Nuclear Manufacturing Outreach - Nuclear Energy...

Transcript of Nuclear Manufacturing Outreach - Nuclear Energy...

Opening and Logistics

Carol BerriganSenior Director, Industry Infrastructure

Nuclear Energy Institute

Anthony F. Earley, Jr. Chairman and Chief Executive Officer

DTE Energy

Remarks before the Nuclear Energy Institute Nuclear Manufacturing Outreach Workshop

Cleveland, Ohio April 14, 2008

Good morning. Sometimes timing in life is everything. Being at the right place, at the right time can mean tremendous opportunities. Ladies and gentlemen, you are at the right place, at the right time and my objective today is to prove that to you. Today our nation faces a dual challenge -- keeping the lights on and our air clean. Every year that we don’t start building new baseload power plants is one year closer to a power crisis. Reserve margins in every part of the country are shrinking. At the same time, the call for action on Climate Change has risen to a clamor. Faced with these two trends, the inescapable conclusion is we need more nuclear plants. I believe we’re at the dawn of a nuclear renaissance. I’m guessing you feel that way too, and that’s why you’re here. The next several decades should be a period of some risk and yet great opportunity for nuclear suppliers. Today I’d like to talk about the resurgence of nuclear energy – why it’s happening, what it means to our nation’s future, and what it means to you as suppliers or potential suppliers to this growing industry. It wasn’t too many years ago I was predicting that no new nuclear power plants would be built in the U.S. in my working lifetime. While I believed most plants would have their licenses renewed, I was fairly certain that new nuclear power plants were just not in the cards. Boy, how quickly things change! Today it’s clear that I was dead wrong in my prediction. Despite the condition of our economy, within the next decade, our nation will need more electricity . . . a lot more. And pollution-free nuclear power has to be an important part of the mix. Seven in ten Americans now favor nuclear energy to produce electricity, according to a recent NEI sponsored poll. The good news for those of you in this room is that as demand grows for electricity, so should nuclear energy’s stake in our nation’s fuel mix … and so should your role in expanding the nuclear infrastructure. It’s a great time to be in this industry!

2

Today about half of our nation’s electricity is generated by coal. Nuclear power represents about 20 percent, and natural gas represents about 20 percent. The remainder is generated by oil, hydro-electric and other renewables. A report by the North American Electric Reliability Council warns that U.S. demand for electricity is increasing three times as fast as resources are being added to our electric grid. The U.S. Energy Information Administration predicts that by 2030, electricity sales in our country will increase by 40 percent. Just to keep our current fuel mix, we’ll need 50 additional nuclear plants, 93 wind farms (with thousands of windmills), 279 natural gas plants and 261 new coal plants. So when you hear environmentalist call for meeting our energy needs with renewables, or coal interests saying we are the Saudi Arabia of coal and we can do it all with coal, you can tell them they are nuts. We need them all. We have to start an all out infrastructure renewal program in this country and nuclear energy must play a prominent role. I’ve witnessed tremendous change in the nuclear industry since I began my career. My experience dates back 37 years when I became a commissioned officer on a nuclear submarine. Later, I left the Navy for a career in a large law firm where I worked on licensing proceedings for nuclear plants. That led to a position at Long Island Lighting Company where I was introduced to the bare-knuckles politics of nuclear licensing proceedings. When I moved to DTE Energy in 1994, our electric utility had just recovered from the overwhelming stress associated with building the Fermi 2 nuclear plant. It was with that background that I started predicting I’d never see a new nuclear plant built in the U.S. in my working lifetime. I am thrilled to admit now that I was sorely mistaken. After almost 20 years without construction of a single new nuclear power plant, today there are plans pending to build more than 30 new reactors across the country. Utilities have already spent more than $2 billion in the planning stages. We expect four to eight new U.S. nuclear plants in operation in the second half of the next decade. And if those first plants stay on schedule and within budget -- and if they avoid licensing difficulties -- a second wave of plants could be well underway as this first wave reaches commercial operation. What’s prompting this turnaround?

3

I’ve already mentioned the growing need for large-scale baseload electric generation. If we don’t start soon, the California energy crisis will seem like a minor inconvenience. The increased volatility of natural gas prices and limited supply also has played a role. While 95% of all new power plants built in the last decade have been gas fired, at today’s prices, natural gas-fired power is not a cost-effective option. Nuclear power is produced at a stable price without the punishing volatility of gas-fired generation. One of the great ironies of the energy scene is that my electric utility, Detroit Edison, and others around the country were criticized for “cost overruns” on the last generation of nuclear plants. People were shocked by the $4-5 billion price tags. But today, those plants produce the cheapest electricity on our systems. Growing environmental concern is another major factor causing the public to take a second look at nuclear energy. With mounting questions about the negative impact of carbon emissions and greenhouse gases, nuclear power is an attractive alternative to fossil-fuel generation. In fact, the U.S. Department of Energy says that the single most effective emission control strategy for utilities has been to increase nuclear power production. Nuclear plants emit no carbon dioxide which creates greenhouses gases. They emit no sulfur dioxide which produces acid rain. And they emit no nitrogen oxide. That means no ozone. And with climate legislation looming on the horizon, nuclear energy has become an even more attractive option. The superb performance of our nation’s 104 operating nuclear plants is another reason nuclear energy is building momentum. Nuclear power provides low-cost electricity at extremely high levels of safety and reliability. In 2007, the U.S. fleet of nuclear plants operated at almost 92 percent capacity – the highest level ever. Just as a side note, wind turbines, at best, hit 30% and are in the high teens in the hot summer months. Nuclear total output in ‘07 was at an all-time high, too, while production costs reached a record low. These levels of electricity production and efficiency couldn’t be sustained if our facilities weren’t operating at superior levels of safety. Nuclear power has proven itself safe, clean, reliable and affordable. And that’s with a generation of plants designed in the 1960s and 1970s. Today’s advanced designs are much improved. The Nuclear Regulatory Commission has already certified new standardized advanced-plant designs for

4

the U.S. that incorporate features to make them simpler, safer, and less costly to build and operate. Most of America’s existing nuclear power plants are virtually one-of-a-kind, because they were designed and built at a time when regulatory requirements, licensing standards and the technology were evolving rapidly. But over time, we’ve learned that customized designs can create inefficiencies, duplication of effort and higher costs. As a result, our nation is moving toward greater standardization for new nuclear plants.

Standardization means that new U.S. reactors will be built in families of the same design, except for a limited number of site-specific differences. New nuclear power plant designs have less cable and far fewer valves than today’s operating power reactors. The new control systems are simpler, more compact, and easier to operate – which makes them safer and cuts construction time. In addition, display panels and controls have been completely redesigned.

Another area that we hope is streamlined is the new building cycle. The timeline for new plants -- from construction application to commercial operation – will take around 10 years. Under the new process a number of activities will be conducted concurrently rather than consecutively. For instance, when the Nuclear Regulatory Commission is reviewing the construction/operating license application, companies will be ordering long-lead items, preparing the site and arranging financing. So theory about a Nuclear Renaissance is great – what about the reality? My company, DTE Energy, needs a new baseload plant sometime around 2020. We looked at all the alternatives and decided nuclear energy is the best alternative. So my company has already started the long licensing application process, and under the right regulatory conditions, we’ll invest billions of dollars on an additional nuclear unit at our existing Fermi 2 site near Monroe, Michigan. Right now we’re preparing a combined license agreement and compiling lists of potential vendors. This first step will take between 18-24 months and will result in an application some 20,000-pages long – and that’s under the simplified process! Once we file our application later this year, the Nuclear Regulatory Commission says the license review could take up to 42 months. Under this timetable, we’d get approval to build in 2012. Then, when we decide to start construction, it will take an additional 5-6 years to complete the project. Because of these long lead times, we have started the process now, even though we won’t commit to the new construction until the regulatory structure Michigan changes.

5

One of the challenges we’ll face is sourcing the parts we’ll need. Global competition is already heating up for the limited material and manpower currently available. That’s because overseas, the nuclear construction boom is well underway. Currently, 30 countries worldwide are operating 442 nuclear reactors for electricity generation.

An additional 35 new nuclear plants are under construction worldwide, including seven in Russia, six in India and six in China. France is the largest user of nuclear power as a percentage of its total demand. Its 59 nuclear plants generate more than 78 percent of the country’s electricity.

The growth of the nuclear industry will compete with other industrial projects worldwide. This global competition for scarce resources will increase costs and extend lead times. Commodity pricing will escalate for steel, copper and other materials. Price volatility will make it difficult to commit to long-term contracts. Suppliers will need to be creative in mitigating these risks. Hedging will be key. So will building alliances with established suppliers for guidance and a foot in the door. Additional capacity will be required for a range of products from very small components to ultra-heavy steel forgings and castings. The opportunities in supply chain will be huge. Today, forgings, particularly the ultra-heavy ones used to fabricate reactor pressure vessels, are a constraint. That’s because only one Japanese supplier has the capacity to make these 350-ton-plus parts. I’m encouraged to see you and other companies taking the first steps toward rebuilding U.S. capability for nuclear-grade component manufacturing. We need that. Some are also upgrading quality assurance programs and working toward “N-stamp” certification by the American Society of Mechanical Engineers. This certification, of course, qualifies manufacturers to produce nuclear-grade components and equipment, and to perform nuclear-grade construction. In the mid-80s, there were more than 400 N-stamp holders globally. Today there are probably 100. There’s no doubt, we need more suppliers. Just to get the first eight nuclear plants on line will require an estimated 320,000 fasteners, over 3 million cubic feet of concrete, and 1,800 miles of control and power cable. Not to mention steel, electrical components, pumps, piping and more. Another challenge will be hiring the highly-skilled construction workers needed to build nuclear units. At the peak of construction, a nuclear plant will employ an estimated 2,300 skilled workers. And upon completion, approximately 700 skilled

6

workers will be required to operate and maintain the plant – at wages 40 percent above those for workers in similar jobs at non-nuclear facilities. Qualified boilermakers, pipefitters, electricians, and ironworkers are expected to be in short supply in local labor markets. Our industry is working with the federal government, state governments, universities and community colleges, high schools, labor unions, and others to expand this workforce pool. We’re looking for skilled trades workers with the most current knowledge on the next generation of tools and technical advances in the building and construction industry. Safety is vital to us, as is the continuation of a drug-free workplace. The fight for talent will be challenging. America and nations around the world are contemplating nuclear power’s role in their future … and it will be considerable. I was going to tell you that a nuclear renaissance is coming ... but that would be wrong. A nuclear renaissance is here. I’m spending real money today on things nuclear. This sentiment about a nuclear revival is shared by a diverse mix of people from environmentalists and scientists … to the media and politicians from both sides of the table … to progressive think tanks, businesses and homemakers. All are reaching the same conclusion: nuclear energy will play a crucial role in meeting our country’s growing electricity needs and in addressing global climate change. Those of you in this room have the opportunity to participate in the early stages of this nuclear energy resurgence while providing solid solutions for concerns about the environment, energy reliability and energy costs. This is an exciting new chapter for our industry. I hope you agree with my original assertion that you are at the right place at the right time.

New Nuclear PlantsGlobal Status (Jan 2008)

• 35 plants under construction ~ 28 GW• 93 plants on order or planned in 18 countries

– Expected to be in operation -- 2017• 200 projects under consideration in 27 countries

– Statement of intent/proposal• Media reports US Navy production expansion to

two Virginia class submarines per year in 2012– Reactor equipment orders in 2010– Additional equipment orders for nuclear aircraft

carriers periodically

Source WNA Jan 2008

Short-Term

2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017

COL review

Order long-lead items

Construction

Site preparation

Arrange financing

COL Approval

Load fuel

COL submitted

Start-up testing (4-6 months)

Commercial operation

Pre-COL construction

General procurement

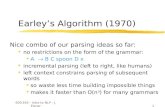

Licensing & Construction Then and Now

Plant designed before construction beginsDesign as you build

More opportunities to intervene at well-defined points in process. Intervention at the end of the process must be based on objective evidence that acceptance criteria, defined in the license, have not been, and will not be met

Main opportunity public intervention when plant is essentially complete

Lessons learned from overseas projectsModular construction practices

Inefficient construction practices

Standard NRC-certified designs – 70+% StandardNo design standardization

More stable process: NRC approves site, design, construction & operation before construction begins and significant capital is placed “at risk”

Changing regulatorystandards and requirements

NOWTHEN

US Commercial Outlook to 2020

• First 4 – 8 plants expected to start commercial operations in 2016– Others under construction– Building rate and projects adjusted based on

the success of the first few projects

• Potential for new plants – 15 - 20 in 2020; 35+ in 2030– If first projects are successful

Equipment & Commodities for First Eight Plants (Examples)

• Cable – over 1800 miles• Nuclear grade valves -- Over 11,000 • Pumps -- 1400 to 2200 • Nuclear grade piping – 30 – 150 miles• Concrete – over 3 million cubic yds• Electrical components -- Over 700,000• Structural & reinforcing steel -- 500,000 tons

approx.• Large and small heat exchangers -- 500 to 1300 • Fasteners -- 320,000

Support for New Nuclear & Expanded US Manufacturing Base• Bipartisan political support• Strong public support• Solid support from labor• Strong support from other industries• Growing support from environmental

community– Increasing concern about carbon emissions

The Future

• New nuclear power plants will be built– Need for power, environmental limitations and

need for long-term stability in electricity prices

• Strong policymaker support– High potential for incentives for US

manufacturing sector

• Opportunity is there -- will US-based manufacturers be able to take advantage?

What Does a Nuclear Project

Look Like?Nuclear New Builds Team USA

Sig BergSenior Vice President Industry

Infrastructure UniStar Nuclear Energy

UniStar Nuclear Energy (UNE)• UNE is a 50/50 joint venture between

Constellation Energy and EDF

• UNE intends to develop and build a fleet of four new nuclear power plants in North America based on the AREVA design (US EPR)

• UNE’s Calvert Cliffs 3 (MD) will be the first US EPR

UniStar Partners

Flamanville 3EPR

Nine Mile 3U.S. EPR

Calvert Cliffs 3U.S. EPR

Bell Bend 1U.S. EPR

Callaway 2U.S. EPR

UniStar Nuclear: Fleet Benefits of a Standardized Design

+ + =+• Engineering (initial and operating)

• Licensing (COL and operating)

• Construction productivity

• Operator training & Maintenance task training (specialized crews)

• Shared resources during Refueling Outages

• Work practices & procedures

• Reduced/common spare parts

• Information systems

“New Nuclear U.S.” – Why such a challenge now?

• Lack of U.S. nuclear infrastructure – Manufacturing, craft labor, services

• Untested licensing process– Two-Step process should resolve many issues

• “Last time” knowledge / experience from nuclear construction is in “fast fade”– Minimize risk

• Global competition for resources

The Participants

• The Owner(s)

• Original Equipment Manufacturer (OEM)

• The Contractors

• The Qualified Equip/Material Suppliers

• The Regulators

• The Public

A Successful Nuclear Project

• An Effective Plan:– A Detailed Scope of Work

– A Detailed List of Required Equipment and Materials

– An Integrated Project Schedule

– High Quality – Do right the first time!

– On Cost, On Schedule

Project Estimation: A Sample

• Browns Ferry 1:–1,800,000 feet of cable

–10,000 instruments

–53,000 feet of small bore pipe

–33,000 feet of large bore pipe

–243,000 feet of conduit

–12,000 feet of cable tray

–238,000 electrical terminations

Lessons Learned From Several Projects

• Allow Ample Time For Project Contracting • Consider All Economic Ordering Options• Supplier Partnerships Can Benefit

Everyone• Increased Supplier Surveillance For Critical

Items• Conduct An In-depth Labor Assessment

What You Can Do

• Understand Your Capabilities—And Make Sure Others Know

• Engage Active Nuclear Supply Chain Groups, Owners, and Prime Contractors

• Expand Your Capabilities

• Don’t Wait Too Long

The Opportunity Before Us

• A Generation of New Nuclear Generation

• Growth of U.S. Infrastructure

• The Right Solution to Baseload Power Needs—Clean Air Energy.

Purpose of Presentation

• Regulatory environment • Quality assurance role • Basic QA requirements • Component classifications and vendor types• Quality assurance requirements for vendors • Next steps and where do you go for help

Regulatory Environment

• The NRC Commissioners set policy, direction, and approve new regulations.

• Code of Federal Regulations contain requirements that must be met (10CFR 50 Appendix B).

• The nuclear industry operates in a regulated environment.

• The Nuclear Regulatory Commission (NRC) provides regulatory oversight of the nuclear industry.

Regulatory Environment (cont)

• NRC– Washington office approves license

amendments, applications, etc.– Regional inspectors perform site inspections.– Resident inspectors on current operating sites

to provide continuous inspection oversight. – Plans to have at least five full time resident

inspectors at each new nuclear site.

Regulatory Environment (cont.)

• Licensee– NRC rules and requirements for almost all activities– NRC provides continuous oversight – NRC may impose fines or penalties for rule violations

• Engineering, Procurement, and Construction (EPC) vendors – required to follow rules per procurement contracts

with Licensees.• Reactor designers

– required to follow rules per procurement contracts with Licensees.

Quality Assurance Role

• Utilities have their own internal Quality Assurance (QA) inspectors/auditors.

• QA inspectors conduct audits and surveillance to ensure the utility is following the rules and requirements.

• The QA organization is independent of the line organization to ensure no conflict of interest.

Customer Requirements and Vendor Categories

• Customer provides requirements in purchase order

• Vendors are related to the classification of the Systems, Structures and Components (SSC) provided.– Safety Related– Non-Safety Related.

Component Categories

• Safety Related– ASME– Commercial Grade Item Dedication

• Non-Safety Related – Supplemented Quality Requirements

• Non-Safety-Related, Significant Contributor to Plant Safety• Non-Safety-Related, Radioactive Waste• Non-Safety-Related, Credited for Regulated Events

(Augmented Quality)

– Commercial

Safety Related Definition

Safety-related (10 CFR Part 50.2) • This term applies to structures, systems, components,

procedures, and controls of a facility or process that are relied upon to remain functional during and following design basis events to assure:– (1) The integrity of the reactor coolant pressure boundary– (2) The capability to shut down the reactor and maintain it in

a safe shutdown condition; or– (3) The capability to prevent or mitigate the consequences of

accidents which could result in potential significant offsite exposures.

Typical Examples and Requirements

• Safety Related (NRC Reg. Guide 1.26)– Reactor Vessel, Pressurizer, Primary Piping,

– Class 1E emergency ac power (Emergency Diesel Generator)

– Seismic Design Class I

• Non Safety Related – Turbine

– Condenser Cooling Water

– Lighting

Typical Examples and Requirements

• Non-Safety-Related, Significant Contributor to Plant Safety ( NRC SECY 95-132)– Associated with passive plant design:

• Chemical and volume control system• Normal residual heat removal system• Backup feedwater system.

• Non-Safety-Related, Radioactive Waste (NRC Reg. Guide 1.143)– Liquid Radioactive Waste System– Gaseous Radioactive Waste System– Solid Radioactive Waste System

Typical Examples and Requirements

• Non-Safety-Related, Credited for Regulated Events (Augmented Quality) ( NUREG 0800-SRP-17.5)– Fire Protection ( 10 CFR 50.48) (NRC Reg. Guide 1.189)

• Fire water pumps, fire main piping system, fire detection

– ATWS (Anticipated transients w/o SCRAM) (10 CFR 50.62) (NRC Generic Ltr. 85-06)

• BWR: Alternate Rod Injection (ARI), Standby liquid control system (SLCS)• PWR: Sensor output to final actuation device,• Diverse SCRAM system

– SBO (Station Blackout) (10 CFR 50.63) (NRC Reg. Guide 1.155)• Alternate Battery Systems, Alternative off-site AC power sources

Typical Examples and Requirements

• ASME (10 CFR 50.55a)– S/R Vessels and Piping (NCA-4000)– Material Supplier (NCA-3800 or 3900)

• Commercial – Commercial Grade Item (10CFR Part 21)

• Not design or manufactured as a basic component– Basic Component-designed and manufactured under a

nuclear QA program

Quality Assurance Program Requirements

• Requirements flow down from COL applicant through vendors and sub vendors– 10 CFR Part 21– 10 CFR Part 50.55e– QA Requirements as specified in Purchase

document

QA Program

• Written QA program that covers 10 CFR Part 50, Appendix B and NQA-1-1994.

• Criterion IV to Part 50 and Requirement 4 NQA-1

– Part 50 requirement

• To the extent necessary procurement documents shall require suppliers to have a quality assurance program consistent with the applicable requirements of this appendix

– NQA-1

• similar wording

• Vendors exist that can help with development of QA Programs

DOE/DOD/NRC Differences

• DOE/DOD requirements are different than NRC requirements.

• DOE and nuclear industry uses NQA-1• NRC Requires a Program that implements

10CFR50 Appendix B

Auditing

• Owner– Supplier-Triennial Audits, perform audits themselves or use NUPIC– Internal-Annual or once during the activity being performed – Right of Access– Surveillance

• NUPIC (Nuclear Procurement Issues Committee)– Audit performed by owner under NUPIC agreement that allows multiple

owners to utilize audit results.– NUPIC performs audit based on vendors being placed on the approved

supplier list.

• NIAC (Nuclear Industry Assessment Committee)– Similar to NUPIC but allows suppliers to audit sub suppliers and utilize for

multiple suppliers.

Impact of Nuclear QA

on Suppliers

Jeff KikelManager, Welding Engineering

Nuclear Operations GroupThe Babcock & Wilcox Company

1

NEI Manufacturing Outreach Workshop Columbia, SC. March 27, 2008

Good morning. I would like to thank the Nuclear Energy Institute for providing me the opportunity to share with you some insights on the impact of commercial nuclear quality assurance on suppliers of nuclear components, materials and services. My presentation will focus on discussing what is required to supply nuclear qualified, safety related components. Some aspects of my discussion are equally applicable for components or materials that are considered balance-of- the-plant.

I am employed by Babcock & Wilcox Nuclear Operations Group, Inc., a wholly owned subsidiary of The Babcock & Wilcox Companies. The Babcock & Wilcox Company, also known as B&W, was formed in 1867 by Stephen Wilcox and George Babcock. Eleven years earlier, in 1856, Stephen Wilcox patented the water tube boiler. This invention provided for the rapid development of a commercial supply of electricity and was a major factor in the industrial revolution. Ever since the early days, B&W has been a leader in the design and manufacture of power generation equipment. In the 1940’s the Company participated in research projects aimed at developing viable nuclear power systems for naval applications and in the 1950’s participated in the design and manufacture of the power system for the world’s first nuclear powered submarine, the USS Nautilus. In 1956 the Company designed and built the first privately licensed commercial Critical Experiment Laboratory and began operations at the Lynchburg Research Center, the first privately financed US nuclear facility. In 1962 we designed and furnished reactor systems for the first commercial reactor using Highly Enriched Uranium 233. B&W was a major supplier of reactor equipment and steam generators from the 1960’s and into the 1980’s when a substantial portion of today’s North American commercial nuclear power generation capacity was developed. Today the Company serves a broad spectrum of energy related markets and continues our 50 plus year record as a premier designer and manufacturer of heavy equipment and fuel for nuclear systems. Notably, B&W is the only North American company to continuously manufacture nuclear steam generators for the industry since the 1950s. B&W has supplied the nuclear industry with over 1,300 large, heavy‐walled vessels worldwide. With dedicated manufacturing operations in the U.S. and Canada, B&W has the skills, knowledge base and infrastructure for fabricating pressure vessels, reactors, steam generators, heat exchangers, drive mechanisms, and other auxiliary equipment. Though many nuclear businesses lost their manufacturing proficiency as a result of the decline in the commercial nuclear market, B&W kept its sites operational by strategically using its capabilities to develop products for the government as well as other customers.

Our long history allows us to share with you a solid perspective of how to successfully operate in an industry that requires a high level of discipline in all related activities. The design, manufacture, construction and operation of commercial nuclear power plants are highly regulated activities. Properly executed, these activities provide a highly reliable, safe, clean and affordable source of commercial power. Properly managed these can also

2

provide substantial financial returns for those that choose to participate. Properly led, society as a whole will benefit.

In order to qualify as an “N” stamp supplier of equipment and services to the commercial nuclear market requires implementation of a quality assurance program that meets the requirements of ASME Section III, Subsection NCA, Article NCA‐4000 and NQA‐1. Additionally, NRC 10 CFR Part 50 Appendix B provides the regulatory framework for quality assurance for the licensing of production and utilization of nuclear facilities and any components, equipment, materials, or other goods or services, that relate to a licensee's or applicant's activities . The NRC endorses NQA‐1‐1983 in regulatory guide 1.28. NQA‐1 is the only US standard specifically developed for commercial nuclear quality assurance. The standard reflects industry experience and the current understanding of the quality assurance requirements necessary to achieve safe, reliable and efficient use of nuclear power. NQA‐1 covers eighteen specific quality assurance requirements including items such as design control, control of purchased items and control of special processes, inspection, quality assurance records and audits.

These standards are focused on meeting the overall requirements necessary to ensure the safe use of nuclear power and as a result substantially increase the burden on nuclear suppliers as compared to generic quality assurance standards such as ISO 9001. In a November 2002 letter to the NRC, ASME provided its perspective on the use of ISO 9001 as a replacement to the 10 CFR Part 50 Appendix B and NQA‐1 requirements. ASME cautioned that although ISO 9001 may be initially appealing, ISO 9001 is a management or process standard and not a safety related standard. Requirements in NQA‐1 are more definitive than ISO 9001 in areas such as design controls, independence of design verification, software controls, configuration control, audits and training, qualification and evaluation of personnel.

No other industry is more scrutinized or contested by the public than nuclear power. In Joseph Rees’s book titled “Hostages of Each Other, the Transformation of Nuclear Safety since Three Mile Island” the Institute of Nuclear Power Operations’ board of directors chairman was quoted as stating “Each licensee is a hostage of every other licensee”. In the US a single catastrophic failure at any nuclear power plant would destroy the entire nuclear industry and undermine any public support of nuclear power. We have all read newspaper accounts of nuclear facilities where lapses in values have resulted in potential equipment or system failures, and each of these events resulted in an increase in the negative perception by the public, not to mention the risk of a significant nuclear accident. As a nuclear supplier, quality and compliance to requirements cannot be comprised.

In making a decision about participating as a nuclear supplier one must first fully recognize the significance of the responsibility that must be accepted and the potential consequences of failure to properly execute, manage and lead. Seemingly minor failures can ultimately lead to dire consequences with devastating potential. The primary mission of those

3

engaged in this industry must be to safeguard the public, the environment, the national security, the international relations, the employees and the investors alike. Such a responsibility suggests that only those truly committed to excellence should apply.

Proper execution and management of all activities depend first and foremost on leadership. Although leadership can be described or defined in many different ways, effective leadership results in an organization which reflects the values and commitment of its leaders. Leadership establishes the principles under which the organization will behave. Leadership determines the minimum standards which will be accepted by the organization. Leadership establishes the clarity of the direction in which the organization will move and the pace at which it will travel.

In the commercial nuclear industry effective leadership is essential to assure that the mission is always known, understood, embraced and accomplished. Our experience suggests that there are number of essential characteristics that effective leaders must possess in this business. Their behavior will always demonstrate ownership and personal accountability. Their behavior will further demonstrate that:

They do what is right even when it hurts; they place the success of the mission ahead of personal, financial or other goals.

They passionately pursue, promote and expect continuous improvement and a relentless pursuit of excellence of their operations.

They recognize that humans are fallible and even the best err; they promote organizational structures, systems, procedures and behavior that defend against error and minimize the effects of error.

They value diversity of thought and welcome dissenting opinions as they seek to understand the basis and what is meant not just what is said.

They encourage identification of organizational and system weaknesses and promote the reporting of non conformance.

They nurture a culture that is open to oversight and critique recognizing that this is a key element in the pursuit of excellence.

They devote resources necessary to assure that specification requirements are known and understood.

They place high value on training and development and recognize that the success of the organization and the accomplishment of the mission is a function of the education, experience, talent and dedication of the individuals involved.

They are intolerant of behavioral choices that do not comply with these requirements.

4

They do not tolerate normalization of deviation and act to ensure that complacency does not take root.

And finally, they exhibit and demand the highest level of integrity in word and action.

In a moment I will move on to some more tangible aspects of operating in the commercial nuclear environment. Before I do however I want to acknowledge that the leadership characteristics that I have discussed are ones that most would agree should be common tenets of leadership regardless of the mission. However, most individual and organizational failures do not rise to the same level of potential consequence. If one chooses to participate in the nuclear arena, one must be fully prepared to provide this type of leadership; anything less is to ignore the mission.

Now, I would like to provide you with some specifics needed to effectively operate in the commercial nuclear industry. The first area I would like to discuss in more detail is the infrastructure needed to support a commercial nuclear quality assurance program.

The quality assurance organization which supports the construction of commercial nuclear products must be independent from, and have equal authority to the design and manufacturing organizations. A nuclear industry quality system is driven by the Quality Manual which defines the delineation of roles and responsibilities at the highest levels of the organization. The Quality Manual is a requirement of the ASME Code and converts the Code and NQA‐1 requirements into your organization’s quality system. The Quality Manual requires approval by an independent authorized nuclear inspection agency, such as Hartford Steam Boiler. Once the Quality Manual is in place, the high level roles and responsibilities must be further broken down into policies, procedures, and work instructions that direct and control the day‐to‐day activities required to design, manufacture, inspect, and ship components.

A strong and well‐constructed quality system will not succeed without developing a culture that consciously designs and manufactures your product with quality at the forefront of all activities and decisions. Simply having a quality control department that inspects and tests product features will not achieve the quality levels demanded by the commercial nuclear industry. The quality focus must be integrated into all activities every minute of every day. A quality conscious culture must also encourage and accept a questioning attitude and open communication throughout your organization. Each of your employees must feel they can speak up with a dissenting view, quality concern or error without fearing reprisal.

5

A commercial nuclear based quality system must establish strong controls to meet the stringent requirements for document development, document control, and retention of documents and records. The document control system must address both the generation of the original document and the control of subsequent revision of the documents to design, manufacture, inspect, and test your product. Traceability of a specific activity to a specific revision level of documents is paramount to a successful quality system. Detailed record keeping and configuration management are fundamental to the successful operation of your business. Quality records document nearly all phases of production including the design, material procurement, fabrication and testing. Without proper certification, a piece of material is rendered useless. Detailed fabrication travelers follow each production component and document signoffs at each stage of the production and inspection phase. All testing operations require test plans and test reports. A major component can easily generate in excess of 10,000 pages of quality records. Additionally, a records retention system must be established to retain the records as required by contract. Some typical documents requiring such controls are the Code Design Data package, procurement documents, manufacturing documents and records, and inspection and test results.

When product deviations or deficiencies occur, the quality system has to be structured to thoroughly evaluate and document the impact of the deficiency as well as capture and disseminate lessons learned from the deficiency. Commercial nuclear quality systems require technical evaluation of the deviated condition, identification of cause and corrective action for the condition, and preventive actions to avoid future recurrence of the condition. Follow up actions to determine the effectiveness of corrective actions are also a key element of the quality system. Trending of deficiencies along with cause and corrective action data becomes a tool for your continuous improvement program.

The commercial nuclear industry imposes stringent requirements for the qualification of personnel performing inspection and testing activities. For example, to qualify as a level II radiographer requires upwards of 600 hours of documented experience over three years in addition to minimum training requirements and qualification testing. Not only must your personnel be qualified to strict industry standards, but maintenance and possible requalification of those personnel are also required. The maintenance of personnel qualifications can be demonstrated by performing the qualified inspection or test during a defined time frame or requalification is required. Level 3 Examiners must be developed to administer the qualification of Level 1 and Level 2 personnel. The Examiner also has duties to perform periodic overchecks of the Level 1 and Level 2 qualified personnel. The number

6

of available people with commercial nuclear NDE experience is limited which may require you to sublet some or all of your NDE until documented experience is obtained by your employees. Similar to personnel qualification, a formal gage management system is needed to manage calibration and usage of gages and tools used for acceptance inspections and tests.

In his book Quality Without Tears, Phil Crosby postulates that “quality is free” and zero defects are achievable. While this philosophy is true, the quality system to support commercial nuclear design and construction is NOT free. The staffing level and infrastructure for a nuclear industry quality system must be larger in number, well‐trained, and more technically qualified than a comparable quality assurance organization for a non‐nuclear facility.

The second area I will discuss with you in more detail is the human resources side of your organization. Even with a commercial nuclear quality system, your ultimate success in the commercial nuclear market will come down to the people in your organization and their willingness to embrace and implement the changes I am outlining to you today.

As most companies are acutely aware, skilled craftsmen and engineering professionals are becoming harder to find and it is expected that this shortage will worsen as the baby boom generation starts to retire in large numbers. Retaining your current employees will become a challenge as companies start competing for the available talent. Probably the most significant challenge you will face is staffing your company to support your nuclear quality assurance system. We are already experiencing this competition for human resources today and the commercial nuclear renaissance is still in its infancy. A successful nuclear quality assurance system must have a strong and extensive training program. In addition to initial employee process and qualification training, recurrent mandatory training that includes reiteration of the company’s quality culture, values and employee expectations must be incorporated into the program. The value of this recurring training cannot be overstated in maximizing your long term success in this business. Each employee must be acutely aware of the consequences of noncompliance and substandard workmanship in your products. Incorporation of lessons learned from other critical component failures or near misses such as the NASA Challenger Launch Decision, Davis Bessie Reactor Head Corrosion Incident, as well as others should be incorporated into your training programs to provide real world examples of how even highly regulated and controlled operations are not immune to failure and can have disastrous consequences. Each person in your organization must feel they are personally responsible for the quality

7

of their work and the product your organization supplies to the commercial nuclear industry. Quality concerns must be promptly investigated and formal documented responses should be provided to the employee raising a concern. And legitimate concerns must be quickly and formally addressed while the reporting of errors must be positively recognized in order to reinforce and ingrain the desired nuclear quality assurance culture. And finally, I would like to provide you with some insights to barriers that can impede your success. For a company entering into the commercial nuclear market, it is critical to understand the barriers that must be overcome on the path to becoming a commercial nuclear component, material or service supplier.

In order to be successful in the commercial nuclear supplier environment, all sectors of the business must have a solid understanding of the requirements that their organizations must meet. These requirements which have been previously discussed may easily exceed 10,000 pages of text including administrative, regulatory and technical requirements. It is therefore critical to establish key organizations and key staffing to understand the body of requirements. Understanding the requirements imposed by the contract and the regulations is the key to compliance. The understanding of requirements must permeate throughout your organization, beginning with the proposal process, carrying through material procurement, fabrication, testing and acceptance by the customer and concluding with contract closeout and records retention. Proceeding with a “Business As Usual” culture is a sure fire way to find your business wounded in a mine field. Countless pitfalls exist; to illustrate my point is the simple breaking of a fluorescent light bulb in the manufacturing shop. In a nuclear quality assurance system this breakage may bring your production process to a halt due to concerns with mercury contamination. Recovery can involve costly testing programs to prove the component has not been degraded or worse yet the solution may be to scrap and replace the item. In most other industries the breakage of a fluorescent bulb would not get a second thought relative to component quality.

Both of these barriers have highlighted the importance of providing resources to support the increased overhead requirements. There is significant investment required in human capital to design and implement the systems and controls required to successfully design and construct nuclear components. Do not underestimate the need for people as you enter into this business. In your drive to succeed and to meet your financial and production goals caution must be exercised in trying to do more with less so as to not compromise product quality and requirement compliance.

8

With quality paramount in this business, another barrier to success is oppression of communications. When production or quality issues arise, management must exercise great care in their reaction to the issue. If the reaction is one of anger, blaming, and negativity, it can promote a culture of oppression and secrecy which is highly counterproductive. Management must therefore strive to resist blaming and punishment and seek to understand the underlying reasons why things have gone awry. Failures should be viewed as milestones to strength rather than opportunities for punishment. Another potential pitfall that your business may experience is a gap between what the written procedure states and what actually occurs in the execution of day‐to‐day activities. This is known as the “work as perceived versus the work as performed gap”. Open communications and gaining employee input during development of the quality system can reduce this gap. Ongoing involvement of your management team in the daily activities can also be used to reduce this gap and insure procedure compliance. At Toyota, where their quality is world renowned this process is known as “genchi genbutsu” which means “go and see “.

As a goal, authority should be pushed down to the lowest practical level of the organization. If one places the responsibility for a process or product with an individual process owner, then the authority to change and improve that process should also be granted. And finally, I would recommend that your organization consider using Human Performance Improvement techniques developed by INPO, the Institute of Nuclear Power Operations, to help you reduce the number of errors as you develop and implement your nuclear quality system. These techniques can be used to identify error likely situations, and latent organizational weaknesses which can lead to human errors. INPO has successfully utilized Excellence in Human Performance principles in the commercial nuclear industry to drive down the annual average significant events since INPO’s inception in 1978 to levels previously thought unattainable. In closing, I would encourage your organization to take advantage of the opportunities that will develop as the nuclear energy renaissance grows. The commitment to developing the systems and staff to meet the demands of a commercial nuclear supplier cannot be overstated. Leadership, culture and values cannot be changed overnight, and there are no shortcuts. Your leadership team and employees must be committed for the long term.

9

However, when properly developed and implemented, the combination of solid systems and talented, trained staff will increase the likelihood of your success as a nuclear component, material or service supplier.

What do you do next?

• Talk to EPC Vendors/Utilities to indicate interest • Vendors/utilities will describe their wants and

needs. • Vendors/utilities will discuss their requirements. • Don’t contact NUPIC/NIAC and ask for an audit.

– Utility/Vendor will do this once added to approved supplier list

• Our QA panel will be available to answer any questions

Conclusions

• Support for new nuclear power is strong• The market in the U.S. is viable and has

growth potential• Today’s nuclear industry is better focused

on certainty of outcome• Quality is a key component for success• The time to get involved is now

Reactor Designer Panel

William A. Fox IIIVice President, Construction and

ProcurementAreva NP New Plants Deployment

AREVA’s 2030 Scenario: Construction or LifeExtension of More than 500 GWe of Nuclear Power

2006 2030

GWe net installed

Theoretical end of life

Life extension

Newconstruction

267

186

635

372

344

AREVA Seeks to Deploy its Range of Reactors

Europe N. America Asia Africa World

New installed nuclear generating capacity after 2006by geographic area

(2007 - 2030)

0

50

100

150

200

250

300

350

400

2007 2009 2011 2013 2015 2017 2019 2021 2023 2025 2027 2029

GWe Net

0

50

100

150

200

250

300

350

400

Our Goals

• We will:

– Manage multiple large projects on an international scale

– Meet industry requirements

– Satisfy demand from new customers

“We expect to deliver 30 to 40 new power plants by 2020 all

over the world”

AREVA Vision: Share with more suppliers

• A new generation of suppliers for a new generation of reactors

– Increase the capacity of the current supply base / add new suppliers

• Long-term partnerships will be developed with suppliers in order to:

– Offer competitive solutions worldwide to our customers

• INTERNATIONAL PROJECTS

– Respond to national localization programs

• DOMESTIC PROJECTS

Involve Suppliers in a Continuous Improvement Approach

• Stimulate supplier creativity through contracts focused on quality, cost and delivery objectives

• Encourage active supplier participation in co-development initiatives

• Develop and formalize long-term partnerships

– Including multi-project agreements

40 to 60 billion dollars at stakefor EPR suppliers through 2020

GEGE--Hitachi Nuclear Hitachi Nuclear EnergyEnergy

Stephun E. CliverStephun E. Cliver

Supply Chain Vice PresidentSupply Chain Vice President

Nuclear Plant ProjectsNuclear Plant Projects

•Operating in 100+countries … 125+ years … 300,000+ employees worldwide … 2006 Revenue $163B•Operating in 100+countries … 125+ years … 300,000+ employees worldwide … 2006 Revenue $163B

Structured For Growth … The “New GE”

Infrastructure Industrial

Commercial FinancialServices

NBCUniversal Healthcare

ConsumerFinance

• Energy•GEH Nuclear

• Oil & Gas• Water• Energy Fin Svcs• Aircraft Engines• Rail• Aviation Fin Svcs

• Consumer & Ind.• Equip Svcs• Plastics• Silicones/Quartz• Security• Sensing• Fanuc• Inspect Tech

• Network• Stations• Entertainment• Universal• Sports/Olympics

• Diagnostic Imaging• Clinical Systems• Info Technology• Services• Bio Sciences

• Insurance• Leasing• Real Estate• Corp Fin Svcs• Healthcare Fin Svcs

• Europe• Asia• Americas• Australia /

New Zealand

ServicesTubes

Powder &Components

Tubes, Powder &

Components

Marketing JV

Kurihama, Japan (GNF-J) Wilmington, NC USA (GNF-A)

Juzbado, Spain (ENUSA)

Tubes, CANDU Fuel

Toronto,Peterboro, Armprior

SJ/VallecitosTraining Center

EngineeringHot Cells

Nuclear HQGNF

Nuclear’s Global Footprint~2500+ employees

Morris Custom Fab

Nuclear Fuel• BWR & Candu Fuel• MOX Fuel• Fuel Engineering Services

Nuclear Power Plants• ABWR• ESBWR• Next Gen / Hydrogen

Nuclear Services• Reactor & Field Services• Performance Services• Medical Isotopes & Nuclides

GEH Nuclear Energy …Profile

ABWR ESBWR

New Unit Platforms

• 1350MWe Net• Certified in USA, Japan and Taiwan• Built in 39 months (1st pour to Fuel)• Global Supply Chain in place• Licensed design to Toshiba & Hitachi• The only Gen 3 design in operation• Japan � Taiwan � US � Other…

• 1520MWe Net• Simplified, passive design• Natural circulation• ~20% cost reduction• Improved Safety & Security• Lower Dose / Reduced Rad waste• US � UK � Other…

• Contracted for long lead items• COL application submitted• Full contract negotiations underway

• Contract for long lead items• Full contract negotiations underway

• Selected ESBWR technology• Contract for long lead items

New Unit Update - Customers

• UK licensing proceeding on schedule• Multiple utilities in support

Dominion

Entergy

Exelon

UK

Parts(Debris Strainers,

Motors, Valves, CRD, CRB’s, Parts

Inventory Management)

Water& Chemistry

(TEPCO Flowmeter, NobleChem, Autocatalytic Recombiners)

Uranium Supply(Uranium Enrichment and Supply, Uranium

Management)

Steam Turbines(Main Steam

Turbine, Turbine

Services)

Financial Services

(EFS)

ESBWR/ABWR Technology Cross-Flow

Optimization & Controls(Mark VI, γ

Thermometers, OC Solutuons)

Inspection & Outage

Services(Multi-Bundle Fuel

Mover, Training Facility, Startup)

Core Optimization(N-Streaming, e-

Prometheus, AETNA)

“Digital” Plant(Simulation

Assisted Engineering, e-Configuration Management)

Fuel(GNF-4, Debris

Filters, Channeled Fuel)

Nuclear Vertical

New Plants• ABWR• ESBWR• Control Systems

• ST (50 & 60 Hz)• Generators

Power Gen Energy Svcs Nuclear

Nuclear Fuel• BWR• CANDU• Components• Container IP

Fuel Engineering Services• Core Design• Reload Optimization• Technical Services

• Outages• Mods & Repairs• Inspection Services

Field Services

Performance Services

• Outages• Mods & Repairs• BOP Services

• BOP

• Power Uprates• Water Chemistry• Control Systems• Technical Services

• ST Gen Upgrades• I & C• ST & Gen M&D• BOP M&D

• Economic Analysis• Grid Analysis

Parts

• Control Rods, Drives & BOP

• ST & Gen• BOP

Plus Water, Security, Financing & Healthcare

ESBWR Procurement NeedsHeat Exchangers

PCCSICS

Turbine Island Condensers/Exchangers

• Numerous Exchangers throughout Nuclear Plant

• Estimated # = 56

• Different Metallurgies

Valves

Safety Relief Valves

Squib Valves

• Numerous Valves throughout Nuclear Plant

• Estimated # = ~14,000

• Different Metallurgies

1

23

4

6 5

79

10

8

ESBWR Procurement Needs

DCIS, Control Room• DCIS characteristics: High reliability, tight control, stronger HFE

• Safety & Non-Safety Related Systems

• Greater Diversity

• 40,000 points

ESBWR Procurement Needs

Concrete/Structural• Emphasis on Modules –Base Mat, Drywell, Pool Liner, etc

BIMAC Concrete/Rebar Containment

ESBWR Procurement Needs

Modularization

• Need for Ultra Large Cranes, Ocean Going Vessels, Transporters

• Large Haul Equipment: Reactor, Reactor Internals, Turbines, Generator, Modules, Gantry Cranes

• Module fabricators, factories needed, location critical

Reactor Pressure Vessel

Reactor Internals Cranes, Pressure Vessels, Turbines, Etc

ESBWR Procurement Needs

ESBWR Procurement Needs

Miscellaneous Equipment

• Numerous Miscellaneous Equipment:

Fuel Systems

Instrumentation

Pressure Vessels

Cranes – TI, RB, FB

Nuclear Doors & Hatches

Quenchers/Strainers

Inclined Fuel Transfer

Incore Instrumentation

Standby Liquid Control

E S B W R

C o n t a i n m e n t

R e a c t o rP r e s s u r e

V e s s e l

C o r e

F l e x i b l e C a b l e s

S R N MA s s e m b l y

Your Important Part in ESBWR…..

• Support Quoting Activity

• Provide Design Engineering Support

• Provide us Your Ideas to Minimize Costs

• Work with GEH and EPC Partners

• Be More Than Just a Supplier

• Be Patient

Reactor Designer Panel

Joe HutterVice President, NSSS Components and

Nuclear ServicesMHI Nuclear Energy Systems

April 14, 2008Mitsubishi Heavy Industries, Ltd.

Mitsubishi US-APWRNEI Manufacturing Outreach Workshop

The basic design concept of the US-APWR is the same as that of the Japanese APWR.New technologies of the APWR are fully tested, well-verified and established. The US-APWR, 1700MWe class, is based on the established APWR technology with

The latest technologies to improve plant efficiencyMinor modifications to meet U.S. utility requirements

What is US-APWR

1,700 MWe Class1,538 MWe1,180 MWeElectric Output4,451 MWt4,451 MWt3,411MWtCore Thermal Output

3/4”3/4”7/8”Tube size

LP last-stage blade

Model

Model

44 inch

93A-1

54F

Current4 Loop

70 inch class54 inchTurbine

100A100AReactor Coolant Pump

91TT-170F-1Steam Generator

US-APWRAPWR

Plant Parameters and Major componentsComparison of US-APWR to PWR

US-APWR NRC Licensing Schedule

DC :Design CertificationCOL:Combined construction permit and conditional operating license

2006 2007 2008 2009 2010 2011 2012 2013

#1(July)

COLA

DC application (Dec. 2007) DC

Design Certification

Pre-application review

DCD

FSAR

US-APWR Construction Schedule

Aux. Buildings

Turbine Island

Nuclear Island

YardConstruction

Pre-Application

Design CertificationCOL

Licensing

PJ Milestone

0-1-2-3-4-5-6-7-8-9

LOI COLA First Con. Power Supply Fuel Load CO

DC Application

Site Preparation Work

Basemat

PCCV Base LinerPCCV

Heavy Components Set

Polar Crane Set

Inner Con. ModuleMechanical / Elec. Installation

HFTFlushing & Test

Commissioning

Building

T/G Foundation

Mech. / Elec. Installation

Civil Work

Mech. / Elec. Installation

US-APWR Equipment Requirements

Equipment supplied from Japan:Reactor VesselsSteam GeneratorsPressurizersReactor Coolant PumpsAccumulatorsSteam Turbines / Generators / AuxiliariesEmergency Power Systems

US-APWR Equipment Requirements

Equipment supplied from U.S. / Canada:Containment VesselsCranes, Hoists. MonorailsEquipment HatchesAir LocksTanksHeat Exchangers, CondensersFeedwater SystemsPiping, Valves, Silencers, Filters, SupportsPumps, Motors, Baskets, Screens, StrainersCooling Towers Fire Detection and SuppressionFuel Storage Racks

US-APWR Equipment RequirementsEquipment supplied from U.S. / Canada cont’d:

Compressors, Coolers, ChillersSensors, Alarms, PanelsInsulationInstrumentation, Switch Gear, Transformers, Relays, Controls, CabinetsConduit, Cables, Trays, PenetrationsLighting, MonitorsHVAC, Fans, DampersSecurity systems Radiation Monitoring, Protection

US-APWR Equipment Requirements

Equipment supplied from U.S. / Canada cont’d:Structural Steel, PlatformsConcrete, Re-barBuildings, Warehouses, Maintenance Shops

US-APWR Equipment Requirements

U.S. Supplier Lists:Engineering, Manufacturing, QA Assessments (started)Qualification of Safety Related Equipment Suppliers (May 2008 to Sept. 2009)Qualification of non-Safety Related Equipment

(in-progress)First Purchase Orders

Engineering (Started)Manufacturing (*Fall 2009)

(*): Estimated

Reactor Designer Panel

Brenda PetrilenaDirector, Programs and Engineering

Westinghouse Electric Company

Presentation Overview

• The Demand for Nuclear Power – AP1000 in the US

• AP1000 Overview - Simplification

• Westinghouse Challenge

• Supply Chain Challenges

• Summary

The Demand for Nuclear PowerAP1000 in the US

Lee NuclearDuke/Southern Co.

2 AP1000s

HarrisProgress Energy

2 AP1000s

BellefonteTVA/Southern Co.

2 AP1000s

RiverbendEntergy

1 ESBWR

Grand GulfEntergy

1 ESBWR

VC SummerSCE&G/Santee Cooper

2 AP1000

VogtleSouthern Co./Co-owners

2 AP1000s

North AnnaDominion1 ESBWR

Constellation1 EPR

Levy CountyProgress Energy

South TexasNRG Energy, Inc.

.2 ABWRs

2 AP1000s

Lee NuclearDuke/Southern Co.

2 AP1000s

HarrisProgress Energy

2 AP1000s

BellefonteTVA/Southern Co.

2 AP1000s

RiverbendEntergy

1 ESBWR

RiverbendEntergy

1 ESBWR

Grand GulfEntergy

1 ESBWR

Grand GulfEntergy

1 ESBWR

VC SummerSCE&G/Santee Cooper

2 AP1000

VogtleSouthern Co./Co-owners

2 AP1000s

North AnnaDominion1 ESBWR

North AnnaDominion1 ESBWR

Constellation1 EPR

Levy CountyProgress Energy

Levy CountyProgress Energy

South TexasNRG Energy, Inc.

.2 ABWRs

2 AP1000s

Best Solution for New Plants–Simplification

Simplicity in:• Design

• Safety

• Construction

• Procurement

• Operations

• MaintenanceAP1000 Design Certification Approved by the NRC on 12/30/2005

4 AP1000 Units contracted in China (Haiyang & Sanmen)2 AP1000 Combined Operating Licenses (COL) submitted to date

“Can the Supply Chain Support the Nuclear Renaissance?”

Answer: “Yes”If

• As an Industry, we address macro level issues in support of the Nuclear Renaissance including both New Plant Builds and Existing Plant Life Extensions

• We identify and mitigate potential constraints in the supply chain early

Supply Chain ChallengesHigh Level Concerns

• The US Commercial Nuclear Industry is competing for limited domestic manufacturing capacity with:

– Fossil Fuel– Petrochemical– Aerospace– DOD

• Does the supply chain consider the renaissance real?

• The risk and cost of investment for suppliers must be addressed

Summary• Make the US Commercial Nuclear Industry the

“customer of choice” for critical suppliers– A balanced sharing of cost, risk, and benefit

• Communicate to the supply chain, the enormous gain to be realized by the nuclear renaissance and acknowledge and deal with the risk and cost at all levels of the supply chain

• Owners, A/Es, NSSS Suppliers, and industry organizations must demonstrate an unwavering commitment to Nuclear Energy

Engineering, Procurement and Constructor Panel

Mark ZeigerManager, Business Development

Bechtel Power Corporation.

Snapshot of Bechtel Today

– 110 years of experience– Over 40 offices worldwide—

40,000 employees– Active on 380 projects in 44

countries– Bechtel … ranked # 1 contractor

per ENR every year since 1998– Commitment to Safety and First

Time Quality– Privately held organization

Bechtel Group … One of the World’s Most Experienced Builders

Nuclear InnovationsPeach BottomFirst HTGR reactor

VallecitosGeneral Electric’sfirst BWR

Turkey PointFirst pre-stressed, post-tensioned

concrete containment

EBR-1First nuclear reactor

NPDCanada’s first

CANDU

Humboldt Bay

First pressure suppression containment

A Historyof Firsts

8272-2/80-100

Nuclear Innovations

A Historyof Firsts

Gen III—ALWRsLicensing (COLs, ESPs)

StandardizationModularization

Indian Point 3One piece

replacement

PalisadesTemporary containment opening

V. C. SummerLaser templating

R. E. GinnaThrough-

domereplacement

8272-2/80-101

Nuclear Industry’s Most Experienced Contractor

–Industry leader• Engineered, constructed, or

managed 88 of the 104 U.S. nuclear power units

• Worked on over 150 nuclear plants worldwide

• Thirty-four SGRs ongoing and completed

• Eight RPVHs completed

• Maintenance and operating contractor for seven U.S. national laboratories

Professional Resources

20,000employees with

nuclear experience

5,000engineers with nuclear

power experience

Nuclear—Market Segments

Operating Plant

Services

Steam Generator and Reactor Head

Replacements

New Generation

8272-2/80-104

New Generation Activities– TVA—Bellefonte

• ABWR cost study • COL support for AP-1000

– TVA—Watts Bar Unit 2• DSEP• EPC for Completion Project

– Dominion—North Anna• Siting and constructability studies• ESP• COL for ESBWR

– Southern—Vogtle• ESP• COL support for AP 1000• Site-specific engineering

– Exelon—Victoria County• COL for ESBWR

Bellefonte

North Anna

Vogtle

New Generation Activities– AREVA

• U.S. adaptation of EPR• DCD support for EPR

– Constellation—Calvert Cliffs• ESP• COL for EPR

– UniStar• Detailed engineering for generic design• EPC lead contractor

– South Carolina Electric & Gas• COL for AP-1000• Site-specific engineering

– Florida Power & Light• COL for AP 1000

– STP Nuclear Operating Company• COL for ABWR

Calvert Cliffs

V.C. Summer

South Texas

New Generation Activities– Browns Ferry Unit 1

Restart• Design engineering• Start-up services• Bechtel peak staffing = 700• Total project = $1.8 billion

– Watts Bar Unit 2 Completion

• Lead EPC Contractor• Bechtel peak staffing = 2,300• Total project = $2.4 billion

– Waste Treatment Plant (WTP)

• Lead EPC Contractor

Calvert Cliffs

V.C. Summer

South Texas

Supply Chain– Global procurement and

vendor relationships• $15 billion annual spending

• Global Supply Network— vendor surveillance,

expediting, logistics, quality control

– Types of Suppliers• Broad spectrum of components and

services• Many multiple project, long term

partnerships developed

Supply Chain– What do we look for in our

suppliers?• Similar Culture and Values

• Certainty of outcome…deliver as sold

– Quality

– Value

– On Time

• Make our end product to the ultimate customer better

Engineering, Procurement and Constructor Panel

Jay BristerVice President, Business Development

CH2M Hill

CH2M HILL At A GlanceHistory• Employee owned since 1946• Merged with Clair A. Hill and Associates in

1971• Included on the Fortune “100 Best

Companies To Work For” list in 2003, 2006, and 2007

• Included on the Fortune “Most Admired Companies” list for six consecutive years

• Global HQ in Englewood, CO

23,000 people workingin 40 countries

Integrated Client Solutions

Each client and project has access to the collective knowledge and skill of the entire enterprise.

C O

R E

S

E R

V I

C E

S

C L I E N T G R O U P S

PROGRAM MANAGEMENTCONSULTING

ARCHITECTUREENGINEERING

PROCUREMENTCONSTRUCTION

CONSTRUCTION MANAGEMENTOPERATIONS & MAINTENANCE

APPLIED TECHNOLOGIES

CivilInfrastructure

CivilInfrastructureIndustrialIndustrial FederalFederal

Nuclear is in our Federal Client Group

Nuclear Business Group Serves Four Market Segments

• Nuclear Generation– Program Management for new build– Siting, licensing, permitting of new nuclear power plants– Balance of plant, capital upgrades, program management/owner’s

engineer for existing power plants• Liabilities Management

– Federal and non-federal traditional environmental management (D&D, waste management, environmental restoration, etc)

• Nuclear Infrastructure Management– DOE NNSA/Science/Nuclear processing operations and maintenance,

infrastructure upgrades, process and facility engineering/design and facility EPC

• Nuclear Fuel Cycle Management– Enrichment, fuel reprocessing – Spent nuclear fuel handling, storage and disposition

Nuclear New Build

• 2008 is a Critical Year– Need for Power

• Must meet long term load demand growth• Environmental drivers point to nuclear as source

– Federal Incentives• COL Applications submitted by end of 2008

– NRC expecting 15 applications for 22 units

• Federal Loan Guarantees

– Designs Moving Forward

Now is the time to get involved!

Engineering, Procurement and Constructor Panel

R. Wayne ParkerDirector, Procurement and Contracts

Flour Corporation

Who is Fluor Employees: 46,000+ (2,750 with nuclear experience)

Corporate HQ: Dallas, TX

Five Business Groups

Nuclear Power HQ: Greenville, SC

International Nuclear Power Office: Camberley, UK

Recent Annual Spend: $14 billion

Fluor Nuclear Experience

Fluor has provided Nuclear Services to clients since 1946

Reactor Design & Modification

Recent Non-Reactor Nuclear Design / Build

Self Perform Reactor Construction

Reactor Operating Plant Support Services

Nuclear Facility Decommissioning

Fluor Nuclear Renaissance Commitment

January 2007 re-established Fluor Nuclear Power to focus on the following markets:

Nuclear new build in U.S., UK and other (selective) global markets

Capital projects at operating nuclear plants

During 2007 we stood ASME audits for regaining Nuclear Code Stamp and Nuclear Certificates

February 2008 we received our Nuclear Code Stamp and Nuclear Certificates

Fluor Current Nuclear Projects

Oconee Nuclear FacilityDuke Oconee – Plant Upgrades

Engineering, Procurement and Construction

South Texas Project

STPNOC Units 3 & 4Engineering, Procurement and Construction of 2 x 1300 MW ABWR

Fluor Strategic Supplier Relationships

pROCUREMENT

CO

STIN

FLU

ENC

E

T I M EThe ability to influence the cost of a project is greatest at the beginning of a

project – bringing strategic suppliers in early is essential to success

EPCbecomes

PEpCENGINEERING

CONSTRUCTION

PROCUREMENT

FLUORStrategic

Suppliers

Construction Industry

Institute (CII) indicates:

4%–8% cost savings

10%–15% savings in

time

Supplier Integration – The PEpC Process

Strategic RelationshipsStrategic Relationships

Fluor Supply Chain Agreements

Supplier Relationship Agreements (SRA)

Contractor Strategic Relationship Agreements (CSRA)

Becoming a Fluor Supplier/ContractorBecoming a Fluor Supplier/Contractor

SCORE

Fluor's Supplier and Contractor Online Registry E-version

Register TODAY! www.fluor.com

Click on Supplier / Contractor and then on SCORE

Please be sure to enter the keyword "Nuclear" in the referral field in SCORE!

Complete the Questionnaire

Sargent & Lundy...

• More than 117 years of power industry leadership and experience

• 100% exclusive dedication to power industry

• Reputation for consistently providing high quality engineering services

• Extensive state-of-the-art technical resources (people, tools, and processes)

• More than 2,500 staff resources

• Consistently ranked by Engineering News-Record as a top global power industry consultant

What we know for sure…..• We are and will be performing engineering and

design services for new nuclear units for at least the next 10 years.

• We are and will be preparing, evaluating, and recommending procurement of nuclear equipment, materials, and services for new nuclear units over this time period.

• Our information on manufacturing suppliers of equipment, materials, and services is limited.

• Ohio, Michigan, and Pennsylvania are well positioned to supply the market.

Ohio and Nearby States are Well Positioned to Supply the Market

• Piping• Steel• Concrete• Cable• Instruments• Pumps• Valves• Heat Exchangers

What Manufacturers Need to Know

• There exists three types or levels of equipment that will be used in new nuclear plants– Safety related– Important to safety– Non-safety related

• Manufacturing capabilities and qualifications must be robust…

Manufacturing Requirements

• Sargent & Lundy will issue procurement specifications requesting detail, accuracy, specific schedules, and hard commitments.

• Codes and standards requirements must be known and followed.

• AISC • ASTM• ANSI B31.1 • HEI• ASHRAE • IEEE• ASME Section III • ISA

• NFPA

Examples

Types• Nuclear Safety-Related

– ~60%

• Important to Safety– 10%

• Non-Safety Related– 30%

• Piping• Steel• Concrete• Cable• Instruments• Pumps• Valves• Heat Exchangers

Requirements to Sell to the Nuclear Market

• Safety-Related– N-Stamp– NQA-1 Program– NUPIC OK

• Important to Safety– NUPIC OK– Scaled down QA Program

• Non-Safety Related– Commercial Grade

Capacity to meet demand

What Sargent & Lundy Will Do to Assist Manufacturers

• We will provide opportunities for lunch and learn meetings to highlight your products.

• Sargent & Lundy will work with you for mutual success.

Conclusion

Get involvedPrepare a PlanExecute the Plan with the end in mind…Contact Sargent & Lundy when you are ready.

Sargent & Lundy55 East Monroe StreetChicago, IL 60603312-269-6630www.sargentlundy.com

Engineering, Procurement and Constructor Panel

Ed TerresDirector, Nuclear AP1000 Procurement

Shaw Power

Corporate ProfileCorporate Profile

• Name: The Shaw Group Inc.• Headquarters: Baton Rouge, Louisiana• Public corporation: NYSE Symbol: SGR• 2007 Revenue: $5.7 Billion• Backlog: $14.0 Billion*• Number of employees: 27,000 • Web site www.shawgrp.com

Founded in 1987, The Shaw Group Inc. provides premier engineering, design, construction, maintenance, fabrication and manufacturing services to private-sector and government clients in the energy, chemicals, power, nuclear, environmental, infrastructure and emergency response markets.

* As of the three month period ending 11/30/07

Shaw Power- Nuclear• Full service engineering,

design, procurement and construction

• Configuration management

• Licensing support and safety analysis

• Major component replacement

• Operating plant services

• Maintenance & modifications services

• Decontamination & decommissioning services

• Environmental services

• Spent fuel dry storage

• China State Nuclear Power Technology Company

• Duke• Southern• Entergy• SCANA• Exelon• Progress • LES - National Enrichment

Facility• Tennessee Valley Authority • Dominion• Entergy• TXU• KOPEC• Florida Power and Light• FENOC

AP1000 Consortium awarded 4- Nuclear reactors in China;

Nuclear new-build backlog over $700 million

AP1000 Consortium awarded 4- Nuclear reactors in China;

Nuclear new-build backlog over $700 million

Services Significant Customers

Westinghouse/ Shaw Consortium furnishes AP1000 to domestic utilities• Conceptual design• Detailed engineering• Project management• Construction

management• Engineering and

design services• Site-specific

engineering

AP1000 Domestic Opportunities

AP1000 Domestic Opportunities

Doing Business with Shaw Nuclear

• Need suppliers that can provide Balance of Plant and Construction Support Materials and Equipment

– Pumps (CCW, Condensate, Misc. Vertical, Misc. Horizontal)– Mechanical Equipment (Heat Exchangers, Water Treatment)– Electrical Equipment (Switchgear, Bus Duct, MCCs, Panel

boards, etc.)– Civil Support ( Rebar, Structural Steel, Grating, Decking)– Bulk (Electrical & Mechanical)– Instrumentation– Construction Support (Welding, Safety Supplies, Hand Tools

Doing Business with Shaw Nuclear

• Perspective new suppliers need to complete Shaw Pre-Qualification Questionnaire to begin the qualification process

• Key Attributes for Qualification Considerations

• Meeting quality & schedule requirements • Technical expertise and problem solving• Demonstrated financial strength • Strong Quality Program in accordance with industry norms• Adequate capacity to meet long term supply commitments • History of competitiveness in product group or market

• Contact Shaw Procurement representatives for information regarding the qualification process

Engineering, Procurement and Constructor Panel

Bob PascucciNuclear Procurement

URS – Washington Division

Washington Division

• Fully integrated engineering, construction and technical services organization with the capabilities to support the project life cycle—from inception through start-up and operation to decommissioning and closure

• Washington Division Headquarters―Boise, Idaho

• Power Business Unit Headquarters—Princeton, New Jersey

• Recently opened the URS Nuclear Center in Fort Mill, SC

• Internet sites— www.urscorp.comwww.wgint.com

Formed from a Rich HeritageRustIsbill

LitwinKaslerEbasco

CatalyticGibbs & Hill

HK FergusonStearns-Roger

Morrison KnudsenCentennial Engineering