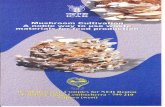

Mushroom Cultivation - unam.edu.na

Transcript of Mushroom Cultivation - unam.edu.na

Selection of Fresh Mushroom

You need a young, fresh and healthy mushroom and a very clean work area to prepare good quality tissue culture. Beginners in mushroom cultivation are encouraged to obtain their tissue cultures from the University of Namibia.

Culture Preparation

In a Mayonnaise glass bottle, dissolve 19.5g of Potato dextrose agar in 500ml of clean water and close the bottle loosely. Cover the bottom of the bottle with aluminium foil and boil in a pot or pressure cooker for 1 hour until the agar is completely dissolved.

Clean the area where you are going to work on with 70% ethanol or methylated spirits. Cool the solution to about 50 - 60 0C and pour into 20 petri dishes to about 0.5cm from the bottom. Cover the petri dishes and allow the agar to cool and solidify.

Wipe your hands and instrument you are using with ethanol or methylated spirits and cut a piece from the fresh mushroom or from a pure culture and place it on the agar in the petri dish. Close the petri dish and seal it around the edges to prevent it from opening in order to avoid contaminations.

Store the Petri dishes in a box at room temperature until the mycelia has covered the agar, about 5-10 days. Use the cultures to make spawn and store the remaining cultures in a fridge for not longer than 30 days.

Fig.1.Preparing tissue culture from a fresh mushroom Tissue culture growing after inoculation

Spawn (Seed) Preparation

Soak raw wheat, sorghum, millet or maize in water overnight. Drain off excess water and fill clear bottles up to 2/3 with the grain. Close the bottles loosely and pasteurize them in a drum or pressure cooker for about 1 hour.

Clean the area where you are going to work on with 70% ethanol or methylated spirits. Also Wipe the bottles with ethanol and place them on your workstation and allow the grains to cool.

Wipe your hands and a knife with ethanol or methylated spirits and cut 4 pieces from the culture and place them into the bottle. Mix with the grains and close the bottle securely. Store the bottles in a box or in a cool dark place until the grains are fully invaded by the mycelia. This should take about two weeks.

Keep all the spawn which is not used up immediately in the fridge but do not keep it longer than two months.

Fig.2.Inoculating the grains with tissue culture Spawn in plastic bottles

Substrate Preparation

You can use all types of agricultural waste such as straw from maize, millet, sorghum or crushed corn cobs and veld grass as substrate for mushrooms.

Chop your substrate into pieces of about 5-10cm long and place it in sacks. Soak the substrate in water until all of it is wet and remove the sack from the water and allow it to drain overnight. Squeeze out excess running water, add a handful of wheat bran or pearl millet husks and mix the substrate well. Pack the substrate into plastic bags.

Fig.3. Mixing and packing substrates into plastic bags

Pasteurization, Inoculation and Incubation

Pasteurize the bags in a drum for about two hours. Remove the bags from the drum and allow cooling before planting.

It is important to work in a clean place when inoculating your substrate with spawn. Clean your hands and the area you are going to work on with ethanol or methylated spirits and make sure all doors are closed to prevent dust from entering.

Fig.4. Putting bags in the drums for pasteurization Pasteurizing substrates in drums

Select pure spawn and spread a few grains evenly into your substrate. Close the bags securely and label with the name of the mushroom, the date, and your name.

Fig.5. Trainees preparing to inoculate the substrate with spawn

Keep the planted bags in a cool dark place until the mycelia have invaded all the substrate and the bag is completely white.

Fig.6. Bags waiting for the mycelia to invade the substrate completely.

Fruiting and Harvesting

Once the bags are completely white, it means the mycelia have fully invaded the substrate and it is ready to produce mushrooms. Take the bags to the fruiting room where the temperature and humidity can be controlled. Using a knife or a scissors, Cut openings on the bags where the mushrooms will start sprouting. Wet the room to increase humidity and to keep temperature between 18-300C to allow optimal mushroom growth. The first mushrooms start to appear about 1 week after opening the bags and are ready to harvest 5 days from day they start pinning. Harvest the mushrooms by plucking them off with your hand. Do not cut them off with a knife because this may prevent them from pinning again.

Fig.7. Mushrooms ready for harvest

Marketing

Make sure the mushrooms are of good quality to increase sales. Do not wait too long before you harvest them, trim the stems to remove traces of grass and store them in paper bags or Styrofoam plates. Never use plastic! Mushrooms can also be dried naturally under the shade where there is no dust.

Sell your mushrooms directly to consumers, can be your neighbors, family, friends or wholesalers and at local markets. Mushrooms can also be ground into powder which can be added to porridge, soup or used in making cookies.

Fig.8. Mushrooms harvested at UNAM Main Campus Weighing the mushrooms produced at Community

Mushroom House

The mushroom house is a very important part of mushroom farming. This is where the bags which are fully invaded by mycelia are kept so that the mushrooms can grow. It must be built in a manner which allows enough humidity and insulation so that the house is warm in winter and cool in summer. The mushroom house must also have windows to allow in cool fresh air. These houses can be built from either modern or traditional building materials, using what is readily available in your area.

Fig.9. Traditional Mushroom house in Katima Mulilo Fig.10. Modern Mushroom House at UNAM Main Campus

ZERO EMISSIONS RESEARCH INITIATIVES

Mushroom CultivationZERI Regional Project: University of Namibia

Tel: +264 - 61 - 206 3458 / 3340, Fax: +264 – 61- 206 3505,

E-mail: [email protected] / [email protected]