Alaska Peninsula-Aleutian Islands Management Area food and ...

North Aleutian Basin, Alaska Energy/Fisheries Workshop ... · Shell Exploration & Production Page 4...

Transcript of North Aleutian Basin, Alaska Energy/Fisheries Workshop ... · Shell Exploration & Production Page 4...

Shell Exploration & Production

Page 4

North Aleutian Basin, Alaska

Energy/Fisheries Workshop

Offshore Oil and GasDevelopment Scenarios

March 18, 2008

Shell Exploration & Production

Page 5

2006 Minerals Mgmt. Service ResourceAssessment for Offshore North Aleutian

Natural Gas: 8.6 trillion cubic feetOil/Condensate: 753 million barrelsNatural gas equivalent: 12.8 trillion cubic feet equivalent

Mean, Risked, Conventionally Recoverable Reserves (all in Cenozoic).

Eastern Gulf, Florida. Senate Passed Leasing Bill August,

2006

8 3 illi 12 9 t f ti t d (1 26 bb & 5 8 t f

North Aleutian Basin

~950 OCS blocks

~5.5 million acres

Oil

33%

Natural Gas

67%

Shell Exploration & Production

Page 6

Exploration Process

• Disclaimer: Chance of finding commercial amounts of gas and/or oil is probablyin the 10-20% range

• Acquire leases at lease sale

• Acquire seismic data over leases (optional, but 3D seismic likely preferred)

• If viable prospects are identified, acquire site specific shallow hazard surveys.

• File for drilling permit (including OSRP) & conduct environmental assessment

• Drill several exploration wells

• If gas and/or oil are discovered, appraisal wells drilled to determine the size of thefind

• If sufficient volumes of gas and/or oil are found, development & production planswould be prepared

– Additional environmental impact statement required for each development

• Timing: best case scenario – Exploration & Appraisal drilling from 2012-2014

• Southeast Bering Sea would only host production facilities.

– Export route to be pipeline over peninsula. Shipping would occur on thesoutheast side of the peninsula.

Shell Exploration & Production

Page 7

Well Rig

St. George COST Sedco 708

NAB COST Well Sedco 708

530 Big Dipper

Intrepid Sedco 712

Rat Sedco 708

527 Big Dipper

Bertha Sedco 712

Segula Sedco 708

Fern Ocean Odyssey

Camelot Big Dipper

Segula 1A Sedco 708

Monkshood Ocean Odyssey

Timeline for 10 Exploration Wells

Drilled in the St. George BasinJuly, 1984 – March, 1985 (9 months)

Navarin Basin - 9 wells

6/7/85-11/25/85 (6 months, 4 semi-submersible rigs)

Norton Basin – 6 wells

6/19/84-8/19/84 & 7/2/85-8/24/85 (4 months, 2 jack-up rigs, 2 seasons with ice limitations)

Gulf of Alaska – 11 wells

9/1/76-7/1/78 (22 months, 5 semi-submersible rigs)

Lower Cook Inlet Federal – 13 wells

7/21/78-6/24/80 & 9/19/84-3/13/85 (30 months, 5 rigs (various types)

Jul-84 Aug-84 Sep-84 Oct-84 Nov-84 Dec-84 Jan-85 Feb-85 Mar-85

Shell Exploration & Production

Page 8

Bristol BayBorough

Lake & PeninsulaBorough

Dutch Harbor

Aleutians EastBorough

Port Heiden

Chigniks

KodiakIsland

False Pass

Akutan

Shell Exploration & Production

Page 9

Industry Advances Relating to Exemplary WellBlowout Track Record

1. Shallow hazard surveys: These are mini-seismic surveys and sonar surveys required by the MMS before a drilling permit is issued.These detect shallow, high pressure, gas pockets which can cause a well to blow-out. They also detect any other obstructions on thesea floor (such as topography or ship wrecks) prior to putting a drilling rig in place.

2. Bottom hole pressure prediction (aka pore pressure prediction): Using nearby well information and seismic data, we can predictzones of high pressure prior to drilling by using seismic velocity data. Higher pressure zones will have slower seismic velocities. Also,while we are drilling, lower resistivity zones indicate higher pressure zones. If we encounter such a zone while drilling, we can prepareto balance the weight of the drilling fluid to prevent a well blow out.

3. Previous well data provides bottom hole pressure information (COST & onshore wells)

4. Drilling Wells on Paper (DWOP): Process to review all well plans with multi-disciplined group prior to starting any work at the well site.Mud weights are designed for various stages of the well based on the foregoing input.

5. Real time bottom-hole pressure sensors while drilling (aka measurement while drilling or MWD): We now monitor drilling realtime with bottom hole sensors which continuously measure bottom hole pressures. Again, if abnormal conditions are detected, we canreact before a well control problem arises.

6. 24 hour manned remote duplicate drilling control centers (RTOC): We no longer rely solely on the staff on the rig floor to managethe drilling operation. We have staff in Houston and Anchorage who also monitor the well bore conditions and are in constantcommunication with the rig floor to take any needed corrective action. Data from rig is transmitted in milliseconds to the RTOC. Thisprocess includes having well engineering expertise located at the RTOC so all issues can be dealt with immediately.

7. MMS in Alaska has regulators on the drilling rigs to monitor activity 24 hours a day, 7 days a week.

8. Drilling Mud: Developed benign drilling muds – formerly oil based mud, then synthetic mud, now using water based mud forexploration wells. If well pressures increase beyond expectation, then mud weight is increased to control formation pressure.

9. Blowout preventer (BOP) advances: Standard BOP’s have 4 shut down systems in place: 1) rig floor annular seal (closes around drillpipe), 2) 3 sealing devices below the rig floor (operated from rig floor or 2 back-up locations at other platform locations) – 2 mid-ratedtypically 5000 psi and a 10,000 psi shear ram which will cut the drill pipe and completely seal the wellbore. In the Beaufort Sea, Shell isusing BOP’s with 6 sealing devices. All BOP’s must be tested every 2 weeks.

• These technologies have been developed over the past 30 years and are a key reason for the excellent performance in recent years.

• 13,500 exploration & appraisal wells drilled in the U.S. OCS since 1956 & only 4 have released oil to the ocean. Largest was200 barrels, others were 100, 11 & 0.8 barrel spills. Never a significant exploration well blowout in the U.S.

• If there is a blowout, spill response plan in place in the theatre of operations and relief well technology can intersect an 8” wellbore from3 miles away.

Shell Exploration & Production

Page 10

Artists rendering of the topsides for an Offshore Platform

which could be deployed in the North Aleutian

Crew Quarters

Helicopter-deck

Power Generation

Drilling RigFlare Boom

Equipment Packages

Process Equipment Decks

Equipment Crane

Shell Exploration & Production

Page 11

Artists rendering of the Jacket for an Offshore Platform

which could be deployed in the North Aleutian Basin

Sea Floor

Water Surface

“Jacket”

Piling Conductors

Well Conductors

Shell Exploration & Production

Page 12

Artists rendering of the Well Spread from an Offshore Platform

which could be deployed in the North Aleutian Basin

Sea Floor

Piling Conductors

Well Casing

Deviated Wells

“Jacket”

Impermeable Layers

Reservoir Layers

Shell Exploration & Production

Page 13

Sea Floor

Surface

Artists rendering of the Jacket for an Offshore Platform

which could be deployed in the North Aleutian Basin

Single Pier “Jacket”

Ballast Chambers

Topsides

Shell Exploration & Production

Page 14

Sea Floor

Deviated Wells

Single Pier “Jacket”

Impermeable Layers

Reservoir Layers

Artists rendering of the Well Spread from an Offshore Platform

which could be deployed in the North Aleutian Basin

Ballast Chambers

Shell Exploration & Production

Page 16

NaKika Daily Prod:

Oil 100,000 B/D

Gas 450 million

CF/D

NaKika Subsea Development

Shell Exploration & Production

Page 18

Miles

0 50

North Aleutian Liquified Natural Gas (LNG)

Offshore Platforms

(shallow water)

LNG Liquefaction

Lefthand

Bay

export site

LNG transport tomarkets2-4 tankers per month

MMS Mean Resource

Estimate supports 2 LNG

trains for 25 years

Shell Exploration & Production

Page 19

North Aleutian – Severe Weather Comparison

Fulmar – Central North SeaBrent B – Northern North Sea

Cook Inlet100 Year Data Eastern Canada North Sea Cook Inlet North Aleutian

Signif wave ht-ft 41 51 30 40

Max wave ht-ft 77 94 65 75

Max wind-mph 107 110 80+ 100

Min air temp-deg F 14 19 12 12

Current-mph 5.1 2 7 4.5

Water depth-ft 92 456 62 164

Shell Exploration & Production

Page 20

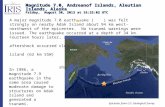

North Aleutian – LNG and Seismic Conditions

LNG Carrier

Sakhalin -

schematic

Location Plant size Trains Start up Tankage Seismic zone

Country Mtpa No year km3

Australia 4.4 2 1989 280 Mid

Australia 2.5 1 1992 0 Mid

Oman 6.4 2 2000 240 Mid

Australia 4.2 1 2004 0 Mid

Oman 3.4 1 2006 240 Mid

Russia 9.5 2 2007 200 Mid

Japan Storage 150+ 73 - 03 12,000+ High

Shell LNG Facilities in Seismic Areas

Shell Exploration & Production

Page 21

North Aleutian – LNG and Seismic Conditions

Location Plant size Trains Start up Tankage Seismic zone

Country Mtpa No year km3

Australia 4.4 2 1989 280 Mid

Australia 2.5 1 1992 0 Mid

Oman 6.4 2 2000 240 Mid

Australia 4.2 1 2004 0 Mid

Oman 3.4 1 2006 240 Mid

Russia 9.5 2 2007 200 Mid

Japan Storage 150+ 73 - 03 12,000+ High

Shell LNG Facilities in Seismic Areas

Australia LNG

LNG Tank –note seismicpads

Shell Exploration & Production

Page 22

Kenai, Alaska. Built in 1969, this is the oldest LNG marineterminal in the United States and the only one built for export(to Japan). The Kenai terminal, owned by ConocoPhillips andMarathon Oil, is located in Nikiski near the Cook Inlet gasfields. Since 1969 the terminal has exported an average ofapproximately 34 LNG shipments each year.

Cook Inlet Liquified Natural Gas & Oil and Gas Fields

Kenai Pen. Borough Resolution 2000-019, Mat.-Su. BoroughResolution Serial No. 00-028 excerpt (5/2/2000), and Homer ElectricAssoc., Inc. Resolution Serial No. 00-45 excerpt (7/11/2000)

Whereas, the LNG Industry at Nikiski has flourished inthe Cook Inlet area, with 31 years of safe, successful, and profitabletransport, production and marketing of LNG; and

Whereas, Kenai Peninsula Borough residents haveenjoyed a long history of cooperation and benefit from our NikiskiLNG industry neighbors; …

Cook Inlet Oil & Gas Infrastructure and Field MapMap courtesy of the Alaska Department of Natural Resources, Division of Oil & Gas

Principal tax payers in Kenai Peninsula Borough (2003):Unocal, Agrium US, ConocoPhillips, Tesoro Alaska Petro.,BP Exploration Alaska, Alaska Communications, Marathon Oil,XTO Energy, Forest Oil Alaska ($1 billion tax base)

Dillon Platform:16 miles to Kenai River

Center of 14 platforms:25 miles to Kenai River

Shell Exploration & Production

Page 23

Additional BenefitsFrom Norwegian Oil Industry Assoc. Fact Sheet

• Increased safety offshore

– Oil industry standby vessels improve offshore safety:

» Towing capability

» Improved emergency response treatment facilities

» Fire fighting equipment

• Search & Rescue helicopters save lives

– Permanently stationed search & rescue helicopters on some platforms

– Within easy reach of important fishing fields & shipping lanes

– 1/16/2003 SAR helicopter saved 11 fisherman off the Stalegg Seniorwhich had run into a rock, 4 rescued from the water in Norway.

• Other Benefits:

– Larger oil spill response capability in the region

» 8400 barrel Selendang Ayu spill in Dec., 2004

– Aid to distressed fishermen or other vessels

– SP70 fishing sonar developed as by-product of pipeline surveyingequipment.

Shell Exploration & Production

Page 24

Recent Shell Search & Rescue Stories

• Alaska Daily Operations Report – Health, Safety & Environment

– August 5, 2006 - While conducting winching practice over Lake Tuslkvoak the S-61 crew noticed a

family in distress. The SAR Tech was winched to investigate and it turned out that their transportation

had failed while out hunting. The S-61 landed a distance off and loaded the family of 6 onboard and flew

them back to Barrow. Family was Ronald Brower Sr. and family, ages 5 to 57 years old.

• Another Successful Search and Rescue

– Week of June 14, 2007 - Shell and the Cougar SAR Team responded to another mission in Canada

near the Kulluk Operation. A young man was reported missing for more than 12 hours. The RCMP

requested Shell’s assistance, and the Cougar 61 Helicopter was dispatched. The search was a success

and the subject male, early 20’s, was found. Survivor is reported in good condition, and the Cougar 61

returned to Tuk Base. Estimated total flight time for this sortie is just over 1 hour.

• 8/15/2006 Gulf of Mexico Weekly Operations Report

– Last week, a summer squall in the Gulf of Mexico caught five fishermen off guard near the WD-143

platform. The fishermen's boat was quickly capsized and the men swam to the platform, clinging to the

legs until they could reach the safety of the lower deck using the access ladder. Many thanks go to the

platform personnel, Don Hamilton, Byron Miller, Jim Sprowl, Ron Lejeune, Joey Taylor, Chris Odum,

Chris Barrois and Terry Bennett, for making the men comfortable, providing dry clothes, administering

first aid and giving them a hot meal. Since the US Coast Guard was responding to a myriad of more

serious distress calls, they were unable to pick up the stranded fishermen. The WD-143 folks secured

for them a flight to shore and they flew back on the evening flight, shaken, but very much alive.

Shell Exploration & Production

Page 25

Generic LNG Plant Personnel

Operators 32

Operations Line Management 3

Mechanical 15

Civil 5

Electrical 7

Instruments 6

Industrial Cleaning 5

Work Preparation & Planning 1

Field, Office & Advisory Eng. 7

Inspection 2

Materials & Transport 6

Management 4

Economics & Scheduling 2

Technology 3

Laboratory 2

Finance 3

Computing 3

Personnel & Training 4

Office Services 10

Health, Safety, Environment 3

Security 18

Total 141

Shell Exploration & Production

Page 26

Category Plan (two crews)

Staff Positions

Offshore Installation Manager 2

Process Team Leader 2

Utilities Team Leader 2

Process Staff Associate 2

Resource Coordinator 2

Marine Supervisor 2

Craft Positions

Instrumentation Technician 4

Electrician 4

Electronic Technician 4

Mechanic 6

Production Operator 16

Total 46

Comments: Typically 100% of staff positions are

Shell employees. Craft positions are resourced with

Shell employees and up to 20% contract employees.

Typical Offshore Operations Staffing Profile2 crews on platform at all times each working 12 hour shifts.

Crews will work 2 weeks straight and then have 2 weeks off.

4 crews (~90 staff) needed to man a platform continuously.