Murree Brewery Final

-

Upload

usman-aziz-khan -

Category

Documents

-

view

335 -

download

1

description

Transcript of Murree Brewery Final

-

MURREE BREWERY

Submitted To:

MR. NAZIK HUSSAIN

In-Charge Internship and Placement

Submitted By:

M.UMAR HAYAT ABBASI

ROLL #: 39, BBA 6th (Morning) Session (2007-2011)

Department of Management Sciences

The Islamia University of Bahawalpur, Pakistan

-

Internship report on Murree Brewery

The Department of Management Sciences Page 2

Table of Contents Page No.

Preface

Acknowledgement

Dedication

Executive Summary 3

Introduction Of Organization 5

History Of Brewery 6

Introduction Of Organization 13

History 14

Board of Directors 17

Introduction 18

Pakistans only Beer and Whisky firm 19

Management Techniques 22

Mission, Vision And Objectives Of Organization 23

Corporate, Business And Departmental Level Strategies 24

Organizational Structure 27

Social Responsibility 29

Products 30

Production Process 38

Distillary Process 39

Brewery Process 43

NAB Hall 46

Reserve Osmosis Plant 48

Pet Plant (1&2) 51

Botteling Hall 54

Bio Gas Plant 57

TOPS foods and Beverages 60

Quality Policy of TOPS 64

Adverisement/Promotional activities and Demand

Creation.

65

ISO 14001 67

Enviornmental Factors 70

Enviornmental Aspects at Murree Brewery 71

Different Accounting Policies of the Company 74

Financial Analysis 76

SWOT Analysis 106

Work Done By Me 108

Suggestions And Recommendations 109

Conclusion 111

Annexure

-

Internship report on Murree Brewery

The Department of Management Sciences Page 3

Executive Summary

The Murree Brewery Company Ltd was established in 1860.It is a Pakistan-based

company .Its products are only legally available in Pakistan owing to a prohibition on

the exportation of alcohol from Pakistan.

The Company is principally engaged in the manufacturing of Pakistan made foreign

liquor (PMFL) including alcoholic beer, non-alcoholic beer (NAB), non-alcoholic

products (NAP), which includes juices in tetra packs in Rawalpindi and food

products, juices, glass bottles and jars in Hattar. Murree Brewery Company Limited

operates in three divisions: liquor division, which includes PMFL, alcoholic beer,

NAB, Big Apple, Lemonade, Cindy and Malt -79; tops division, which includes food

products and juices, and glass division, which includes glass bottles and jars.

The Murree Brewery Company Ltd has been certified from ISO 9001(Quality

Management System).Now they are working on ISO 14001(Environmental

Management System).

The Murree Brewery is one of the oldest public companies of the sub-continent. Its

shares were traded on the Calcutta Stock Exchange as early as 1902, and are now the

oldest firm continuing industrial enterprise of Pakistan.

Is aimed to have a good quality of products and it is providing different types of

liquids to upper class, middle class and low class people. The company believes that

whatever we provide to the customers should be the best for them. They should get

the maximum satisfaction in this product.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 4

This internship program helped me in the polishing of communication skills, a must-

have to survive and make it big in the present world. It even gave a good

understanding of behavior of customers when placed in different situations. It was a

good opportunity to work on the skill of patience, as a large number of customers

were to be dealt with. It helped in developing the kind of relations one needs to

uphold in the corporate world and it helped in building up the right attitude.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 5

Introduction of Organization

-

Internship report on Murree Brewery

The Department of Management Sciences Page 6

History of Brewery Beer is one of the worlds oldest beverges. Beer-like beverages were independently invented among

various cultures throughout the world. The invention of beer has been argued to be responsible for

humanitys ability to develop technology and build civilization. The earliest known chemical

evidence of beer dates to circa 3500-3100 BC from the site of Godine Tepe in the Zagros

Mountains of western Iran.

Beer produced before the Industrial Revolution continued to be made and sold on a domestic scale,

although by the 7th

century AD beer was also being produced and sold by European monasteries.

During the Industrial Revolution, the production of beer moved from artisanal manufacture to

industrial manufacture, and domestic manufacture ceased to be significant by the end of the 19th

century. The development of hydrometers and thermometers changed brewing by allowing the

brewer more control of the process, and greater knowledge of the results.

Today, the brewing industry is a global business, consisting of several dominant multinational

companies and many thousands of smaller producers ranging from brewpubs to regional breweris.

Historical documentation shows that around 5,000 years ago, ancient Chinese civilizations were

breweing a beer-like substance known as Kui.

In ancient Mesopotamia, clay tablets indicate that brewing was a fairly well respected occupation

during the time, and that the majority of brewers were women. The discovery that reuse of the same

container for fermenting the mash provided more reliable results was an early one: brewers on the

move carried their tubs with them.

Some types of beers were used especially in relegious ceremonies. In 2,100 BC, the Babylonian

King Hammurabi included regulations governing tavern keepers in his law code for the kingdom.

Beer drinking accessories, such as mugs, have also been found in Israel, and date back to nearly

2000 BC.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 7

Beer was part of the daily diet of Egyptian Pharaohs over 5,000 years ago. Then, it was made from

baked barley bread, and was also used in religious practices.

The role of beer in Egyptian society was far greater than just a drink. Often, beer was prescribed to

treat various illnesses. Beer was considered to be the most proper gift to give to Egyptian Pharaohs

and it was also offered as a sacrifice to the gods.

The process of brewing beer grew tremendously during the rise of Christianity. This was primarily

because of the roles that monks had in the production of beer. Monasteries were some of the first

organizations to brew beer as a trade. Monks built breweries as part of their efforts to provide food,

shelter and drink to various travelers and pilgrims.

A large number of Christian saints are patrons of brewing. Saint Augustine of Hippo, Saint Luke

the Evangelist, and Saint Nicholas all are considered to be patrons of brewing.

Emperor Charlemagne, the ruler of the Christian kingdom around 770 AD considered beer to be an

important part of living, and is often thought to have trained Christian brewers himself.

As in ancient times, women were the primary brewers during the middle Ages. Women took over

brewing after the monasteries had really established the process.

A funerary model of a bakery and

brewery, from the Eleventh dynasty

of Egypt, circa 2009-1998 BC

-

Internship report on Murree Brewery

The Department of Management Sciences Page 8

Early Beers

As almost any cereal containing certain sugars can undergo spontaneous fermentation due to wild

yeasts in the air, it is possible that beer-like beverages were independently developed throughout the

world soon after a tribe or culture had domesticated cereal. Chemical tests of ancient pottery jars

reveal that beer was produced about 5,500 years ago in what is today Iran, and was one of the first-

known biological engineering tasks where the biological process of fermentation is used. Also

recent archaeological findings showing that Chinese villagers were brewing fermented alcoholic

drinks as far back as 7000 BC on small and individual scale, with the production process / methods

similar to that of ancient Egypt and Mesopotamia.

Beer became vital to all the grain-growing civilizations of Eurasian and North African antiquity,

including Egyptso much so that in 1868 James Death put forward a theory in The Beer of the

Bible that the manna from heaven that God gave the Israelites was a bread-based, porridge-like beer

called wusa.

Medieval Europe

Beer was one of the most common drinks during

the Middle Ages. It was consumed daily by all

social classes in the northern and eastern parts of

Europe where grape cultivation was difficult or

impossible. Though wine of varying qualities was

the most common drink in the south, beer was still

popular among the lower classes. Since the purity

of water could seldom be guaranteed, alcoholic

drinks were a popular choice, having been boiled

as part of the brewing process. Beer also provided

a considerable amount of the daily calories in the northern regions. In England and the Low

Countries, the per capita consumption was 275-300 liters (60-66 gallons) a year by the Late Middle

Ages, and beer was downed with every meal Though probably one of the most popular drinks in

Europe, beer was disdained by science as being unhealthy, mostly because ancient Greek and more

contemporary Arab physicians had little or no experience with the drink.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 9

Laws to enforce the use of hops in beer were introduced in England in the 14th century, and later

similar laws were introduced in other countries. In England, these laws led to peasant uprisings,

since it was considered to spoil the taste, but these uprisings were brutally put down.

Early modern Europe

In Europe, beer largely remained a homemaker's activity, made in the home in medieval times. The

oldest still operating commercial brewery is the Weihenstephan (Bavaria) abbey brewery, which

obtained the brewing rights from the nearby town of Freising in 1040. By the 14th and 15th

centuries, beermaking was gradually changing from a family-oriented activity to an artisan one,

with pubs and monasteries brewing their own beer for mass consumption.

In 15th century England, an unhopped beer would have

been known as ale, while the use of hops would make it a

beer. Hopped beer was imported to England from the

Netherlands as early as 1400 in Winchester, and hops were

being planted on the island by 1428. The popularity of

hops was at first mixedthe Brewers Company of London

went so far as to state "no hops, herbs, or other like thing

be put into any ale or liquore wherof ale shall be made

but only liquor (water), malt, and yeast."

In 1516, William IV, Duke of Bavaria, adopted the

Reinheitsgebot (purity law), perhaps the oldest food regulation still in use through the 20th Century

(the Reinheitsgebot passed formally from German law in 1987). The Gebot ordered that the

ingredients of beer be restricted to water, barley, and hops; yeast was added to the list after Louis

Pasteur's discovery in 1857. The Bavarian law was applied throughout Germany as part of the 1871

German unification as the German Empire under Otto von Bismarck, and has since been updated to

reflect modern trends in beer brewing. To this day, the Gebot is considered a mark of purity in

beers, although this is controversial.

Most beers until relatively recent times were top-fermented. Bottom-fermented beers were

discovered by accident in the 16th century after beer was stored in cool caverns for long periods;

they have since largely outpaced top-fermented beers in terms of volume.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 10

The Industrial Revolution

Following significant improvements in the efficiency of the steam engine in 1765, industrialization

of beer became a reality. Further innovations in the brewing process came about with the

introduction of the thermometer in 1760 and hydrometer in 1770, which allowed brewers to

increase efficiency and attenuation.

Prior to the late 18th century, malt was primarily dried over fires made from wood, charcoal, or

straw, and after 1600, from coke.

In general, none of these early malts would have been well shielded from the smoke involved in the

kilning process, and consequently, early beers would

have had a smoky component to their flavors; evidence

indicates that maltsters and brewers constantly tried to

minimize the smokiness of the finished beer.

Writers of the period describe the distinctive taste

derived from wood-smoked malts, and the almost

universal revulsion it engendered. The smoked beers

and ales of the West Country were famous for being undrinkable - locals and the desperate

accepted. This is from "Directions for Brewing Malt Liquors" (1700):

Modern Beer

Many European nations have unbroken brewing traditions dating back to the earliest historical

records. Beer is an especially important drink in countries such as Belgium, Germany, Ireland, and

the UK, with nations such as France, the Scandinavian countries, the Czech Republic, and others

having strong and unique brewing traditions with their own history, characteristic brewing methods,

and styles of beer.

Unlike in many parts of the world, there is a significant market in Europe (the UK in particular) for

beer containing live yeast. These unfiltered, unpasteurised brews are awkward to look after

compared to the commonly sold dead beers: live beer quality can suffer with poor care, but many

people prefer the taste of a good live beer to a dead one. While beer is usually matured for relatively

short times (a few weeks to a few months) compared to wine, some of the stronger so-called real

-

Internship report on Murree Brewery

The Department of Management Sciences Page 11

ales have been found to develop character and flavour over the course of as much as several

decades.

In some parts of the world, breweries that had begun as a family business by Germans or other

European migrs grew into large companies, often passing into hands with more concern for

profits than traditions of quality, resulting in a degradation of the product.

In 1953, New Zealander Morton W. Coutts developed the technique of continuous fermentation.

Coutts patented his process which involves beer flowing through sealed tanks, fermenting under

pressure, and never coming into contact with the atmosphere, even when bottled. His process was

introduced in the US and UK, but is now used for commercial beer production only in New

Zealand.

In some sectors brewers are

reluctant to embrace new

technology for fear of losing the

traditional characteristics of their

beer. For example Marston's

Brewery in Burton on Trent still

uses open wooden Burton Union

sets for fermentation in order to

maintain the quality and flavour of

its beers, while Belgium's lambic

brewers go so far as to expose their

brews to outside air in order to pick up the natural wild yeasts which ferment the wort. Traditional

brewing techniques protect the beer from oxidation by maintaining a carbon dioxide blanket over

the wort as it ferments into beer.

Modern breweries now brew many different types of beer, ranging from ancient styles such as the

spontaneously-fermented lambics of Belgium; the lagers, dark beers, wheat beers and more of

Germany; the UK's stouts, milds, pale ales, bitters, golden ale and new modern American creations

such as Chili Beer, Cream Ale, and Double India Pale Ales.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 12

Today, the brewing industry is a huge global business, consisting of several multinational

companies, and many thousands of smaller producers ranging from brewpubs to regional breweries.

Advances in refrigeration, international and transcontinental shipping, marketing and commerce

have resulted in an international marketplace, where the consumer has literally hundreds of choices

between various styles of local, regional, national and foreign beers.

The next great development occurred in the mid-nineteenth century, through work done by Louis

Pasteur, the first to propose an explanation of how yeast worked. Shortly thereafter, samples of

Bavarian yeast provided the successful identification of a single-cell and strain of the bottom-

fermenting lager yeast. German brewers had started to make beer by lagering (storing) in 1402.

Brewing was not possible in the warm months because wild yeasts prevalent in the warmer weather

of summertime would sour the beer. Brewers discovered that brewing in the cold months and

storing the beer in caves in the nearby Alps impacted stability to the beer and enhanced it with a

cleaner taste, although they did not know why. Today, we know that the reason the beer was clearer

and cleaner was due to the fermentation process the beer underwent in the cold, during which the

chemicals and bacteria responsible for clouding beer were unable to thrive and were therefore

filtered out of the beer. In 1880, there were approximately 2,400 breweries operating in the US

embracing many of the classic brewing styles. Today, there are 375 breweries. The change can be

traced back to the era of the Volstead Act of 1919 - this Eighteenth Amendment to the Constitution

ushered in Prohibition. During this time, the smaller breweries lay idle as the larger establishments

limped by with the production of cereal malts and near-beers.

Following Prohibition in World War II, with corresponding food shortages and therefore increased

substitution of adjuncts for malt - a lighter beer resulted. With a large part of the male population

off fighting the war, the work force in America was made up largely of women; thus marketing to

this population solidified the hold of a lighter-styled beer. Following the war, the large national

breweries catered to the tastes of this expanded beer market. Today, there is a revolution in America

as brewing returns to its roots, and a great variety of high-quality beers are being revived, imported

and enjoyed!

-

Internship report on Murree Brewery

The Department of Management Sciences Page 13

Introduction of Organization

-

Internship report on Murree Brewery

The Department of Management Sciences Page 14

History

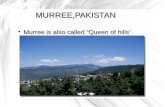

Consequent to the British annexation of the Punjab in 1849 from sikh rule, and more so after 1857

when the British Crown formally extended its sovereignty over india, a structured administration

commenced in the Punab.

To meet the beer requirements of British personnel (mainly army), the Murree Brewery was

established in 1860 and incorporated a year later at Ghora Galli, located in Pir Punjal range of the

Western Himalyas at an elevation of 6000 above sea level, near the resort town of murree.

Between 1885 & 1890 the company established Breweries in Rawalpindi & Quetta & acquired an

interest in the Oticumand (South India) & Norailiya (ceylon) breweris. A distillery was also

established in the above period in Rawalpindi next to the Brewery.

The Murree Brewery at Ghora Galli was therefore among the first modern beer breweries

established in Asia. Murree Beer proved to be very popular among the British troopers who were

largerly barracked in tha Galis of these hills.

The virtues of the beer brewed form barley malt & hos as a light alcoholic beverage were not lost

on the local population who rapidly became avid consumers. By the turn of the 20 century, the

name Murree was famous for its beer in Keg and bottle in the bars, beer halls and army messes of

British India. Murree Beer was first awarded a medal for product excellence at the Philadelphia

Exhibition in 1876, followed by numerous awards over the past 140 years.

In 1935, a massive earthquake totally demolished the Quetta brewery as well as substantial part of

Quetta town, killing thousands of persons, including a number of our employees. At Ghora Galli

(Murree), the scarcity of water became an emerging problem.

By the 1920s, brewing was mostly transferred to the Rawalpindi brewery but malting continued at

Ghora Galli till the 1940s, when this property was sold. The historic brewery built in Gothic style

architecture was burnt during the partition riots of 1947/48.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 15

Park Lodge a handsome resedential property was purchased by the company from Mrs. H.

Whymper in 1888. It was the principal residence and head office of the company till 1959, when it

was taken by the Government of Pakistan to house the office of the President of Pakistan. It remains

an office of the Head of State of Pakistan from 1960 till the present day. The original brewery was

founded by two closely connected english families. Edward Dyer was the first General Manager of

the Company. He was also the founder of the Dyer Meaken breweries, Simla hills. Edward

Whymper, a member of this family was the first person to climb Matterhorn mountain in 1865.

The Rawalpindi brewery is blessed with deep aquifers of good watter. A railway siding was

extended to the premises in the 19th

century, which is now derelict.

Under the present prohibition law, only non-Muslims and foreigners are permitted to consume

alcohol. Notwithstanding the consequent reduction in demand, the Company decided as policy to

concentrate on product excellence. It was decided to modernize the plants.

A Ziemann (German) brew house was installed in 1967, 'Saladin' Box Meltings in 1971. Also in

the late sixties, it was decided to embark on an ambitious long-term program to mature Malt

Whiskies. Over the past four decades white oak casks and vats have been procured from North

America, Australia and Spain

Our two underground cellars now hold over half a million liters of Malt Whisky for varying periods

of maturation up to 12 years under controlled temperature conditions.

Another wave of modernization was undertaken in the 1990s. New beer canning and modern bottle

filling facility from Holstein and Kappert (Germany) was installed. Two units of alcohol

rectification columns for producing extra neutral grade of potable alcohol from Molasses were

procured from France and Italy, respectively, to give our Vodkas and Gins a qualitative edge.

Also in this period, the beer fermentation capacities were renewed. It is pertinent to point out that

our basic beer fermentation system installed in the 1930s was then at the cutting edge of this

technology. Known at the time as the Nathan system, it incorporates fermentation and the laagering

of beer in a single double jacketed vessel. A variation of this system is now in extensive use

worldwide.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 16

Tops Food and Beverages a division of the Company was established in 1969. It processes fruits

and markets fruit juices and allied food products. Two manufacturing units are located in

Rawalpindi and Hattar (NWFP) respectively. A Tetra Pak packaging facility was added in 2001.

The Hattar plant was installed in 1992.

The plant is based on a Recuperative Melter and two Emhart I.S. container manufacturing machines

and has the latest quality control equipment for online inspection of containers.

The Murree Brewery is one of the oldest public companies of the sub-continent. Its shares were

traded on the Calcutta Stock Exchange as early as 1902, and are now the oldest continuing

industrial enterprise of Pakistan.

In 1997-1998 and 1998-1999, we were judged among the top 25 performing public companies by

the Karachi Stock Exchange.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 17

Board of Directors

Chairman Mr. Khurram Muzaffar

Chief Executive Mr. Isphanyar M. Bhandara

Mr. M. M. Shahbaz

Mr. Asadullah Khawaja

Ch. Mueen Afzal

Mr. Aamir H. Sherazi

Mrs. Goshi M. Bhandara

PRINCIPAL OFFICERS

Company Secretary Mr. M. Zaffar Iqbal

Chief Financial Officer Kh. Mushtaq Ahmed, FCA

General Manager (Brewery Division) Mr. Mohammad Javed

Director (Glass Division) Mr. M. M. Shahbaz

Acting General Manager (Tops) Major Sabih-ur-Rehman

AUDIT COMMITTEE

Mr. Khurram Muzaffar (Chairman)

Ch. Mueen Afzal (Member)

Mrs. Goshi M. Bhandara (Member)

AUDITORS PRINCIPAL BANKERS

M/s KPMG Taseer Hadi & Co. Bank Alfalah Ltd, Rawalpindi

Chartered Accountants Standard Chartered Bank, Rawalpindi/Lahore

6th

Floor, State Life Bldg, Askari Commercial Bank Ltd, Rawalpindi

Jinnah Avenue, Islamabad. National Bank of Pakistan, Rawalpindi/Hattar

The Bank of Khyber,Hattar.

Allied Bank Ltd, Lahore / Gujranwala.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 18

Introduction

Murree Brewery is the maker of Pakistan's premier beer brand known Murree Beer. Its products are

only legally available in Pakistan owing to a prohibition on the exportation of alcohol from

Pakistan. The brewery has two manufacturing units located in Rawalpindi and Hattar (North-West

Frontier Province).

In 1977 the Murree Brewery suffered a

significant setback when Zulfiqar Ali

Bhutto imposed a total prohibition in

Pakistan, to appease Islamic elements

of the electorate. Subsequently the

government of General Zia-ul-Haq

amended this law, requiring anyone

wishing to consume alcohol to present

credentials demonstrating that they

were non-Muslim. The small Christian,

Hindu and Parsi communities were not large enough to support the enterprise, and production had

to be scaled back.

However, gradual relaxation of the prohibition laws has allowed Murree to introduce variations of

Murree beer, vodka, gin and whisky. Today, all Murree products are readily available in legal liquor

shops that operate openly in Karachi in places like Zamzama and Defense. It is also available in the

interior of Sindh. Although the consumption of alcohol in public is still nominally banned, it is

becoming increasingly available in clubs and high-class restaurants. Murree Beer was initially being

produced in Austria for European markets and was available in various Pakistani and Indian

restaurants, an enterprise which has since ceased since 2004.

The Murree Brewery is one of the oldest public companies of the sub-continent. Its shares were

traded on the Calcutta Stock Exchange as early as 1902, and are now the oldest continuing

industrial enterprise of Pakistan and among the top 25 performing public companies by the Karachi

Stock Exchange.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 19

Murree's biggest competitor is the Quetta Distillery and its products have to increasingly vie with

smuggled brands from the West and India.

Pakistans only Beers and Whisky firm

Understandably, making beer and whiskey in a Muslim country, where 97 per cent of the

population is officially banned from enjoying your products, has never been an easy business. Non-

Muslims are exempt from the ban, but even for them getting a drink can be complicated: some five-

star hotels require foreigners to affirm in writing that they are non-Muslims and will be responsible

for anything that happens when they are under the influence before they can order a drink.

And amid the upsurge of militant violence of the last two years that has seen the Taliban attacking

targets across the country, setting fire to girls' schools and even banning the sale of videos and

DVDs, common sense might suggest that the fortunes of this establishment, which celebrates its

150th anniversary next year, might be on the wane. Yet the opposite is happening: sales are

booming embarrassingly so.

"Sales are good," said Isphanyar Bhandara, the brewery's 36-year-old chief executive, "but we don't

want to shout about it because that also brings negative publicity and criticism, because this is a

Muslim country and yet sales are growing."

Pervaded by a rich smell of fermenting yeast and equipped with Victorian maturing cellars, the

brewery is located in the heart of the military cantonment area of Rawalpindi, the garrison city

where 30 people died in a suicide bomb attack earlier this week. The scenes within the thick stone

walls are reminiscent of a British brewery of the remote past. Located opposite the residence of the

Chief of the Army Staff, the brewery says it has never received a direct threat from the militants.

Metaphorically speaking, the Murree brewery sits on one of the major fault lines of Pakistan's often

contradictory society. While Muslims have been banned from buying or drinking alcohol since

1977, few private social gatherings among the country's political or business lite take place

without the lubrication of liquor. A well-established network of bootleggers dealing in both locally

-

Internship report on Murree Brewery

The Department of Management Sciences Page 20

produced and smuggled alcohol ensures that, while bars do not exist except for a couple of gloomy

premises in five-star hotels, a drink in a private home is never far away.

For an institution such as the brewery, this two-faced attitude towards alcohol has meant several

things. Firstly, while Christians, Hindus, Zoroastrians and other non-Muslims officially constitute

its customers, there is a private acknowledgement that the vast majority of drinkers are Muslims

who work their way through the easily exploited permit system. Non-Muslims and foreigners can

get an official permit allowing them to buy 30 bottles of beer or a quart of spirits every month.

Reports suggest that such permits are easy both to copy and to obtain fraudulently.

At the same time, the brewery and distillery have to operate within a set of cramping rules. They are

not allowed to advertise their products, for instance, and they have yet to be given permission to

export them. The Islamic Ideology Council of Pakistan, which advises the government on policy

issues, has made clear that it believes the export of alcohol abroad would damage the country's

international image. The council's secretary Riaz-ur-Rehman confirmed: "We cannot allow anyone

in the country to be engaged in the trade or production of alcohol."

Meanwhile, the company, which earlier this year produced the Muslim world's first 20-year-old

malt, provides the state and federal authorities with around $1m (604,000) a month in taxes and

duty.

"Absurd as it sounds, it's true," said Mr. Bhandara, who is a member of Pakistan's tiny population of

Zoroastrians or Parsis and is also, ironically, a teetotaler, even though he is permitted to drink

because of his religion. "It's totally hypocritical. I'm talking to the government at the moment about

permission to export our beer to Britain [where it would be marketed with the catchphrase 'Have a

Murree with your curry'], as many Asians in Britain are familiar with our products. Carlsberg were

going to brew and sell it in the UK but then they said the beer market was shrinking. I am saying to

them we have a 20 per cent increase in beer sales year-on-year in a Muslim country."

The Murree Brewery, shares of which are publicly traded on the Pakistan stock exchange in

Karachi, was initially established in 1860 among the woods and cooling breezes of the Murree

Hills, 20 miles north of Islamabad, where the elevation of 6,000ft was perfect for producing light

beer for British colonial troops. Growing demand for its award-winning products saw the company

-

Internship report on Murree Brewery

The Department of Management Sciences Page 21

establish additional breweries in Quetta in 1886 and in Rawalpindi in 1889, the site of the current

operation.

On a recent morning, bright with early winter sunshine, Jamshed Iqbal, the company's enthusiastic

quality control manager, led The Independent on a tour of the facilities. "Making liquor is easy, but

brewing beer is an art," he said, describing the challenges of temperature control in a region where

the summer mercury can top 45C.

Part of his duties includes checking the taste of the finished products to ensure consistency. He said

he believed the company's "classic" lager had the best taste. But as a Muslim, was he allowed to

taste it? "Just a mouthful," he replied.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 22

Management Techniques

Consensus based process

Board meeting at different points of time

Annual meetings

Specialized professional team

Incentives and bonus

Adjustable environment and discipline

-

Internship report on Murree Brewery

The Department of Management Sciences Page 23

Mission and Vision Statement

To fulfill customer requirements & expectations

through CARE

Contionous improvement

Alignment of our missions and goals

Responsibility and respect of our jobs and each other

Educate one another

We the people of Murree Brewery Co. make personal

commitment to first understand our customers

requirement then to meet & exceed their expectations,

by performing the correct tasks on time and every time

through.

MOTTO

We respect our past. We are the industry leaders in present

and accept the challenge of the future.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 24

Corporate, Business and

Departmental level Starategeis

Marketing strategy of the company is based on the folloeing points:

First come to know about the who are our customers and what are their requirements.

What do we really know about their needs, preferences, behavior and their life styles?

What can we offer them... at a price... that other companies do not?

How do we perform in comparison to our competitors?

How are we currently performing for our customers?

Where are the gaps, the weak points, the fudges, and the point of excellence... the USPs

(Unique Selling points)?

How are we different?

Why are we different?

How can we better delight?

How do we change?

What do we change?

How clever are we with our market intelligence?

How well is our market research working?

Consider groups who share a similar need and who will respond in a similar

way.

Design a Marketing Strategy

To achieve specific marketing objectives, based (e.g.) on the Marketing mix.

Set Tactical Plans, Budgets, Programs

Assign individual responsibilities to achieve the objectives.

Monitor Progress

-

Internship report on Murree Brewery

The Department of Management Sciences Page 25

Product Strategy

Murree brewery is aimed to have a good quality of products and it is providing different types of

liquids to upper class, middle class and low class people. The company believes that whatever we

provide to the customers should be the best for them. They should get the maximum satisfaction in

this product.

Murree Brewery has launched a new product Big Apple which is now being used at a large scale in

the whole country. The company provides Beers to the upper class that has the authority to do so.

They have energy drinks and soft drinks.

Pricing Strategy

Company has 15 different types of

juices, which come into jars, bottles

and packs. They have to maintain a

price which is affordable to the

customers and which is profitable to

them, it appears that they have

position their product pricing in such a

way that their main focus is middle

and upper middle class. However, they

have some selected range for upper

class as well.

Promotion Strategy

They believe that print media and outdoor activity help them to reach to their target customer. Due

to satellite transmission and having multi channels, it does not pay one unless you have very huge

budget to spend on this media. On promotion, their spending is more on putting banners on the

roads, on bridges and sometimes on the newspapers. Since it pays them and there is direct

relationship between sales and consumer.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 26

Distribution Strategy

TOPS have nationwide users so they have to arrange dealers in the every city. They have their

branch offices in Karachi, Lahore, Islamabad, Faisalabad and all the major cities of Pakistan so that

one can get easy delivery of their product easily in every city or village of country. Provide quick

and timely delivery to their dealers: they have got big warehouses located in almost all big cities

and towns. Whenever they get order from the dealer they try to provide supplies to their dealer from

closest warehouse. They believe that, timely delivery of their product to the dealer is one of an

important element in their success in Pakistan.

Product Life Cycle

It is one of their missions to provide quality product to their customers. Therefore, they ensure that

every product, which is delivered from their factory, must go through rigorous quality check. So

that only perfect product, free from any defect is delivered to their customers.

So, when it is delivered to the customer, it must meet customer's expectations

-

Internship report on Murree Brewery

The Department of Management Sciences Page 27

Organizational Sructure

Cheif Executive

CFO

Computer programmer

CA

GM

Customer Manager

Technical Manager

Distiller

Supervisor

Assistant Supervisor

Workers

Brewery

Assistant Beuru

Supervisor

Assistant Supervisor

Workers

Cheif Engineer

Workshop

Supervisor

Assistant Supervisor

Workers

Presentive Maintainance

Engineer

Supervisor

Assistant Supervisor

Workers

Security Incharge

M(HR)

-

Internship report on Murree Brewery

The Department of Management Sciences Page 28

Corporate Information

Board of Directors

Chairman Mr. Khurram Muzaffar

Chief Executive Mr. Isphanyar M. Bhandara

Mr. M. M. Shahbaz

Mr. Asadullah Khawaja

Ch. Mueen Afzal

Mr. Aamir H. Sherazi

Mrs. Goshi M. Bhandara

PRINCIPAL OFFICERS

Company Secretary Mr. M. Zaffar Iqbal

Chief Financial Officer Kh. Mushtaq Ahmed, FCA

General Manager (Brewery Division) Mr. Mohammad Javed

Director (Glass Division) Mr. M. M. Shahbaz

Acting General Manager (Tops) Major Sabih-ur-Rehman

AUDIT COMMITTEE

Mr. Khurram Muzaffar (Chairman)

Ch. Mueen Afzal (Member)

Mrs. Goshi M. Bhandara (Member)

AUDITORS PRINCIPAL BANKERS

M/s KPMG Taseer Hadi & Co. Bank Alfalah Ltd, Rawalpindi

Chartered Accountants Standard Chartered Bank, Rawalpindi/Lahore

6th

Floor, State Life Bldg, Askari Commercial Bank Ltd, Rawalpindi

Jinnah Avenue, Islamabad. National Bank of Pakistan, Rawalpindi/Hattar

The Bank of Khyber, Hattar

Allied Bank Ltd, Lahore / Gujranwala

-

Internship report on Murree Brewery

The Department of Management Sciences Page 29

Social Responsibility

They provided area to Govt. of

Pakistan in Zia-Ul-Haq era.

Also provided place for Govt. Bhandara

High School.

Place for Golf Club.

Dispensary for employees.

Provide renovation facilities.

Post office for the area people.

Benefit to their employees.

Provident funds.

Pension.

Medical fecilities.

Insurance.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 30

Products of Murree Brewery

-

Internship report on Murree Brewery

The Department of Management Sciences Page 31

Products of Murree Brewery The Murree Brewery produces a wide variety of Beers, liqours and non-alcoholic products. There

premium products include Murrees Millennium Beer, Murrees Classic Beer, Lite Export Pils,

Eight and twelve years old single Malt Whiskies, Vintage with a blend of a Scotch Grain Whisky,

Silver Top Gin, Boskaya Vodka And Doctors Brandy.

Beers:

1) Murree Beer

An all time favourite since 1860. Alc. Contents

4.5% v/v. Brewed from local six row barley,

malts and bavarian hop products. Has a

distinctive taste and flavour.

Murrees Classic Lagger

Premium beer, inputs identical to the

millenium Beer. Alc 5.5% v/v. A real classic.

Smooth on the plate. Taste and flavour close to

classic European lagers.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 32

2) Murrees Millennium

Our flagship beer 8% Alc. v/v. Brewed from highest grade

Australian malt and hallertau a German Hop products. The

millennium is celeberation brew for special occasion

3) Lite Export Pils

Is brewed from continental Malts and Hops. A light beer Alc. 3.5% v/v. Correspond in

flavour and quality to the famous beer brewed in Pilsen, Czech Republic,. An ideal summer

drink.

Liqours

1) Murrees Matured Malt Whiskies

Murrees premium Malt whiskies are brewed from a Barley Malt mash, distilled on

traditional pot stills and matured in imported oak wood casks & vats for guaranteed periods

specified on respective packaging.

Jim Murray, one of Englands best known writers on Scotch Whiskies comments on

Murres 8 years old classic Malt whisky at page 202 in his Complete book of Whisky

(1997) as follows: Not only does

Murrees 8 years old single matured

malts compare favourably, it is much

better than a lesser Scotch malt, which

comes nowhere near matching this

whiskys crisp and delicate

maltiness. Compare in maltiness,

character &crispness to any reputed

Scottish Malt whisky of equal age.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 33

2) BOLSKAYA VODKA & SILVER

TOP GIN

Produce under arrangement with Bols

international B.V. Netherlands

Distilled from extra neutral grade alcohol

under arrangement with Bols international

BV, Netherlands world famous distillers of

fine liquors.

3) MURREE GINS

Tower of London Gin is rich in juniper flavour

extracted from the juniper berries of the world

famous Ziarat juniper forest near Quetta.

London Dry Gin is a typical English s\dry gin

with a delicate flavour, balanced aromatics and

botanicals. Lemo lime & citrus Gins Convey

the flavour of citrus fruits.

Non Alcoholic Beers (NAB)

Malt 79 & cindy malt drinks are brewed from

golden barley malt and hops. Ideal thirst

quenching summer drinks.

Once you get the taste of real grain beverages

rich in natural sugars, you will never look back

to synthetic colas. Non alcoholic malt drinks

are recommended by doctors for a vareity of

elements. Our non alcoholic malt drinks our

genuine earth drinks.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 34

Fizzy Drinks

1) Big Orange

Is an all time favourite all season drink.

2) Big Apple

Pakistan first corbonated drink. A delight for every Pakistani house hold.

3) Big Lemon

-

Internship report on Murree Brewery

The Department of Management Sciences Page 35

There Lemonade are best in Pakistan.

MALTS

Stawerbry Malt

-

Internship report on Murree Brewery

The Department of Management Sciences Page 36

Lemon Malt

Peach Malt

-

Internship report on Murree Brewery

The Department of Management Sciences Page 37

-

Internship report on Murree Brewery

The Department of Management Sciences Page 38

Production Process

-

Internship report on Murree Brewery

The Department of Management Sciences Page 39

Distillary Process The barley is first soaked in water, then spread inside the germination box allowing it to germinate.

The germination produces sugar and thus converts the barley into malt. As the germination releases

heat, the barley has to be turned regurarly, and the temperature need to be controlled. The malt is

then transferred to the kiln, spread over a mesh and dried over a fire.

The malt is coarsely ground

by roller. In the mash tun it is

mixed with hot water at

specified temperatures, in

which the malt sugars are

dissolved. The resulting

sweet solution is called wort.

Wort is cooled, and yeast is

added, while the solid residue

of the malt is sold as cattle feed. The temprature is done in vats till a beer, with around 7-8%

alcohol, is formed.

Distillation takes place in onion-shaped pot still made from copper. In the first distillation, which

takes place in the wash stills, the alcohol fraction is raised to somewhat over 20%. The product,

called low wines, the is distilled a second time in spirit stills, which results in a spirit with over 60%

alcohol. In distillation process, the first and the last fractions are recycled back for Re-distillation

process, while only the middle cut via the spirit safe goes to the spirit store to be filled into barrels.

The spirit safe is locked by the Excisemen.

By law, the spirit can only be called whisky after at least three years of maturation. Usually no

new casks are used, but rather the casks are charred before use, which helps to release vanilla from

the wood.

Once matured, the whisky is bottled. To achieve a more uniform taste, usually many casks are

blended. Whisky may also be filtered a t low temperature (about +5 to -5 Celsius) to remove fat

particles. And finally it is colored with caramel to achieve a Uniform Color.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 40

Flow Diagram of Distillation

Unit

In distillation Unit we prepare Alcohol through fermentation of Molasses

-

Internship report on Murree Brewery

The Department of Management Sciences Page 41

Distillation

Distillation is a method of separating mixtures based on differences in their volatilities in a

boiling liquid mixture. Distillation is a unit operation, or a physical separation process, and

not a chemical reaction.

Distillation of fermented solutions has been used since ancient times to produce distilled

beverages with higher alcohol content. The premises where distillation is carried out,

especially distillation of alcohol are known as a distillery.

Fractional Distillation

Fractional distillation is the separation of a mixture into its component parts, or fractions,

such as in separating chemical compounds by their boiling point by heating them to a

temperature at which several fractions of the compound will evaporate. It is a special type of

distillation. Generally the component parts boil at less than 25 C from each other under a

pressure of one atmosphere (atm). If the difference in boiling points is greater than 25 C, a

simple distillation is used.

Fermentation

Fermentation is a metabolic process whereby electrons released from nutrients are

ultimately transferred to molecules obtained from the breakdown of those same nutrients.

Yeast carries out fermentation in the production of ethanol in beers, wines and other

alcoholic drinks, along with the production of large quantities of carbon dioxide.

Molasses

Molasses is a viscous byproduct of the processing of sugar cane or sugar beets into

sugar.

The quality of molasses depends on the maturity of the sugar cane or sugar beet, the

amount of sugar extracted, and the method of extraction.

Fermenter

Yeast added to fermentation occurs.

8% alcohol is pure here.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 42

Condenser

A device or unit used to condense vapor into liquid.

E10, E11, E50, E51, E43 are condensers.

C10

It is Feed Column and boiling done here

C50

It is Impurity Column.

Alcohol is passed to C40 and Vapours are condensed in E50 & E51.

C40

It is Rectifying Column.

We get 96% alcohol here and remaining fusel oil (have 30 40 % alcohols) is

passed to C10 with wash.

SSR

It is Spirit Receiver and water are added here to reduce the percentage of alcohol

upto 43 or 37 % (depend on requirement).

Essence and Colour are also added here.

Onion Shaped Pot Made from Copper

-

Internship report on Murree Brewery

The Department of Management Sciences Page 43

Brewery Process The brewing process begins when the barley grain is soaked in water, thereby facilitating

germination, and then drying and curing the grain through kilning. The barley has now turned into

barley malt.

The mill uses steel rollers to

crack the grain open before it

enters the mash tun. After the

mixture of malts are cracked

open by the mill they are

mixed with the warm waters

in the German built mash

tun. The mash is then pumped sparged (sprayed) with hot water; this helps extract all the sugars

from the malt as possible.

The base of beer, or wort, is then pumped into the brew kettle where it is boiled, concenterated

and clarified.

The wort is now cooled before it

is moved to a fermentation cellar

where it will become beer. In

order to speed the cooling process

it is passed through a heat

exchanger (Whirl pool).

After the wort is cooled it is

pumped into a fermentation tank

located in the tun room, where specially cultured yeast, Saccharomy cerevisiac, is added to induce

fermentation at 20-21 degree C over the next 48 to 56 hours.

After the beer has been cold cellared and matured in the fermenter it is passed through a filter.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 44

Murree Brewerys bottling line is made up of several components. At the heart of the system is a

counter-pressured filter which is capable of filling 500 bottels per hour. Filled bottles then enter into

a pasteurizor, where hot water is sprayed on them. This ensures elimination of microorganisms, if

any, in the beer. A modern packaging machine, SAMOVI, packs the beer bottles automatically in

specific beer cartons. Beer is then shipped out of the final consumer through proper channel by the

sales department of Murree Brewery Co. Ltd.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 45

Flow Diagram of Brew House

Barley

Screening

A Grade

B Grade

For Beer

For NAB

C Grade

B low C

Grade +

foreign

matter

Steeping to

increase

moisture 40-45%

(1.5 day process)

Germination to

activate Beta +

Alpha enzymes

(6 days process)

Killing (multiage)

to stop the

activator of

enzymes & roasted

Keep safe in silo

Grinding

Mashing to

change starch

into sugar

Wert boiling in Kettle

+ addition of

Nutrients Hops etc.

Filtration D.V (dilution

Vat) to make up

the batch size

and to cool

Chilled process

at 11 degree

Celsius (F.V)

fermenting Vat

fermentation

(Add Yeast)

Maturation

process

4 to 6 weeks

Filtration

process

(Beer)

Bright beer tanks

in BBT room in

BBH hall

-

Internship report on Murree Brewery

The Department of Management Sciences Page 46

NAB Hall

In NAB hall, non alcoholic products are prepared

-

Internship report on Murree Brewery

The Department of Management Sciences Page 47

Rinser

Here empty bottles are washed.

Screening 1

Screening of empty bottles.

Screening 2

Screening of filled bottle (check the particles).

Screening 3

Screening of final product in bottle (again check the particles).

Pasteurization

Pasteurization is a process of heating a food, usually liquid, to a specific temperature for

a definite length of time, and then cooling it immediately. This process slows microbial

growth in food.

Pasteurization is not intended to destroy all pathogenic micro-organisms in the food or

liquid. Instead, pasteurization aims to reduce the number of viable pathogens so they are

unlikely to cause disease (assuming pasteurization product is stored as indicated and

consumed before its expiration date).

In that unit, temperature gradually increase and decrease from 25 to 60 C

-

Internship report on Murree Brewery

The Department of Management Sciences Page 48

Reserve Osmosis Plant

Reverse Osmosis

Reverse Osmosis (RO) is a filtration method that removes many types of large molecules and ions

from solutions by applying pressure to the solution when it is on one side of a selective membrane.

The result is that the solute is retained on the pressurized side of the membrane and the pure solvent

is allowed to pass to the other side. To be "selective," this membrane should not allow large

molecules or ions through the pores (holes), but should allow smaller components of the solution

(such as the solvent) to pass freely.

Reverse osmosis is most commonly known for its use in drinking water purification from seawater,

removing the salt and other substances from the water molecules.

RO Plant

A reverse osmosis plant is a manufacturing

plant where the process of reverse osmosis

takes place. An average modern reverse

osmosis plant needs six kilowatt-hours of

electricity to desalinate one cubic metre of

water.

In RO plant, we remove the hardness of water.

RO can give you all of these benefits:

Delicious, pure, salt-free drinking water

Crystal-clear, pure ice cubes

Peace of mind, knowing your water is highly pure

Compact, simple equipment - nothing to break down

Cheap to operate - only requires water pressur

-

Internship report on Murree Brewery

The Department of Management Sciences Page 49

Ro plant Diagram

Flow Diagram of RO Plant

-

Internship report on Murree Brewery

The Department of Management Sciences Page 50

Sand Filter

Sand filters are used for water purification.

Particles are removed in sand filter.

Carbon Filter

Carbon filtering is a method of filtering that uses a piece of activated carbon to remove

contaminants and impurities, utilizing chemical adsorption

-

Internship report on Murree Brewery

The Department of Management Sciences Page 51

Pet Plant (1&2)

(For 500 and 1500 ml bottles)

In Pet Plant, Big Apple is prepared.

In Pet Plant 1, both 500 and 1500 ml bottles are prepared.

In Pet Plant 2, only 500 ml bottles are prepared.

In Pet Plant 1, Caper machine should be attached to filler machine to reduce the wastage

of Big Apple.

Pet Plant 1

-

Internship report on Murree Brewery

The Department of Management Sciences Page 52

Pet Plant 2

-

Internship report on Murree Brewery

The Department of Management Sciences Page 53

Rinser

Empty bottles are passed to rinser through air conveyer and are washed.

Filling Machine

Menoblock

3 series combine in 1 machine

Capacity 1500 bottles/hour

Weight 7000 kg

Power 7.5 kw

Dryer

Wet bottles are dried here.

Screening

Screening of final product in bottle (check the particles).

Pasteurization

Pasteurization is a process of heating a food, usually liquid, to a specific temperature for

a definite length of time, and then cooling it immediately. This process slows microbial

growth in food.

Pasteurization is not intended to destroy all pathogenic micro-organisms in the food or

liquid. Instead, pasteurization aims to reduce the number of viable pathogens so they are

unlikely to cause disease (assuming pasteurization product is stored as indicated and

consumed before its expiration

date).

Temperature is kept from 0 to

C.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 54

Botteling Hall

-

Internship report on Murree Brewery

The Department of Management Sciences Page 55

(For bottles & canes)

In bottling hall, especially alcoholic products are prepared.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 56

Rinser

Here empty bottles are washed.

Screening 1

Screening of empty bottles.

Screening 2

Screening of filled bottle (check the particles).

Screening 3

Screening of final product in bottle (again check the particles).

Pasteurization

Pasteurization is a process of heating a food, usually liquid, to a specific temperature for

a definite length of time, and then cooling it immediately. This process slows microbial

growth in food.

Pasteurization is not intended to destroy all pathogenic micro-organisms in the food or

liquid. Instead, pasteurization aims to reduce the number of viable pathogens so they are

unlikely to cause disease (assuming pasteurization product is stored as indicated and

consumed before its expiration date).

In that unit, temperature gradually increase and decrease from 2 to 60 C.

PU Meter

For alcoholic 30 to 40 PU

For non alcoholic 50 to 60 PU

Gamma Level Detector

That unit is before pasteurizer and for canes.

If we give standard value for cane (e. g product filling till 320ml).Then less than of

that has rejected and equal or greater has passed.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 57

Bio Gas Plant Biogas typically refers to gas produced by the biological breakdown of organic matter in the

absence of oxygen.

The biogas plant consists of two components:

Digester (or fermentation tank)

Gas holder

The digester is a cube-shaped or cylindrical waterproof container with an inlet into which the

fermentable mixture is introduced in the form of liquid slurry.

The gas holder is normally an airproof steel container that, by floating like a ball on the

fermentation mix, cuts off air to the digester (anaerobiosis) and collects the gas generated.

The decomposition of organic matter

releasing various gases.The main gases

released are methane, carbon dioxide,

hydrogen and hydrogen sulphide.

Bacteria carry out the decomposition or

fermentation. The organic waste matter is

generally animal or cattle dung, plant wastes,

etc. These waste products contain

carbohydrates, proteins and fat material that

are broken down by bacteria. The waste

matter is soaked in water to give the bacteria

a proper medium to grow. Absence of air or

oxygen is important for decomposition

because bacteria then take oxygen from the waste material itself and in the process break them

down.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 58

It is assumed that one kg of fresh (wet) cow dung manure will give about 1.66 cubic feet of gas per

day.

Murree Brewery boiler tank used almost 30% of gas from bio gas plant.

Flow Diagram

-

Internship report on Murree Brewery

The Department of Management Sciences Page 59

Spend Wash

It is a liquid waste which comes from Distill House (Alcohol preparation house).

Digester

It is a closed tank. Here we feed cattle dung. Bacteria feeds through spend wash in the

absence of oxygen. Digester has gas aeration coils which mixed the cattle dung and

spend wash and generate gas.

Gas Washer

Here we used caustic soda (NaOH) to remove sulphur gas.

Gas Holder Tank

We collect the methane gas in gas holder tank. If order to supply, then supply the gas to

boiler tank through blower.

Blower

It is used to push the gas to boiler tank.

Clarified Tank

In clarified tank, amylases settled down in lower cone which again moved to chamber no

1 through primary clarified tank and remain liquid waste drain out to Nala Lei.

Environmental factor

There is no smell and a good plantation in bio gas plant.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 60

TOPS foods and Beverages

-

Internship report on Murree Brewery

The Department of Management Sciences Page 61

TOPS is the division of Murree Brewery. It was established in 1969. It processes fruits and markets

fruit juices and allied food products. Two manufacturing units are located in Rawalpindi and Hattar

(NWFP) respectively. A Tetra Pack packaging facility was added in 2001. The Hattar plant was

installed in 1992. Its products are:

Fruit Juices (Mango, Orange, Lychee etc.)

Fruit squashes(Mango,Orange,lemon & Diet)

Conserves( Apple & Strawberry Jam, Orange Marmalade)

Vinegar ( Malted & Plain)

Tomato Ketchups in various sizes, flavors & containers

Malt Extract

-

Internship report on Murree Brewery

The Department of Management Sciences Page 62

Flow Diagram

Tops

-

Internship report on Murree Brewery

The Department of Management Sciences Page 63

Sugar Dissolver Tank

Here we dissolve the sugar through heating (steam) provided by boiler tank.

Blending tank

Juice preparation

Pasteurization Plant

Pasteurization is a process of heating a food, usually liquid, to a specific temperature for

a definite length of time, and then cooling it immediately. This process slows microbial

growth in food. Pasteurization is not intended to destroy all pathogenic micro-organisms

in the food or liquid. Instead, pasteurization aims to reduce the number of viable

pathogens so they are unlikely to cause disease (assuming pasteurization product is

stored as indicated and consumed before its expiration date).

Water tank

The water come from pasteurization plant are collected in water tank and recycled

and again used for pasteurization.

Homogenizer

Here we thick the juice.

Tetra Pack Machine

Filling of the juice

Straw Machine

Straw are attached with tetra pack

-

Internship report on Murree Brewery

The Department of Management Sciences Page 64

Quality Policy of TOPS

Prepare the best quality products, believing that quality is

first priority and will take all steps to encourage quality

consciousness.

Meet all applicable regulatory requirements and system

standards.

To recognize that our workforce is our strength.

To satisfy the customer.

Continuously improve the skills systems and business of

the organization.

They are commited to consistently meet their customers

needs and expectation on product quality and performance of

optimum cost through their competent human resource and

continual improvement of process and system.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 65

Advertisement / Promotional

Activities and Demand

Creation

The marketing and promotional

activities of fruit juice and related

commodity groups are crucial in

increasing the demand for fruit juices.

These activities include, but are not

limited to, promotion, advertising, new

product development, and packaging

innovations. Marketers adopt their

strategies in accordance with specified

consumer wants and needs. They also

create product image and influence

consumer purchases. Often, consumer

demands for processed food like juices

are difficult to categorize. Consumers

tend to purchase products and services

that cover a broad spectrum of price

and value combinations.

Servicing the educated, nutritionally aware consumer who dwells in the localities i.e. E-8, F Sectors

of Islamabad, Blue Area etc. and same type of Consumer category in Lahore and other metro cities

is a complex role which marketers strive to master. In these types of areas people use to have a pure

fruit juice at least once a day, with an imported or prime local fruit juice. Similarly this market

could be catered through intensive marketing and promotion campaign on television or other

sophisticated media.

New product developments in conjunction with technological advancements have improved the

marketing of fruit juices like many other food items. Relatively recent innovations appearing on

-

Internship report on Murree Brewery

The Department of Management Sciences Page 66

supermarket shelves are single serving aseptically packaged fruit juices, fruit roll-ups and fruit juice

blends.

Marketing infrastructure, which includes refrigerated transportation facilities and the composition

of retail and wholesale markets, is correlated to the consumer demand for high quality produce.

Equipment that transports from the field to the supermarket, field wrapping machines, improved

cooling techniques, and temperature controlled distribution centers have been developed to ensure

the delivery of quality produce to retail outlets.

It is also important to ensure that the product has a meaningful point of difference i.e. sophisticated

and healthy attractive packaging, less use of preservatives and clearly mentioning of purity of the

juice etc. Most new products fail in the market because they are "me-too" products with no unique

benefit (or attraction) for the consumer. Generally for the fruit juice business advertising budget is

around 5% of the Total Revenue but for a small or medium scale unit, it may vary (on the higher

side). Billboards, Television, Radio, F.M Channels, and Newspapers are the conventional mediums,

which have been powerfully used for the promotion of fruit juice products.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 67

ISO 14001 ISO 14000 is primarily concerned with environmental management. This means what the

organization does to eliminate harmful effects on the environment caused by its activities.

It is the Environmental Management System specification with guidance for use. The design

of EMS is an on-going, interactive process which consists of defining, documenting and the

continually improvement of required capabilities.

Environmental Aspects and Impacts

The key to a successful registration for conformance with ISO 14001 is to accurately

determine the organization's Environmental Aspects and Impacts

Environmental Aspect

Element of an organization's activities, products or services that can

Interact with the environment.

Interact may be positive, negative or neutral.

Environmental Impact

Any change to the environment, whether adverse or beneficial, wholly or partially resulting

from an organization's activities, products or services.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 68

The combination of environmental aspects and impacts is the first step in establishing the

significance of environmental aspect.

A significant environmental aspect is an environmental aspect that has

or can have a significant environmental impact.

There are three distinct requirements contained within this section of ISO 14001.

First, the organization shall identify the environmental aspects of its activities, products

and/or services. In other words the organization must understand how it interacts with the

environment.

Second, the organization shall identify the specific environmental aspects that can be

controlled, and over which it can be expected to have influence.

Third, arrive at a list of significant environmental aspects based upon the individual

environmental impact of each environmental aspect. The importance of this third step

cannot be underestimated. The final list of significant environmental aspects will provide the

basis for the Environmental Policy statement, and the Environmental Objective(s) and

Targets. In other words the list of significant environmental aspects drives the entire content

and scope of the operational portion of the environmental management system.

Identify Environmental Aspects

All of the organization's activities, products and/or services must be included within the

environmental aspects review framework. The organization must assemble a listing of

potential environmental aspects. The listing might include the following:

1. releases of material to the air, water and/or soil;

2. Disposal of waste;

3. Energy and natural resource consumption;

4. Noise levels;

5. Transportation and/or storage of materials;

6. Manufacturing processes;

The purpose of this activity is not to determine the importance of each aspect. The purpose

is to create a complete listing of how the organization interacts with the environment. The

organization must include the effect of non-routine situations in the listing such as

emergency conditions, start-up and shutdown activities. The procedure that is developed to

produce the list of environmental aspects must recognize the conceptof continual

improvement

-

Internship report on Murree Brewery

The Department of Management Sciences Page 69

Continual Improvement

The term continual improvement refers to an ongoing process of performance enhancement.

In the context of this environmental standard, it means that you need to enhance your

organizations overall environmental performance by enhancing its environmental

management system and by improving its ability to manage the environmental aspects of its

activities, products, and services.

Continual improvements can be achieved by carrying out internal audits, performing

management reviews, analyzing data, and implementing corrective and preventive actions.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 70

Environmental Factors

Environmental Aspects

Environmental Aspect is an element of an organization's activities, products or services that

can interact with the environment. There are two types of environmental aspects:

(i) Direct Environmental Aspect Activities over which a company can be expected to have

an influence and control.For example, emissions from processes.

(ii) Indirect Environmental Aspect Actual or Potential activities over which the organization

can be expected to have an influence, but no control. For example, supply chain

controlled aspects, customer controlled aspects, aspects managed elsewhere within the

same company.

Environmental Impact

Any change to the environment, whether adverse or beneficial, wholly or partially resulting

from an organization's activities, products or services.

The combination of environmental aspects and impacts is the first step in establishing the

significance of environmental aspect.

Identification of Environmental Aspects

(a) Identify Activities, Services and Products.

(b) Consider direct and indirect environmental aspects.

(c) Consider:

Emissions to air.

Release to water.

Waste Management.

Contamination of land.

Impact on communities.

Use of raw materials and natural resources.

Other local environmental and community issues.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 71

Environmental Aspects at

Murree Brewery There are seven aspects in Murree Brewery

i. Gas Emissions

ii. Solid waste

iii. Effluent

iv. Noise

v. Heat

vi. Spillage

vii. Dust

Gas Emissions

Gas emissions are any gaseous material released, either naturally or artificially, into the

atmosphere. These gas emissions exist in a variety of forms: most notably water vapor,

carbon dioxide, methane, nitrous oxide and ozone. The effects of these gas emissions

come in the form of the greenhouse effect. Each of these gases absorbs radiation in the

atmosphere, increasing the temperature of the Earth.

Gas emissions from Boiler and Power House should have proper treatment because it

causes air pollution, acid rain, global warming , ozone depletion

We can minimize or pure the gases that come from Boiler and Power House through

Electro precipitator technique.

An electrostatic precipitator (ESP) or electrostatic air cleaner is a particulate collection

device that removes particles from a flowing gas (such as air) using the force of an

induced electrostatic charge. Electrostatic precipitators are highly efficient filtration

devices that minimally impede the flow of gases through the device, and can easily

remove fine particulate matter such as dust and smoke from the air stream. In contrast to

wet scrubbers which apply energy directly to the flowing fluid medium, an ESP applies

energy only to the particulate matter being collected and therefore is very efficient in its

consumption of energy (in the form of electricity).

-

Internship report on Murree Brewery

The Department of Management Sciences Page 72

Trucks enters in Murree Brewery should have tuning well because if tuning not well, truck

will emitted harmful gases which causes air pollution.

The harmful gases are CO, NOx , Lead Compounds, Unburnt hydrocarbons etc

Solid Waste

Solid wastes are any discarded (abandoned or considered waste-like) materials. Solid wastes

can be solid, liquid, and semi-solid or containerized gaseous material.

In Murree Brewery, solid wastes are carton, glass, and paper, wood.

Glass (silica) creates land contamination.

-

Internship report on Murree Brewery

The Department of Management Sciences Page 73

Noise Pollution

Noise pollution is displeasing human, animal or machine-created sound that disrupts the

activity or balance of human or animal life.

In Murree Brewery, noise level is very high at Power house, Boiler plant and Pet plant.

It damages the human ears.

It can be minimized by using ear muff or ear plugs.

Spillage

Water and Molasses leakages in still house

Water and Big Apple wastage in Pet plant

Any product that prepared in NAB hall have wastages

Waste water of Murree Brewery and Tops

-

Internship report on Murree Brewery

The Department of Management Sciences Page 74

Different Accounting Policies of

the Company 1. Taxation policy of the Company