NEEDLE ROLLER BEARINGS - Bianchi Industrial

Transcript of NEEDLE ROLLER BEARINGS - Bianchi Industrial

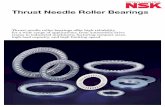

CAT-1586E

CAT-1586E

NEEDLE ROLLER BEARINGS

NEED

LE R

OLLER

BE

AR

ING

S

Recognizing that conservation of the global environment is the top-priority challenge for the world’s population, Nippon Thompson will conduct its activities with consideration of the environment as a corporate social responsibility, reduce its negative impact on the environment, and help foster a rich global environment.

ISO 9001 & 14001 Quality system registration certificate

• The specifications and dimensions of products in this catalog are subject to change without prior notice.

• When these products are exported, the exporter should confirm a forwarding country and a use, and, in case of falling under the customer's requirements, take necessary procedures such as export permission application.

• Although all data in this catalog has been carefully compiled to make the information as complete as possible, NIPPON THOMPSON CO., LTD. shall not be liable for any damages whatsoever, direct or indirect, based upon any information in this catalog. NIPPON THOMPSON CO., LTD. makes no warranty, either express or impiled, including the impiled warranty of merchantability or fitness for a particular purpose.

• Reproduction and conversion without permission are prohibited.

CAT-1586E

CAT-1586E

NEEDLE ROLLER BEARINGS

NEED

LE R

OLLER

BE

AR

ING

SRecognizing that conservation of the global environment is the top-priority challenge for the world’s population, Nippon Thompson will conduct its activities with consideration of the environment as a corporate social responsibility, reduce its negative impact on the environment, and help foster a rich global environment.

ISO 9001 & 14001 Quality system registration certificate

• The specifications and dimensions of products in this catalog are subject to change without prior notice.

• When these products are exported, the exporter should confirm a forwarding country and a use, and, in case of falling under the customer's requirements, take necessary procedures such as export permission application.

• Although all data in this catalog has been carefully compiled to make the information as complete as possible, NIPPON THOMPSON CO., LTD. shall not be liable for any damages whatsoever, direct or indirect, based upon any information in this catalog. NIPPON THOMPSON CO., LTD. makes no warranty, either express or impiled, including the impiled warranty of merchantability or fitness for a particular purpose.

• Reproduction and conversion without permission are prohibited.

J15CRBHV

K37PBK11K15K23

SBGESBB

J19J19

CRBCCRB

J23CRBTJ17CRBFV J25CRBTF

K58K59K59

SNASNMSNPT

I25I31I35I39I43

CF…BCFKRCFE…BCFKRECFES…B

I45I49I49I51I53

CF…WBCF-RU1CF-FU1CF-SFU…BCF…G

I55I57I61I65

CF…/SGCFSCFS…WNUCF…B

I67I67I77I22

CRCR…BCRH…BCL

K38K39K42

PHSPOSPHSA

J27CRBS

K49K51

LHSALHS

I101I103

NURTCRY

(R)NASTNARTNART…/SG

(I89)I90I93I99

M55

D75(D83)D89

1

This catalog adopts the SI system (system of international units) in conformance with ISO (International Organization for Standardization) Standard 1000.

In the table of dimensions, standard products are referred to using identification numbers marked with . The products are reputed for high quality, reasonable price and quick delivery. The identification numbers marked with refer to our semi-standard products.The specifications and dimensions of products in this catalogue are subject to change without prior notice.

The IKO Needle Roller Bearing Series are manufactured through a control system that alleviates

their impact on the global environment to meet the quality requirements of ISO 14001 in

compliance with the quality requirements level of ISO 9001 for quality improvement.

The standard products listed in this catalog comply with the specifications of the ten hazardous

materials mentioned cited in the European RoHS Directive.

CAT-1586E

2 3

A

B

C

D

E

F

G

H

I

J

K

L

M

TA・TLA・BA・BHA

KT・KT…N

KT…EG・KTV…EG

NA・TAFI・TRI・BRI

TAF…/SG

NAF

NAG・NAU・TRU・NAS

NTB・AS・AZK・WS・GS

NAX・NBX・NATA・NATB

IRT・IRB・LRT・LRB

CF…B・CFKR・CFS・NUCF…B・CR…B・CR

CF…/SG

NAST・NART・NURT・CRY

NART…/SG

CRBHV・CRBFV・CRBC・CRB・CRBT・CRBTF・CRBS

SB・GE・SBB

PB・PHS・POS・PHSA

LHSA・LHS

SNA・SNM・SNPT

OS・DS・WR・AR・Needle Roller

Description of Each Series & Table of Dimensions

Shell Type Needle Roller Bearings

Needle Roller Cages for general usage

Needle Roller Cages for engine connecting rods

Machined Type Needle Roller Bearings

C-Lube Machined Type Needle Roller Bearings

Needle Roller Bearings with separable cage

Roller Bearings

Thrust Bearings

Combined Type Needle Roller Bearings

Inner Rings

Cam Followers

C-Lube Cam Followers

Roller Followers

C-Lube Roller Followers

Crossed Roller Bearings

Spherical Bushings

Pilloballs

L-balls

Super Flexible Nozzles

Parts For Needle Roller Bearings

Characteristics of Needle Roller Bearings

Types and Features of Bearings

Outline of Bearing Selection

Basic Dynamic Load Rating and Life

Basic Static Load Rating and Static Safety Factor

Calculation of Bearing Loads

Boundary Dimensions and Identification Number

Accuracy

Clearance

Fit

Design of Shaft and Housing

Lubrication

Friction and Allowable Rotational Speed

Operating Temperature Range

Handling of Bearings

General Explanation

1

1

17

1

75

79

1

1

1

1

1

55

81

99

1

1

29

45

55

1

B

C

C

D

D

D

E

F

G

H

I

I

I

I

J

K

K

K

K

L

A 3

A 5

A 16

A 17

A 21

A 22

A 26

A 30

A 37

A 39

A 44

A 49

A 56

A 57

A 57

M33Miscellaneous Tables

M59Alphabetical Index

A1 A2

Nippon Thompson Co., Ltd. is a bearing manufacturer that launched the technical development of needle roller bearings for the first time in Japan and is proud of the high quality level and abundant varieties of its products.Needle roller bearings are bearings for rotary motion that incorporate needle- shaped thin rollers instead of ordinary bearing balls or rollers. Compared with other rolling bearings, they are small-sized and lightweight but have a large load capacity. They are widely used with high reliability in the fields of automobiles, industrial machinery, OA equipment, etc. as resource-saving type bearings that make the whole machine compact.

A3 A4

A

B

C

D

E

F

G

H

I

J

K

L

M

Bearings can be classified into two main types, namely rolling bearings and sliding bearings. Rolling bearings

can be subdivided further into ball bearings and roller bearings according to the rolling elements.

IKO Needle Roller Bearings are high-precision rolling bearings with a low sectional height, incorporating needle

rollers as the rolling element. They have the following features.

Merits of Rolling Bearings

Compared with sliding bearings, rolling bearings

have the following merits:

Radial ballbearings

Thrust ballbearings

Radial rollerbearings

Thrust rollerbearings

Bal

l bea

rin

gs

Ro

ller

bea

rin

gs

Metals, bushings, others

Deep groove ball bearings

Angular contact ball bearings

Self-aligning ball bearings

Others

Thrust ball bearings with flat back face

Thrust ball bearings with aligning seat washer

Double-direction angular contact thrust ball bearings

Others

Needle roller bearings

Cylindrical roller bearings

Tapered roller bearings

Self-aligning roller bearings

Others

Thrust needle roller bearings

Thrust cylindrical roller bearings

Thrust tapered roller bearings

Others

Classification of bearings

Characteristics of Needle Roller Bearings

Stable accuracy can be maintained for long periods.

Owing to less wear, stable accuracy can be maintained for long periods.

Static and kinetic friction is low.

Since the difference between static friction and kinetic friction is small and the frictional coefficient is also small, drive units or machines can be made more compact and lightweight, saving machine costs and power consumption.

Machine reliability is improved.

Since the bearing life can be estimated based on rolling fatigue, machine reliability is improved.

Lubrication is simplified.

Since grease lubrication is sufficient in most cases, lubrication can be simplified for easy maintenance.

Merits of Needle Roller Bearings

Compared with other rolling bearings, IKO Needle

Roller Bearings have the following advantages:

Rotating torque is small, improving mechanical efficiency.

Since the rotating radius is small, the rotating torque is also small under the same frictional conditions, thus improving mechanical efficiency.

With a low sectional height, they can withstand heavy loads.

Since they have a low sectional height compared with other rolling bearings and yet can withstand heavy loads, machines can be made more compact and lightweight, thus saving costs.

Inertia is minimized.

Since the bearing volume and weight are small, the moment of inertia of the bearing is minimized when it is put in motion.

Most suited to oscillating motions.

Many rolling elements are arranged at a small spacing pitch, and this configuration is most suited to oscillating motions.

Ro

llin

g b

eari

ng

s

Bea

rin

gs

Slid

ing

bea

rin

gs

Bearings can be classified into two main types, namely rolling bearings and sliding bearings. Rolling bearings

can be subdivided further into ball bearings and roller bearings according to the rolling elements.

IKO Needle Roller Bearings are high-precision rolling bearings with a low sectional height, incorporating needle

rollers as the rolling element. They have the following features.

Merits of Rolling Bearings

Compared with sliding bearings, rolling bearings

have the following merits:

Radial ballbearings

Thrust ballbearings

Radial rollerbearings

Thrust rollerbearings

Bal

l bea

rin

gs

Ro

ller

bea

rin

gs

Metals, bushings, others

Deep groove ball bearings

Angular contact ball bearings

Self-aligning ball bearings

Others

Thrust ball bearings with flat back face

Thrust ball bearings with aligning seat washer

Double-direction angular contact thrust ball bearings

Others

Needle roller bearings

Cylindrical roller bearings

Tapered roller bearings

Self-aligning roller bearings

Others

Thrust needle roller bearings

Thrust cylindrical roller bearings

Thrust tapered roller bearings

Others

Classification of bearings

Characteristics of Needle Roller Bearings

Stable accuracy can be maintained for long periods.

Owing to less wear, stable accuracy can be maintained for long periods.

Static and kinetic friction is low.

Since the difference between static friction and kinetic friction is small and the frictional coefficient is also small, drive units or machines can be made more compact and lightweight, saving machine costs and power consumption.

Machine reliability is improved.

Since the bearing life can be estimated based on rolling fatigue, machine reliability is improved.

Lubrication is simplified.

Since grease lubrication is sufficient in most cases, lubrication can be simplified for easy maintenance.

Merits of Needle Roller Bearings

Compared with other rolling bearings, IKO Needle

Roller Bearings have the following advantages:

Rotating torque is small, improving mechanical efficiency.

Since the rotating radius is small, the rotating torque is also small under the same frictional conditions, thus improving mechanical efficiency.

With a low sectional height, they can withstand heavy loads.

Since they have a low sectional height compared with other rolling bearings and yet can withstand heavy loads, machines can be made more compact and lightweight, thus saving costs.

Inertia is minimized.

Since the bearing volume and weight are small, the moment of inertia of the bearing is minimized when it is put in motion.

Most suited to oscillating motions.

Many rolling elements are arranged at a small spacing pitch, and this configuration is most suited to oscillating motions.

Ro

llin

g b

eari

ng

s

Bea

rin

gs

Slid

ing

bea

rin

gs

A

B

C

D

E

F

G

H

I

J

K

L

M

A5 A6

C-Lube Machined Type Needle Roller Bearings TAF… /SG

Classification of Bearings

Combined Type Needle Roller Bearings

Thrust Roller Bearings

Shell Type Needle Roller Bearings

Needle Roller Cages

Machined Type Needle Roller Bearings

Roller Bearings

Thrust Needle Roller Bearings

NAFW, RNAFW

with Three-point Contact Ball Bearing

with Angular Contact Ball Bearing

with Thrust Roller Bearing

with Thrust Ball Bearing

Roller Bearings for Sheaves

Needle Roller Bearings with Separable Cage

Needle Roller Cages for Engine Connecting Rods

Needle Roller Cages for General Usage

TA, TAM

TLA, TLAM

BA, BAM

BHA, BHAM

YT

YTL

YB

YBH

KT, KT…N

KTW

KT…EG

KTV…EG

NA, RNA

TAFI, TAF

TRI, TR

BRI, BR

GTRI, GTR

NAF, RNAF

NAU

NAG

TRU

NAS

NTB

AZK, AZ

NAXI, NAX

NBXI, NBX

NATA

NATB

IKO Bearings can be roughly classified into radial bearings and thrust bearings according to applicable load direction. Radial Bearings are grouped into Shell Type Needle Roller Bearings, Machined Type Needle Roller Bearings, and various other types. Thrust Bearings are grouped into Thrust Needle Roller Bearings and Thrust Roller Bearings.Follower Bearings that are used for cam mechanisms and linear motion are grouped into Cam Followers and Roller Followers.

Crossed Roller Bearings are special shape bearings that can simultaneously receive loads in all directions with a single bearing.Bearings other than rolling bearings, such as self-aligning Spherical Bushings that can support radial loads and axial loads and PILLOBALLs and L-Balls that are used for link mechanisms, are also available.

Types and Features of BearingsR

adia

l Bea

rin

gs

Thru

stBe

arin

gsCo

mbi

ned T

ype

Bear

ings

High Rigidity Type Crossed Roller Bearings (V) CRBHV

CF…B, CFKR

CFES…B

CFE…B, CFKRE

CF…WB

CF-RU1, CF-FU1

CF-SFU…B

NUCF…B

CR, CR…B, CRH

NURT

Mounting Holed Type High Rigidity Crossed Roller Bearings (V) CRBFV

CRBC, CRB

Mounting Holed Type Super Slim Crossed Roller Bearings CRBTF

NAST, RNAST

NART, CRY

C-Lube Machined Type Needle Roller Bearings TAF… /SG

Classification of Bearings

Combined Type Needle Roller Bearings

Thrust Roller Bearings

Shell Type Needle Roller Bearings

Needle Roller Cages

Machined Type Needle Roller Bearings

Roller Bearings

Thrust Needle Roller Bearings

NAFW, RNAFW

with Three-point Contact Ball Bearing

with Angular Contact Ball Bearing

with Thrust Roller Bearing

with Thrust Ball Bearing

Roller Bearings for Sheaves

Needle Roller Bearings with Separable Cage

Needle Roller Cages for Engine Connecting Rods

Needle Roller Cages for General Usage

TA, TAM

TLA, TLAM

BA, BAM

BHA, BHAM

YT

YTL

YB

YBH

KT, KT…N

KTW

KT…EG

KTV…EG

NA, RNA

TAFI, TAF

TRI, TR

BRI, BR

GTRI, GTR

NAF, RNAF

NAU

NAG

TRU

NAS

NTB

AZK, AZ

NAXI, NAX

NBXI, NBX

NATA

NATB

IKO Bearings can be roughly classified into radial bearings and thrust bearings according to applicable load direction. Radial Bearings are grouped into Shell Type Needle Roller Bearings, Machined Type Needle Roller Bearings, and various other types. Thrust Bearings are grouped into Thrust Needle Roller Bearings and Thrust Roller Bearings.Follower Bearings that are used for cam mechanisms and linear motion are grouped into Cam Followers and Roller Followers.

Crossed Roller Bearings are special shape bearings that can simultaneously receive loads in all directions with a single bearing.Bearings other than rolling bearings, such as self-aligning Spherical Bushings that can support radial loads and axial loads and PILLOBALLs and L-Balls that are used for link mechanisms, are also available.

Types and Features of Bearings

Rad

ial B

eari

ng

sTh

rust

Bear

ings

Com

bine

d Typ

eBe

arin

gs

High Rigidity Type Crossed Roller Bearings (V) CRBHV

CF…B, CFKR

CFES…B

CFE…B, CFKRE

CF…WB

CF-RU1, CF-FU1

CF-SFU…B

NUCF…B

CR, CR…B, CRH

NURT

Mounting Holed Type High Rigidity Crossed Roller Bearings (V) CRBFV

CRBC, CRB

Mounting Holed Type Super Slim Crossed Roller Bearings CRBTF

NAST, RNAST

NART, CRY

A

B

C

D

E

F

G

H

I

J

K

L

M

A7 A8

Shell Type Needle Roller Bearings are lightweight with the lowest sectional height among needle roller bearings with outer ring, because they employ a shell type outer ring made from a thin special-steel plate which is accurately drawn, carburized and quenched.Since these bearings are press-fitted into the housing, no axial positioning fixtures are required. They are ideal for use in mass-produced articles that require economy.

Shell Type Needle Roller Bearings

Radial Bearings Page B1

Needle Roller Cages for General Usage are bearings that display excellent rotational performance. Their specially shaped cages with high rigidity and accuracy, precisely guide the needle rollers.Since needle rollers with extremely small dimensional variations in diameter are incorporated and retained, Needle Roller Cages for General Usage are useful in small spaces when combined with shafts and housing bores that are heat treated and accurately ground as raceway surfaces.

Radial Bearing Page C1

Machined Type Needle Roller Bearings have an outer ring made by machining, heat treatment, and grinding. The outer ring has stable high rigidity and can be easily used even for light alloy housings.These bearings are available in various types and optimally selectable for different conditions such as heavy loads, high-speed rotation and low-speed rotation. They are most suitable for general-purpose applications.

Radial Bearing Page D1

In Needle Roller Bearings with Separable Cage, the inner ring, outer ring and Needle Roller Cage are combined, and they can be separated easily. This type has a simple structure with high accuracy. In addition, the radial clearance can be freely selected by choosing an assembly combination.These bearings have excellent rotational performance, because Needle Roller Cages are used.

Radial Bearing Page D79

Roller Bearings, in which rollers are incorporated in double rows, are non-separable heavy-duty bearings.They can withstand not only radial loads but axial loads as well, which are supported at the contacts between the shoulders of inner and outer rings and the end faces of rollers. Therefore, they are most suitable for use at the fixing side of a shaft.

Radial Bearing Page E1

Needle Roller Gages for Engine Connecting Rods are used for motor cycles, small motor vehicles, outboard marines, snow mobiles, general-purpose engines, high- speed compressors, etc. that are operated under extremely severe and complex operating conditions such as heavy shock loads, high speeds, high temperatures, and stringent lubrication.Needle Roller Cages for Engine Connecting Rods are lightweight and have high load ratings and high rigidity as well as superior wear resistance.

Radial Bearing Page C17

Needle Roller Cages for General Usage

Needle Roller Cages for Engine Connecting Rods

Machined Type Needle Roller Bearings

Roller Bearings

Needle Roller Bearings with Separable Cage

Shell Type Needle Roller Bearings are lightweight with the lowest sectional height among needle roller bearings with outer ring, because they employ a shell type outer ring made from a thin special-steel plate which is accurately drawn, carburized and quenched.Since these bearings are press-fitted into the housing, no axial positioning fixtures are required. They are ideal for use in mass-produced articles that require economy.

Shell Type Needle Roller Bearings

Radial Bearings Page B1

Needle Roller Cages for General Usage are bearings that display excellent rotational performance. Their specially shaped cages with high rigidity and accuracy, precisely guide the needle rollers.Since needle rollers with extremely small dimensional variations in diameter are incorporated and retained, Needle Roller Cages for General Usage are useful in small spaces when combined with shafts and housing bores that are heat treated and accurately ground as raceway surfaces.

Radial Bearing Page C1

Machined Type Needle Roller Bearings have an outer ring made by machining, heat treatment, and grinding. The outer ring has stable high rigidity and can be easily used even for light alloy housings.These bearings are available in various types and optimally selectable for different conditions such as heavy loads, high-speed rotation and low-speed rotation. They are most suitable for general-purpose applications.

Radial Bearing Page D1

In Needle Roller Bearings with Separable Cage, the inner ring, outer ring and Needle Roller Cage are combined, and they can be separated easily. This type has a simple structure with high accuracy. In addition, the radial clearance can be freely selected by choosing an assembly combination.These bearings have excellent rotational performance, because Needle Roller Cages are used.

Radial Bearing Page D79

Roller Bearings, in which rollers are incorporated in double rows, are non-separable heavy-duty bearings.They can withstand not only radial loads but axial loads as well, which are supported at the contacts between the shoulders of inner and outer rings and the end faces of rollers. Therefore, they are most suitable for use at the fixing side of a shaft.

Radial Bearing Page E1

Needle Roller Gages for Engine Connecting Rods are used for motor cycles, small motor vehicles, outboard marines, snow mobiles, general-purpose engines, high- speed compressors, etc. that are operated under extremely severe and complex operating conditions such as heavy shock loads, high speeds, high temperatures, and stringent lubrication.Needle Roller Cages for Engine Connecting Rods are lightweight and have high load ratings and high rigidity as well as superior wear resistance.

Radial Bearing Page C17

Needle Roller Cages for General Usage

Needle Roller Cages for Engine Connecting Rods

Machined Type Needle Roller Bearings

Roller Bearings

Needle Roller Bearings with Separable Cage

A

B

C

D

E

F

G

H

I

J

K

L

M

A9 A10

Cam Followers

Inner Rings

Thrust Bearings consist of a precisely made cage and rollers, and can receive axial loads. They have high rigidity and high load capacities and can be used in small spaces.Thrust Needle Roller Bearings use needle rollers, whileThrust Roller Bearings use cylindrical rollers.

Thrust Bearings

Thrust Bearing Page F1

Cam Followers are bearings with a stud incorporating needle rollers in a thick walled outer ring.They are designed for outer ring rotation, and the outer rings run directly on mating cam guide surfaces.Various types of Cam Followers are available. They are widely used as follower bearings for cam mechanisms and for linear motions.

Follower Bearing Page I1

Roller FollowersRoller Followers are bearings in which needle rollers are incorporated in a thick walled outer ring.These bearings are designed for outer ring rotation, and the outer rings run directly on mating cam guide surfaces.They are used as follower bearings for cam mechanisms and for linear motions.

Follower Bearing Page I81

Crossed Roller BearingsCrossed Roller Bearings are high-rigidity and compact bearings with their cylindrical rollers alternately crossed at right angles to each other between inner and outer rings. A single Crossed Roller Bearing can take loads from any directions at the same time such as radial, thrust, and moment loads.These bearings are widely used in the rotating parts of industrial robots, machine tools, medical equipment, etc. which require compactness, high rigidity and high rotational accuracy.

Crossed Roller Bearing Page J1

Combined Type Needle Roller Bearings are combinations of a radial bearing and a thrust bearing. Caged Needle Roller Bearings are used as radial bearings and Thrust Ball Bearings or Thrust Roller Bearings are used as thrust bearings.They can be subjected to radial loads and axial loads simultaneously.

Combined Type Needle Roller Bearings

Combined Type Bearing Page G1

Inner Rings are heat-treated and finished by grinding to a high degree of accuracy and are used for Needle Roller Bearings.In the case of Needle Roller Bearings, normally the shafts are heat-treated and finished by grinding and used as raceway surfaces. However, when it is impossi-ble to make shaft surfaces according to the specified surface hardness or surface roughness, Inner Rings are used.

Component part Page H1

Cam Followers

Inner Rings

Thrust Bearings consist of a precisely made cage and rollers, and can receive axial loads. They have high rigidity and high load capacities and can be used in small spaces.Thrust Needle Roller Bearings use needle rollers, whileThrust Roller Bearings use cylindrical rollers.

Thrust Bearings

Thrust Bearing Page F1

Cam Followers are bearings with a stud incorporating needle rollers in a thick walled outer ring.They are designed for outer ring rotation, and the outer rings run directly on mating cam guide surfaces.Various types of Cam Followers are available. They are widely used as follower bearings for cam mechanisms and for linear motions.

Follower Bearing Page I1

Roller FollowersRoller Followers are bearings in which needle rollers are incorporated in a thick walled outer ring.These bearings are designed for outer ring rotation, and the outer rings run directly on mating cam guide surfaces.They are used as follower bearings for cam mechanisms and for linear motions.

Follower Bearing Page I81

Crossed Roller BearingsCrossed Roller Bearings are high-rigidity and compact bearings with their cylindrical rollers alternately crossed at right angles to each other between inner and outer rings. A single Crossed Roller Bearing can take loads from any directions at the same time such as radial, thrust, and moment loads.These bearings are widely used in the rotating parts of industrial robots, machine tools, medical equipment, etc. which require compactness, high rigidity and high rotational accuracy.

Crossed Roller Bearing Page J1

Combined Type Needle Roller Bearings are combinations of a radial bearing and a thrust bearing. Caged Needle Roller Bearings are used as radial bearings and Thrust Ball Bearings or Thrust Roller Bearings are used as thrust bearings.They can be subjected to radial loads and axial loads simultaneously.

Combined Type Needle Roller Bearings

Combined Type Bearing Page G1

Inner Rings are heat-treated and finished by grinding to a high degree of accuracy and are used for Needle Roller Bearings.In the case of Needle Roller Bearings, normally the shafts are heat-treated and finished by grinding and used as raceway surfaces. However, when it is impossi-ble to make shaft surfaces according to the specified surface hardness or surface roughness, Inner Rings are used.

Component part Page H1

A11 A12

A

B

C

D

E

F

G

H

I

J

K

L

M

L-Balls

Seals for Needle Roller BearingsSpherical BushingsSpherical Bushings are self-aligning spherical plain bushings, which have inner and outer rings with spherical sliding surfaces. They can take a large radial load and a bi-directional axial load at the same time.They are divided into steel-on-steel types that are suitable for applications where there are alternate loads or shock loads, and maintenance-free types which require no lubrication.

Spherical Sliding Bearing Page K1

PILLOBALLsPILLOBALLs are compact self-aligning spherical plain bushings which can support a large radial load and a bi- directional axial load at the same time.PILLOBALL Rod Ends have either a female thread in the body or a male thread on the body, so they can be easily assembled onto machines.PILLOBALLs are used in control and link mechanisms in machine tools, textile machines, packaging machines, etc.

Spherical Sliding Bearing Page K29

L-Balls are self-aligning rod-ends consisting of a special zinc die-cast alloy body and a studded ball which has its axis at right-angles to the body.They can perform tilting movement and rotation with low torque, and transmit power smoothly due to the uniform clearance between the sliding surfaces.They are used in link mechanisms in automobiles, construction machinery, farm and packaging machines, etc.

Spherical Sliding Bearing Page K45

Seals for Needle Roller Bearings have a low sectional height and consist of a sheet metal ring and special synthetic rubber.As these seals are manufactured to the same sectional height as Needle Roller Bearings, grease leakage and the penetration of foreign particles can be effectively prevented by fitting them directly to the sides of combinable bearings.

Component Part Page L1

Cir-clips for Needle Roller BearingsCir-clips for Needle Roller Bearings have been specially designed for needle roller bearings on which, in many cases, generally available Cir-clips cannot be used. They have a low sectional height and are very rigid.There are Cir-clips for shafts and for bores, and they are used for positioning to prevent bearing movement in the axial direction.

Component Part Page L17

Needle RollersNeedle Rollers are used for needle roller bearings and are rigid and highly accurate.These needle rollers are widely used as rolling elements for bearings, and also as pins and shafts.

Component Part Page L23

L-Balls

Seals for Needle Roller BearingsSpherical BushingsSpherical Bushings are self-aligning spherical plain bushings, which have inner and outer rings with spherical sliding surfaces. They can take a large radial load and a bi-directional axial load at the same time.They are divided into steel-on-steel types that are suitable for applications where there are alternate loads or shock loads, and maintenance-free types which require no lubrication.

Spherical Sliding Bearing Page K1

PILLOBALLsPILLOBALLs are compact self-aligning spherical plain bushings which can support a large radial load and a bi- directional axial load at the same time.PILLOBALL Rod Ends have either a female thread in the body or a male thread on the body, so they can be easily assembled onto machines.PILLOBALLs are used in control and link mechanisms in machine tools, textile machines, packaging machines, etc.

Spherical Sliding Bearing Page K29

L-Balls are self-aligning rod-ends consisting of a special zinc die-cast alloy body and a studded ball which has its axis at right-angles to the body.They can perform tilting movement and rotation with low torque, and transmit power smoothly due to the uniform clearance between the sliding surfaces.They are used in link mechanisms in automobiles, construction machinery, farm and packaging machines, etc.

Spherical Sliding Bearing Page K45

Seals for Needle Roller Bearings have a low sectional height and consist of a sheet metal ring and special synthetic rubber.As these seals are manufactured to the same sectional height as Needle Roller Bearings, grease leakage and the penetration of foreign particles can be effectively prevented by fitting them directly to the sides of combinable bearings.

Component Part Page L1

Cir-clips for Needle Roller BearingsCir-clips for Needle Roller Bearings have been specially designed for needle roller bearings on which, in many cases, generally available Cir-clips cannot be used. They have a low sectional height and are very rigid.There are Cir-clips for shafts and for bores, and they are used for positioning to prevent bearing movement in the axial direction.

Component Part Page L17

Needle RollersNeedle Rollers are used for needle roller bearings and are rigid and highly accurate.These needle rollers are widely used as rolling elements for bearings, and also as pins and shafts.

Component Part Page L23

A

B

C

D

E

F

G

H

I

J

K

L

M

A13 A14

F1~

G1~

I1~

I81~

Bearing series Appearance Direction ofmotion

Load directionand capacity

Allowable rotational speed

Sectionalheight

ReferencepageFriction

Thrust Bearings

Combined Type Needle Roller Bearings

Cam Followers

Roller Followers

Needle roller bearings

Roller bearings

With thrust ball bearing

With thrust roller bearing

With angular contact ball bearing

With three-point contact ball bearing

Caged type

Full complement type

Separable caged type

Non-separable caged type

Non-separable full complement type

Bearing series Appearance Direction ofmotion

Load directionand capacity

Allowable rotational speed

Sectionalheight

ReferencepageFriction

Shell TypeNeedle RollerBearings

NeedleRoller Cages

Machined TypeNeedle RollerBearings

Needle RollerBearings withSeparable Cage

Roller Bearings

Caged type

Caged type

Caged type

Caged type

Fullcomplementtype

Fullcomplementtype

Fullcomplementtype

For sheaves

Forgeneral usage

For engineconnectingrods

B1~

C1~

C17~

D1~

D79~

E1~

Rotation Oscillating motion

Radial load

Axial load

Light load

Medium load

Heavy load

Especially excellent Excellent NormalSymbol

Features of Bearings

F1~

G1~

I1~

I81~

Bearing series Appearance Direction ofmotion

Load directionand capacity

Allowable rotational speed

Sectionalheight

ReferencepageFriction

Thrust Bearings

Combined Type Needle Roller Bearings

Cam Followers

Roller Followers

Needle roller bearings

Roller bearings

With thrust ball bearing

With thrust roller bearing

With angular contact ball bearing

With three-point contact ball bearing

Caged type

Full complement type

Separable caged type

Non-separable caged type

Non-separable full complement type

Bearing series Appearance Direction ofmotion

Load directionand capacity

Allowable rotational speed

Sectionalheight

ReferencepageFriction

Shell TypeNeedle RollerBearings

NeedleRoller Cages

Machined TypeNeedle RollerBearings

Needle RollerBearings withSeparable Cage

Roller Bearings

Caged type

Caged type

Caged type

Caged type

Fullcomplementtype

Fullcomplementtype

Fullcomplementtype

For sheaves

Forgeneral usage

For engineconnectingrods

B1~

C1~

C17~

D1~

D79~

E1~

Rotation Oscillating motion

Radial load

Axial load

Light load

Medium load

Heavy load

Especially excellent Excellent NormalSymbol

Features of Bearings

A

B

C

D

E

F

G

H

I

J

K

L

M

A15 A16

An example of procedure for bearing selection

J1~

K1~

K29~

K45~

Identify the machine and place where the bearing is to be used. Confirm the requirements for bearings such as required bearing performance, and also confirm the operating conditions and special environment conditions.

Select the bearing type suitable for the operating conditions by considering load direction and magni- tude, rigidity, friction, allowable rotational speed, bearing space, etc.

See page

A5

Select the bearing dimensions by calculating bearing load, life, static safety factor, etc.

1

2

3

4

5

6

7

8

9

Features of Bearings

Bearing series Appearance Direction ofmotion

Load directionand capacity

Allowable rotational speed

Sectionalheight

ReferencepageFriction

Crossed Roller Bearings

Spherical Bushings

PILLOBALLs

L-Balls

Caged type,Separator type

Full complement type

Slim type

Steel-on-steel type

Maintenance-free type

Maintenance-free type

Lubrication type

Insert type, Lubrication type

Die-casting type, Lubrication type

Rotation Oscillating motion

Radial load

Axial load

Light load

Medium load

Heavy load

Especially excellent Excellent NormalSymbol

IKO Bearings are available in many types and sizes. To obtain satisfactory bearing performance in machines and equipment, it is essential to select the most suitable bearing by carefully studying the requirements for the application.Although there is no particular procedure or rule for bearing selection, an example of a commonly adopted procedure is shown in the figure below.

Outline of Bearing Selection

Selection of bearing type

Selection of bearing dimensions

Selection of accuracy class, etc.

Selection of radial clearance and fit

Determination of bearing dimensions, accuracy, radial clearance and fit

Selection of lubrication and dust-proof methods

Design of surrounding part

Determination of final specifications of the bearing and the surrounding part

Confirmation of requirements and operating conditions

See page

A17

Select the accuracy as required by the machine or equipment. See page

A30

Select the radial clearance considering the fit, temperature, rotational speed, inclination of the inner and outer rings, etc.

See page

A37

Select oil or grease lubrication. After selection of lubricant, in case of oil lubrication, select the oil application method. Select the sealing method according to the lubricant.

See page

A49

Design the surrounding part based on how to mount or dismount and based on mounting dimensions. See page

A57

An example of procedure for bearing selection

J1~

K1~

K29~

K45~

Identify the machine and place where the bearing is to be used. Confirm the requirements for bearings such as required bearing performance, and also confirm the operating conditions and special environment conditions.

Select the bearing type suitable for the operating conditions by considering load direction and magni- tude, rigidity, friction, allowable rotational speed, bearing space, etc.

See page

A5

Select the bearing dimensions by calculating bearing load, life, static safety factor, etc.

1

2

3

4

5

6

7

8

9

Features of Bearings

Bearing series Appearance Direction ofmotion

Load directionand capacity

Allowable rotational speed

Sectionalheight

ReferencepageFriction

Crossed Roller Bearings

Spherical Bushings

PILLOBALLs

L-Balls

Caged type,Separator type

Full complement type

Slim type

Steel-on-steel type

Maintenance-free type

Maintenance-free type

Lubrication type

Insert type, Lubrication type

Die-casting type, Lubrication type

Rotation Oscillating motion

Radial load

Axial load

Light load

Medium load

Heavy load

Especially excellent Excellent NormalSymbol

IKO Bearings are available in many types and sizes. To obtain satisfactory bearing performance in machines and equipment, it is essential to select the most suitable bearing by carefully studying the requirements for the application.Although there is no particular procedure or rule for bearing selection, an example of a commonly adopted procedure is shown in the figure below.

Outline of Bearing Selection

Selection of bearing type

Selection of bearing dimensions

Selection of accuracy class, etc.

Selection of radial clearance and fit

Determination of bearing dimensions, accuracy, radial clearance and fit

Selection of lubrication and dust-proof methods

Design of surrounding part

Determination of final specifications of the bearing and the surrounding part

Confirmation of requirements and operating conditions

See page

A17

Select the accuracy as required by the machine or equipment. See page

A30

Select the radial clearance considering the fit, temperature, rotational speed, inclination of the inner and outer rings, etc.

See page

A37

Select oil or grease lubrication. After selection of lubricant, in case of oil lubrication, select the oil application method. Select the sealing method according to the lubricant.

See page

A49

Design the surrounding part based on how to mount or dismount and based on mounting dimensions. See page

A57

A

B

C

D

E

F

G

H

I

J

K

L

M

A17 A181N=0.102kgf=0.2248lbs.1mm=0.03937inch

Basic Dynamic Load Ratingand Life

CP( )

p

Operating conditions

Occasional or short term usage ・Power tools ・Agricultural machines

・Construction machinery ・Conveyors・Elevators

・Roll neck of rolling mills ・Small motors・Deck cranes・General cargo cranes・Passenger cars

・Factory motors・Machine tools・General gear units・Printing machines

・Crane sheaves・Compressors・Important gear units

Infrequent usage but requiring reliable operation

Intermittent operation but for comparatively long periods

・Escalators ・Centrifugal separators・Blowers・Wood working machines・Plastic extruding machines

・Paper making machinesOperated in excess of 8 hours per day or continuously for an extended time

・Water supply equipment・Power station equipment

Continuous use for 24 hours and accidental stops not allowed

Machine and life factor fh

〜 3 2〜 4 3〜 5 4〜 7 6〜

Basic rating life

The basic rating life is defined as the total number of revolutions that 90% of a group of identical bearings can be operated individually under the same condi-tions free from any material damage caused by rolling fatigue.For rotation at a constant rotational speed, the basic rating life can be represented by the total service hours.

Basic dynamic load rating

The basic dynamic load rating is defined as the con-stant radial load (in the case of radial bearings) or the constant axial load acting along the bearing central axis (in the case of thrust bearings) that allows a basic rating life of 1,000,000 revolutions.

Calculation of rating life

The relationship among the basic rating life, basic dynamic load rating and dynamic equivalent load (bearing load) of rolling bearings is as follows:

L10

= ……………………………………(1)

where, L10 :Basic rating life, 106 rev. C :Basic dynamic load rating, N P :Dynamic equivalent load, N p : Exponent, Roller bearing: 10/3

Ball bearing: 3Accordingly, when the rotational speed per minute is given, the basic rating life is represented as the total service hours according to the following equations:

Lh = = 500 f h ……………………(2)

f h= f n …………………………………(3)

f n = …………………………………(4)

where, Lh :Basic rating life represented by

service hours, h n :Rotational speed, min-1

f h :Life factor

f n :Velocity factorIn addition, the rating life can be calculated by obtain-

ing f h and f n from the life calculation scales of Fig. 2.

Life

Rolling bearings will suffer damage due to various causes during service. Damage such as abnormal wear, seizure, and cracks is caused by improper use, including incorrect mounting, lack of oil, dust intrusion and so on, and can be avoided by remedying these causes. However, bearings will eventually be dam-aged due to fatigue-flaking even if used properly. When a bearing rotates under load, the raceways and the rolling elements are subjected to repeated stress-es concentrated on the part close to the surface. Fatigue, therefore, occurs in the surface layer, pro-ducing damage in the form of scaling. This is called flaking (spalling). When this occurs, the bearing can no longer be used.

Bearing Life

Bearing life is defined as the total number of revolu-tions (or total service hours at a constant rotational speed) before a sign of the first flaking appears on the roll ing surface of raceway or roll ing elements. However, even when bearings of the same size, structure, material and heat treatment are subjected to the same conditions, the bearing lives will show variation (See Fig. 1.). This results from the statistical nature of the fatigue phenomenon.In selecting a bearing, it is incorrect to take an aver-age life for all bearings as the design standard. It is more practical to consider a bearing life that is reliable for the greater propor t ion of bear ings used. Therefore, the basic rating life defined in the following is used.

106L1060n

CP

p

33.3n( )

1/p

Bearing life factors for various machines

The required life of the bearing must be determined according to the machine in which the bearing is to be used and the operating conditions.Table 1 shows reference values of life factors for selecting a bearing for each machine.

Table 1 Life factor of bearings f h for various machines

Fig. 2 Scales for rating life calculation

Rotational speed

Velocity factor

Basic rating life represented by service hours

Life factor

Rotational speed

Velocity factor

Basic rating life represented by service hours

Life factor

Roller bearings10

200 1000 10000 80000

100 1000 10000

1.44

0.76 1.0 2.0 3.0 4.0 4.6

1.0 0.20

15 20

300 400 500 600 700 800 900 2000 3000 4000 6000 8000 20000 40000 60000

30 40 60 80 150 200 300 400 600 800 1500 2000 3000 4000 6000 8000 15000 20000 30000 40000 60000

1.4 1.3

0.80 0.85 0.90 0.95 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.5 3.5 4.5

1.2 1.1 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.28 0.24 0.22 0.18 0.16 0.14 0.12 0.106

min-1

nfn

hLhfh

10

200 1000 10000 80000

100 1000 10000

1.49

0.74 1.0 2.0 3.0 4.0 5.0 5.4

1.0 0.20 0.10

15 20

300 400 500 600 700 800 900 2000 3000 4000 6000 8000 20000 4000030000 60000

30 40 60 80 150 200 300 400 600 800 1500 2000 3000 4000 6000 8000 15000 20000 30000 40000 60000

1.4 1.3

0.80 0.90 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2.5 3.5 4.5

1.2 1.1 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.28 0.24 0.22 0.18 0.16 0.14 0.12 0.09 0.082

min-1

nfn

hLhfh

Ball bearings

Fig. 1 Variation of rolling fatigue life

Failu

re p

roba

bility

den

sity

(Fre

quen

cy o

f fai

lure

)

Bas

ic r

atin

g lif

e

Ave

rage

life

Rolling fatigue life

A

B

C

D

E

F

G

H

I

J

K

L

M

A19 A201N=0.102kgf=0.2248lbs.1mm=0.03937inch

Life of oscillating bearing

The life of an oscillating bearing can be obtained from equation (5).

LOC=

………………………………(5)

where, LOC: Basic rat ing l i fe of osci l lat ing

bearing, 106 cycles 2θ: Oscillating angle, deg. (See Fig.3)

P : Dynamic equivalent load, NTherefore, when the oscillating frequency n 1min-1 is given, the basic rating life as represented by total

oscillating hours can be obtained by substituting n 1 for n in equation (2) on page A17.When 2θ is small, an oil film cannot be formed easily between the contact surfaces of the raceway and the rolling elements. This may cause fretting corrosion. In this case, please consult IKO.

2θ

Fig. 3 Oscillating motion

Corrected rating life

When a rolling bearing is used in ordinary applica-tions, the basic rating life can be calculated by equa-tions (1) and (2) mentioned previously.This basic rating life applies to bearings which require a reliability of 90%, have ordinary bearing properties being made of materials of ordinary quality for rolling bearings, and are used under ordinary operating con-ditions.In some applications, however, it is necessary to obtain a rating life that applies to bearings which require high reliability, have special bearing properties or are used under special operating conditions. The corrected rating life for these special cases can be obtained from the following equation by using the

bearing life adjustment factors a1, a2 and a3, respec-tively.

Lna= a1a2a3L10 …………………………… (6)

where, Lna:Corrected rating life, 106 rev. a1 : Life adjustment factor for reliability

a2 : Life adjustment factor for special bearing properties

a3 : Life adjustment factor for operat-ing conditions

Life adjustment factor for reliability a1

The reliability of rolling bearings is defined as the pro-portion of bearings having a life equal to or greater than a certain specified value when a group of identi-cal bearings are operated under identical conditions. With respect to individual bearings, it refers to the probability of the life of a bearing being equal to or greater than a certain specified value.

The corrected rating life for a reliability of (100-n)% can be obtained using equation (6). Table 2 shows

the values of the life adjustment factor a1 for various reliabilities.

Table 2 Life adjustment factor for reliability a1

909596979899

L10L5L4L3L2L1

10.620.530.440.330.21

Reliability % Ln a1

Life adjustment factor for special bearing properties a2

The bearing life is extended or shortened according to the quality of the material, the manufacturing technol-ogy of the bearing and its internal design. For these special bearing life properties, the life is corrected by the life adjustment factor for special bearing proper-

ties a2.The table of dimensions for IKO Bearings shows the values of the basic dynamic load rating which are determined taking into consideration the fact that bearing life has been extended by improved quality of materials and advances in manufacturing technolo-gies. Therefore, the bearing life is calculated using

equation (6) usually assuming a2 = 1.

Life adjustment factor for operating conditions a3

This factor helps take into account the effects of oper-ating conditions, especially lubrication on the bearing.The bearing life is limited by the phenomenon of fatigue which occurs, in general, beneath surfaces subjected to repeated stresses. Under good lubrica-tion conditions where the rolling element and raceway surfaces are completely separated by an oil film and

surface damage can be disregarded, a3 is set to be 1. However, when conditions of lubrication are not good, namely, when the viscosity of the lubricating oil is low or the peripheral speed of the rolling elements is

especially low, and so on, a3< 1 is used.On the other hand, when lubrication is especially

good, a value of a3 > 1 can be used. When lubrica-tion is not good and a3 < 1 is used, the life adjustment factor a2 cannot generally exceed 1.

When selecting a bearing according to the basic dynamic load rating, it is recommended that a suitable

value for reliability factor a1 is chosen for each appli-cation. The selection should be made using the

(C/P) or fh values determined by machine type and based upon the actual conditions of lubrication, tem-perature, mounting, etc., which have already been experienced and observed in the same type of machines.

Limiting conditions

These bearing life equations are applicable only when the bearing is mounted and lubricated normally with-out intrusion of foreign materials and not used under extreme operating conditions.Unless these conditions are satisfied, the life may be shortened. For example, it is necessary to separately consider the effects of bearing mounting errors, excessive deformation of housing and shaft, centrifu-gal force acting on rolling elements at high-speed rev-olution, excessive preload, especially large radial internal clearance of radial bearings, etc.When the dynamic equivalent load exceeds 1/2 of the basic dynamic load rating, the life equations may not be applicable.

CP( )

p90θ

Correction of basic dynamic load rating for temperature and hardness

Temperature factor

The operating temperature for each bearing is deter-mined according to its material and structure. If spe-cial heat treatment is performed, bearings can be used at temperatures higher than +150°C. As the allowable contact stress gradually decreases when the bearing temperature exceeds 150°C, the basic dynamic load rating is lowered and can be obtained by the following equation:

C t = f t C …………………………………… (7)

where, C t : Basic dynamic load rating

considering temperature rise, N f t : Temperature factor (See Fig. 4.)

C : Basic dynamic load rating, N

Temperature

°C 150 200 250

0.750.80.850.90.951.0ft

Fig. 4 Temperature factor

Further, if the bearing is used at high temperature, i.e. 120°C or above, the amount of dimensional displace-ment gets larger. So special heat treatment is neces-sary. If needed, please contact IKO.

Hardness factor

When the shaft or housing is used as the raceway surface instead of the inner or outer ring, the surface hardness of the part used as the raceway surface should be 58〜 64HRC.If it is less than 58HRC, the basic dynamic load rating is lowered and can be obtained by the following equation:

CH = f H C…………………………………… (8)

where, CH : Basic dynamic load rating

considering hardness, N fH : Hardness factor (See Fig. 5.)

C : Basic dynamic load rating N

Hardness of raceway surface

HRC 60 50 40 30 20

0.10.20.41 0.8 0.6fH

Fig. 5 Hardness factor

A21 A221N=0.102kgf=0.2248lbs.1mm=0.03937inch

The loads acting on bearings include the weight of the machine parts supported by the bearings, the weight of the rotating body, loads produced when operating the machine, loads by belts or gears transmitting power, and various other loads.These loads can be divided into radial loads perpen-dicular to the central axis of the bearings and axial loads parallel to the central axis, and they act inde-pendently or in combination with other loads. In addi-tion, the magnitude of vibration or shocks on the bear-ings varies depending on the application of the machine. Thus, theoretically calculated loads may not always be accurate and have to be corrected by multiplying various empirical factors to obtain the actual bearing loads.

Load distribution to bearings

Table 5 shows examples of calculations where static loads are acting in radial direction.

Load factor

Although radial loads and axial loads can be obtained by calculation, it is not unusual for the actual bearing loads to exceed the calculated loads, due to vibration and shocks produced when operating the machine. The actual bearing load is obtained from the following equation, by multiplying the calculated load by the load factor:

F= fw Fc ……………………………………(10)

where, F :Bearing load, N fw :Load factor (See Table 6.)

Fc :Theoretically calculated load, N

Table 6 Load factor

Smooth operation without shocks

Electric motors, Air conditioning equipment, Measuring instruments, Machine tools

Reduction gearboxes, Vehicles, Textile machinery, Paper making machinery

Rolling mills, Rock crushers, Construc-tion machinery

Ordinary operation

Operation subjected to vibration and shocks

1 〜 1.2

1.2〜 1.5

1.5〜 3

Operating conditions Example fw

Basic Static Load Rating andStatic Safety Factor

Calculation of Bearing Loads

Basic static load rating

When a bearing at rest sustains a heavy load or a bearing rotating at a relatively low speed receives a heavy shock load, the contact stress may exceed a certain limiting value, producing a local permanent deformation in the raceways or the rolling elements, and subsequently causing noise or vibration or lower-ing the rotating performance. The basic static load rating is, therefore, determined as a guideline for the maximum allowable load for the bearing at rest, under which the permanent deformation will not exceed a certain limit value, and the lowering of the rotating performance will not occur. Its definition is given as follows.The basic static load rating is the static load that gives the contact stress shown in Table 3 at the center of the contact area of the rolling element and the race-way receiving the maximum load. A radial load con-stant in direction and magnitude is used in the case of radial bearings, while an axial load constant in magni-tude acting along the bearing central axis is used in the case of thrust bearings.

Table 3

Roller bearings

Self-aligning ball bearings

Other ball bearings

4 000

4 600

4 200

Type of bearing Contact stress MPa

Static safety factor

The basic static load rating gives the theoretical allow-able limit of the static equivalent load. Normally, this limit is corrected by considering the operating condi-tions and the requirements for the bearing. The cor-

rection factor, namely, the static safety factor f s is defined as in the following equation and its general values are shown in Table 4.

f s= ………………………………………(9)

where, C0 : Basic static load rating, N P0 : Static equivalent load, N

Table 4 Static safety factor

When high rotational accuracy is required

For ordinary operation conditions

For ordinary operation conditions not requiring very smooth rotation When there is almost no rotation

≧ 3

≧ 1.5

≧ 1

Operating conditions of the bearing f s

In case of Shell Type Needle Roller Bearings of which outer ring is drawn from a thin steel plate and then carburized and quenched, it is necessary to use a sta-tic safety factor of 3 or more.

C0P0

Table 5 Load distribution to bearings

F r1=dK r1+ bK r2

f

Fr1=

Fr2=

gK r1+ bK r2− cK r3f

aK r2+ dK r3− eK r1f

F r2=cK r1+ aK r2

f

Example Bearing load

a b

c d

f

Fr1Kr1 Kr2

Fr2

d

a b c

e f

g

Kr1 Kr2 Kr3Fr1 Fr2

A

B

C

D

E

F

G

H

I

J

K

L

M

A23 A241N=0.102kgf=0.2248lbs.1mm=0.03937inch

Bearing loads in case of belt or chain transmission

When power is transmitted by a belt or chain, the load acting on the pulley or sprocket wheel is obtained from the following equations:

T=9550000 ……………………………(11)

K t= ……………………………………(12)

where, T : Torque acting on pulley or sprocket

wheel, N-mm K t :Effective transmitting force of belt or chain, N H :Transmitting power, kW n :Rotational speed, min-1

R : Ef fec t i ve rad ius o f pu l l ey o r

sprocket wheel, mm

For belt transmission, the load K r acting on the pulley shaft is obtained from the following equation, multiply-

ing the effective transmitting force K t by the belt factor fb shown in Table 7.

K r = fb K t ………………………………………(13)

Table 7 Belt factor

V-belts

Timing belts

Plain belts (with tension pulley)

Plain belts

2 〜 2.5

1.3〜 2

2.5〜 3

4 〜 5

Type of belt fb

In the case of chain transmission, a value of 1.2 to 1.5

is taken as the chain factor corresponding to fb. The

load acting on the sprocket wheel shaft is obtained from equation (13) in the same manner as the belt transmission.

Bearing loads in case of gear transmission

When power is transmitted by gears, the force acting on the gears varies according to the type of gear. Spur gears produce radial loads only, but helical gears, bevel gears and worm gears produce axial loads in addition to radial loads. Taking the simplest case of spur gears as an example, the bearing load is obtained from the following equations:

T=9550000 ……………………………(14)

K t= ……………………………………(15)

K s=K t tan θ ………………………………(16)

K c= K t +K s =K t sec θ …………………(17)

where, T:Torque applied to gear, N-mm K t:Tangential force acting on gear, N Ks:Radial force acting on gear, N K c:Resultant normal force on gear tooth surface, N H:Transmitting power, kW n :Rotational speed, min-1

R:Pitch circle radius of drive gear, mm θ:Pressure angle of gear, deg.

Kt

Ks R

Fig. 6

In this case, the resultant normal force on the tooth surface acts as the radial force to the shaft and the magnitude of vibration or shocks varies depending on the accuracy and sur face f in ish of the gear. Therefore, the radial load K r applied to the shaft is obtained from the following equation, multiplying the

resultant normal force Kc on gear tooth surface by the gear factor fz shown in Table 8.

K r= f z K c ……………………………………(18)

Table 8 Gear factor

Precision gears (Pitch error and form error: Less than 0.02mm)

1.05〜 1.1

Ordinary machined gears(Pitch error and form error: 0.02 〜 0.1mm)

1.1 〜 1.3

Type of gear f z

Hn

TR

Hn

TR

2 2√

Mean equivalent load corresponding to fluctuating load

When the load applied to the bearing fluctuates, the bearing life is calculated by using the mean equivalent

load Fm, which is a constant load that will give the bearing a life equal to that produced under the fluctu-ating load. The mean equivalent load is obtained from the following equation:

……………………(19)

where, Fm:Mean equivalent load, N N :Total number of revolutions, rev. Fn:Fluctuating load, N p : Exponent, Roller bearing = 10/3 Ball bearing = 3

Table 9 shows examples of the calculation of mean equivalent loads for various fluctuating loads.

Fm= ∫ Fn dN1N

N

0

pp

Table 9 Mean equivalent load for the fluctuation load

p

Type of fluctuating load Mean equivalent load Fm

Step load

Monotonously changing load

Sinusoidally fluctuating load

Stationary load plus rotating load

where, N1:Total number of revolutions under load F1 rev. N2:Total number of revolutions under load F2 rev. Nn:Total number of revolutions under load Fn rev.

where, Fmax:Maximum value of fluctuating load, N Fmin :Minimum value of fluctuating load, N

Fm ≒ 0.65Fmax

Fm ≒ 0.75Fmax

where, FS:Stationary load, N FR:Rotating load, N

Fm = (F1 N1 + F2 N2 +…+ Fn Nn)1N

p p pp

Fm = (2Fmax + Fmin )13

Fm =FS + FR − FS FR

FS+ FR

F1

F2

N1 N2

NNn

Fm

Fn

F

F

Fmin

Fmax

Fm

N

Fmax

Fm

N

F

FmaxFm

N

F

Fs

FR

A

B

C

D

E

F

G

H

I

J

K

L

M

A25 A261N=0.102kgf=0.2248lbs.1mm=0.03937inch

Boundary Dimensions and Identification Number

Equivalent load

The loads applied to the bearing are divided into radi-al loads that are applied perpendicular to the central axis and axial loads that are applied in parallel to the central axis. These loads act independently or in com-bination with other loads.

Dynamic equivalent load

When both radial load and axial load are applied to the bearing simultaneously, the virtual load, acting on the center of the bearing, that will give a life equal to that under the radial load and the axial load is defined as a dynamic equivalent load.In the case of needle roller bearings, radial bearings receive only radial loads and thrust bearings receive only axial loads. Accordingly, radial loads are directly used in the life calculation of the radial bearings, while axial loads are directly used for the thrust bearings.

[For radial bearings]

P r =F r ………………………………………(20)[For thrust bearings]

P a=F a ………………………………………(21)

where, P r:Dynamic equivalent radial load, N Pa:Dynamic equivalent axial load, N F r:Radial load, N F a:Axial load, N

Static equivalent load

When both radial load and axial load are applied to the bearing simultaneously, the virtual load, acting on the center of the bearing, that will produce a maxi-mum contact stress on the contact surface between the rolling element and the raceway equal to that given by the radial load and the axial load is defined as a static equivalent load. In the case of needle roller bearings, radial bearings receive only radial loads and thrust bearings receive only axial loads. Accordingly, radial loads are directly used for the radial bearings, while axial loads are directly used for the thrust bearings.

[For radial bearings]

P0r =F r………………………………………(22)[For thrust bearings]

P0a=Fa ………………………………………(23)

where, P0r:Static equivalent radial load, N P0a:Static equivalent axial load, N F r :Radial load, N F a :Axial load, N

Boundary dimensions

Examples of symbols for quantities indicating the boundary dimensions of IKO Needle Roller Bearings are shown below. For details, see the table of dimen-sions for each model.

Machined Type Needle Roller Bearing

d : Nominal bearing bore diameter

D : Nominal bearing outside diameter

B : Nominal inner ring width

C : Nominal outer ring width

Fw : Nominal roller set bore diameter

r : Chamfer dimensions of inner and outer rings

r s min : Smal lest permissible s ingle chamfer dimensions of inner and outer rings

BC

D d

r

r

r

r

Fw

Fig. 7 Machined Type Needle Roller Bearing

Shell Type Needle Roller Bearing

D :Nominal bearing outside diameter

Fw:Nominal roller set bore diameter

C :Nominal outer ring width

C

D Fw

Fig. 8 Shell Type Needle Roller Bearing

Needle Roller Cage

Ew:Nominal roller set outside diameter

Fw:Nominal roller set bore diameter

B c:Nominal cage width

Bc

Ew Fw

Fig. 9 Needle Roller Cage

Thrust Roller Bearing

D c:Nominal cage outside diameter

d c:Nominal cage bore diameter

Dw:Nominal roller diameter

Dw

Dc

dc

Fig. 10 Thrust Roller Bearing

A

B

C

D

E

F

G

H

I

J

K

L

M

A

B

C

D

E

F

G

H

I

J

K

L

M

A27 A281N=0.102kgf=0.2248lbs.1mm=0.03937inch

Note(1) The nominal dimensions of inch series bearings are indicated in units of 1/16 inch.

Model code

Shell Type Needle Roller Bearings

Needle Roller Cages for General Usage

Needle Roller Cages for Engine Connecting Rods

Machined Type Needle Roller Bearings

Needle Roller Bearings with Separable Cage

Roller Bearings

Thrust Bearings

Combined Type Needle Roller Bearings

Cam Followers

Roller Followers

Crossed Roller Bearings

Spherical Bushings

PILLOBALLs

L-Balls

Seals for Needle Roller Bearings

Cir-clips for Needle Roller Bearings

Roller set bore diameter + Outer ring width

Roller set bore diameter + Outer ring width (1)

Roller set bore diameter + Roller set outside diameter + Cage width

Roller set bore diameter + Roller set outside diameter + Cage width

Dimension series + Bore diameter number

Roller set bore diameter + Bearing outside diameter + Bearing width

Bearing bore diameter + Bearing outside diameter + Outer ring width

Roller set bore diameter + Bearing outside diameter + Bearing width (1)

Bearing bore diameter + Bearing outside diameter + Outer ring width (1)

Roller set bore diameter + Bearing outside diameter + Bearing width

Bearing bore diameter + Bearing outside diameter + Bearing width

Dimension series + Bore diameter number

Bearing bore diameter + Bearing outside diameter + Bearing width

Bearing bore diameter + Bearing outside diameter

Bearing bore diameter + Bearing outside diameter + Bearing height

Bearing bore diameter + Bearing outside diameter + Roller diameter

Roller set bore diameter + Assembled bearing width

Inner ring bore diameter + Assembled bearing width

Dimensional series + Bore diameter number

Stud diameter

Bearing outside diameter

Bearing outside diameter (1)

Bearing bore diameter

Bearing outside diameter (1)

Bearing bore diameter + Bearing width

Inner ring bore diameter

Inner ring bore diameter (1)

Inner ring bore diameter

Screw size

Shaft diameter + Seal outside diameter + Seal width

Shaft diameter

Bore diameter

Bearing typeModel number

Indication of boundary dimensions

8 Classification symbol

(None)

P6

P5

P4

JIS Class 0

JIS Class 6

JIS Class 5

JIS Class 4

Symbol Descriptions

Table 11 Indication of boundary dimensions

Identification Number

The identification number of IKO Bearings consists of a model number and supplemental codes. The descriptions of typical codes and their arrangements are shown below. There are many codes other than those described. See the section of identification number of each bearing.

Table 10 Arrangement of identification number of bearing

1

2

3

4

5

6

7

8

Model code

Boundary dimensions

Material symbol

Cage symbol

Shield symbol Seal symbol,

Bearing ring shape symbol

Clearance symbol

Classification symbol

Model number

Supplemental code

Model codeThe model code represents the bearing series. The features of each bearing series are shown on pages A5 to A15.

Boundary dimensionsOne of the following four kinds of presentation meth-ods is used for showing boundary dimensions in the identification number, which vary depending on the bearing series. Table 11 shows the presentation methods of boundary dimensions for each model code.

(a)Dimension series + Bore diameter number

(b) Bore diameter or roller set bore diameter + Outside diameter or roller set outside diameter +

Width

(c)Bore diameter or roller set bore diameter + Width

(d)Basic diameter

Material symbol

F Stainless steel for bearing rings and rolling elements

Symbol Type of material

Cage symbol

N

V

Made of synthetic resin

No cage or full complement

Symbol Descriptions

Seal or shield symbol

Z

ZZ

U

UU

S(1)

2RS

With dust cover

With shields on both sides

With a seal on one side

With seals on both sides

With ThrustDisk SealsTM

With seals on both sides

Symbol Descriptions

Note(1) ThrustDisk SealsTM are embedded on both sides.

Bearing ring shape symbol

NR

OH (1)

J

With stop ring on outer surface of outer ring

With oil hole in bearing ring

No oil hole

Symbol Descriptions

Note(1) This differs depending on the type of bearing. See the section of each bearing.

Clearance symbol

C2

(None)

C3

C4

C5

T1

C1

C2

C2 clearance

CN clearance

C3 clearance

C4 clearance

C5 clearance

Special radial clearance(Applicable to Crossed Roller Bearings)

Symbol Descriptions

1

2

3

4

5

6

7

TA,TLA,YT,YTL

BA,BHA,YB,YBH

KT,KTW

KT…EG,KTV…EG

NA,RNA

TR,TAF,GTR

TRI,TAFI,GTRI

BR

BRI

RNAF,RNAFW

NAF,NAFW

NAU,NAG,NAS

TRU

NTB,AS,WS,GS

AZ

AZK

NAX,NBX

NAXI,NBXI

NATA,NATB

CF…B,CFS,NUCF…B

CFKR

CR…B,CR,CRH…B

NAST,NART,NURT

CRY

CRBHV,CRBFV,CRBC,CRB,CRBT,CRBTF,CRBS

SB…A,GE

SBB

PB,PHS,POS,PHSB,POSB,PHSA

LHSA,LHS

OS,DS

WR

AR

A29 A30

A

B

C

D

E

F

G

H

I

J

K

L

M

Model number

NA 02 C2 P649

Example of identification number

Bore diameter number

Dimension series

Model code

Clearance symbol

Classification symbol

(a) Example of "Dimension series + Bore diameter number"

Model number

NAX 30 Z20

Roller set bore diameter

Model code

Assembled bearing width

Shield symbol

(c) Example of "Bore diameter or roller set bore diameter + width"

Model number

CF V UU10 B

Cage symbol

Shape of stud head

Basic diameter (Stud diameter)

Model code

Seal symbol

Model number

KT 8 N5 8

Roller set outside diameter

Roller set bore diameter

Model code

Cage symbol

Cage width

(b) Example of "Bore diameter or roller set bore diameter + Outside diameter or roller set outside diameter + width"

(d) Example of "Basic diameter"

Supplementalcode

Supplementalcode

Supplementalcode

Supplementalcode

AccuracyThe accuracy of IKO Needle Roller Bearings con-

forms to JIS B 1514-1~-3 (Rolling bearings - Tolerances of bearings), and the dimensional accura-cy and rotational accuracy are specified. The speci-fied items are shown in Fig. 11.Needle Roller Bearings are classified into 4 classes of accuracy. These classes are represented by the numbers 0, 6, 5 and 4, written in order of increasing accuracy.Table 12 shows the accuracy for the inner rings of radial bearings, Table 13 shows the accuracy for the outer rings of radial bearings, Table 14 shows the tol-erances for the smallest single roller set bore diame-ter of radial bearings, and Table 15 shows the permis-sible limit values of chamfer dimensions of radial bearings. For thrust bearings, see the section on accuracy of Thrust Bearings. Note that the series of Shell Type Needle Roller Bearings, Roller Bearings, Cam Followers, Roller Followers, Combined Type Needle Roller Bearings, and Crossed Roller Bearings have special accuracy. For further details, see the section on accuracy of each bearing series.

RemarksThe meanings of the new symbols for quantities

used for accuracy of radial bearings are as

follows:

①∆ represents the deviation of a dimension from the specified value.

② V represents the variation of a dimension.

③ Suffixes s, m, and p represent a single (or

actual) measurement, a mean measurement,

and a measurement in a single radial plane,

respectively.

[Example] Vdp means the difference between

the largest and the smallest of the bore

diameters in a single radial plane (circularity).

Vdmp means the difference between the largest

and the smallest of the single plane mean bore

diameters (cylindricity).

Deviation of boundary dimensions

Accuracy of boundary dimensions

Rotationalaccuracy

Accuracy of bearings

Variation of boundary dimensions

Fig. 11 Accuracy of bearings

Single bore diameter deviation ∆ ds

Single plane mean bore diameter deviation ∆ dmp

Single outside diameter deviation ∆Ds

Single plane mean outside diameter deviation ∆Dmp

Deviation of a single inner ring width ∆Bs

Deviation of a single outer ring width ∆Cs

Bore diameter variation in a single radial plane Vdsp

Mean bore diameter variation Vdmp

Outside diameter variation in a single radial plane VDsp

Mean outside diameter variation VDmp

Inner ring width variation VBs