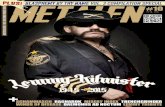

Natalia Luzginova - VeMet · Photo by Natalia Luzginova. Introduction 7 … and lots of energy!...

Transcript of Natalia Luzginova - VeMet · Photo by Natalia Luzginova. Introduction 7 … and lots of energy!...

Materials development for fusion application

Natalia LuzginovaMaterials Consultant

22/06/2015 1VeMet-Dag 2015

Metalen onder extreme condities

Outline

Introduction

The ITER project Main components and materials

Materials selection and challenges

Beyond ITER New materials development

Summary

22/06/2015 2VeMet-Dag 2015

Metalen onder extreme condities

Introduction

References:1. Nuclear Energy Today © OECD/Nuclear Energy Agency 20122. http://www.gen-4.org/Technology/roadmap.htm3. Fusion Electricity - EFDA November 20124. http://www.iter.org

ITER

Fiss

ion

Rea

cto

rsFu

sion

Rea

ctors

DEMO

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities3

Introduction

ITER is a large-scale scientific experiment

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities4

Introduction

ITER is a large-scale scientific experiment

Location: Cadarache, Provence, France

Time frame: first plasma – 2020; first fusion reaction – 2027

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities5

Introduction

ITER is a large-scale scientific experiment

Location: Cadarache, Provence, France

Time frame: first plasma – 2020; first fusion reaction – 2027

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities6

March 2015Photo by Natalia Luzginova

Introduction

7

… and lots of energy!

deuterium tritium helium neutron

Fusion reaction

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities

Introduction

ITER is a large-scale scientific experiment

Location: Cadarache, Provence, France

Time frame: first plasma – 2020; first fusion reaction – 2027

The ITER Agreement was signed by China, the European Union, India, Japan, Korea, Russia and the United States

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities8

ITER(overview)

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities9

Introduction

Fusion advantages No air pollution or greenhouse gases

No risk of a nuclear accident

No high-level waste

Abundant fuel supply

Fusion challenges Unknown technology

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities10

Outline

Introduction

The ITER project Main components and materials

Materials selection and challenges

Beyond ITER New materials development

Summary

22/06/2015 11VeMet-Dag 2015

Metalen onder extreme condities

Main components and materials

Materials for the ITER components have been selected based on Nuclear design codes

Extensive R&D programs carried out by ITER parties

Comprehensive assessments of the various functional, design, safety, operational and technological requirements

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities12

Main components and materials

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities13

Picture from ITER Organization

Materials selection

ITER vacuum vessel The vacuum vessel is a hermetically-sealed steel

container inside the cryostat that houses the fusion reaction and acts as a first safety containment barrier

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities14

Picture from ITER Organization

Materials selection

ITER vacuum vessel 316L(N)-IG steel is selected based on more than 30 years

of experience from fast-breeder reactor applications in France and EU

IG – ITER Grade accommodates additional ITER requirements for steel composition Radioprotection (Co, Nb, Ta)

Magnetic permeability < 1.03

Inclusion content (vacuum requirements)

Additional limit for P, S

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities15

Materials selection

Neutron effects on 316L(N)-IG steel have been extensively studied and assessed Strengthening and loss of ductility

Loss of strain hardening

However, at doses up to 1 dpa it is a ductile material

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities16

G. Kalinin, MPH 2005

Materials selection

Neutron effects on 316L(N)-IG steel have been extensively studied and assessed Fatigue – no effects

Fracture toughness – reduction, but material is still ductile

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities17

Challenges

Nuclear components in the fusion reactors may face repairs or (partial) replacements: Vacuum vessel sectors

In-vessel components

Coolant tubes and piping

Replacement or repair of the failed components Re-welding of irradiated stainless steel

problematic -> cracking in the heat-affected and fusion zones

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities18

Picture from ITER Organization

Challenges

He is formed in austenitic stainless steels by the reaction of thermal neutrons and alloying elements:

58Ni + n 59Ni + 59Ni + n 56Fe + 4He;10B + n 7Li + 4He

Ni is an alloying element in 316L(N) steel

B is an impurity element coming from scrap material

He is practically insoluble in metal

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities19

Challenges

To minimize the probability of crack

formation during re-welding, it is

recommended* to minimize He

content in the irradiated material

< 0.5 -1 appm for multi-pass welding

< 1 - 3 appm for single pass (thin pipe) low

energy welding

The exact limitation of He content for sound re-

weldability depends on the welding method and material

* V. Barabash, First Joint ITER-IAEA Technical Meeting , 2010, Monaco

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities20

Picture from ITER Organization

Challenges

Re-welding after irradiation

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities21

* H.T. Lin, et.al., 1990, Met. Trans. A. Regime III - weld solidification

Regime I - heat-up period before temperature reaches the melting point

Regime II - peak temperature period

Heat Input vs. Helium Content

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities22

*Wang [1996], Asano [1998/2000]; Schuring [2000/2001], van Thoor [2001/2002], Luzginova [2010/2011]

0

500

1000

1500

2000

2500

0.01 0.1 1 10 100 1000

Hea

t In

pu

t (J

/mm

)

Helium contents (appm)

single pass no micro and macro cracks

single pass micro cracks

single pass micro and macro cracks

multipass no micro and macro cracks

multipass micro cracks

0

500

1000

1500

2000

2500

0.01 0.1 1 10 100 1000

Hea

t In

pu

t (J

/mm

)

Helium contents (appm)

single pass no micro and macro cracks

single pass micro cracks

single pass micro and macro cracks

multipass no micro and macro cracks

multipass micro cracks

multipass micro and macro cracks

0.5 -1 appm for thick plates

1 - 3 appm for thin pipes

Fusion power plant

References:1. Nuclear Energy Today © OECD/Nuclear Energy Agency 20122. http://www.gen-4.org/Technology/roadmap.htm3. Fusion Electricity - EFDA November 20124. http://www.iter.org

ITER

Fiss

ion

Rea

cto

rsFu

sion

Rea

ctors

DEMO

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities23

Outline

Introduction

The ITER project Main components and materials

Materials selection and challenges

Beyond ITER New materials development

Summary

22/06/2015 24VeMet-Dag 2015

Metalen onder extreme condities

Advanced materials

Advanced nuclear systems require high performance materials

Excellent Creep Properties

Corrosion resistance

Radiation Tolerance?

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities

VHTR – Very High Temperature Reactor

SCWR – Supercritical Water Reactor

GFR – Gas Fast Reactor

LFR – Lead Fast Reactor

SFR – Sodium Fast Reactor

MSR – Molten Salt Reactor25

Advanced materials

Requirements for materials for fusion application Attractive high temperature physical and mechanical

properties

High radiation resistance

Low activation for recycling potential

Reliable manufacturing processes

New structural materials Basic performance: Reduced activation

ferritic/martensitic (RAFM) steel

Enhanced performance: Oxide dispersion strengthened (ODS) steel

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities26

RAFM steel – 9Cr steelWhy 9Cr steel? --> Minimum of DBTT around 9 wt.% Cr

Tempered martensitic microstructure

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities27

Tavassoli, et.al, JNM, 2014

Schuring, 2000

RAFM steel – 9Cr steelWhy 9Cr steel? --> Minimum of DBTT around 9 wt.% Cr

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities28

Tavassoli, et.al, JNM, 2014

RAFM steel – 9Cr steelWhy Ferritic/martensitic structure? --> Good swelling resistance

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities29

P. Yvon, 2009

RAFM steel – 9Cr steelWhy Ferritic/martensitic structure? --> Good swelling resistance

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities30

Fast fluence (E>1.0 MeV) of 1.5x1027 n/m2 at 533 ºC F. A. Garner, PNNL

P. Yvon, 2009

RAFM steel – 9Cr steelStarting material is a T91steel (9Cr/1Mo/0.2V/0.08Nb)

W as a solution hardener Ta as a carbide former

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities31

RAFM steel – 9Cr steel

Reduced Activation: Low level waste already

after 80-100 years

R. Lindau et al., Fusion Eng. and Design 75-79 (2005) 989-996

The Eurofer97 specification is a result of 20 years R&D effort

Eurofer97 is manufactured by Böhler

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities32

RAFM steel – Eurofer97 steel

A.-A.F. Tavassoli, 2014

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities33

RAFM steel – Eurofer97 steel

Ferritic/martensitic steel Eurofer97 will be used in the ITER Test Blankets Modules (TBM’s) developed in EU, and it is the main structural material of the Breeding Blankets Modules for DEMO reactor.

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities34

Where is TBM in ITER?Vacuum vessel (stainless steel)

TBM (in green)It is a box built of Eurofer97 steel

zoomed in

ITER Blanket (in yellow) is a layered component, where first layer is Be -facing plasma. The rest of the Blanket is high-strength copper (for heat sink) and then stainless steel (structural material).

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities35

Pictures from ITER Organization

RAFM steel – Eurofer97 steel

Ferritic/martensitic steel Eurofer97 will be used in the ITER Test Blankets Modules (TBM’s) developed in EU, and it is the main structural material of the Breeding Blankets Modules for DEMO reactor

Limitations The maximum operational temperature for Eurofer97 steel is 550 oC

Possible solution Development of Oxide Dispersion Strengthened (ODS) alloys

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities36

RAFM steel – ODS steel

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities37

Rainer Lindau, KIT, 2010

RAFM steel – ODS steel

Combination of nano-sized oxide particles and fine grains is believed to result in improved high-temperature strength/creep properties microstructural stability under irradiation and high resistance to radiation-induced swelling

Iracane et al., Generation IV Systems;

R&D needs and research reactors policy, 2006

Y. de Carlan et al., Mechanical Properties

of Nuclear ODS Alloys, 2012

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities38

RAFM steel – ODS steel

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities39

RAFM steel – ODS steel

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities40

RAFM steel – ODS steel

ODS steels have better high temperature/creep properties There are promising results on microstructural

stability under irradiation

Key technological issues: Industrial scale production and processing of ODS steels

Mechanical properties before, under and after irradiation

ODS steel joining/welding

Interaction with coolant

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities41

Summary

Materials for ITER have been selected based on comprehensive assessment of many different requirements

Fusion power plant will require new material that can withstand harsh fusion conditions

Both RAFM and ODS steels are showing promising results. However, materials R&D is not yet completed

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities42

+31618074914

www.inMaterials.nl

22/06/2015VeMet-Dag 2015

Metalen onder extreme condities43

Thank you for your attention