New Manual1

Transcript of New Manual1

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 1/30

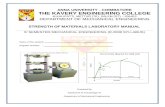

Ex.No:01 STABILITY ANALYSIS OF LINEAR SYSTEMS USING BODE

PLOTDate :

AIM:

To Analysis the stability of linear systems using bode plot

APPARATUS REQUIRED:

SI.NO APPARATUS RANGE TYPE QUANTITY

1. Personal Computer - - 1NO.

2. Matlab Software - - -

THEORY:

The Bode plot is a frequency response plot of the transfer function of a system. A bode

plot Consists of two graphs. One is a plot of the magnitude of a sinusoidal transfer function

versus log ω. The other is a plot of the phase angle of a sinusoidal transfer function versus log ω.

The bode plot can be drawn for both open loop and closed loop transfer function.

ALGORITHM:

Step1: Get the transfer function of system whose bode plot is to be obtained.

Step2:Get the numerator value

Step3:Get the denominator Value.

Step4:Obtain the bode response using bode (num, den)

Step5:Print the result

Step6:Stop the execution

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 2/30

FLOWCHART:

PROGRAM:

clc

num = [ 1 0 0 ]

den = [ 0.04 0.22 1]

sys=tf (num,den)

bode(sys)

START

STOP

Obtain the bode plot from the numerator andDenominator Value

Read the numerator and Denominator Value

Get the Transfer function

Print the Result

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 3/30

MANUAL CALCULATION:

Obtain the bode plot for the given transfer function.

( )( )( )

Solution:

The Sinusoidal transfer function G(j ω) is obtained by replacing s by j ω in the given sdomain transfer function.

( ) ( ω)( ω)( ω)

Magnitude plot:

The corner frequencies are

ωc1=

ωc2=

Tabular column for magnitude plot:

Term Corner frequency rad/sec Slope db/dec Change in slope db/dec

( ) - +40 -

( ω) ωc1= -20

40-20=20

( ω) ωc2= -2020-20=0

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 4/30

Choose a low frequency ω l such that ω l< ωc1 and choose higher frequency such that ωh< ωc2.Let as assume ω l=0.5 rad/sec and ωh=100rad/sec.

Let A = | ( )| in db

Let us calculate A at ω l,, ωc1, ω c2, ωh.

At ω= ω l, A=20 log (j ω)2 =20log( ω l)2=20log(0.5) 2 = -12db

At ω= ωcl, A=20 log (j ω)2 =20log( ωcl)2=20log(5) 2 = 28db

At ω= ωc2,

A=[ ]+A (at ω= ωcl)

A=20x +28 = 48

At ω= ωh,

A=[ ]+A (at ω= ωc2)

A= 0 x +48 = 48

Plot the magnitude plot in the semi log sheet for the following tabular column

ω in rad/sec 0.5 5 50 100

A in db -12db 28db 48db 4db

Phase Plot:The phase angle of ( ) as a function of ω is given by

Φ = ( ) = 180 0 – tan -1(0.2 ω)- tan -1(0.02 ω)

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 5/30

Tabular column for Phase plot

rad/sec tan - (0.2ω) tan - (0.02ω) Φ = ( )

0.5 5.7 0.6 174

1 11.3 1.1 168

5 45 5.7 130

10 63.4 11.3 106

50 84.3 45 50

100 87.1 63.4 30

Plot the phase plot between ω and φ in semi log sheet

RESULT:

Thus the frequency response of given transfer function is obtained by using bode plot in MATLAB.

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 6/30

AIM:

To Analysis the stability of linear systems using nyquist plot

APPARATUS REQUIRED:

SI.NO APPARATUS RANGE TYPE QUANTITY

1. Personal Computer - - 1NO.

2. Matlab Software - - -

THEORY:

The polar plot of a sinusoidal transfer function G(j ω) is a plot of the magnitude of G(j ω)

versus the phase angle of G(j ω) on polar coordinates as ω is varied from zero to infinity. It is also

called Nyquist plot.

ALGORITHM:

Step1: Get the transfer function of system whose nyquist plot is to be obtained.

Step2:Get the numerator value

Step3:Get the denominator Value.

Step4:Obtain the polar response using nyquist (num, den)

Step5:Print the result

Step6:Stop the execution

Ex.No:02 STABILITY ANALYSIS OF LINEAR SYSTEMS USING NYQUIST

PLOTDate :

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 7/30

FLOWCHART:

PROGRAM:

clc

num = [ 1 0 0 ]

den = [ 0.04 0.22 1]

sys=tf (num,den)

nyquist(sys)

START

STOP

Obtain the polar or nyquist plot from thenumerator and Denominator Value

Read the numerator and Denominator Value

Get the Transfer function

Print the Result

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 8/30

MANUAL CALCULATION:

Obtain the polar plot for the given transfer function.

G(S) = ( )( )

Solution:

Put S=j ω for the given G(S) then

G(jω) =ω( )( )

The corner frequencies are

ωc1 = =0.5 rad/sec;

ωc2= = 1 rad/sec ω 2

G(jω) = ( )( )

= 2tan41tan190

11212

=

2tantan90)41)(1(

1 11

22

)( jG)41)(1(

122

=422 441

1

=42

451

1

2tantan90)( 11 jG

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 9/30

Tabular Column for magnitude and phase of G(jω) at various frequencies

ω inrad/sec

0.35 0.4 0.45 0.5 0.6 0.7 1.0

( ) 22 1.8 1.5 1.2 0.9 0.7 0.3

( ) in deg

-144 -150 -156 -162 -171 -180 -198

Plot the polar or nyquist plot from the above table ω in rad/sec and ( ) in deg

Gain margin Kg = ( ) = 0

Phase margin =180 + φgc = 180-270 = -90

RESULT:

Thus the frequency response of given transfer function is obtained by using polaror nyquist plot in MATLAB.

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 10/30

AIM:

To Analysis the stability of linear systems using root locus plot

APPARATUS REQUIRED:

SI.NO APPARATUS RANGE TYPE QUANTITY

1. Personal Computer - - 1NO.

2. Matlab Software - - -

THEORY:

The root locus technique was introduced by W.R Evans in 1948 for the analysis of

control systems. The root locus technique is powerful tool for adjusting the location of closed

loop poles to achieve the desired system performance by varying one or more system parameters.

ALGORITHM:

Step1: Get the transfer function of system whose nyquist plot is to be obtained.

Step2:Get the numerator value

Step3:Get the denominator Value.

Step4:Obtain the polar response using nyquist (num, den)

Step5:Print the result

Step6:Stop the execution

Ex.No:03 STABILITY ANALYSIS OF LINEAR SYSTEMS USING ROOT

LOCUSDate :

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 11/30

FLOWCHART:

PROGRAM:

clc

num = [ 1 0 0 ]den = [ 0.04 0.22 1]

sys=tf (num,den)

rlocus(sys)

START

STOP

Obtain the polar or nyquist plot from thenumerator and Denominator Value

Read the numerator and Denominator Value

Get the Transfer function

Print the Result

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 12/30

MANUAL CALCULATION:

Find the Root locus for the given transfer function G(S) =

)134( 2

S S S

K

Solution:

Step1: To locate poles and zeros

The poles of open loop transfer function is )134( 2 S S S =0

The roots are 322

13444 2

j s

The poles are 0, -2+j3 and -2-j3

The poles are marked by X (cross) as shown in graph.

Step2: To find the root locus on real axis

There is only one pole on real axis at the origin. Hence if we choose any test pointon the negative real axis then to the right of that point the total number of real poles and zeros isone, which in an odd number. Hence the entire negative real axis will be part of root locus. Theroot locus on real axis is shown in graph as bold line.

For the given transfer function one root locus branch will start at the pole at the originand travel through the negative real axis to meet the zero at infinity.

Step3: To find angle of asymptotes and centroid

Since there are three poles, the number of root locus branches are three. There is no finite zero.Hence all the three root locus branches ends at zeros at infinity. The number of asymptotesrequired are three.

Angle of asymptotes =mn

q )12(180

Here n=3 and m=0

If q=0, Angles =3

180 =60

If q=1, Angles =3

3180 x =180

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 13/30

If q=2, Angles = 53

180 x =300=60

If q=3, Angles =3

7180 x =420=60

It is enough if you calculate the required number of angles. Here it is given by first three valuesof angles. The remaining values will be repetitions of the previous values.

Centroid =

= = -1.33

The centroid is marked on real axis and from the centroid the angles of asymptotes are markedusing a protractor. The asymptotes are drawn as dotted line in the graph.

Step 4: To find the breakaway and breaking point

The closed loop transfer function ( )( ) =

( )( ) =

)134(1

)134(

2

2

S S S k S S S

k

= K S S S

K )134( 2

The characteristic equation is S(S 2+4S+13)+K =0

S3+4S 2+13S+K=0

K=- S 3-4S2--3S

On differentiating the equation of K with respect of S we get

ds

dK = -( 3S 2+8S+13)

PutdsdK

=0

-( 3S 2+8S+13)=0

3S 2+8S+13=0

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 14/30

S=32

313488 2

S=-1.33 j1.6

Check for K

When S=-1.33+j1.6 the value of K is given by

K=-( S 3+4S 2+13S)

=-[(-1.33+j1.6) 3+4(-1.33+j1.6) 2+13(-1.33+j1.6)]

≠ Positive and real

Also when S=-1.33-j1.6 the value of K is not equal to real and positive.

Since the value of K for S=(-1.33±j1.6) are not real and positive, the points are not an actual breakaway or breaking points. The root locus has neither breakaway nor breaking point.

Step5: To fine angle of departure

Let us consider the complex pole A as shown in R. Draw vectos from all other poles to the poleA as shown in fig R. Let the angles of the vectors be θ1=180-tan -1(3/2)=123.7

θ2=90

Angle of departure from the complex pole A=180- (θ1 + θ2)

=180-(123.7+90) = -33.7

The angle of departure at complex A is negative of the angle of departure at complex pole A

Angle of departure at pole A=+33.7

Mark the angles departure at complex poles using protractor.

Setp6: To find the crossing point on imaginary axis

The characteristic equation is given by

S3+4S 2+13S+K=0

Put s=jω

(jω) 3+4(jω) 2+13(jω)+K =0

- jω 3-4ω 2+13jω+K = 0

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 15/30

On equating imaginary part to zero we get

-ω3+13ω=0

- ω3=-13 ω

ω2= 13

ω = ± 3 = ± 3.6

on equating real part to zero we get

-4 ω2+K=0

K=4 ω2 = 4(13) =52

The crossing point of root locus is ± 3.6 and the value of K is 52.

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 16/30

AIM

To determine the performance characteristic of a DC motor angular position controlsystem.

APPARATUS REQUIRED:

SI.NO APPARATUS RANGE TYPE QUANTITY

1. DC position controlsystem kit

- - 1NO.

2. Patch chord - - -

THEORY:

Angular position control using a DC motor forms a fine example of feedbackcontrolled system. A DC motor whose speed can be varied by application of various voltage is

used through an appropriate gear drive to rotate a shaft.

Then angular position of the shaft is sensed using an appropriate sensor and depending onthe set value and the measured value of anglular position, an error voltage is obtained which isamplified and feed back to control the motor. When in equilibrium the shaft position willcorrespond to the angular position dictated by the set value.

However in this simple feedback system the performance of the system will be highlyunder damped and as a result the system will take a long time to come to stable shaft position. Astheory shows it is advantageous to use either tachometric feedback or derivative feed back toincrease the damping of the system to acceptable limits.

Ex.No:04DC POSITION CONTROL SYSTEMS

Date :

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 17/30

TABULAR COLUM FOR WITHOUT TACHO FEED BACK(OPEN LOOP)

Sl. No

Input angular

position in

degrees

Output angular

position in

degrees

Without stabilizing

feedback (open loop)SW1

upward ( Tacho out)

Remarks

1. 15 13 Tendancy forOscillations

2. 30 29 As above

3. 90 87 As above

4. 180 178 As above

5. 270 268 As above

TABULAR COLUM FOR WITH DEGENRATIVE (-VE) TACHO FEEDBACK(CLOED LOOP)

Sl.No Input angularposition indegrees

Output angularposition indegrees

Without stabilizing feedback (closed loop)SW1down ward ( Tacho out)

Remarks for SW2in Degenerativemode

1. 15 13 No Tendancy forOscillations if P4

is suitably adjusted2. 30 29 As above

3. 90 87 As above

4. 180 178 As above

5. 270 268 As above

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 18/30

TABULAR COLUM FOR WITH DEGENRATIVE (-VE) TACHO FEED

BACK(CLOED LOOP)

Sl. NoInput angular

position indegrees

Output angularposition in

degrees

With feed back( Closedloop) SW1 down ward

( Tacho in)

Remarks for SW2in Regenerative

mode

1. 60 13Systems oscillatesaround 60 degrees

positions

2. 120 29 As above Around120

TOP VIEW OF DC POSITION CONTROL SYSTEM.

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 19/30

FRONT PANEL LAYOUT OF DC POSITON CONTROL SYSTEMS.

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 20/30

Result:

Thus the experiement were conducted and readings were tabulated

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 21/30

AIM

To study the operation of AC Servomotor position control with PI Controller using PEC-02 module

APPARATUS REQUIRED:

SI.NO APPARATUS RANGE TYPE QUANTITY

1. PEC-02 Module. - 1no.

2. Motor Set up - - 1no.

3. Patch chords. 1no.

THEORY:

The Controlled variable is the quantity or condition that is measured and controlled. The

manipulated variable is the quantity or condition that is varied by the controller so as to affectthe values of controlled variable. Normally the control variable is the output of the system.

Control means measuring the value of controlled variable of the system and applyingmanupilated variable to the system to correct or limit deviations of the measured value formdesired value. In study control engineering, we need to define additional terms that arenecessary to describe control systems.

CONNECTION PROCEDURE :

1. Connect terminal P7( pulse input-1) to P3( pulse output) and P10(pulse imput-2)to

P4(pulse output).2. Connect Gate terminal P8 to P19 and P11 to P21.3. Connect MT1(1) terminal P9 to P20 and MT1(2) terminal P12 to P224. Connect terminal P23 to P24, P25 to P26 and P27 to P28.5. Connect terminal P15 to P17 and P16 to P18.6. Connect terminal P1(SP input) to P13(SP output) and connect terminal P2(PV input)

to P14 (PV output)

Ex.No:04AC SERVOMOTOR POSITION CONTROL SYSTEMS

Date :

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 22/30

7. Connect Servo Motor to P31 by using serial cable.8. Connect the main winding of motor to 230V AC supply through a PC power chord.

EXPERIMENTAL PROCEDURE:1. Check whether the connection are made as per the connection procedure. 2. Switch ON trainer power ON/OFF 3. Switch ON the constant 230V AC main winding voltage to the servo motor. 4. Set the motor positon using set position knob(POT1) and take the reading for set

position and actual position and tabulate the readings. 5. Repeat the same procedure step step upto 340 0 6. For each step note down set position and actual position and tabulate the reading.

CONNECTION DIAGRAM

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 23/30

TABULATION:

Sl. No Set Position Actual Position

1. 2.

3.

4.

5.

6.

RESULT:

Thus the AC Servomotor position control experiment was conducted and their readingare tabulated.

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 24/30

AIM:

To Study the working of stepper motor

APPARATUS REQUIRED:

SI.NO APPARATUS RANGE TYPE QUANTITY

1. Stepper Motor - - 1no.

2. Microprocessor Kit - - 1no.

3. Interfacing Card - - 1no.

4. Power supply - - -

THEORY:

A Motor in which the rotor is able to assume only discrete stationary angular position is astepper motor. The rotory motion occurs in a stepwise manner from one equilibrium position to

the next.

Stepper motor control is very popular application of microprocessor in control area. Theyare widely used in ( simple position control systems in the open and closed loop mode) a varietyof application such as computer pheripherals ( printers, disck driver etc.) and in the areas of

process control machine tools, medicine, numerically controlled machines and robotics.

A stepper motor could be either of the reluctance type or of the permanent magnettype(PM). A PM stepper motor consists of multiphased stator and two part permanent magnetrotor. The VR Stepper motor has unmagnetised rotor. PM stepper motor is the most commonlyused type.

Ex.No:05STEPPER MOTOR CONTROL SYSTEM

Date :

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 25/30

Program:

Memory Address Hex code Label Opcode & Operand4100 21 1A 41 START : LXI H, LOOK UP4103 06 04 MVI B,044105 7E REPT: MOV A,M4106 D3 C0 OUT 0C0H4108 11 03 03 LXI D, 0303H410B 00 DELAY NOP410C 1B DCX D410D 7B MOV A, E410E B2 ORA D

410F C2 0B 41 JNZ DELAY4112 23 INX H4113 05 DCR B4114 C2 05 41 JNZ REPT4117 C3 00 41 JMP START411A 09 05 06 0A LOOK UP: DB 09 05 06 OA

RESULT:

Thus the experiment were conducted and result were noted.

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 26/30

AIM:

To Derive the transfer function equation of the given field controlled DC Servo motorexperimentally and to determine the transfer function parameters.

APPARATUS REQUIRED:

SI.NO APPARATUS RANGE TYPE QUANTITY

1. Trainer Kit - - 1no.

2. DC Motor - - 1no.

3. Tachometer - - 1no.

4. CRO - - -

5. Multimeter - - -

6. Patch Cards - - As per requirement

THEORY:

An electric motor is machine which converts electrical energy into mechanical energy.This principle of motor is “When a current carrying conductor is placed in a magnetic field itexperience a force. The direction of force is given by Fleming’s Left hand rule and whosemagnitude is given by F=BIL Newton

The speed N is inversely proportional to flux. By decreasing the flux the speed can beincreased or decreased vice versa. The flux of the DC motor can be changed by changing Ish[varying shunt field rheostat]. By reducing Ish we can reduce the (Ish) 2 R losses. Therefore this

method is very efficient method. Over weakening of the flux will neglect the communication andhave put a limit to the maximum speed obtainable with this method. This method is used whenthe speed above the no load speed is required.

Ex.No:06 TRANSFER FUNCTION OF FIELD CONTROLLED DC SERVO

MOTORDate :

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 27/30

CALCULATIONS:

Torque is proportional to the product of flux and armature current

T α If * Ia

T=KIf * Ia

If the moment of Inertia J and frictional coefficient B is given by,

T= J (d 2θ/dt 2)+B dθ/dt

Taking laplace transform for the above equations we got.

Rf If(S) + Lf S If(S) = V(S)

T(S) = Kf If(S)

JS2 θ (S) + BS θ (S) =T(S)

Kf If(S) = JS 2 θ (S) + BS θ (S)

If(S) = S (JS+B)θ(S)/Kf )=Vf(S)

θ(S)/Vf(S) = Kf/S(Rf+LfS)(JS+B)

= Kf/[S.Rf(1+LfS/Rf)B(1+JS/B)

= Kf/RfB/[S(1+STf)(1+STm)

θ(S)/Vf(S)= Km/S(1+STf)(1+STm)

Where,

Motor gain constant Km = Kf/RfB.

Field time constant Tf=Kf/Rf.

Mechanical time constant Tm=J/B

Toque constant Kf = T/If

Rf= Field resistance in ohms.

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 28/30

B=Frictional co-efficient Nm rad/sec.

Lf=Field inductance in Hendry.

J= Moment of inertia Kgm 2 /rad.

PROCEDURE:

Check the MCB switch ie., it is in OFF condition. Press the reset switch to reset the over speed. Patch the patch cards as per the patching diagram. Put the selection button in field control method. Check the position of potentiometer. If should be in maximum resistance position. Connect the armature of DC motor to bridge output. Switch ON the MCB and vary the potentiometer. The motor speed is varied by

according to the potentiometer position. Apply rated voltage to the field and note down the field current and speed. Tabulate the readings.

RESULT:

Thus the transfer function of field controlled DC motor has been derived the parametersare obtained experimentally.

Transfer function θ (S)/Vs(S)=0.155102/(0.1005S 3+5.02S 3+S)

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 29/30

AIM:

To derive the transfer function of the AC Servo motor and experimentally determine thetransfer function parameters.

APPARATUS REQUIRED:

SI.NO APPARATUS RANGE TYPE QUANTITY

1. Trainer Kit - - 1no.

2. DC Motor - - 1no.

3. Tachometer - - 1no.

4. CRO - - -

5. Multimeter - - -

6. Patch Cards - - As per requirement

TRNSFER FUNCTION:

Let

Tm= Torque developed by servomotor

W=d θ /dt = angular speed

T1=torque required by the load

J=moment of inertia of load and rotor

B=Viscous frictional coefficient of load and rotor

K1= slope of control phase voltages Vs torque characteristics

K2=slope of speed torque characteristics

Tm=K1ec – K2 dθ/dt

Ex.No:07 DETERMINATION OF TRANSFER FUNCTION PARAMETERS

OF SERVOMOTORDate :

8/12/2019 New Manual1

http://slidepdf.com/reader/full/new-manual1 30/30