

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

25

TOCCEMENTING: 18 of 38 BATCH MIXERS: CBS-965 1 of 2

CBS-965 Applications ■ Transfer of fluids from remote sources ■ Recirculation of cement slurry to blending tanks ■ Delivery of cement slurry or fluids to pumping unit

Benefits ■ Allows for individual tank mixing and cross mixing ■ Handles large volumes of cement slurry ■ Allows for pneumatic feeding of dry cement directly

to the batch mixer ■ Uniform cement slurry

Features ■ Two 150-hp AC electric motors, 690 VAC 60 HZ, 3-phase ■ Two mixing/pressurizing pumps ■ Two 50-bbl batch tanks ■ Pressurized packing lubrication for C-pumps ■ Hopper and cutting table

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

26

TOCCEMENTING: 19 of 38 BATCH MIXERS: CBS-965 2 of 2

DescriptionThe CBS-965 electric batch mixer skid mixes and recirculates cement slurry for the pumping unit. The unit is equipped with two 50-bbl blending tanks capable of handling large volumes of cement slurry.

Two centrifugal pumps are capable of transferring fluids from remote sources. The pumps also recirculate cement slurry back to the tanks and discharge fluids to the pumping unit. The unit is equipped with piping and valves that enable individual mixing and discharge of the two 50-bbl tanks, as well as cross mixing.

SpecificationsGeneralElectric motors Two x 150 hp 3-phase AC electric motors, 690 V/60

hz, IEC w/ 110 V heaterDrive mechanism Drive shaft 1,410 series Pulley Gates Belt Gates predator-5vp Powerband Agitators 10 hp electric motor driven Lightning agitators Centrifugal pumps RA56 pumpsBatch tanks Two x 50 bbl

Unit SpecificationsLength, m [ft] 7,010 mm (23 ft)Width, m [ft] 2,500 mm (8 ft 2 in)Height Transportation mode (railing down)

3,945 mm (13 ft)

Railing up 4,380 mm (14 ft 4 in)Weight (wet) 15 MT unladenAmbient rating 0 to 40 degCOptionRemote control available

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

27

TOCCEMENTING: 20 of 38 BATCH MIXERS: CBS-967 1 of 2

CBS-967 Applications ■ Preparation of various types of liquid/solid blends

to exact specifications for delivery to the pumping unit ■ High-power pumping services

Benefits ■ Use of Exd starters and ATEX approved

electrical components ■ Large volumes of uniform cement slurry ■ Allows for pneumatic feeding of dry cement directly

to the batch mixer ■ Transfers fluids from remote sources

Features ■ Two 150-hp, 480 VAC 60 HZ, explosion-proof IEC motors

(optional 440 VAC, 460 VAC, and 690 VAC) ■ Two mixing/pressurizing pumps ■ Two 100-bbl batch tanks ■ RA-56 C-pumps (2,300-2,400 rpm) ■ Hopper and cutting table

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

28

TOCCEMENTING: 21 of 38 BATCH MIXERS: CBS-967 2 of 2

DescriptionThe CBS-967 electric batch mixer skid allows the preparation of various types of liquid/solid blends to exact specifications for delivery to the pumping unit. The unit is equipped with two 100-bbl blending tanks with agitators to prevent solids settling.

Two centrifugal pumps are capable of recirculating fluid through the tanks, mixing jet and discharge slurry or fluids to the pumping unit. The cement blender skid meets Zone 2 hazardous area electrical requirements for offshore use.

SpecificationsGeneralElectric motors Two x150 hp, 480 VAC/60 HZ explosion-proof IEC

motors. Optional 440 VAC, 460 VAC, 690 VACDrive mechanism Drive shaft 1,410 series Pulley Gates Belt Gates predator-5vp Powerband Agitators Driven by two x 10 hp, 440 VAC, 60 HZ, explo-

sion-proof IEC motors Centrifugal pumps RA56 pumpsBatch tanks Two x 100 bbl

Unit SpecificationsLength, m [ft] 9,665 mm (31ft 8.5 in)Width, m [ft] 2,729 mm (8 ft)Height 4,292 mm (14 ft)Weight, dry 19,000 kg (calculated)Weight, operating (1.9 sg fluid)

80,000 kg (calculated)

OptionRemote control available

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

29

TOCCEMENTING: 22 of 38 BATCH MIXERS: CBS-955 1 of 2

CBS-955 Applications ■ Transfer of fluids from remote sources ■ Recirculation of cement slurry back to the blending tanks

Benefits ■ Allows for individual tank mixing and cross mixing ■ Capable of handling large volumes of cement slurry ■ Allows for pneumatic feeding of dry cement directly

to the batch mixer

Features ■ Hydraulic power pack with electronic diesel engine,

EPA Tier 3 and Euro Stage IIIA emission compliant ■ Two 50-bbl batch tanks ■ Oil-lubricated centrifugal pump packing ■ Hopper and cutting table

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

30

TOCCEMENTING: 23 of 38 BATCH MIXERS: CBS-955 2 of 2

DescriptionThis unit is equipped with two 50-bbl blending tanks capable of handling large volumes of cement slurry. Two centrifugal pumps are capable of transferring fluids from remote sources. The pumps also recirculate cement slurry back to the tanks, mixing jet and discharge fluids to the pumping unit.

SpecificationsGeneralEngines DEUTZ® BF6M1015C Capability 365 bhp at 1,950 rpmGear box Funk™ gearbox, model 28102AADrive mechanism Hydraulic motors Two x Parker® Denison hydraulic vane motor Hydraulic pumps Two x Parker Denison hydraulic vane pumps Centrifugal pumps Two x Schlumberger RA-56Residence tanks Two x 50-bbl capacityEngine Emissions Compliance

EPA Nonroad Tier II/Euro Nonroad Stage II

Unit SpecificationsLength, m [ft] 8.1 [26.6]Width, m [ft] 2.8 [9]Height, m [ft] 3.3 [10.8]Weight, kg [lbm] 15,000 [33,070]Ambient rating, degC [degF] 0 to 48 [32 to 188.4]

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

31

TOCCEMENTING: 24 of 38 BATCH MIXERS: CBS-957 1 of 2

CBS-957 Applications ■ Blends uniform cement slurry in large amounts ■ Recirculates cement slurry back to the blending tank ■ Delivers cement slurry or fluids to the pumping unit

Benefits ■ Standard unit designed for operations from 0 degC

to 48 degC ambient temperature ■ Two RA56 centrifugal pumps capable of transferring

fluids from remote sources ■ Allows for pneumatic feeding of dry cement directly

to the batch mixer ■ Accurately provides cement slurry to the pumping unit

while greatly reducing cement density fluctuation

Features ■ Hydraulic power package with electronic diesel engine,

EPA Tier 3 and Euro Stage IIIA ■ Mixing/pressurize pumps ■ Two 100-bbl batch tanks ■ Oil-lubricated centrifugal pump packing ■ Hopper and cutting table

CEMENTING: BATCH MIXERS: CBS-957 1 of 2

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

32

TOCCEMENTING: 25 of 38 BATCH MIXERS: CBS-957 2 of 2

DescriptionThe CBS-957 cement batch mixer skid mixes and recirculates cement slurry for the pumping unit. The unit is equipped with two 100-bbl blending tanks capable of handling large volumes of cement slurry.

Two centrifugal pumps are capable of transferring fluids from remote sources. The cement slurry is continuously recirculated and agitated until ready to be discharged to the pumping unit.

SpecificationsGeneralEngine Caterpillar C9, 350 bhp at 2,200 rpm, dry manifoldGear box Funk gearbox, model 28102 AADrive mechanism Hydraulic motors Two x Parker Denison vane motors Hydraulic pumps Two x Parker Denison vane pumps Centrifugal pumps Two x Schlumberger RA-56 pumps Agitators Two x Level impeller mixer driven by Poclain®

hydraulic motorsResidence Tanks Two x 100-bbl capacityEngine Emissions Compliance

EPA Nonroad Tier III/Euro Nonroad Stage IIIA

Unit SpecificationsLength, m [ft] 9.6 [31.5]Width, m [ft] 2.7 [9 ft]Height, m [ft] Operational, m [ft] 4.3 [14.1) Transportation, m [ft] 3.5 [11.5]Weight, kg [lbm] 16,600 [36,597]Ambient rating, degC [degF] 0 to 48 [32 to 118]

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

33

TOCCEMENTING: 26 of 38 LIQUID ADDITIVE SYSTEMS

Liquid Additive SystemsOur modular systems (such as the CMP-351 unit) deliver metered amounts of liquid additives to the cement slurry as it is mixed. Metering of liquid additives adds versatility to the mixing process, enabling the mixing of various slurry systems from bulk storage of neat cement.

Metering can be manual or automatic when the CMP-751 liquid additive system (LAS) metering unit is used. With the CMP-751 unit, electromagnetic flow meters control the additive metered into displacement tanks.

CMP-756

CMP-754

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

34

TOCCEMENTING: 27 of 38 LIQUID ADDITIVE SYSTEMS: CMP-355 1 of 2

CMP-355 Applications ■ Meters and delivers liquid additives for cement

slurry blending ■ Meters up to six different liquid additives into

the displacement tanks

Benefits ■ Each of the four pneumatic diaphragm pumps

can provide up to 35 gal/min (132.5 l/min) for various liquid additives, tailored to the cement slurry recipe

■ The additive metering can be accomplished with the metering tank or optional computerized metering racks CMP-751 or CMP-756

Features ■ Up to six rack-mounted diaphragm pumps with suction

and discharge manifolds ■ Control panel ■ Metering rack with up to four tanks. Control valves

and support for installation onto displacement tanks ■ Two lightning mixers

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

35

TOCCEMENTING: 28 of 38 LIQUID ADDITIVE SYSTEMS: CMP-355 2 of 2

DescriptionThe CMP-355 liquid additive system meters and delivers liquid additives for cement slurry blending. Liquid additives are shipped into

the rig and dispensed out of the tote tanks, reducing transfer of chemicals and cleaning of tanks on location.

SpecificationsGeneral 4 Line 6 LinePumps Pneumatic - diaphragm type Pneumatic - diaphragm typeDischarge pressure 100 psi (7 bars) 100 psi (7 bars)Discharge flow rate (each pump) 35 gal/min (132.5 liters/min) 35 gal/min (132.5 liters/min)Air supply 70 to 115 psi (5 to 9 bars) maximum 150 psi (10 bars) 70 to 115 psi (5 to 9 bars) maximum 150 psi (10 bars)

Pump air consumption 50 scfm at 100 psi each, 200 scfm total (1,416 l/min each, 5,664 l/min total)

50 scfm at 100 psi each, 300 scfm total (1,416 lpm each, 8,496 lpm total)

Operating temperature -4 degF to 158 degF (-20 degC to 70 degC) -4 degF to 158 degF (-20 degC to 70 degC)Lightning mixers for installation in displacement tanks Standard (2 each) Standard (2 each)

Lightning mixers air consumption 15 scfm at 60 psi each, 30 scfm total (425 lpm each, 850 lpm total)

15 scfm at 60 psi each, 30 scfm total (425 lpm each, 850 lpm total)

Pumps RackLength 1,905 mm (75 in) 2,934 mm (9 ft 8 in)Width 711 mm (28 in) 722 mm (2 ft 4 in)Height 1,727 mm (68 in) 1,740 mm (5 ft 9 in)Weight 500 kg (1,100 lbs) 800 kg (1,764 lb) Metering TanksLength 1,070 mm (42 in) 1,842 mm (6 ft)Width 430 mm (17 in) 908 mm (3 ft)Height 1,200 mm (47 in) 1,286 mm (4 ft 3 in)Dry weight 230 kg (960 lbs) 230 kg (960 lbs) Compartment volumes 3 x 30 gal 4 x 30 galOverflow protection Level switches Level switchesControl panel Pneumatic Pneumatic

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

36

TOCCEMENTING: 29 of 38 LIQUID ADDITIVE SYSTEMS: CMP-756 1 of 2

CMP-756 Applications ■ Meters liquid additives for cement slurry blending ■ Meters up to six liquid additives to the displacement tanks

to prepare the base fluid

Benefits ■ High accuracy with four to six different additives which

can be metered simultaneously or in sequence ■ A programmable logic controller (PLC) enables operator

to remotely control CMP-756 from a human-machine interface (HMI) computer in the safe area

■ Can be controlled by a standalone HMI computer with appropriate software interface

Features ■ Remote-actuated high- and low-rate pneumatic valves ■ Other equipment required for operating CMP-756

(not in scope) ■ Electromagnetic flowmeters measure the additive

quantities, and preset amounts are metered into the displacement tanks by remote control

■ Used in conjunction with the CMP-355 pump rack and proportioning tanks

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

37

TOCCEMENTING: 30 of 38 LIQUID ADDITIVE SYSTEMS: CMP-756 2 of 2

DescriptionThe CMP-756 remote control liquid additive system meters liquid additives for cement slurry blending. This unit is capable of high accuracy and up to six different additives can be metered simultaneously or in sequence.

In combination with proportioning tanks, the CMP-756 provides all the advantages of process control while allowing a manual override as backup. The unit is Zone 2 hazardous area compliant.

SpecificationsGeneral 4 Line 6 LineMetering RackOverall length Doors closed 1,725 mm (5 ft 8 in); doors open 1,893 mm (6 ft 3 in) Doors closed 2,533 mm (8 ft 4 in); doors open 2,733 mm (9 ft)Overall width Doors closed 600 mm (2 ft); doors open 940 mm (3 ft 1 in) Doors closed 600 mm (2 ft); doors open 1,000 mm (3 ft 4 in)Overall height 1,086 mm (3 ft 7 in) 1,086 mm (3 ft 7 in)Weight 326 kg (719 lb) 425 kg (937 lb)Flowmeters Electromagnetic Electromagnetic Application Conductive liquids: four 2-in lines (up to 8 maximum) Conductive liquids: five 2-in linesFlowmeters - Coriolis mass Application - Non-conductive liquids: one x 2-in lineAccuracy 2% for a 50-liter volume 2% for a 50-liter volumeElectrical supply 24 VDC 24 VDCAir supply 70 to 115 psi (5 to 9 bars), maximum 150 psi (10 bars) 70 to 115 psi (5 to 9 bars), maximum 150 psi (10 bars)Control CabinetMaterial Polyester Polyester

Certifications Zone 2 hazardous area compliant II 3G Ex nA ib op is [ib] IIB/ IIC T4 - ENC.10

Zone 2 hazardous area compliant II 3G Ex nA ib op is [ib] IIB/ IIC T4 - ENC.10

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

38

TOCCEMENTING: 31 of 38 LIQUID ADDITIVE SYSTEMS: CMP-751 1 of 2

CMP-751 Applications ■ Meters liquid additives for cement slurry blending

Benefits ■ Up to four different additives can be preprogrammed ■ In combination with a proportioning tank, the CMP-751

provides all the advantages of process control ■ Allows for a manual override ■ Electromagnetic flowmeters measure the additive

flow rates and preset amounts are measured remotely ■ The computerized liquid additive system (LAS) includes

a metering control module and electromagnetic flowmeters with control valves

Features ■ Certified for use in Zone 2 hazardous areas ■ Four electromagnetic flowmeters ■ Four pneumatic control valves and four pneumatic

restriction valves ■ Control cabinet ■ Solenoid valve box

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

39

TOCCEMENTING: 32 of 38 LIQUID ADDITIVE SYSTEMS: CMP-751 2 of 2

DescriptionThe CMP-751 computerized LAS meters liquid additives for cement slurry blending. The unit is capable of high accuracy and four different additives can be metered simultaneously or in sequence.

Electromagnetic flowmeters measure the additive flow rates and preset amounts are measured by remote control flowing into the displacement tank. The computerized LAS includes a metering control module and electromagnetic flowmeters with control valves.

In combination with a proportioning tank, the CMP-751 provides all the advantages of process control and allows for a manual override as backup.

The CMP-751 only operates with cementing units that have the Advanced Cement Control (ACC) data acquisition and monitoring system.

SpecificationsGeneralMetering RackOverall length 1,692 mm (67 in)Overall width 610 mm (24 in)Overall height 1,006 mm (40 in)Unladen weight 310 kg (683 lb)Flowmeters (4) Four x electromagneticApplication Conductive liquids: four x 2-in linesAccuracy 98% for a 50-liter volumeElectrical supply 110/220 VAC

Control CabinetOverall length 560 mm (22 in)Overall width 360 mm (15 in)Overall height 250 mm (10 in)Material 316L stainless steelElectrical supply 380-500 VAC 50 HzCertification/ ingress protection

EExD IIB T5 (Certificate CESI 02 ATEX 075)/IP65

Solenoid Valve BoxOverall length 590 mm (24 in)Overall width 200 mm (8 in)Overall height 120 mm (5 in)Material 316L stainless steel

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

40

TOCCEMENTING: 33 of 38 LIQUID ADDITIVE SYSTEMS: CMP-754 1 of 2

CMP-754 Applications ■ In-line injection of liquid additives into a cement

mixer base fluid

Benefits ■ Up to six different additives can be preprogrammed ■ Skid designed for use in Zone 2 hazardous areas ■ Variable frequency drive (VFD) and programmable logic

controller (PLC) cabinets are designed for safe area

Features ■ Six positive displacement pumps driven by variable

speed AC motors through gear reducers ■ Remote-actuated process valves with position feedback

and pneumatic backup control ■ Six electromagnetic flowmeters (conductive

additive) and one Coriolis mass flowmeter (nonconductive additive)

■ VFD cabinet (ENC.14) is provided together with CMP-754 standard package

■ PLC cabinet is provided as a part of the cementing pumper skid (CPS) package

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

41

TOCCEMENTING: 34 of 38 LIQUID ADDITIVE SYSTEMS: CMP-754 2 of 2

DescriptionThe CMP-754 continuous liquid additive system controls the base fluid rate, which is measured by a flowmeter on the base fluid manifold. Flowmeters on pump discharge measure additive rate and adjust pump speed through close loop control. This control maintains additive concentrations within 98% accuracy of the preset value given by the slurry recipe.

The CMP-754 has two operation modes: remote mode and manual/backup mode. In the remote mode, displacement tanks are bypassed as the additives are injected directly into the mix water line. In the manual/backup mode, pumps are set to a constant speed and additives are measured using metering tanks placed on top of the displacement tanks.

Detailed flowmeter details available on request

SpecificationsGeneralMetering SkidOverall length 3,800 mm (150 in)Overall width 1,430 mm (57 in)Overall height 2,052 mm (81 in)Unladen weight 2,800 kg (6,160 lb)Base fluid flowmeter Electromagnetic flowmeterFlowmeter 1 Coriolis mass flowmeterFlowmeter 2,3,4,5,6 Electromagnetic flowmeter

Application Conductive liquids: four x 2-in lines (up to six maximum)

Accuracy 98% for a 50-liter volume

Air supply 70 to 110 psi (5 to 8 bars)VFD (ENC.14)Overall depth 1,400 mm (56 in)Overall width 860 mm (34 in)Overall height 2,460 mm (97 in)Unladen weight 160 kg (353 lb)Electrical supply 380-500 VAC/3-phase/50-60 Hz/50A/20 kW

230 VAC/1-phase/50-60 HzCertifications

Hazardous area Zone 2 compliant with IEC60079-10CEC Class 1

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

42

TOCCEMENTING: 35 of 38 LIQUID ADDITIVE SYSTEMS: CMP-351 1 of 2

CMP-351 Applications ■ This liquid additive system (LAS) is designed to deliver

a predetermined quantity of different liquid additives into the displacement tanks of the cementing unit

Benefits ■ Delivers liquid additives for cement blending to metering

tank or metering rack ■ Constructed of 316L stainless steel for corrosion

resistance and ease of maintenance ■ Two split tanks consist of two compartments each

Features ■ Twin-split stainless steel tanks (two compartments each) ■ Lightning mixers ■ Metering tank ■ Remote control panel ■ Optional metering rack (CMP-751)

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

43

TOCCEMENTING: 36 of 38 LIQUID ADDITIVE SYSTEMS: CMP-351 2 of 2

DescriptionThe CMP-351 LAS is designed to deliver a predetermined quantity of a number of different liquid additives into the displacement tanks of the cementing unit.

Constructed of 316L stainless steel for corrosion resistance and ease of maintenance, the two split tanks consist of two compartments each.

SpecificationsGeneralMetering SkidGeneral assembly part no 100305361Nozzle diagram part no 529605000Load diagram part no 529555000P & ID diagram part no 529604000Length 3,048 mm (120 in) 3,048 mmWidth 2,440 mm (96 in)Height 2,413 mm (94 in)Dry weight 3,000 kg (6,614 lb)Capacity of compartment 1 3,785 (1,000 gal)Capacity of compartment 2 1,135 L (300 gal)Capacity of compartment 3 2,082 L (550 gal)Capacity of compartment 4 2,839 L (750 gal)

Air requirements (maximum) 100 psi at 120 scfm (6.9 bar at 56.6 L/sec)Discharge pressure (maximum) 110 psi (7.6 bar)Discharge flow rate (maximum) 140 GPM (529 L/min)Gauges available Imperial and metricMetering tank StandardControl panel StandardMetering rack StandardLightning mixers 2

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

44

TOCCEMENTING: 37 of 38 CEMENTING PACKAGE: 1 of 2

Cement Equipment Package

CPS-3000 ■ Remote controlled with local backup ■ Electrically driven: total of 3,000 hhp, 15,000-psi maximum

allowable working pressure (MAWP) ■ 22 bpm maximum pump rate

CBS-593 ■ Dual mixing system

CBS-967 ■ Twin 100-bbl batch mixer

CMP-366/756 ■ 6-line liquid additive system

CMS-531/532 ■ CPCS remote control cabin

CUS-916 ■ Dust collector

CUS-916

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

45

TOCCEMENTING: 38 of 38 CEMENTING PACKAGE: 2 of 2

CBS-593CBS-967

CPS-3000

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

46

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 1 of 17 INTRODUCTION

Solids Control, Cuttings Management, Fluids Processing and Pressure ControlM-I SWACO, a Schlumberger company, designs, manufactures, and services a complete line of variable-motion shakers, OEM and replacement shaker screens, centrifuges, and cuttings dryers. These technologies

■ optimize drilling efficiency by minimizing fluid losses ■ preserve fluid quality to protect downhole equipment,

prevent NPT, and improve drilling performance ■ minimize produced solid and liquid waste volumes.

M-I SWACO cuttings management and fluids processing techniques further reduce HSE footprint. Specifically

■ CLEANCUT† cuttings collection and containment system fully contains drill cuttings and fluid for safe transport

■ AUTOMATIC TANK CLEANING LITE† technology has improved the industry standard for storage tank cleaning by providing ultra-efficient recovery of fluid waste materials.

Specialists at M-I SWACO have put decades of experience, expertise, and field-proven technical performance into developing a line of drilling chokes, separators, and D-GASSERs that are uniquely designed for a range of highly pressure-sensitive applications, including

■ managed pressure drilling (MPD) ■ underbalanced drilling (UBD) ■ coiled-tubing (CT) ■ frac-plug drillout ■ frac flowback ■ equivalent circulating density (ECD) control ■ H2S applications ■ well control ■ cleanup operations.

†Mark of M-I SWACO

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

47

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 2 of 17 SOLIDS CONTROL: 518 CENTRIFUGE 1 of 2

Applications ■ Increased fluid handling and improved solids separation

Benefits ■ Quasi-axial scroll provides an increased flow area which

minimizes turbulence ■ Increased flights wear resistance thereby reducing

maintenance requirements ■ High bowl speed assures a high g-force, solids removal

efficiency percentage and finest cut points ■ Complete control of g-force and differential settings

for improved separation efficiency ■ Six bowl speed/differential combinations on fixed drive

units for enhanced simplicity and efficiency

Features ■ High bowl speed and variable feed pump speed ■ Variable bowl and scroll speed1

■ Fixed bowl and differential speed2

■ Perfectly balanced stainless steel rotating assembly ■ Programmable logic controller (PLC) control3

1Not applicable to fixed drive 2Only applicable to fixed drive 3Only on fully hydraulic drive types

518 HV Centrifuge

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

48

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 3 of 17 SOLIDS CONTROL: 518 CENTRIFUGE 2 of 2

Description518† HV high-volume centrifuge unit replaces the operation of two standard 518 centrifuges combined through an increased fluid handling capacity and improved solids separation. The 518 HV centrifuge is designed to handle higher fluid processing rates by providing more power and improving fluid flow.

Increased power for the main drive (50 hp) and back drive (15 hp) allows more fluid to be fed into the bowl, while providing the necessary torque to remove the increased solids load resulting from the higher feed rate. It features a split pillow block, dual-deck quasi-axial scroll, and tungsten carbide tiles (scroll).

SpecificationsPerformanceHydraulic capacity 248 GPM 939 LPMOperating speed 3,200 rpmG-force 1,975 GSigma value 24,326 ft2 2,260 m2

Solids discharge 27 GPM 6.1 m3/hRotating AssemblyBowl diameter 13.9 in 353.1 mmBowl length 57.5 in 1,461.1 mmPond depth 2.3, 2.42, 2.54 in 58.5, 61.5, 64.5 mmScroll type Single lead quasi-axial flowScroll pitch 4.31 in 109.5 mmMain bearings Grease lubricatedInternal bearings Grease lubricatedFeed tube Open endedGearboxType PlanetaryGear ratio 57:1Torque, maximum 2,531 ft-lb 3,432 Nm

Differential range Fixed drive 10 to 79 rpm VFD 1 to 55 rpm FHD 1 to 80 rpmWeight 159 lbs 72 kgMotor SpecificationsLiquid discharge 8 in VictaulicSolids discharge 21.0 x 13.8 in 530 x 350 mmFeed tube 2 in NPT [male connection]Fixed Drive TypePower 400/460 V - 50/60 Hz, 3 PhaseMain drive motor 50 Hp 37 kWBack drive motor 15 Hp 11 kWVFD TypePower 400/460 V - 50/60 Hz, 3 PhaseMain drive motor 50 Hp 37 kWBack drive motor 15 Hp 11 kWFHD TypePower 400/460 V - 50/60 Hz, 3 PhaseMain drive motor 60 Hp 45 kWHydraulic pump Variable displacement pump

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

49

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 4 of 17 SOLIDS CONTROL: MD-2 SHALE SHAKER 1 of 2

MD-2 Shale Shaker Applications ■ Primary solids removal from both oil- and water-base

drilling fluids ■ Flexible fluid distribution

Benefits ■ Delivers high processing capacities and conveys solids

quickly out of fluid pool ■ Deceases NPT and removes harmful vapors ■ Reduces maintenance, drilling, and waste disposal costs ■ Helps ensure environmental compliance

Features ■ Patent-pending dual motion: balanced elliptical/

progressive elliptical ■ Pneumo-hydraulic controls mounted on front of shaker

for deck adjustment. Fluid is a water/low-toxicity antifreeze mixture

■ Pneumatic screen clamping system for durable pre-tensioned composite screens

■ Dual-deck design with full primary and half-width scalping decks

■ Adjusts instantly to changing drilling conditions

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

50

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 5 of 17 SOLIDS CONTROL: MD-2 SHALE SHAKER 2 of 2

DescriptionBy providing primary solids removal from both oil- and water-base drilling fluids, the MD-2† dual-deck shale shaker delivers high-capacity separation efficiency and operational flexibility in a value-added footprint. It provides longer screen life, generates drier cuttings and enhances overall solids control efficiencies.

Capable of easily switching between balanced elliptical and progressive elliptical motions, the MD-2 shaker adapts instantly to the continual changes in drilling conditions.

SpecificationsDimensionsLength 125.0 in 3,175 mmWidth 74.7 in 1,898 mmHeight at 0° 63.5 in 1,613 mmWeir height 39.8 inch 1011 mmWeight 6,200 lbs 2,812 kgScreen Deck and ScreensGross screen area Scalping deck 16.9 ft2 1.6 m2

Primary decks 33.9 ft2 3.1 m2

Net (API) surface area Scalping deck 10.6 ft2 1.0 m2

Primary decks 21.1 ft2 2.0 m2

Deck-adjustment system Scalping deck -1° to +3° Primary decks +3° to +7°

Vibratory Motion TypeNormal mode 6.5 GCapacity mode 7 GMotor SpecificationsVoltage 220-690 VACSpeed 1800RPM/60Hz; 1500RPM/50HzCertifications UL/cUL, CE, ATEX rated

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

51

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 6 of 17 SOLIDS CONTROL: MD-3 SHALE SHAKER 1 of 2

MD-3 Shale Shaker Applications ■ Primary solids removal from both oil- and water-base

drilling fluids ■ Flexible fluid distribution

Benefits ■ 7.2 G balanced elliptical motion in capacity mode,

6.3 G progressive elliptical motion in efficiency mode ■ Modular bolting provisions for installation allow flexible

shaker configurations ■ Composite screen technology increases effective open

area, improves process capacity, and maximizes screen life

Features ■ Pneumo-hydraulic controls mounted on front of shaker

for deck adjustment. Fluid is a water/low-toxicity antifreeze mixture

■ Pneumatic screen clamping system for durable pre-tensioned composite screens

■ Dual-deck design with full primary and half-width scalping decks

■ Adjusts instantly to changing drilling conditions ■ Lightweight screens (<15 lbs [6.8 kg])

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

52

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 7 of 17 SOLIDS CONTROL: MD-3 SHALE SHAKER 2 of 2

DescriptionThe MD-3† triple-deck shale shaker has a small footprint, effective solids-control options, and the ability to adapt quickly to changing drilling conditions, all in a compact, high-performance solution.

Movement of fluid and cuttings over all three of the unit’s decks maximizes use of the screen area for high-fluid capacity. The ability to adjust deck angles as conditions change is just one of many features that distinguish the MD-3 shale shaker.

SpecificationsDimensions (Parallel Mode)Length 103.2 in 2,621 mmWidth 77.4 in 1,967 mmHeight 67.7 in 1,720 mmWeight 6,450 lbs 2,926 kgDimensions (Series Mode)Length 113.5 in 2,882 mmWidth 77.4 in 1,967 mmHeight 67.7 in 1,720 mmWeight 6,780 lb (3,075 kgScreen Deck and ScreensGross screen area Scalping deck 25.4 ft2 2.4 m2

Primary decks 50.8 ft2 4.7 m2

Net (API) surface area Scalping deck 15.8 ft2 1.5 m2

Primary decks 31.7 ft2 2.9 m2

Deck-adjustment system Scalping deck +3° to -1° Primary decks +8° to +4°

Screen Deck and Screens (continued)Screen type Scalping deck Pre-tensioned composite Primary decks Pre-tensioned compositeScreen clamping Scalping deck Pneumatic Primary decks PneumaticVibrating basket Carbon steelMotor SpecificationsTwo vibrator motors 460V (220 to 690V available)

ATEX, CE, NORSOK and UL-ratedMotor weight (each) 550 lb 249 kg

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

53

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 8 of 17 CUTTINGS MANAGEMENT: CLEANCUT SYSTEM 1 of 2

CLEANCUT Cuttings Collection and Transport System

Applications ■ Safe and efficient drill-cuttings containment

and disposal, for compliance with offshore regulatory requirements

Benefits ■ Minimized crane lifts, improving offshore safety ■ Flexible installation to suit rig layout with small

equipment footprints ■ Environmental protection

Features ■ Fully enclosed and automated conveyance, requiring

minimum personnel involvement ■ Equipment specified to hazardous-zone classifications ■ Transfer of untreated cuttings at high rates ■ Can encompass the entire cuttings supply chain

CLEANCUT † ISO-pump.

CLEANCUT † cuttings blower (CCB M8).

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

54

TOC

DescriptionThe CLEANCUT cuttings collection and transport system from M-I SWACO gives operators a flexible solution for improving the safety and efficiency of drill-cuttings containment and disposal. The system captures the drill cuttings as they exit the shaker and keeps them contained in a sealed system all the way to final processing, using positive pressure pneumatic conveyance. The temporary bulk storage of drill cuttings provided by the CLEANCUT system protects drilling logistics from interruption by weather, allowing peak drill-cuttings volumes to be held for later processing while drilling continues. This flexibility can prevent expensive downtime on critical drilling operations.

The CLEANCUT technology has been extensively field proven in operations worldwide since 2000, adding flexibility and reliability

to operations including shipping cuttings to shore, inter-field transfer, slurrification and disposal, and thermal treatment offshore and onshore. The bulk transfer of drill cuttings from rig to supply boat, and from supply boat to final process location enables large volumes of drill cuttings to be handled safely offshore, eliminating the numerous, potentially risky crane lifts normally required.

The CLEANCUT system has two main components: ■ The CLEANCUT cuttings blower (CCB) is the primary conveyer

of cuttings from shakers into the system. ■ The ISO-pump unit is a combination storage vessel and conveying

device built within standard, 20 ft (6.1 m) ISO container dimensions. (ISO-pumps can be transported fully laden with cuttings by supply boat or truck to a discharge location).

SOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 9 of 17 CUTTINGS MANAGEMENT: CLEANCUT SYSTEM 2 of 2

Specifications CLEANCUT Cuttings Blower (CCB M8)GeneralWeight Empty 1.65 tons (1.5 tonnes) Full 2.5 tons (2.3 tonnes)Length 55.1 in (1,400 mm)Width 52 in (1,320 mm)Height 100.2 in (2,545 mm) including feed hopperWorking volume 1.4 bbl/8 ft3 (0.227 m3)Power 3-phase, 440V, 60 Hz, 10A supplyAir supply 116 psi 750 cfm, (8 bar 21 m3/min)

Specifications CLEANCUT ISO-PumpGeneralWeight Empty 6.6 tons (6 tonnes) Full 35.8 tons (32.5 tonnes)Length 96 in (2,438 mm)Width 102 in (2,591 mm)Height 238.5 in (6,059 mm)Working volume Approx. 95 bbl/530 ft3 (15 m3)Air supply 116 psi 750 cfm, (8 bar 21 m3/min)

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

55

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 10 of 17 FLUIDS PROCESSING: ATC LITE 1 of 2

AUTOMATIC TANK CLEANING LITE

Applications ■ Automated WBM/OBM/SBM/brine tank cleaning ■ Offshore rigs and supply boats

Benefits ■ Can eliminate (or greatly reduce) confined space entry

into tanks ■ Uses small quantity of water to clean tanks by constantly

recycling the wash water ■ Slop generated is less than 10% of the traditional tank

cleaning methods ■ Greatly reduces the time taken to clean tanks

Features ■ ATEX Zone 1 or UL certified water recycling system ■ Includes all necessary pumps to wash tanks ■ Programmable tank cleaning machines (TCMs)

strategically located inside tank ■ High-volume, low-pressure pumps deliver powerful jets

of water and surfactant via the TCMs in the tanks to break up sediment and wash all internal surfaces

■ Slop pumps return the slurrified sediment to the recycling unit to separate the solids and re-use the wash water

■ Approximately 6.5 m³ of wash water required to clean all tanks on rig

■ No heater required for wash water

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

56

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 11 of 17 FLUIDS PROCESSING: ATC LITE 2 of 2

DescriptionThe M-I SWACO AUTOMATIC TANK CLEANING (ATC) LITE system is designed to reduce cleaning time and personnel requirements. Developed for offshore drilling installations and supply boats, the ATC LITE system greatly reduces, and in some cases eliminates, the need for pit and tank entry.

This patented system cleans the pit without prevacuuming of the settled solids. It incorporates a full recycling system which separates out the solids on the fly, allowing the same small volume of wash water to be reused tank after tank. It eliminates or vastly reduces confined-space entry and can cut cleaning times by up to 80%.

Examples of Savings Using the M-I SWACO ATC LITE SystemWell 1 Well 2 Well 3 Well 4

Number of tanks cleaned 14 30 29 22Time saved (hours) 122 90 130 138Savings (USD) 32,000 25,600 38,400 38,400

SpecificationsGeneralMaterial Carbon steelStructural frame / sheet metal Carbon steelVoltage 400-690 V (other voltages available)Maximum powerconsumption

63 kW

Slop processing rate Maximum 44 m3/h (with expansion pack)Total cleaning water capacity 6,500 litersOperating temperature 0 degC to 40 degCAir consumption 200 l/min at 5-12 bar (400 l/min w/expansion pack)

Weight (dry) 5,390 kg (5,090 without expansion pack feed pump)

Dimensions L x W x H: 3,100 mm x 2,435 mm x 2,708 mm (h = 3,608 mm including handrails)

Lifting and handling Crane or fork lift (lift only when empty)Lifting approval No offshore lifting certification. (Unit designed

to industrial lifting standard)Other certificates Explosion proof: ATEX zone 1 or UL zone 1

(class 1 Div. 1)Maximum noise level 83dbExpansion pack (optional) Weight: 1,600 kg, dimensions

L x W x H: 1,850 mm x 1,200 mm x 1,950 mm lifting approval: DNV 2-7.1

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

57

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 12 of 17 PRESSURE CONTROL: SUPERCHOKE 1 of 2

SUPERCHOKE Drilling Choke

Applications ■ Multiple pressure-sensitive applications: well kicks, well

testing, and well clean-up operations ■ High-pressure pumping

Benefits ■ Delivers easy, precise, and reliable well pressure control

during transition operations ■ Equally effective when mud and gas are flowing

alternately through the choke ■ Designed and manufactured for H2S service

and abrasive fluid applications

Features ■ Full system redundancies ■ Dependable choke-disc design ■ Designed, manufactured, and monogrammed

in accordance with API 6A and 16C ■ High-pressure rating ■ Positive closure

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

58

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 13 of 17 PRESSURE CONTROL: SUPERCHOKE 2 of 2

DescriptionThe highly advanced 5K, 10K, and 15K SUPERCHOKE† drilling chokes are among the industry’s most widely used chokes, particularly for well kill and high-pressure applications. The SUPERCHOKE drilling choke delivers easy, precise, and reliable well pressure control during mud pump startup or shutdown.

Specificationspsi (bar) Length

in (mm)Width in (mm)

Height in (mm)

Weight lb (kg)

Temperature Rating degF (degC)

Pressure psi (bar)

10,000

(689)

35.7(906.8)

21.6(548.6)

11.5(292.1)

441(200)

-20 to 250(-29 to 121)

10,000(689)

15,000

(1,034)

43.3(1,099.8)

21.6(548.6)

11.5(292.1)

600(272)

-20 to 250(-29 to 121)

15,000(1,034)

20,000

(1,378)

43.4(1,102.4)

24.3(617.2)

13.2(335.3)

650(295)

-20 to 250(-29 to 121)

20,000(1,378)

Control Consoles

Single55(1,397)

27(686)

65(1,651)

588(267)

N/A N/A

Dual55(1,397)

27(686)

69(1,753)

690(313)

N/A N/A

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

59

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 14 of 17 PRESSURE CONTROL: AUTOCHOKE 1 of 2

AUTOCHOKE Drilling Choke

Applications ■ Provides automatic, precise pressure control

for pressure-intensive UBD and MPD applications ■ High-pressure pumping ■ Compliance

Benefits ■ Delivers precise, reliable pressure control ■ Maintains casing pressure ■ Simplifies predictable casing and drill pipe ■ Reduces effects of abrasive solids ■ Eliminates leakage

Features ■ Highly responsive control consoles and controls easily

during transition periods ■ Provides effective control in wide temperature

and pressure ranges ■ Helps manage ECD ■ Frac plug drillout operation ■ Allows ‘hot swapping’ of actuators

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

60

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 15 of 17 PRESSURE CONTROL: AUTOCHOKE 2 of 2

DescriptionThe AUTOCHOKE† drilling choke is the cornerstone of the M-I SWACO portfolio and continues to set the standard for high-pressure drilling chokes. The 3K, 10K, and 15K AUTOCHOKE units provide automatic, precise pressure control and incorporate the best choke technology available for pressure-intensive UBD and MPD applications. This pace-setting choke automatically regulates casing pressure under all conditions, including regulating mud pump startup or shutdown, and making and breaking drillpipe

connections. It is highly effective in H2S and abrasive-fluid applications. With its capacity to automatically maintain casing pressure, the AUTOCHOKE drilling choke makes stripping pipe simpler and safer.

Specificationspsi (bar) Length

in (mm)Width in (mm)

Height in (mm)

Weight lb (kg)

Temperature Rating degF (degC)

Bore Size in (mm)

Pressure psi (bar)

API inlet flange in (mm)

API outlet flange in (mm)

10,000

(689)

41.51(1054.3)

11.50(292.1)

16.31(414.3)

580(263)

-20 to 250(-29 to 121)

3(76)

10,000(689)

3.06 (78) x 10,000 psi (689 bar)

3.06 (78) x 10,000 psi (689 bar)

15,000

(1,034)

44.26(1,124.2)

12.50(317.5)

19.75(501.7)

700(317.5)

-20 to 250(-29 to 121)

3(76)

15,000(1,034)

3 √15 (77.8) x 15,000 psi (1,034 bar)

3 √15 (77.8) x 15,000 psi (1,034 bar)

Control Consoles

10,000

(689)

24(610)

26(660)

55(1,397)

655(298)

N/A N/A N/A N/A N/A

15,000

(1,034)

35(889)

28.5(724)

55(1,448)

730(332)

N/A N/A N/A N/A N/A

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

61

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 16 of 17 PRESSURE CONTROL: VERSA-CHOKE 1 of 2

VERSA-CHOKE Drilling Choke

Applications ■ Advanced well-control applications, requiring large trim

with high pressure and temperature ratings

Benefits ■ Ease of maintenance: actuators can be replaced

by disassembling internal components ■ Designed, manufactured, and monogrammed

in accordance with API 6A and 16C ■ Modular design and components allow configuration

to be customized ■ Multiple advanced pressure control for pressure-

sensitive applications

Features ■ Precise position-based control system with worm-gear

hydraulic actuator and piston-style hydraulic actuator ■ High temperature rating: P-X -20 degF to 350 degF

(-29 degC to 177 degC) ■ High pressure rating: 5K, 10K, and 15K ■ Quick-change internal components

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

62

TOCSOLIDS CONTROL, CUTTINGS MANAGEMENT, FLUIDS PROCESSING AND PRESSURE CONTROL: 17 of 17 PRESSURE CONTROL: VERSA-CHOKE 2 of 2

DescriptionThe M-I SWACO 15K VERSA-CHOKE† drilling choke is engineered for advanced well-control applications, requiring large trim with high pressure and temperature ratings.

The highly flexible VERSA-CHOKE drilling choke is ideally suited for high-end pressure management, managed pressure drilling, underbalanced drilling, frac plug drillouts, and frac flowback.

Cementing Solids Control, Cuttings Management, Fluids Processing and Pressure Control Wireline Logging Well Testing Surface and Mud Logging Drilling Tools,

Tubulars & Inspection

63

TOCWIRELINE LOGGING: 1 of 7 INTRODUCTION

Wireline LoggingSchlumberger offers in-house designed, best-in-class, integrated deepwater and ultradeepwater wireline conveyance solutions. The brochure presents

■ high-tension offshore units