Note: 51694 Using TGA-IR - Thermo Fisher Scientific · Complete Materials Deformulation Using...

Transcript of Note: 51694 Using TGA-IR - Thermo Fisher Scientific · Complete Materials Deformulation Using...

Complete Materials Deformulation Using TGA-IRMichael Bradley, Thermo Fisher Scientific, Madison, WI, USA

Introduction

Key applications in analytical laboratories often involvefailure analysis and competitive deformulation. For example,black rubber gaskets from two suppliers stating the sameproduction process behave differently – one seals, the otherfails – or two expanded polymer foams exhibit very differentmechanical behavior. These situations call for deformulation,and a qualitative and quantitative comparison of the results,to determine the source of the differences.

Thermal Gravimetric Analysis (TGA) is a powerfuldeformulation tool common in material analysis. Basically,a small amount of sample placed on a pan is inserted into afurnace, with the pan hanging on a sensitive microbalance.A slow temperature ramp is applied with the samplebathed in an inert purge gas. The increasing temperatureforces various components of the material into the vaporphase, resulting in weight loss. TGA provides excellentquantitative information about weight losses as a functionof temperature, but does not identify the vapors beingdriven off.

Coupling the TGA to a Fourier Transform infrared(FT-IR) spectrometer adds considerable utility to themethod. The vapors released from the material pass througha gas cell inserted in the FT-IR, where the spectrum isobtained. Spectral searching provides the last link –identification of the vapors. The weight loss data from theTGA, the rapid response and high sensitivity of thespectrometer, and spectral searching combine to providepotent analytical insights into the chemistry of the sample.

Traditionally, the one difficulty with the infraredportion of the analysis has been the simultaneous evolutionof gases. The TGA does not discriminate between simpleand complex gas evolutions, but the instantaneous IRspectra are summations of all the gases being driven off atthat time. This complexity normally requires some skill tountangle. The need to use multiple search regions toselectively extract individual components and the generallyunfamiliar look of gas phase spectra to many investigatorscontribute to the potential for missed critical answers. Asshown below, this difficulty is largely surmounted with thepowerful Thermo Scientific OMNIC™ Specta™ spectroscopysoftware, which performs multi-component searches at asingle click.

We will examine three different scenarios, based onindustrial situations with finished products and feedstocksupplies. The first involves an epoxy, examining thecomponents of the mixture prior to and during setting.The second situation compares black rubber samplessimilar to those used in gasket manufacturing. The thirdstudy involves two, blown polymer foam materials. Thisrange of experiments illustrates both the power and theflexibility of TGA-IR.

Experimental

An in-sample compartment TGA accessory equipped witha double pass gas cell heated to 220 °C was coupled tothe TGA with a heated transfer line. The samplingaccessory was inserted into a Thermo Scientific Nicolet™

iZ™10 sampling module coupled to the Nicolet iS™10 FT-IR spectrometer; shown in Figure 1. The FT-IR wasdriven using OMNIC spectroscopy software and OMNICSeries time-base software. In all cases, data were collectedat 4 cm-1 resolution with background and Gram-Schmidt(GS) basis vector collection occurring just before datacollection. The GS display is, in short, a simple way tovisualize the total change in the spectrum from the initialtime. Multi-component searching was performed bysending the OMNIC data to OMNIC Specta.

The thermal analysis was performed with a TAInstruments Q5000 TGA with autosampler. Pre-taredplatinum pans were used to contain the samples, and thesamples were between 10 and 50 mg in size. The samecomputer was used to control both instruments, and atrigger cable allowed simultaneous initiation of datacollection. Various temperature ramps were applied to thematerials, as noted below. The TGA data was imported to OMNIC via the Universal Analysis (UA) software (TA Instruments). Similar export of experimental profiles,including the Gram-Schmidt profile, to UA is available.

Key Words

• FeedstockSupplies

• FinishedProducts

• Multi-componentSearch

• OMNIC SeriesSoftware

• OMNIC SpectaSoftware

• Polymers

• Rubbers

• TGA-IR

• ThermalGravimetricAnalysis

• Vapor PhaseSpectral Library

ApplicationNote: 51694

Figure 1

Results

Epoxy

A single drop of a freshly mixed two-part epoxy (normal12 hour cure time) was placed in a TGA sample pan. Thetemperature was ramped from ambient to 500 °C at therate of 15 °C/min.

Figure 2 shows the FT-IR data in OMNIC Series. Theupper trace reveals the evolution of the overall IR signal intime (the GS plot), while the lower trace is the IR spectrumpresent at the time point indicated by the scroll bar in theupper window. The small signals in the GS plot around11-12 minutes (190–210 °C) result from CO2 and waterbubbles evolving from the sample. The larger peak risingafter 15 minutes (about 250 °C) is associated with manyfeatures in the infrared.

The single spectrum shown in Figure 2 (bottom)demonstrates the multiple gas evolution discussed above.A simple search on this spectrum indeed extracts one ofthe components, but leaves the user in need of multiplesubtraction steps. Unfortunately, gas phase spectra arevery sensitive to environmental conditions (temperature,pressure, mixtures), which affect both peak shapes andline intensities, making spectral subtraction based onlibrary spectra a difficult proposition. Figure 3 shows a 3-dimensional view (time-wavenumber-intensity) of theentire file in the OMNIC Series software – the overlappingemissions and complex time behavior are quite apparent.

OMNIC Specta permits these complexities to beunraveled. Choosing the HR (High Resolution) NicoletTGA Vapor Phase library and executing the multi-component search in OMNIC Specta provides the resultsshown in Figure 4 for multiple time points in the OMNICSeries file. The visual agreement between the originalspectrum and the composite is outstanding in all cases,giving the user high confidence in the results. Further, eachof these multi-component searches required less than oneminute. The slight differences seen in the composite andthe original are due to the same factors discussed aboveregarding spectral subtraction – spectral changes due toenvironmental variations between the experimental andlibrary collection conditions.

Figure 2

Figure 3

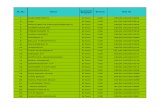

OMNIC Specta’s multi-component search algorithm identifies three unique compounds

in an epoxy in less than a minute.

The first gases to emerge areclearly from the unreacted basematerials of the epoxy and hardener,including the common epoxy ingredientbisphenol-A. As the temperature rises,ester peaks appear, indicative of theaccelerated curing. Late in time,methane evolution along with lowlevels of bisphenol-A are evident asthe epoxy breaks down. Broadeningthe idea of using a TGA to drivemore general reactions, the ability toramp and hold, or to change thepurge gas during a run, gives greatflexibility. Indeed, elevated temperatureoften accelerates reactions, and thepurge gas could even be a reactant.

Black Rubber Samples

Pieces of raw rubbers (one light, onedark) used in producing high perfor-mance black rubbers were analyzedusing a two-step TGA ramp. Figure 5shows GS profiles for the two rubbersamples, along with the derivativeweight loss and temperature rampinformation imported from the TGA.The GS curves clearly point todifferences in the formulations. Below200 °C, neither material shows majorgas evolution, but above 350 °C,strong signals appear. The derivativeweight loss and the GS trace are alsohighly correlated in time, which allowsthe temperature profile to be coor-dinated with the IR data confidently.

a

b

c

Figure 4

Figure 5

Comparing spectra from various time intervals in thetwo samples shows both similarities and differences. Thehigh carbon-filled (dark colored) rubber releases many ofthe same gases as the light rubber, but at a much lowertemperature. Figure 6 shows spectra from the two samplesat different times, and the same basic materials are presentin both – but separated in temperature of release. Figure 7,in contrast, shows the 40 minute time points (sametemperature point) for both samples. The dark rubbershows CO2, CO and water while the light rubber is showingthe strong release of many components.

The multiple component gas phase spectra wereexported to OMNIC Specta. Preliminary searches over theentire spectrum showed the expected hits – CO, CO2 andwater plus one rubber component. However, we focusedthe multi-component search algorithm on a narrow rangeof the spectrum where there were small features. Thenarrow range, multi-component search result, shown inFigure 8, reveals four materials, included butenes, methanoland methyl-ethyl ketone.

In normal infrared spectroscopy, water and CO2 oftenoriginate from the atmosphere, and produce undesiredsignals in the spectrum, which is why atmospheric correctionsand instrument purging are often used. However, in the TGAexperiment, both water and CO2 provide information, asthey are generated by the sample during heating. Thus,software corrections should be avoided, while purge, ifapplied, must be maintained at a constant level.

The two rubbers are apparently similar in underlyingchemistry. However, the large difference in the temperatureof release shows the formulations or treatments applied tothe samples cause differences. In a high performanceapplication, it may well be that the lower temperature ofevolution causes a failure; at the least, it would indicate apotential target for further analytical investigation.

Figure 6

Figure 7

Figure 8

Normally atmospheric water and carbon dioxide are to be avoided in FT-IR. With TGA they both

provide useful information as the sample is heated.

Blown Polymeric Foam

Decorative or functional covers for many manufactureditems are often produced in a “blowing” process. A two(or more) component mixture of a base polymer and ablowing agent are inserted into a mold. The mold is thensubjected to heating, which melts the base polymer. At ahigher temperature, the blowing agent releases gas, usuallywith a sharp onset, which quickly expands the material tofill the mold. In the present study, the mechanical propertiesof two plastics made with the same base polymer, butdifferent blowing agents, were similar. Either would havebeen useable mechanically, but one of the materials emittedunacceptable levels of noxious vapors.

Pieces of the blown polymers and pellets of the twoblowing agents and the base polymer were analyzed byTGA-IR; only a critical subset of this data is shown here.The temperature ramp ended at 200 °C, as the thermaldecomposition of the base polymer was not of interest –only the behavior of the residual blowing agents or trappedgases. The entire piece melted around 190 °C, releasinggases caught in the matrix, but there was little or nodecomposition of the base polymer at this temperature.

GS profiles for the blowing agents and a cover blownwith Agent 2 are shown in Figure 9. Agent 1 shows a single,rapid-onset, gas emission (which is almost explosive innature). Agent 2 shows two transitions, and blown covermaterial shows the same transitions. The 3-D plot inFigure 10 for Agent 2 shows only CO2 in either of the two emissions. In Figure 11, the same region is shown forAgent 1. The onset is rapid and only occurs at onetemperature, but the signals show more than one gas iscoming off. The OMNIC Specta multi-component searchresult, shown in Figure 12, reveals that the second peak isisocyanate. A very small shoulder on the low wavenumberside of the isocyanate is due to CO. The OMNIC Seriesresults for the base polymer alone (not shown here) revealnone of these signals, so the problem lies with the choiceof blowing agent.

Figure 9

Figure 10

Figure 11

The additional information provided by FT-IR enables the analyst to identify which Agent is proper to use

in blown polymeric foam.

Both blowing agents work very well so far as themechanical properties of the final material are concerned.However, the additional gases evolved permitted themanufacturer to prefer Agent 2. Note that the weight lossprofiles alone would be insufficient to discriminate betweenthe two materials. The additional information provided bythe infrared analysis provides the needed differentiation.

Conclusions

TGA-IR is a general purpose, powerful technique for thedeformulation of materials in many industries, includingplastics, resins, rubbers, coatings and pharmaceuticals.The melding of the two techniques more than doubles theanalytical power for these applications. With the additionof OMNIC Specta multi-component searching, theidentification of the overlapped vapor emissions no longerrequires spectral interpretation skills, greatly reducing thetime per analysis for experienced and inexperienced usersalike. Consistency in the analysis is also assured.

The key conclusion from the examples shown here isthat TGA-IR coupled with OMNIC Specta providesactionable results. In essence, the operations personnel canmake process modification decisions based on a solidfoundation.

©2008 Thermo Fisher Scientific Inc. All rights reserved. All trademarks are the property of Thermo Fisher Scientific Inc. and its subsidiaries. Specifications, terms and pricing are subject to change. Not all products are available in all countries. Please consult your local sales representative for details.

In addition to these

offices, Thermo Fisher

Scientific maintains

a network of represen-

tative organizations

throughout the world.

Africa+43 1 333 5034 127Australia+61 2 8844 9500Austria+43 1 333 50340Belgium+32 2 482 30 30Canada+1 800 530 8447China+86 10 8419 3588Denmark+45 70 23 62 60 Europe-Other+43 1 333 5034 127France+33 1 60 92 48 00Germany+49 6103 408 1014India+91 22 6742 9434Italy+39 02 950 591Japan +81 45 453 9100Latin America+1 608 276 5659Middle East+43 1 333 5034 127Netherlands+31 76 579 55 55South Africa+27 11 570 1840Spain +34 914 845 965Sweden / Norway /Finland+46 8 556 468 00Switzerland+41 61 48784 00UK+44 1442 233555USA+1 800 532 4752

www.thermo.com

AN51694_E 08/08M

Thermo Electron ScientificInstruments LLC, Madison, WIUSA is ISO Certified.

Part of Thermo Fisher Scientific

Figure 12

OMNIC Specta is shown to greatly improve an analyst’s to interpret overlapped gas phase spectra.