Multipurpose usage list of s 2 c ABPF type cutter …...More option, more possibility The insert of...

Transcript of Multipurpose usage list of s 2 c ABPF type cutter …...More option, more possibility The insert of...

New Produc t News No.1708E-1 2019-4

Clamp screw Parts Screw driver / Wrench Screw anti-seizure agent

581-140581-141581-142581-143

581-144

581-145

581-146

581-147

581-147

0.51.12.24.9

4.9

6.9

9.8

9.8

9.8

104-T6104-T8104-T10

105-T20

101-T25S

105-T30A

AAA

B

B

B

P-37

Cutter Body

Shape

A B

Fasteningtorque(N・m)

ABPF06S (W/WL )ABPF08S (L/W/WL/WL /WLT )ABPF10S (L/W/WL/WL /WLT )ABPFM10ABPF12S (L/W/WL/WL /WLT )ABPFM12ABPF16S (L/W /WL /WE/WE /WLT )ABPFU16W220 ABPFM16ABPF20S (L/W /WL /WE/WE /WLT )ABPF20MT2 ABPFU20W270 ABPFM20ABPF25S (L/W /WL /WE/WE /WLT )ABPF25MT3 ABPFU25W300 ABPFM25ABPF30S (L/W /WL /WE/WE /WLT )ABPF30MT4 ABPFU30W300 ABPFM30ABPF32S (L/W /WL /WE )ABPF32MT4 ABPFM32

Shape

2019-4(K)2017-4:FP

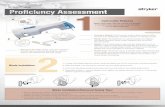

Clean the insert seat:Using air-blow or alike, clean the seat.1

Put in the insert with its top positioned to the screw-tightening side of the tool body.2

This is the end of insert set-up.4

Clamp screw (high precision screw)

Tool body

Top mark

Tighten the clamp screw with the special wrench.Please do not press down the insert during this tightening process.

3

In order to satisfy runout of 0.02mm or less, follow the procedure at left.

Note Cutting conditions and suggested retail price are referred in product catalogue or product newsABPF:No.0902 ARPF:No.0901 GP1LB:No.1711 GP1T:No.1711

L1 L1 L1 L1

ABPF ARPF GP1LB GP1T

Head figure of each insert

ABPFU16W220ABPFU20W270ABPFU25W300ABPFU30W300

16202530

39.651.661.373.2

-516173

43566770.2

39516173

ZDFG160…/ZPFG160… ZDFG200…/ZPFG200… ZDFG250…/ZPFG250… ZDFG300…/ZPFG300…

ZCFG160… ZCFG200… ZCFG250… ZCFG300…

-ZPHW200-LB20ZPHW250-LB25ZPHW300-LB30

ZDHW160-T43-R1.5-40 ZDHW200-T43-R2-50 ZDHW250-T43-R2.5-62.5 ZDHW300-T43-R3-75

15192429

181219239227

15182328

Item codeTooldia.Dc(mm)

Underneck

lengthL1

(mm)

InsertUnderneck

lengthL1

(mm)

Underneck

lengthL1

(mm)

InsertUnderneck

lengthL1

(mm)

Insert Insert

φD2

(mm)

ShanklengthRs(mm)

Shankdia.DS(mm)

Under neck length of each item

s

φD

c

L1 R

ABPF(Ball) ARPF(Radius) GP1LB(Special shape) GP1T(Special shape)

3

φD

s

φD

2

Carbide shank (Under neck type)

Parts

Set-up Procedures of Inserts

The diagrams and table data are examples of test results, and are not guaranteed values.“ ” is registered trademarks of Mitsubishi Hitachi Tool Engineering, Ltd. in Japan.

Specifications for the products listed in this catalog are subject to change without notice due to replacement or modification. Printed in JAPAN

Printed using vegetable oil ink.

Official Web Site

Database for selection Cutting Tool Products 【TOOL SEARCH】

http://www.mmc-hitachitool.co.jp/e/Head OfficeHulic Ryogoku Bldg. 8F, 4-31-11, Ryogoku, Sumida-ku, Tokyo, 130-0026 JapanInternational Sales Dept. : TEL +81-3-6890-5103 FAX +81-3-6890-5128

MMC Hitachi Tool Engineering Europe GmbHItterpark 12, 40724 Hilden,Germany. Tel +49-(0)2103-24820 Fax +49-(0)2103-248230

MITSUBISHI MATERIALS U.S.A. CORPORATIONDETROIT OFFICE Customer service41700 Gardenbrook Road, Suite 120, Novi, MI 48375-1320 U.S.A.Tel +1(248) 308-2620 Fax +1(248) 308-2627CHICAGO OFFICE1314B North Plum Grove Road, Schaumburg, IL 60173 U.S.A. Tel +1(847) 252-6371 Fax +1(248) 308-2627

MMC METAL DE MEXICO, S.A. DE C.V.IAv. La Cañada No.16, Parque Industrial Bernardo Quintana, El Marques,Querétaro, CP 76246, MéxicoTel +52-442-1926800

MMC Hitachi Tool Engineering(Shanghai),Ltd.Room 2604-2605, Metro Plaza, 555 Loushanguan Road, Changning Disctrict, Shanghai, 200051, CHINA Tel +86-(0)21-3366-3058 Fax +86-(0)21-3366-3050

MMC Hardmetal(Thailand)Co.,Ltd. HT-DivisionCTI Tower 24 Floor, 191/32 Ratchadapisek Road, Klongtoey, Klongtoey, Bangkok 10110, Thailand Tel: +66-(0)2-661-8170 Fax: +66-(0)2-661-8175

Hitachi Metals (India) Pvt. Ltd.Plot No 94 & 95,Sector 8, IMT Manesar ,Gurgaon-122050 , Haryana, India Tel +91-124-4812315 Fax +91-124-2290015

Search Web

DISTRIBUTED BY:

Europe China

America

Mexico

Thailand

India

Attentions on Safety

1. Attentions regarding handling(1)When removing the tool from the case(package), be careful not to drop it on your foot or drop it onto the tips of your bare fingers.(2)When actually setting the inserts, be careful not to touch the cutting flute directly with your bare hands.

2. Attentions regarding mounting(1)When preparing for use, be sure that the inserts are firmly mounted in place and that they are firmly mounted on the arbor, etc.(2)If abnormal chattering occurs during use, stop the machine immediately and remove the cause of the chattering.

3. Attentions during use(1)Before use, confirm the dimensions and direction of rotation of the tool and milling work material.(2)The numerical values in the standard cutting conditions table should be used as criteria when starting new work. The cutting conditions should be adjusted as

appropriate when the cutting depth is large, the rigidity of the machine being used is low, or according to the conditions of the work material.(3)The inserts are made of a hard material. During use, they may break and fly off. In addition, cutting chips may also fly off. Since there is a danger of injury to

workers, fire, or eye damage from such flying pieces, a safety cover should be installed and safety equipment such as safety glasses should be worn to create a safe environment for work.・Do not use where there is a risk of fire or explosion.・Do not use non-water-soluble cutting oils. Such oils may result in fire.

(4)Do not use the tool for any purpose other than that for which it is intended, and do not modify it.

Multipurpose usage list of ABPF type cutter body

05

More option, more possibility More option, more possibility The insert of ARPF, GP1LB and GP1T is able to set onto ABPF type cutter body.

GP1LBGP1LB

· Joint usage4 different types of insert fits into one cutter body.

· More optionSteel & carbide shank type would be additional choice for the item which had limited in modular type.

· Cost reductionCost of the cutter body will be reduced by sharing.

· High rigid clamping systemOriginal V-shaped clamping system & special screw(patented) brings out stable performance in each different insert geometry.

Special shapedtool.Big-R shaped lens & barrel edges shorten the finishing time drastically.

GP1TGP1TSpecial shapedtool.Maximize the advantage of 5-axis milling, one tool fits in two different processes.

ABPFABPFHigh precision

ball tool.High helix geometry provides lower cutting force and longer tool life in various work materials.

ARPFARPFHigh precision

radius tool.Original edge geometries cover up from semi-finishing to precise finishing process.

Modular type

Steel shank (MT shank)

Carbide shankSteel shank

ABPF06S10 ABPF08S12 ABPF10S12 ABPF12S12 ABPF16S20 ABPF20S25 ABPF25S32 ABPF30S32 ABPF32S32 ABPF08S12L ABPF10S16L ABPF12S16L ABPF16S20L ABPF20S25L ABPF20S20L120 ABPF20S20L150 ABPF25S32L ABPF25S32L150 ABPF30S32L ABPF30S32L150 ABPF30S32L200 ABPF32S32L

68

101216202530328

101216202020252530303032

3022.225.330.650.660.670.380.290.250.250.360.665.680.6

120.6150.690.3

150.3100.2150.2200.2100.2

- - - - - 607080- - - - - 80

12015090

150100150200

-

- - - 34.5 54 65 76 87.2 - - - 64.5 69 85 125 155 96 156 107.2 157.2 207.2 -

----

2.7°2.9°3.5°0.9°

---

2.1°2.0°2.1°

--

2.6°1.5°0.7°0.5°0.3°

-

-----

2.9°3.5°1.2°

-----

2.1°--

2.6°1.5°0.7°0.5°0.3°

-

3022253050607080905050606580

12015090

150100150200100

4.3°6.4°2.9°

-2.8°2.9°3.5°1.2°

-2.5°3.9°2.2°2.1°2.1°

--

2.6°1.5°0.7°0.5°0.3°

-

4.1°5.8°2.6°

-2.6°2.7°3.3°0.9°

-2.4°3.7°2.0°1.9°2.0°

--

2.5°1.5°0.7°0.5°0.3°

-

ZDFG06…/ZPFG06… ZDFG080…/ZPFG080…ZDFG100…/ZPFG100…ZDFG120…/ZPFG120…ZDFG160…/ZPFG160…ZDFG200…/ZPFG200…ZDFG250…/ZPFG250…ZDFG300…/ZPFG300…ZDFG320…/ZPFG320…ZDFG080…/ZPFG080…ZDFG100…/ZPFG100…ZDFG120…/ZPFG120…ZDFG160…/ZPFG160…ZDFG200…/ZPFG200…ZDFG200…/ZPFG200…ZDFG200…/ZPFG200…ZDFG250…/ZPFG250…ZDFG250…/ZPFG250…ZDFG300…/ZPFG300…ZDFG300…/ZPFG300…ZDFG300…/ZPFG300…ZDFG320…/ZPFG320…

ZCFG06… ZCFG080… ZCFG100… ZCFG120… ZCFG160… ZCFG200… ZCFG250… ZCFG300… ZCFG320… ZCFG080… ZCFG100… ZCFG120… ZCFG160… ZCFG200… ZCFG200… ZCFG200… ZCFG250… ZCFG250… ZCFG300… ZCFG300… ZCFG300… ZCFG320…

-----

ZPHW200…ZPHW250…ZPHW300…

-----

ZPHW200…ZPHW200…ZPHW200…ZPHW250…ZPHW250…ZPHW300…ZPHW300…ZPHW300…

-

- - - ZDHW120… ZDHW160… ZDHW200… ZDHW250… ZDHW300… - - - ZDHW120… ZDHW160… ZDHW200… ZDHW200… ZDHW200… ZDHW250… ZDHW250… ZDHW300… ZDHW300… ZDHW300… -

AAABAAAABAAAAABBABABBB

5078758080808080808010010095100100100110100120100100120

10121212202532323212161620252020323232323232

Item codeTooldia.Dc(mm)

Underneck

lengthL1

(mm)

InsertInterferenceangle

θn

Underneck

lengthL1

(mm)

Interferenceangle

θn

Underneck

lengthL1

(mm)

Interferenceangle

θnInsert

Underneck

lengthL1

(mm)

Interferenceangle

θnInsert Insert

Bodytype

ShanklengthRs(mm)

Shankdia.DS(mm)

Reg

ular

Type

Und

er n

eck

long

ABPF(Ball) ARPF(Radius)Under neck length and interference angle of each item

GP1LB(Special shape) GP1T(Special shape)

s

φD

c

φD

s

θn

L1 R s

φD

c

φD

s

L1L1

R

θn

L1 L1 L1

ABPFA type B type ARPF GP1LB GP1T

ABPFM10ABPFM12ABPFM16ABPFM20ABPFM25ABPFM30ABPFM32

10121620253032

26.326.632.638.638.343.243.2

---

383843-

-30.536434450.2 -

26263238384343

ZDFG100…/ZPFG100… ZDFG120…/ZPFG120… ZDFG160…/ZPFG160… ZDFG200…/ZPFG200… ZDFG250…/ZPFG250… ZDFG300…/ZPFG300… ZDFG320…/ZPFG320…

ZCFG100… ZCFG120… ZCFG160… ZCFG200… ZCFG250… ZCFG300… ZCFG320…

---

ZPHW200-LB20ZPHW250-LB25ZPHW300-LB30

-

- ZDHW120-T43-R1.2-30 ZDHW160-T43-R1.5-40 ZDHW200-T43-R2-50 ZDHW250-T43-R2.5-62.5 ZDHW300-T43-R3-75 -

9.89.8

12.817.820.828.828.8

14.514.51719222323

M6M6M8M10M12M16M16

Item codeTooldia.Dc(mm)

Lf

(mm)Insert

Lf

(mm)

Lf

(mm)Insert

Lf

(mm)Insert Insert

φDb ConnectionpartL2

(mm)

MABPF(Ball) ARPF(Radius)Under neck length of each item

GP1LB(Special shape) GP1T(Special shape)

Lf Lf Lf Lf

ABPF ARPF GP1LB GP1T

φD

c

φD

b

L f

L2

M

L1 L1 L1 L1

ABPF ARPF GP1LB GP1T

φD

c

M

MT shank

L1 sR

ABPF06S06WABPF06S06WL65ABPF08S08WABPF08S08WLABPF08S08WL95ABPF08S08WLT75ABPF10S10WABPF10S10WLABPF10S10WL95ABPF10S10WL140ABPF10S12WLT75ABPF12S12WABPF12S12WLABPF12S12WL100ABPF12S12WL120ABPF12S12WL150ABPF12S16WLT85ABPF16S16W60ABPF16S16WL80ABPF16S16WL100ABPF16S16WEABPF16S16WE150ABPF16S20WLT100ABPF20S20W80ABPF20S20WL100ABPF20S20WL120ABPF20S20WEABPF20S20WE220ABPF20S25WLT115ABPF25S25W100ABPF25S25WL120ABPF25S25WL150ABPF25S25WEABPF25S32WLT135ABPF30S32W100ABPF30S32W120ABPF30S32WL150ABPF30S32WEABPF30S32WLT160ABPF32S32W120ABPF32S32WL150ABPF32S32WE220

668888

101010101012121212121216161616161620202020202025252525253030303030323232

2565

30.265.295.275.235.375.395.3

140.375.345.685.6

100.6120.6150.685.660.680.6

100.6120.6150.6100.680.6

100.6120.6150.6220.6115.6100.3120.3150.3190.3135.3100.2120.2150.2230.2160.2120.2150.2220.2

-----------------------80

100120150220115100120150190135100120150230160

---

- - - - - - - - - - - 49.5 89.5 104.5 124.5 154.5 89.5 64 84 104 124 154 104 85 105 125 155 225 120 106 126 156 196 141 107.2 127.2 157.2 237.2 167.2 - - -

----------------

1.5°-----

1.3°-----

1.4°----

1.7°0.7°0.6°0.4°0.3°0.4°

---

----------------------------

1.4°----

1.7°0.7°0.6°0.4°0.3°0.4°

---

256530659575357595

140754585

100120150856080

10012015010080

100120150220115100120150190135100120150230160120150220

-----

1.7°----

0.9°-----

1.5°-----

1.3°-----

1.4°----

1.7°0.7°0.6°0.4°0.3°0.4°

---

-----

1.6°----

0.8°-----

1.5°-----

1.2°-----

1.4°----

1.6°0.7°0.6°0.4°0.3°0.4°

---

ZDFG06…/ZPFG06… ZDFG06…/ZPFG06… ZDFG080…/ZPFG080… ZDFG080…/ZPFG080… ZDFG080…/ZPFG080… ZDFG080…/ZPFG080… ZDFG100…/ZPFG100… ZDFG100…/ZPFG100… ZDFG100…/ZPFG100… ZDFG100…/ZPFG100… ZDFG100…/ZPFG100… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG250…/ZPFG250… ZDFG250…/ZPFG250… ZDFG250…/ZPFG250… ZDFG250…/ZPFG250… ZDFG250…/ZPFG250… ZDFG300…/ZPFG300… ZDFG300…/ZPFG300… ZDFG300…/ZPFG300… ZDFG300…/ZPFG300… ZDFG300…/ZPFG300… ZDFG320…/ZPFG320… ZDFG320…/ZPFG320… ZDFG320…/ZPFG320…

ZCFG06… ZCFG06… ZCFG080… ZCFG080… ZCFG080… ZCFG080… ZCFG100… ZCFG100… ZCFG100… ZCFG100… ZCFG100… ZCFG120… ZCFG120… ZCFG120… ZCFG120… ZCFG120… ZCFG120… ZCFG160… ZCFG160… ZCFG160… ZCFG160… ZCFG160… ZCFG160… ZCFG200… ZCFG200… ZCFG200… ZCFG200… ZCFG200… ZCFG200… ZCFG250… ZCFG250… ZCFG250… ZCFG250… ZCFG250… ZCFG300… ZCFG300… ZCFG300… ZCFG300… ZCFG300… ZCFG320… ZCFG320… ZCFG320…

-----------------------

ZPHW200…ZPHW200…ZPHW200…ZPHW200…ZPHW200…ZPHW200…ZPHW250…ZPHW250…ZPHW250…ZPHW250…ZPHW250…ZPHW300…ZPHW300…ZPHW300…ZPHW300…ZPHW300…

---

-----------

ZDHW120…ZDHW120…ZDHW120…ZDHW120…ZDHW120…ZDHW120…ZDHW160…ZDHW160…ZDHW160…ZDHW160…ZDHW160…ZDHW160…ZDHW200…ZDHW200…ZDHW200…ZDHW200…ZDHW200…ZDHW200…ZDHW250…ZDHW250…ZDHW250…ZDHW250…ZDHW250…ZDHW300…ZDHW300…ZDHW300…ZDHW300…ZDHW300…

---

BBBBBABBBBABBBBBABBBBBABBBBBABBBBABBBBABBB

65557065656565656580656565

1008070657080

10080706580

1201001008080

1201001001108080

1001001208080

10080

66888

12101010101212121212121616161616162020202020202525252525323232323232323232

Item codeTooldia.Dc(mm)

Underneck

lengthL1

(mm)

InsertInterferenceangle

θn

Underneck

lengthL1

(mm)

Interferenceangle

θn

Underneck

lengthL1

(mm)

干渉角θn

Interferenceangle

InsertUnderneck

lengthL1

(mm)

Interferenceangle

θnInsert Insert

Bodytype

ShanklengthRs(mm)

Shankdia.DS(mm)

Under neck length and interference angle of each item

s

φD

c

φD

s

θn

L1 R s

φD

c

φD

s

L1L1

R

θn

L1 L1 L1

ABPFA type B type ARPF GP1LB GP1T

ABPF(Ball) ARPF(Radius) GP1LB(Special shape)GP1T(Special shape)

ABPF20MT2ABPF25MT3ABPF30MT4ABPF32MT4

20253032

65.685.3

115.2115.2

6585

115-

70 91 122.2 -

6585

115115

ZDFG200…/ZPFG200…ZDFG250…/ZPFG250…ZDFG300…/ZPFG300…ZDFG320…/ZPFG320…

ZCFG200… ZCFG250… ZCFG300… ZCFG320…

ZPHW200-LB20ZPHW250-LB25ZPHW300-LB30

-

ZDHW200-T43-R2-50ZDHW250-T43-R2.5-62.5ZDHW300-T43-R3-75 -

MT2MT3MT4MT4

64 81 102.5 102.5

M10M12M16M16

Item codeTooldia.Dc(mm)

Underneck

lengthL1

(mm)

InsertUnderneck

lengthL1

(mm)

Underneck

lengthL1

(mm)

Insert Underneck

lengthL1

(mm)

Insert Insert

MTNo.

ShanklengthRs(mm)

M

Under neck length of each itemABPF(Ball) ARPF(Radius) GP1LB(Special shape) GP1T(Special shape)

03 0402

Head figure of each insert

Head figure of each insert

Head figure of each insert

Head figure of each insert

More option, more possibility More option, more possibility The insert of ARPF, GP1LB and GP1T is able to set onto ABPF type cutter body.

GP1LBGP1LB

· Joint usage4 different types of insert fits into one cutter body.

· More optionSteel & carbide shank type would be additional choice for the item which had limited in modular type.

· Cost reductionCost of the cutter body will be reduced by sharing.

· High rigid clamping systemOriginal V-shaped clamping system & special screw(patented) brings out stable performance in each different insert geometry.

Special shapedtool.Big-R shaped lens & barrel edges shorten the finishing time drastically.

GP1TGP1TSpecial shapedtool.Maximize the advantage of 5-axis milling, one tool fits in two different processes.

ABPFABPFHigh precision

ball tool.High helix geometry provides lower cutting force and longer tool life in various work materials.

ARPFARPFHigh precision

radius tool.Original edge geometries cover up from semi-finishing to precise finishing process.

Modular type

Steel shank (MT shank)

Carbide shankSteel shank

ABPF06S10 ABPF08S12 ABPF10S12 ABPF12S12 ABPF16S20 ABPF20S25 ABPF25S32 ABPF30S32 ABPF32S32 ABPF08S12L ABPF10S16L ABPF12S16L ABPF16S20L ABPF20S25L ABPF20S20L120 ABPF20S20L150 ABPF25S32L ABPF25S32L150 ABPF30S32L ABPF30S32L150 ABPF30S32L200 ABPF32S32L

68

101216202530328

101216202020252530303032

3022.225.330.650.660.670.380.290.250.250.360.665.680.6

120.6150.690.3

150.3100.2150.2200.2100.2

- - - - - 607080- - - - - 80

12015090

150100150200

-

- - - 34.5 54 65 76 87.2 - - - 64.5 69 85 125 155 96 156 107.2 157.2 207.2 -

----

2.7°2.9°3.5°0.9°

---

2.1°2.0°2.1°

--

2.6°1.5°0.7°0.5°0.3°

-

-----

2.9°3.5°1.2°

-----

2.1°--

2.6°1.5°0.7°0.5°0.3°

-

3022253050607080905050606580

12015090

150100150200100

4.3°6.4°2.9°

-2.8°2.9°3.5°1.2°

-2.5°3.9°2.2°2.1°2.1°

--

2.6°1.5°0.7°0.5°0.3°

-

4.1°5.8°2.6°

-2.6°2.7°3.3°0.9°

-2.4°3.7°2.0°1.9°2.0°

--

2.5°1.5°0.7°0.5°0.3°

-

ZDFG06…/ZPFG06… ZDFG080…/ZPFG080…ZDFG100…/ZPFG100…ZDFG120…/ZPFG120…ZDFG160…/ZPFG160…ZDFG200…/ZPFG200…ZDFG250…/ZPFG250…ZDFG300…/ZPFG300…ZDFG320…/ZPFG320…ZDFG080…/ZPFG080…ZDFG100…/ZPFG100…ZDFG120…/ZPFG120…ZDFG160…/ZPFG160…ZDFG200…/ZPFG200…ZDFG200…/ZPFG200…ZDFG200…/ZPFG200…ZDFG250…/ZPFG250…ZDFG250…/ZPFG250…ZDFG300…/ZPFG300…ZDFG300…/ZPFG300…ZDFG300…/ZPFG300…ZDFG320…/ZPFG320…

ZCFG06… ZCFG080… ZCFG100… ZCFG120… ZCFG160… ZCFG200… ZCFG250… ZCFG300… ZCFG320… ZCFG080… ZCFG100… ZCFG120… ZCFG160… ZCFG200… ZCFG200… ZCFG200… ZCFG250… ZCFG250… ZCFG300… ZCFG300… ZCFG300… ZCFG320…

-----

ZPHW200…ZPHW250…ZPHW300…

-----

ZPHW200…ZPHW200…ZPHW200…ZPHW250…ZPHW250…ZPHW300…ZPHW300…ZPHW300…

-

- - - ZDHW120… ZDHW160… ZDHW200… ZDHW250… ZDHW300… - - - ZDHW120… ZDHW160… ZDHW200… ZDHW200… ZDHW200… ZDHW250… ZDHW250… ZDHW300… ZDHW300… ZDHW300… -

AAABAAAABAAAAABBABABBB

5078758080808080808010010095100100100110100120100100120

10121212202532323212161620252020323232323232

Item codeTooldia.Dc(mm)

Underneck

lengthL1

(mm)

InsertInterferenceangle

θn

Underneck

lengthL1

(mm)

Interferenceangle

θn

Underneck

lengthL1

(mm)

Interferenceangle

θnInsert

Underneck

lengthL1

(mm)

Interferenceangle

θnInsert Insert

Bodytype

ShanklengthRs(mm)

Shankdia.DS(mm)

Reg

ular

Type

Und

er n

eck

long

ABPF(Ball) ARPF(Radius)Under neck length and interference angle of each item

GP1LB(Special shape) GP1T(Special shape)

s

φD

c

φD

s

θn

L1 R s

φD

c

φD

s

L1L1

R

θn

L1 L1 L1

ABPFA type B type ARPF GP1LB GP1T

ABPFM10ABPFM12ABPFM16ABPFM20ABPFM25ABPFM30ABPFM32

10121620253032

26.326.632.638.638.343.243.2

---

383843-

-30.536434450.2 -

26263238384343

ZDFG100…/ZPFG100… ZDFG120…/ZPFG120… ZDFG160…/ZPFG160… ZDFG200…/ZPFG200… ZDFG250…/ZPFG250… ZDFG300…/ZPFG300… ZDFG320…/ZPFG320…

ZCFG100… ZCFG120… ZCFG160… ZCFG200… ZCFG250… ZCFG300… ZCFG320…

---

ZPHW200-LB20ZPHW250-LB25ZPHW300-LB30

-

- ZDHW120-T43-R1.2-30 ZDHW160-T43-R1.5-40 ZDHW200-T43-R2-50 ZDHW250-T43-R2.5-62.5 ZDHW300-T43-R3-75 -

9.89.8

12.817.820.828.828.8

14.514.51719222323

M6M6M8M10M12M16M16

Item codeTooldia.Dc(mm)

Lf

(mm)Insert

Lf

(mm)

Lf

(mm)Insert

Lf

(mm)Insert Insert

φDb ConnectionpartL2

(mm)

MABPF(Ball) ARPF(Radius)Under neck length of each item

GP1LB(Special shape) GP1T(Special shape)

Lf Lf Lf Lf

ABPF ARPF GP1LB GP1T

φD

c

φD

b

L f

L2

M

L1 L1 L1 L1

ABPF ARPF GP1LB GP1T

φD

c

M

MT shank

L1 sR

ABPF06S06WABPF06S06WL65ABPF08S08WABPF08S08WLABPF08S08WL95ABPF08S08WLT75ABPF10S10WABPF10S10WLABPF10S10WL95ABPF10S10WL140ABPF10S12WLT75ABPF12S12WABPF12S12WLABPF12S12WL100ABPF12S12WL120ABPF12S12WL150ABPF12S16WLT85ABPF16S16W60ABPF16S16WL80ABPF16S16WL100ABPF16S16WEABPF16S16WE150ABPF16S20WLT100ABPF20S20W80ABPF20S20WL100ABPF20S20WL120ABPF20S20WEABPF20S20WE220ABPF20S25WLT115ABPF25S25W100ABPF25S25WL120ABPF25S25WL150ABPF25S25WEABPF25S32WLT135ABPF30S32W100ABPF30S32W120ABPF30S32WL150ABPF30S32WEABPF30S32WLT160ABPF32S32W120ABPF32S32WL150ABPF32S32WE220

668888

101010101012121212121216161616161620202020202025252525253030303030323232

2565

30.265.295.275.235.375.395.3

140.375.345.685.6

100.6120.6150.685.660.680.6

100.6120.6150.6100.680.6

100.6120.6150.6220.6115.6100.3120.3150.3190.3135.3100.2120.2150.2230.2160.2120.2150.2220.2

-----------------------80

100120150220115100120150190135100120150230160

---

- - - - - - - - - - - 49.5 89.5 104.5 124.5 154.5 89.5 64 84 104 124 154 104 85 105 125 155 225 120 106 126 156 196 141 107.2 127.2 157.2 237.2 167.2 - - -

----------------

1.5°-----

1.3°-----

1.4°----

1.7°0.7°0.6°0.4°0.3°0.4°

---

----------------------------

1.4°----

1.7°0.7°0.6°0.4°0.3°0.4°

---

256530659575357595

140754585

100120150856080

10012015010080

100120150220115100120150190135100120150230160120150220

-----

1.7°----

0.9°-----

1.5°-----

1.3°-----

1.4°----

1.7°0.7°0.6°0.4°0.3°0.4°

---

-----

1.6°----

0.8°-----

1.5°-----

1.2°-----

1.4°----

1.6°0.7°0.6°0.4°0.3°0.4°

---

ZDFG06…/ZPFG06… ZDFG06…/ZPFG06… ZDFG080…/ZPFG080… ZDFG080…/ZPFG080… ZDFG080…/ZPFG080… ZDFG080…/ZPFG080… ZDFG100…/ZPFG100… ZDFG100…/ZPFG100… ZDFG100…/ZPFG100… ZDFG100…/ZPFG100… ZDFG100…/ZPFG100… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG250…/ZPFG250… ZDFG250…/ZPFG250… ZDFG250…/ZPFG250… ZDFG250…/ZPFG250… ZDFG250…/ZPFG250… ZDFG300…/ZPFG300… ZDFG300…/ZPFG300… ZDFG300…/ZPFG300… ZDFG300…/ZPFG300… ZDFG300…/ZPFG300… ZDFG320…/ZPFG320… ZDFG320…/ZPFG320… ZDFG320…/ZPFG320…

ZCFG06… ZCFG06… ZCFG080… ZCFG080… ZCFG080… ZCFG080… ZCFG100… ZCFG100… ZCFG100… ZCFG100… ZCFG100… ZCFG120… ZCFG120… ZCFG120… ZCFG120… ZCFG120… ZCFG120… ZCFG160… ZCFG160… ZCFG160… ZCFG160… ZCFG160… ZCFG160… ZCFG200… ZCFG200… ZCFG200… ZCFG200… ZCFG200… ZCFG200… ZCFG250… ZCFG250… ZCFG250… ZCFG250… ZCFG250… ZCFG300… ZCFG300… ZCFG300… ZCFG300… ZCFG300… ZCFG320… ZCFG320… ZCFG320…

-----------------------

ZPHW200…ZPHW200…ZPHW200…ZPHW200…ZPHW200…ZPHW200…ZPHW250…ZPHW250…ZPHW250…ZPHW250…ZPHW250…ZPHW300…ZPHW300…ZPHW300…ZPHW300…ZPHW300…

---

-----------

ZDHW120…ZDHW120…ZDHW120…ZDHW120…ZDHW120…ZDHW120…ZDHW160…ZDHW160…ZDHW160…ZDHW160…ZDHW160…ZDHW160…ZDHW200…ZDHW200…ZDHW200…ZDHW200…ZDHW200…ZDHW200…ZDHW250…ZDHW250…ZDHW250…ZDHW250…ZDHW250…ZDHW300…ZDHW300…ZDHW300…ZDHW300…ZDHW300…

---

BBBBBABBBBABBBBBABBBBBABBBBBABBBBABBBBABBB

65557065656565656580656565

1008070657080

10080706580

1201001008080

1201001001108080

1001001208080

10080

66888

12101010101212121212121616161616162020202020202525252525323232323232323232

Item codeTooldia.Dc(mm)

Underneck

lengthL1

(mm)

InsertInterferenceangle

θn

Underneck

lengthL1

(mm)

Interferenceangle

θn

Underneck

lengthL1

(mm)

干渉角θn

Interferenceangle

InsertUnderneck

lengthL1

(mm)

Interferenceangle

θnInsert Insert

Bodytype

ShanklengthRs(mm)

Shankdia.DS(mm)

Under neck length and interference angle of each item

s

φD

c

φD

s

θn

L1 R s

φD

c

φD

s

L1L1

R

θn

L1 L1 L1

ABPFA type B type ARPF GP1LB GP1T

ABPF(Ball) ARPF(Radius) GP1LB(Special shape)GP1T(Special shape)

ABPF20MT2ABPF25MT3ABPF30MT4ABPF32MT4

20253032

65.685.3

115.2115.2

6585

115-

70 91 122.2 -

6585

115115

ZDFG200…/ZPFG200…ZDFG250…/ZPFG250…ZDFG300…/ZPFG300…ZDFG320…/ZPFG320…

ZCFG200… ZCFG250… ZCFG300… ZCFG320…

ZPHW200-LB20ZPHW250-LB25ZPHW300-LB30

-

ZDHW200-T43-R2-50ZDHW250-T43-R2.5-62.5ZDHW300-T43-R3-75 -

MT2MT3MT4MT4

64 81 102.5 102.5

M10M12M16M16

Item codeTooldia.Dc(mm)

Underneck

lengthL1

(mm)

InsertUnderneck

lengthL1

(mm)

Underneck

lengthL1

(mm)

Insert Underneck

lengthL1

(mm)

Insert Insert

MTNo.

ShanklengthRs(mm)

M

Under neck length of each itemABPF(Ball) ARPF(Radius) GP1LB(Special shape) GP1T(Special shape)

03 0402

Head figure of each insert

Head figure of each insert

Head figure of each insert

Head figure of each insert

More option, more possibility More option, more possibility The insert of ARPF, GP1LB and GP1T is able to set onto ABPF type cutter body.

GP1LBGP1LB

· Joint usage4 different types of insert fits into one cutter body.

· More optionSteel & carbide shank type would be additional choice for the item which had limited in modular type.

· Cost reductionCost of the cutter body will be reduced by sharing.

· High rigid clamping systemOriginal V-shaped clamping system & special screw(patented) brings out stable performance in each different insert geometry.

Special shapedtool.Big-R shaped lens & barrel edges shorten the finishing time drastically.

GP1TGP1TSpecial shapedtool.Maximize the advantage of 5-axis milling, one tool fits in two different processes.

ABPFABPFHigh precision

ball tool.High helix geometry provides lower cutting force and longer tool life in various work materials.

ARPFARPFHigh precision

radius tool.Original edge geometries cover up from semi-finishing to precise finishing process.

Modular type

Steel shank (MT shank)

Carbide shankSteel shank

ABPF06S10 ABPF08S12 ABPF10S12 ABPF12S12 ABPF16S20 ABPF20S25 ABPF25S32 ABPF30S32 ABPF32S32 ABPF08S12L ABPF10S16L ABPF12S16L ABPF16S20L ABPF20S25L ABPF20S20L120 ABPF20S20L150 ABPF25S32L ABPF25S32L150 ABPF30S32L ABPF30S32L150 ABPF30S32L200 ABPF32S32L

68

101216202530328

101216202020252530303032

3022.225.330.650.660.670.380.290.250.250.360.665.680.6

120.6150.690.3

150.3100.2150.2200.2100.2

- - - - - 607080- - - - - 80

12015090

150100150200

-

- - - 34.5 54 65 76 87.2 - - - 64.5 69 85 125 155 96 156 107.2 157.2 207.2 -

----

2.7°2.9°3.5°0.9°

---

2.1°2.0°2.1°

--

2.6°1.5°0.7°0.5°0.3°

-

-----

2.9°3.5°1.2°

-----

2.1°--

2.6°1.5°0.7°0.5°0.3°

-

3022253050607080905050606580

12015090

150100150200100

4.3°6.4°2.9°

-2.8°2.9°3.5°1.2°

-2.5°3.9°2.2°2.1°2.1°

--

2.6°1.5°0.7°0.5°0.3°

-

4.1°5.8°2.6°

-2.6°2.7°3.3°0.9°

-2.4°3.7°2.0°1.9°2.0°

--

2.5°1.5°0.7°0.5°0.3°

-

ZDFG06…/ZPFG06… ZDFG080…/ZPFG080…ZDFG100…/ZPFG100…ZDFG120…/ZPFG120…ZDFG160…/ZPFG160…ZDFG200…/ZPFG200…ZDFG250…/ZPFG250…ZDFG300…/ZPFG300…ZDFG320…/ZPFG320…ZDFG080…/ZPFG080…ZDFG100…/ZPFG100…ZDFG120…/ZPFG120…ZDFG160…/ZPFG160…ZDFG200…/ZPFG200…ZDFG200…/ZPFG200…ZDFG200…/ZPFG200…ZDFG250…/ZPFG250…ZDFG250…/ZPFG250…ZDFG300…/ZPFG300…ZDFG300…/ZPFG300…ZDFG300…/ZPFG300…ZDFG320…/ZPFG320…

ZCFG06… ZCFG080… ZCFG100… ZCFG120… ZCFG160… ZCFG200… ZCFG250… ZCFG300… ZCFG320… ZCFG080… ZCFG100… ZCFG120… ZCFG160… ZCFG200… ZCFG200… ZCFG200… ZCFG250… ZCFG250… ZCFG300… ZCFG300… ZCFG300… ZCFG320…

-----

ZPHW200…ZPHW250…ZPHW300…

-----

ZPHW200…ZPHW200…ZPHW200…ZPHW250…ZPHW250…ZPHW300…ZPHW300…ZPHW300…

-

- - - ZDHW120… ZDHW160… ZDHW200… ZDHW250… ZDHW300… - - - ZDHW120… ZDHW160… ZDHW200… ZDHW200… ZDHW200… ZDHW250… ZDHW250… ZDHW300… ZDHW300… ZDHW300… -

AAABAAAABAAAAABBABABBB

5078758080808080808010010095100100100110100120100100120

10121212202532323212161620252020323232323232

Item codeTooldia.Dc(mm)

Underneck

lengthL1

(mm)

InsertInterferenceangle

θn

Underneck

lengthL1

(mm)

Interferenceangle

θn

Underneck

lengthL1

(mm)

Interferenceangle

θnInsert

Underneck

lengthL1

(mm)

Interferenceangle

θnInsert Insert

Bodytype

ShanklengthRs(mm)

Shankdia.DS(mm)

Reg

ular

Type

Und

er n

eck

long

ABPF(Ball) ARPF(Radius)Under neck length and interference angle of each item

GP1LB(Special shape) GP1T(Special shape)

s

φD

c

φD

s

θn

L1 R s

φD

c

φD

s

L1L1

R

θn

L1 L1 L1

ABPFA type B type ARPF GP1LB GP1T

ABPFM10ABPFM12ABPFM16ABPFM20ABPFM25ABPFM30ABPFM32

10121620253032

26.326.632.638.638.343.243.2

---

383843-

-30.536434450.2 -

26263238384343

ZDFG100…/ZPFG100… ZDFG120…/ZPFG120… ZDFG160…/ZPFG160… ZDFG200…/ZPFG200… ZDFG250…/ZPFG250… ZDFG300…/ZPFG300… ZDFG320…/ZPFG320…

ZCFG100… ZCFG120… ZCFG160… ZCFG200… ZCFG250… ZCFG300… ZCFG320…

---

ZPHW200-LB20ZPHW250-LB25ZPHW300-LB30

-

- ZDHW120-T43-R1.2-30 ZDHW160-T43-R1.5-40 ZDHW200-T43-R2-50 ZDHW250-T43-R2.5-62.5 ZDHW300-T43-R3-75 -

9.89.8

12.817.820.828.828.8

14.514.51719222323

M6M6M8M10M12M16M16

Item codeTooldia.Dc(mm)

Lf

(mm)Insert

Lf

(mm)

Lf

(mm)Insert

Lf

(mm)Insert Insert

φDb ConnectionpartL2

(mm)

MABPF(Ball) ARPF(Radius)Under neck length of each item

GP1LB(Special shape) GP1T(Special shape)

Lf Lf Lf Lf

ABPF ARPF GP1LB GP1T

φD

c

φD

b

L f

L2

M

L1 L1 L1 L1

ABPF ARPF GP1LB GP1T

φD

c

M

MT shank

L1 sR

ABPF06S06WABPF06S06WL65ABPF08S08WABPF08S08WLABPF08S08WL95ABPF08S08WLT75ABPF10S10WABPF10S10WLABPF10S10WL95ABPF10S10WL140ABPF10S12WLT75ABPF12S12WABPF12S12WLABPF12S12WL100ABPF12S12WL120ABPF12S12WL150ABPF12S16WLT85ABPF16S16W60ABPF16S16WL80ABPF16S16WL100ABPF16S16WEABPF16S16WE150ABPF16S20WLT100ABPF20S20W80ABPF20S20WL100ABPF20S20WL120ABPF20S20WEABPF20S20WE220ABPF20S25WLT115ABPF25S25W100ABPF25S25WL120ABPF25S25WL150ABPF25S25WEABPF25S32WLT135ABPF30S32W100ABPF30S32W120ABPF30S32WL150ABPF30S32WEABPF30S32WLT160ABPF32S32W120ABPF32S32WL150ABPF32S32WE220

668888

101010101012121212121216161616161620202020202025252525253030303030323232

2565

30.265.295.275.235.375.395.3

140.375.345.685.6

100.6120.6150.685.660.680.6

100.6120.6150.6100.680.6

100.6120.6150.6220.6115.6100.3120.3150.3190.3135.3100.2120.2150.2230.2160.2120.2150.2220.2

-----------------------80

100120150220115100120150190135100120150230160

---

- - - - - - - - - - - 49.5 89.5 104.5 124.5 154.5 89.5 64 84 104 124 154 104 85 105 125 155 225 120 106 126 156 196 141 107.2 127.2 157.2 237.2 167.2 - - -

----------------

1.5°-----

1.3°-----

1.4°----

1.7°0.7°0.6°0.4°0.3°0.4°

---

----------------------------

1.4°----

1.7°0.7°0.6°0.4°0.3°0.4°

---

256530659575357595

140754585

100120150856080

10012015010080

100120150220115100120150190135100120150230160120150220

-----

1.7°----

0.9°-----

1.5°-----

1.3°-----

1.4°----

1.7°0.7°0.6°0.4°0.3°0.4°

---

-----

1.6°----

0.8°-----

1.5°-----

1.2°-----

1.4°----

1.6°0.7°0.6°0.4°0.3°0.4°

---

ZDFG06…/ZPFG06… ZDFG06…/ZPFG06… ZDFG080…/ZPFG080… ZDFG080…/ZPFG080… ZDFG080…/ZPFG080… ZDFG080…/ZPFG080… ZDFG100…/ZPFG100… ZDFG100…/ZPFG100… ZDFG100…/ZPFG100… ZDFG100…/ZPFG100… ZDFG100…/ZPFG100… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG120…/ZPFG120… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG160…/ZPFG160… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG200…/ZPFG200… ZDFG250…/ZPFG250… ZDFG250…/ZPFG250… ZDFG250…/ZPFG250… ZDFG250…/ZPFG250… ZDFG250…/ZPFG250… ZDFG300…/ZPFG300… ZDFG300…/ZPFG300… ZDFG300…/ZPFG300… ZDFG300…/ZPFG300… ZDFG300…/ZPFG300… ZDFG320…/ZPFG320… ZDFG320…/ZPFG320… ZDFG320…/ZPFG320…

ZCFG06… ZCFG06… ZCFG080… ZCFG080… ZCFG080… ZCFG080… ZCFG100… ZCFG100… ZCFG100… ZCFG100… ZCFG100… ZCFG120… ZCFG120… ZCFG120… ZCFG120… ZCFG120… ZCFG120… ZCFG160… ZCFG160… ZCFG160… ZCFG160… ZCFG160… ZCFG160… ZCFG200… ZCFG200… ZCFG200… ZCFG200… ZCFG200… ZCFG200… ZCFG250… ZCFG250… ZCFG250… ZCFG250… ZCFG250… ZCFG300… ZCFG300… ZCFG300… ZCFG300… ZCFG300… ZCFG320… ZCFG320… ZCFG320…

-----------------------

ZPHW200…ZPHW200…ZPHW200…ZPHW200…ZPHW200…ZPHW200…ZPHW250…ZPHW250…ZPHW250…ZPHW250…ZPHW250…ZPHW300…ZPHW300…ZPHW300…ZPHW300…ZPHW300…

---

-----------

ZDHW120…ZDHW120…ZDHW120…ZDHW120…ZDHW120…ZDHW120…ZDHW160…ZDHW160…ZDHW160…ZDHW160…ZDHW160…ZDHW160…ZDHW200…ZDHW200…ZDHW200…ZDHW200…ZDHW200…ZDHW200…ZDHW250…ZDHW250…ZDHW250…ZDHW250…ZDHW250…ZDHW300…ZDHW300…ZDHW300…ZDHW300…ZDHW300…

---

BBBBBABBBBABBBBBABBBBBABBBBBABBBBABBBBABBB

65557065656565656580656565

1008070657080

10080706580

1201001008080

1201001001108080

1001001208080

10080

66888

12101010101212121212121616161616162020202020202525252525323232323232323232

Item codeTooldia.Dc(mm)

Underneck

lengthL1

(mm)

InsertInterferenceangle

θn

Underneck

lengthL1

(mm)

Interferenceangle

θn

Underneck

lengthL1

(mm)

干渉角θn

Interferenceangle

InsertUnderneck

lengthL1

(mm)

Interferenceangle

θnInsert Insert

Bodytype

ShanklengthRs(mm)

Shankdia.DS(mm)

Under neck length and interference angle of each item

s

φD

c

φD

s

θn

L1 R s

φD

c

φD

s

L1L1

R

θn

L1 L1 L1

ABPFA type B type ARPF GP1LB GP1T

ABPF(Ball) ARPF(Radius) GP1LB(Special shape)GP1T(Special shape)

ABPF20MT2ABPF25MT3ABPF30MT4ABPF32MT4

20253032

65.685.3

115.2115.2

6585

115-

70 91 122.2 -

6585

115115

ZDFG200…/ZPFG200…ZDFG250…/ZPFG250…ZDFG300…/ZPFG300…ZDFG320…/ZPFG320…

ZCFG200… ZCFG250… ZCFG300… ZCFG320…

ZPHW200-LB20ZPHW250-LB25ZPHW300-LB30

-

ZDHW200-T43-R2-50ZDHW250-T43-R2.5-62.5ZDHW300-T43-R3-75 -

MT2MT3MT4MT4

64 81 102.5 102.5

M10M12M16M16

Item codeTooldia.Dc(mm)

Underneck

lengthL1

(mm)

InsertUnderneck

lengthL1

(mm)

Underneck

lengthL1

(mm)

Insert Underneck

lengthL1

(mm)

Insert Insert

MTNo.

ShanklengthRs(mm)

M

Under neck length of each itemABPF(Ball) ARPF(Radius) GP1LB(Special shape) GP1T(Special shape)

03 0402

Head figure of each insert

Head figure of each insert

Head figure of each insert

Head figure of each insert

New Produc t News No.1708E-1 2019-4

Clamp screw Parts Screw driver / Wrench Screw anti-seizure agent

581-140581-141581-142581-143

581-144

581-145

581-146

581-147

581-147

0.51.12.24.9

4.9

6.9

9.8

9.8

9.8

104-T6104-T8104-T10

105-T20

101-T25S

105-T30A

AAA

B

B

B

P-37

Cutter Body

Shape

A B

Fasteningtorque(N・m)

ABPF06S (W/WL )ABPF08S (L/W/WL/WL /WLT )ABPF10S (L/W/WL/WL /WLT )ABPFM10ABPF12S (L/W/WL/WL /WLT )ABPFM12ABPF16S (L/W /WL /WE/WE /WLT )ABPFU16W220 ABPFM16ABPF20S (L/W /WL /WE/WE /WLT )ABPF20MT2 ABPFU20W270 ABPFM20ABPF25S (L/W /WL /WE/WE /WLT )ABPF25MT3 ABPFU25W300 ABPFM25ABPF30S (L/W /WL /WE/WE /WLT )ABPF30MT4 ABPFU30W300 ABPFM30ABPF32S (L/W /WL /WE )ABPF32MT4 ABPFM32

Shape

2019-4(K)2017-4:FP

Clean the insert seat:Using air-blow or alike, clean the seat.1

Put in the insert with its top positioned to the screw-tightening side of the tool body.2

This is the end of insert set-up.4

Clamp screw (high precision screw)

Tool body

Top mark

Tighten the clamp screw with the special wrench.Please do not press down the insert during this tightening process.

3

In order to satisfy runout of 0.02mm or less, follow the procedure at left.

Note Cutting conditions and suggested retail price are referred in product catalogue or product newsABPF:No.0902 ARPF:No.0901 GP1LB:No.1711 GP1T:No.1711

L1 L1 L1 L1

ABPF ARPF GP1LB GP1T

Head figure of each insert

ABPFU16W220ABPFU20W270ABPFU25W300ABPFU30W300

16202530

39.651.661.373.2

-516173

43566770.2

39516173

ZDFG160…/ZPFG160… ZDFG200…/ZPFG200… ZDFG250…/ZPFG250… ZDFG300…/ZPFG300…

ZCFG160… ZCFG200… ZCFG250… ZCFG300…

-ZPHW200-LB20ZPHW250-LB25ZPHW300-LB30

ZDHW160-T43-R1.5-40 ZDHW200-T43-R2-50 ZDHW250-T43-R2.5-62.5 ZDHW300-T43-R3-75

15192429

181219239227

15182328

Item codeTooldia.Dc(mm)

Underneck

lengthL1

(mm)

InsertUnderneck

lengthL1

(mm)

Underneck

lengthL1

(mm)

InsertUnderneck

lengthL1

(mm)

Insert Insert

φD2

(mm)

ShanklengthRs(mm)

Shankdia.DS(mm)

Under neck length of each item

s

φD

c

L1 R

ABPF(Ball) ARPF(Radius) GP1LB(Special shape) GP1T(Special shape)

3

φD

s

φD

2

Carbide shank (Under neck type)

Parts

Set-up Procedures of Inserts

The diagrams and table data are examples of test results, and are not guaranteed values.“ ” is registered trademarks of Mitsubishi Hitachi Tool Engineering, Ltd. in Japan.

Specifications for the products listed in this catalog are subject to change without notice due to replacement or modification. Printed in JAPAN

Printed using vegetable oil ink.

Official Web Site

Database for selection Cutting Tool Products 【TOOL SEARCH】

http://www.mmc-hitachitool.co.jp/e/Head OfficeHulic Ryogoku Bldg. 8F, 4-31-11, Ryogoku, Sumida-ku, Tokyo, 130-0026 JapanInternational Sales Dept. : TEL +81-3-6890-5103 FAX +81-3-6890-5128

MMC Hitachi Tool Engineering Europe GmbHItterpark 12, 40724 Hilden,Germany. Tel +49-(0)2103-24820 Fax +49-(0)2103-248230

MITSUBISHI MATERIALS U.S.A. CORPORATIONDETROIT OFFICE Customer service41700 Gardenbrook Road, Suite 120, Novi, MI 48375-1320 U.S.A.Tel +1(248) 308-2620 Fax +1(248) 308-2627CHICAGO OFFICE1314B North Plum Grove Road, Schaumburg, IL 60173 U.S.A. Tel +1(847) 252-6371 Fax +1(248) 308-2627

MMC METAL DE MEXICO, S.A. DE C.V.IAv. La Cañada No.16, Parque Industrial Bernardo Quintana, El Marques,Querétaro, CP 76246, MéxicoTel +52-442-1926800

MMC Hitachi Tool Engineering(Shanghai),Ltd.Room 2604-2605, Metro Plaza, 555 Loushanguan Road, Changning Disctrict, Shanghai, 200051, CHINA Tel +86-(0)21-3366-3058 Fax +86-(0)21-3366-3050

MMC Hardmetal(Thailand)Co.,Ltd. HT-DivisionCTI Tower 24 Floor, 191/32 Ratchadapisek Road, Klongtoey, Klongtoey, Bangkok 10110, Thailand Tel: +66-(0)2-661-8170 Fax: +66-(0)2-661-8175

Hitachi Metals (India) Pvt. Ltd.Plot No 94 & 95,Sector 8, IMT Manesar ,Gurgaon-122050 , Haryana, India Tel +91-124-4812315 Fax +91-124-2290015

Search Web

DISTRIBUTED BY:

Europe China

America

Mexico

Thailand

India

Attentions on Safety

1. Attentions regarding handling(1)When removing the tool from the case(package), be careful not to drop it on your foot or drop it onto the tips of your bare fingers.(2)When actually setting the inserts, be careful not to touch the cutting flute directly with your bare hands.

2. Attentions regarding mounting(1)When preparing for use, be sure that the inserts are firmly mounted in place and that they are firmly mounted on the arbor, etc.(2)If abnormal chattering occurs during use, stop the machine immediately and remove the cause of the chattering.

3. Attentions during use(1)Before use, confirm the dimensions and direction of rotation of the tool and milling work material.(2)The numerical values in the standard cutting conditions table should be used as criteria when starting new work. The cutting conditions should be adjusted as

appropriate when the cutting depth is large, the rigidity of the machine being used is low, or according to the conditions of the work material.(3)The inserts are made of a hard material. During use, they may break and fly off. In addition, cutting chips may also fly off. Since there is a danger of injury to

workers, fire, or eye damage from such flying pieces, a safety cover should be installed and safety equipment such as safety glasses should be worn to create a safe environment for work.・Do not use where there is a risk of fire or explosion.・Do not use non-water-soluble cutting oils. Such oils may result in fire.

(4)Do not use the tool for any purpose other than that for which it is intended, and do not modify it.

Multipurpose usage list of ABPF type cutter body

05

New Produc t News No.1708E-1 2019-4

Clamp screw Parts Screw driver / Wrench Screw anti-seizure agent

581-140581-141581-142581-143

581-144

581-145

581-146

581-147

581-147

0.51.12.24.9

4.9

6.9

9.8

9.8

9.8

104-T6104-T8104-T10

105-T20

101-T25S

105-T30A

AAA

B

B

B

P-37

Cutter Body

Shape

A B

Fasteningtorque(N・m)

ABPF06S (W/WL )ABPF08S (L/W/WL/WL /WLT )ABPF10S (L/W/WL/WL /WLT )ABPFM10ABPF12S (L/W/WL/WL /WLT )ABPFM12ABPF16S (L/W /WL /WE/WE /WLT )ABPFU16W220 ABPFM16ABPF20S (L/W /WL /WE/WE /WLT )ABPF20MT2 ABPFU20W270 ABPFM20ABPF25S (L/W /WL /WE/WE /WLT )ABPF25MT3 ABPFU25W300 ABPFM25ABPF30S (L/W /WL /WE/WE /WLT )ABPF30MT4 ABPFU30W300 ABPFM30ABPF32S (L/W /WL /WE )ABPF32MT4 ABPFM32

Shape

2019-4(K)2017-4:FP

Clean the insert seat:Using air-blow or alike, clean the seat.1

Put in the insert with its top positioned to the screw-tightening side of the tool body.2

This is the end of insert set-up.4

Clamp screw (high precision screw)

Tool body

Top mark

Tighten the clamp screw with the special wrench.Please do not press down the insert during this tightening process.

3

In order to satisfy runout of 0.02mm or less, follow the procedure at left.

Note Cutting conditions and suggested retail price are referred in product catalogue or product newsABPF:No.0902 ARPF:No.0901 GP1LB:No.1711 GP1T:No.1711

L1 L1 L1 L1

ABPF ARPF GP1LB GP1T

Head figure of each insert

ABPFU16W220ABPFU20W270ABPFU25W300ABPFU30W300

16202530

39.651.661.373.2

-516173

43566770.2

39516173

ZDFG160…/ZPFG160… ZDFG200…/ZPFG200… ZDFG250…/ZPFG250… ZDFG300…/ZPFG300…

ZCFG160… ZCFG200… ZCFG250… ZCFG300…

-ZPHW200-LB20ZPHW250-LB25ZPHW300-LB30

ZDHW160-T43-R1.5-40 ZDHW200-T43-R2-50 ZDHW250-T43-R2.5-62.5 ZDHW300-T43-R3-75

15192429

181219239227

15182328

Item codeTooldia.Dc(mm)

Underneck

lengthL1

(mm)

InsertUnderneck

lengthL1

(mm)

Underneck

lengthL1

(mm)

InsertUnderneck

lengthL1

(mm)

Insert Insert

φD2

(mm)

ShanklengthRs(mm)

Shankdia.DS(mm)

Under neck length of each item

s

φD

c

L1 R

ABPF(Ball) ARPF(Radius) GP1LB(Special shape) GP1T(Special shape)

3

φD

s

φD

2

Carbide shank (Under neck type)

Parts

Set-up Procedures of Inserts

The diagrams and table data are examples of test results, and are not guaranteed values.“ ” is registered trademarks of Mitsubishi Hitachi Tool Engineering, Ltd. in Japan.

Specifications for the products listed in this catalog are subject to change without notice due to replacement or modification. Printed in JAPAN

Printed using vegetable oil ink.

Official Web Site

Database for selection Cutting Tool Products 【TOOL SEARCH】

http://www.mmc-hitachitool.co.jp/e/Head OfficeHulic Ryogoku Bldg. 8F, 4-31-11, Ryogoku, Sumida-ku, Tokyo, 130-0026 JapanInternational Sales Dept. : TEL +81-3-6890-5103 FAX +81-3-6890-5128

MMC Hitachi Tool Engineering Europe GmbHItterpark 12, 40724 Hilden,Germany. Tel +49-(0)2103-24820 Fax +49-(0)2103-248230

MITSUBISHI MATERIALS U.S.A. CORPORATIONDETROIT OFFICE Customer service41700 Gardenbrook Road, Suite 120, Novi, MI 48375-1320 U.S.A.Tel +1(248) 308-2620 Fax +1(248) 308-2627CHICAGO OFFICE1314B North Plum Grove Road, Schaumburg, IL 60173 U.S.A. Tel +1(847) 252-6371 Fax +1(248) 308-2627

MMC METAL DE MEXICO, S.A. DE C.V.IAv. La Cañada No.16, Parque Industrial Bernardo Quintana, El Marques,Querétaro, CP 76246, MéxicoTel +52-442-1926800

MMC Hitachi Tool Engineering(Shanghai),Ltd.Room 2604-2605, Metro Plaza, 555 Loushanguan Road, Changning Disctrict, Shanghai, 200051, CHINA Tel +86-(0)21-3366-3058 Fax +86-(0)21-3366-3050

MMC Hardmetal(Thailand)Co.,Ltd. HT-DivisionCTI Tower 24 Floor, 191/32 Ratchadapisek Road, Klongtoey, Klongtoey, Bangkok 10110, Thailand Tel: +66-(0)2-661-8170 Fax: +66-(0)2-661-8175

Hitachi Metals (India) Pvt. Ltd.Plot No 94 & 95,Sector 8, IMT Manesar ,Gurgaon-122050 , Haryana, India Tel +91-124-4812315 Fax +91-124-2290015

Search Web

DISTRIBUTED BY:

Europe China

America

Mexico

Thailand

India

Attentions on Safety

1. Attentions regarding handling(1)When removing the tool from the case(package), be careful not to drop it on your foot or drop it onto the tips of your bare fingers.(2)When actually setting the inserts, be careful not to touch the cutting flute directly with your bare hands.

2. Attentions regarding mounting(1)When preparing for use, be sure that the inserts are firmly mounted in place and that they are firmly mounted on the arbor, etc.(2)If abnormal chattering occurs during use, stop the machine immediately and remove the cause of the chattering.

3. Attentions during use(1)Before use, confirm the dimensions and direction of rotation of the tool and milling work material.(2)The numerical values in the standard cutting conditions table should be used as criteria when starting new work. The cutting conditions should be adjusted as

appropriate when the cutting depth is large, the rigidity of the machine being used is low, or according to the conditions of the work material.(3)The inserts are made of a hard material. During use, they may break and fly off. In addition, cutting chips may also fly off. Since there is a danger of injury to

workers, fire, or eye damage from such flying pieces, a safety cover should be installed and safety equipment such as safety glasses should be worn to create a safe environment for work.・Do not use where there is a risk of fire or explosion.・Do not use non-water-soluble cutting oils. Such oils may result in fire.

(4)Do not use the tool for any purpose other than that for which it is intended, and do not modify it.

Multipurpose usage list of ABPF type cutter body

05