NDI Technician Resume

-

Upload

octavius-blackwood -

Category

Business

-

view

2.012 -

download

4

Transcript of NDI Technician Resume

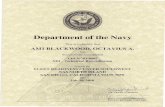

OCTAVIUS A. BLACKWOOD

645 Emerald Street, Imperial California, [email protected]

(760) 355-8784

Objectives: Certified Nondestructive Inspection Technician (NDI) seeking full time/contract employment in the United States of America and overseas.

Qualification Profile: Highly skilled and safety conscious Nondestructive Inspection (NDI) technician with over fifteen years of experience performing on-aircraft and laboratory inspections for the U.S. Navy/Marine Corps and Army fixed and rotary winged aircraft at Organizational (squadron)and Intermediate level (rework) facilitates. Certified Level II in Radiography (RT), Eddy current (ET), Ultrasonic (UT), Fluorenesce Penetrant (PT), Magnetic Particle (MT), Visual/Optical (VT/OT) inspections. Certification is equivalent to SNT-TC-1A, NAS-410, MIL-STD-410E.

NDI Technician: Expert in performing Nondestructive inspection on , internal and external components of GE F404-400, F400-402, and F414-414 engine components, U.S. Air Force B-52, U.S. Army CH-47, UH-60, and AH-64, helicopters, U.S. Navy/Marine Corps C-2, C-40, E-2, EA-6B, P-3, S-3, F/A-18A-D, F/A-18E/F, H-2, H-3,H-46, CH-47, MH-53E, CH-53E, MH-60S, UH-60, and AH-64 aircraft (metallic and composites) components, ejection seats Sea Water Activated System(SEAWARS), bomb racks, and related ground support equipment.

Conducted hardness testing, conductivity testing, on fire damaged aircraft structure, wheel assemblies and manufactured aluminum bracket to determine the extent of structural damage and the adequacy of heat treatment.

Interpret radiographs, blueprints/schematics, technical manuals and directives. Compressive knowledge of radiation safety, radiography in shielded and unshielded facilities,

survey instruments ultrasonic, eddy current, conductivity, magnetic particle, fluorescent liquid Penetrant and optical Inspection and their limitations.

Proficient, over fifteen years experience calibrating, operating and performing preventative maintenance on; Fluorescent Penetrant and Magnetic Particles Inspection units, contour probes, portable black lights, Digital Radiometer/Photometers, Eddy Current Flaw and Ultrasonic Detectors (PD-214, Nortec 2000D+, USN-52 and SONIC 1200M), Composite Bond Tester, Thickness Gauge, Densitometer, Radiac Meter, Portable Ion Chamber Survey Meters, and LPX-160 Digital Portable X-Ray Apparatus, Optical Micrometer Kit, Fiber Optic Borescopes, Ultrasonic Leak Detector, Portable Material Hardness Tester.

Administration: Excellent organization skills successfully managed and prioritized large volumes of time sensitive work orders, radiation and NDI programs. Conduct periodic self-audits in preparation for Quality control Audits and external inspections resulting in zero discrepancies.

Accurately document inspection results, daily labor input and all other required record keeping and traceability recordings. Continuously maintained strict compliance with all safety regulations, policies and procedures.

Actively maintained a safety work center and good housekeeping related activities. Executed daily operations of nondestructive inspection laboratory and effectively mentored and

supervised groups 5 to 68 employees in varied environments. Customer Service: Totally committed to providing quality work and service. Adept at

communication with customers, engineers, team members.

Education and Credentials:

West Hills Community College Lemoore, CA 1997-1998 GPA: 3.7GED California 1994 CertificateCalabar High School Kingston, Jamaica 1976-1981 DiplomaNDI Tech. Level II Vertex Aerospace 2011-2116 CertificateNDI Tech. Level II, Course N-701-0005 U.S. Navy 2010-2013 CertificateNDI Tech. Level I, Course N- C-603-3191 U.S. Navy 1995-1998 CertificateJourneyman NDT Tester 2000 Hours USMAP/Dept of Labor 04/1997 Certificate

Experience Highlights:

Aircraft Inspector:Vertex Aerospace, Madison, MS (Forward Operating Base, Sharana, Afghanistan, Feb-Jun2011)

Responsible for performing process control on equipment and materials. Conducted recurring Fluorescent Liquid Penetrant, Ultrasonic, Eddy Current, Magnetic Particle, and Visual Testing on 36 U.S. Army CH-47, UH-60, and AH-64, helicopters.

Served as Vertex Aerospace field support activity’s NDI subject matter expert (liaison) U.S Army Aviation Task Force at Forward Operating Base Afghanistan which includes Maintenance Control personnel, Conferring with platform specific engineers and aircraft maintenance team leaders/crews.

Aviation Structural Mechanic and Aircraft NDI Technician Level II:United States Navy: California, Guam, Japan, Diego Garcia, U.S.S Peleliu (LHA-5) 1995- 2010

Airframes Division Leading (Supervisor) Petty Officer; at Aircraft Intermediate Maintenance Depart (AIMD). Expertly led and trained employees in schedule, unscheduled and conditional inspections, and repairs on aircraft components in support of U.S Navy Seventh Fleet.

NDI Laboratory supervisor and Senior Radiographer; successfully supervised and trained employees in Schedule, Unscheduled and Conditional inspections on U.S. Navy/Marine Corps fixed and rotary winged Aircraft. Designated NDI and Radiation Safety Program Manager.

Aircraft Corrosion Control Facility Manager; hand-pick to manage the day-to-day operation on the U.S. Navy only overseas aircraft corrosion control facility. Awarded NAM for superior performance.

Proficient in the use of Microsoft Office Suite 2007 and NALCOMIS/OOMA

Awards/Accomplishments:

While assigned to L-3 Vertex Aerospace awarded Certificate of Appreciation for support of Task Force Gambler, 4th Aviation Brigade, 4th infantry Division on Forward Operating Base Sharana during combat operation in Afghanistan from June 2010 to June 2011.

January 2006: Awarded NAM for professional achieve in the superior performance of duties as Aircraft Division First Line Supervisor and Aircraft Corrosion Facility Manager while assigned to Naval Air Facility Atsugi, Japan.

March 2003: Awarded NAM for superior achievement as General Maintenance (400/500/600) Division First Line Supervisor and NDI Laboratory Supervisor/Program Manager while assigned to Aircraft Intermediate Maintenance Detachment Diego Garcia.

May 2002: Awarded NAM for professional achievement as Detachment First Line Supervisor and NDI Technician while assigned to squadron HC-5 in Agana, Guam.

Expertly managed Aircraft Intermediate Maintenance Department’s (AIMD) Radiation Safety Program at both ashore and afloat facilities receiving zero discrepancies on Radiological Affairs Support Office (RASO) Radiation Safety Inspection and routine Quality Assurance audits.