MULTIMETER AN/USM-223 - Liberated Manuals.com · TM 11-6625-654-14 CHAPTER 1 INTRODUCTION Section...

Transcript of MULTIMETER AN/USM-223 - Liberated Manuals.com · TM 11-6625-654-14 CHAPTER 1 INTRODUCTION Section...

TECHNICAL MANUAL

OPERATOR’S, ORGANIZATIONAL, DIRECT SUPPORT,

AND GENERAL SUPPORT MAINTENANCE

REPAIR PARTS AND SPECIAL TOOLS LIST

(INCLUDING DEPOT MAINTENANCE REPAIR PARTS

AND SPECIAL TOOLS LIST)

AN/USM-223

HEADQUARTERS, DEPARTMENT OF THE ARMY

13 SEPTEMBER 1974

TM 11-6625-654-14

FOR

MULTIMETER

WARNINGPrior to connecting test leads and making voltage measurements, turn off power inthe equipment which measurements are being made and discharge any capacitors.Death on contact may result if safety precautions are not observed.

DO NOT TAKE CHANCES!

TM 11-6625-654-14

TECHNICAL MANUAL

No. 11-6625-654-14

CHAPTERSection

CHAPTERSection

CHAPTER

CHAPTERSection

1.I.

II.

2.I.

II.

III.

3.

4. I.

II.

H E A D Q U A R T E R SDEPARTMENT OF THE ARMY

WASHINGTON, D. C., 13 September 1974

Operator's, Organizational, Direct Support,

and General Support Maintenance Repair Parts

and Special Tools Lists

(Including Depot Maintenance Repair Parts

and Special Tools Lists)

for

M U L T I M E T E R A N / U S M - 2 2 3

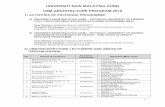

Paragraph Page IllustINTRODUCTIONGeneralScope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1Indexes of publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2Forms and records . . . . . . . . . . . ....................1-3Description and dataPurpose and use .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5Items comprising an operable equipment . . . . . . . . . . . . . . . . . . . . . 1-6Additional equipment required ..... . . . . . . . . . . . . . . . . . . . . . . . 1-7

OPERATING INSTRUCTIONSService upon receipt and installationUnpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1Checking unpackaged equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2Battery installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3Controls and indicatorsDamage from improper settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4Operator’s controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5OperationInitial adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6Operating procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

OPERATOR AND ORGANIZATIONAL MAINTENANCE INSTRUCTIONSTools and equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1Repainting and refinishing instructions . . . . . . . . . . . . . . . . 3-2Lubrication instructions .. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3Preventive maintenance checks and services . . . . . . . . . . . . . . 3-4Preventive maintenance checks and services periods . . . . . . . 3-5Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

FUNCTIONING OF MULTIMETERGeneralFunctional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1Special features .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2Circuit analysisGeneral . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3Dc voltmeter circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4Ac voltmeter circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5Direct current circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6Ohmmeter circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

1-11-11-1

1-11-11-21-2

2-12-32-3

2-42-4

2-52-5

3-13-13-13-13-13-3

4-14-1

4-14-24-34-44-4

fig

i

TM 11-6625-654-14Paragraph Page

CHAPTER 5.Section I.

II.

APPENDIX A.

B.Section I.

II.

APPENDIX C.

Section I.II.

III.IV.

V.

VI.

GENERAL SUPPORT MAINTENANCE INSTRUCTIONSGeneralMaintenance procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Tools and equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .General support testing proceduresGeneral... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... . . . . . . . . . . . . . . . . .Modification work orders.. . . . . . . . . . . . . . . . . . . . . . . . . . . . .Physical tests and inspection . . . . . . . . . . . . . . . . . . . . . . . . . .Ohmmeter function test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dc ammeter function test . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ac voltmeter test . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Dc voltmeter test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE ALLOCATION

Maintenance Allocation chart . . . . . . . . . . . . . . . . . . . . . . . . .

ORGANIZATIONAL, DIRECT SUPPORT, AND GENERAL SUPPORT MAIN-TENANCE REPAIR PARTS AND SPECIAL TOOLS List (INCLUDING DEPOTMAINTENANCE REPAIR PARTS AND SPECIAL TOOLS). . . . . . . . . . .

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...Organizational Repair Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . .Organizational Special Tools List (Not applicable)Repair Parts List–Direct Support, General Support, and

Depot Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....Multimeter AN/USM-223. . . . . . . . . . . . . . . . . . . . . . . . . ............Final panel assembly (less case and cover assemblies) . . . . . . . . . . . . . . . . . . . . .Printed circuit board assembly, A1 . . . . . . . . . . . . . . . . . . . . . . . . . Printed circuit board assembly, A2 . . . . . . . . . . . . . . . . . . . . . . . . . . Case assembly . . . . . . . . . . . . . . . . . . . . . . . .........Cover assembly . . . . . . . . . . . . . . . . . . .Test Adapter Assembly MX-1572/U . . . . . . . . . . . . . . . . . . . . . . .Test Lead Set CX-1331/U. . . . . . . . . . . . . . . . . . . . . . . .Test Lead Assembly CX-927/U. . . . . . . . . . . . . . . . . . .Main wiring harness . . . . . . . . . . . . . . . . . . . . . . .Fuseholder assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Direct Support, General Support, and Depot Maintenance Special

Tools List (Not applicable).Index-Federal Stock Number and Reference Number to Figure and

Item Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-15-25-3

5-45-55-65-75-85-9

5-10

C-1C-1C-5

C-6C-6C-6C-7C-7C-15C-16C-6C-6C-6C-9C-8

C-32

5-15-15-1

5-45-45-45-55-65-9

5-10

B-1B-3

C-1C-2C-3C-3C-6C-7C-1C-9C-l0C-11C-12

A-1

i i

Illustf i g

Packaging diagram

TM 11-6625-654-14

L I S T O F I L L U S T R A T I O N S

Number Title

1-12-12-22-34-14-24-34-44-54-65-l5-25-35-45-55-6C-1C-2C-3C-4C-5C-6C-7C-8C-9C-l0C-11C-12

Multimeter AN/USM-223 . . . . . . . . . . . . . . . . . . . . . . . .

View of battery compartment . . . . . . . . . . . . . . . . . . . . . . . . .Panel controls and jacks .. . . . . . . . . . . . . . . . . . . . . . . . .Block diagram of multimeter . . . . . . . . . . . . . . . . . . . . . . . .

Simplified 1K Ω /Vdc circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Simplified ac voltmeter circuit . . . . . . . . . . . . . . . . . . . . .Simplified direct current circuit . . . . . . . . . . . . . . . . . . . . .Simplified ohmmeter circuit . . . . . . . . . . . . . . . . . . . . . . . .Printed circuit board #1 . . . . . . . . . . . . . . . . . . . . . . . . . . .Printed circuit board #2 . . . . . . . . . . . . . . . . . . . . . . . . . . .Ohmmeter function performance test connection . . . . . . . . . . . .Dc ammeter performance test connection . . . . . . . . . . . . . . . . .Multimeter AN/USM-223, exploded view . . . . . . . . . . . . . . . . . . . .Multimeter AN/USM-223, schematic diagram . . . . . . . . . . . . . . . . .Multimeter AN/USM-223 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Final panel assembly (less case and cover assemblies) . . . . . . . . .Final panel assembly .. . . . . . . . . . . . . . . . . . . . . . . . . . . . .Printed circuit board assembly, A1 . . . . . . . . . . . . . . . . . .Printed circuit board assembly, A2 .. . . . . . . . . . . . . . . . .Case assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Cover assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Test adapter assembly MX-1572/U . . . . . . . . . . . . . . . . .Test lead set CX-133/U . . . . . . . . . . . . . . . . . . . . . . . . . . .Test lead assembly CX-927/U . . . . . . . . . . . . . . . . . . . . . . . . .Main wiring harness . . . . . . . . . . . . . . . . . . . . . . . . . . .Fuseholder assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . ..

Page

1-02-22-32-54-14-24-34-44-44-55-25-35-65-8

5-125-12C-20C-21C-22C-23C-24C-25C-25C-26C-26C-27C-27C-28

Simplified 20K Ω /Vdc circuit . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

TM 11-6625-654-14

CHAPTER 1

INTRODUCTION

Section I.

1-1. Scopea. This manual describes Multimeter

AN/USM-223 and covers its operation; operator,organizational, direct and general supportmaintenance instructions; and functioning.

b. A list of applicable publications andreferences appears in appendix A.

c. The maintenance allocation chart appears inappendix B and the special tools list appears inappendix C.

d. Appendixes B and C are current as of 27April 1974.

1-2. Indexes of Publications.a. DA Pam 310-4. Refer to the latest issue of

DA Pam 310-4 to determine whether there arenew editions, changes, or additional publicationspertaining to the equipment.

b. DA Pam 310-7. Refer to DA Pam 310-7 todetermine whether there are modification workorders (MWO’S) pertaining to the equipment.

1-3. Forms and Recordsa. Reports of Maintenance and Unsatisfactory

Equipment. Maintenance forms, records, andreports which are to be used by maintenance

GENERAL

personnel at all maintenance levels are listed inand prescribed by TM 38-750.

b. Report of Packaging and HandlingDeficiencies. Fill out and forward DD Form 6(Report of Packaging and Handling Deficiencies)as prescribed in AR 700-58/NAVSUP PUB378/AFR 71-4/MCO P4030.29, and DSAR 4145.8.

c. Discrepancy in Shipment Report (DISREP)(SF 361). Fill out and forward Discrepancy inShipment Report (DISREP) (SF 361) asprescribed in AR 55-38/NAVSUPINST4610.33/AFM 75-18/MCO P4610.19A, andDSAR 4500.15.

d. Reporting of Errors. The reporting oferrors, omissions, and recommendations forimproving this publication by the individual useris encouraged. Reports should be submitted onDA Form 2028 (Recommended Changes toPublications and Blank Forms) and forwardeddirect to Commander, US Army ElectronicsCommand, ATTN: AMSEL-MA-C, Fort Mon-mouth, NJ 07703.

e. Administrative Storage. For procedures,forms and records, and inspections requiredduring administrative storage of this equipment,refer to TM 740-90-1.

Section II. DESCRIPTION AND DATA

1-4. Purpose and Usea. Purpose. Multimeter AN/USM-223 is a

portable, general purpose test instrumentdesigned to measure ac and dc voltages, directcurrent, and resistance.

b. Use. Multimeter AN/USM-223 is used tomeasure ac and dc voltages to 5000V, directcurrents to 10A, and resistances to 10 megohms.It has a low output voltage on the ohms ranges toallow safe measurement of components in solidstate circuitry.

1-5. Technical Characteristicsa. Description. Multimeter AN/USM-223 is a

battery-powered, general purpose multimeter,designed to safely test the passive components ofsolid state circuitry. Conventional circuitry isused, consisting of multipliers, shunts, andrectifiers. Range and function switches provide 15dc voltage ranges, 7 ac voltage ranges, 8 directcurrent ranges, and 5 resistance ranges withoutthe need for special external accessories orshunts.

1-1

TM 11-6625-654-14

Length Width DepthMultimeter ME-297/U, SM-D551651 (80063) 1 8¼ 6¼ 5³/8 5¾Test Lead Assembly, CX-927/U, SM-C-469502 (80063) 1 48 ¼Test Lead Set CX-1331/U, SC-C-6878 (80063) 1 63½Adapter Assembly MX-1572/U, SM-C-68255 (86003) 1 4

1-7. Additional Equipment Required battery compartment. For battery installation

Six batteries (BA1312) and one battery (BA42 or instructions, refer to paragraph 2-3.BA2042) are required, but not furnished, to N O T Esupply power to Multimeter AN/USM -223. The Dry batteries are supplied in accordance

operator is required to install the batteries in the with SB 11-6.

N O T EAll resistance range accuracies are inpercent of full scale value, the indicationbeing referred to meter arc length ratherthan to ohms indication.

c. Input Impedance. 1000 and 20,000 Ω /V onDC Voltage Ranges, 1000 Ω /V on AC VoltageRanges.

d. Operating Power Requirements. InternalBatteries.

e. Overload Protection. All ranges protectedto 125V AC/DC and two times full scale value,except for the 10A and 5000V ranges.

f. Frequency Response. Accurancy of the acvoltage measurements, with respect to frequency,are ± 4 %, 25 Hz to 10 kHz; and ± 7 % at 20 kHz;at an ambient temperature of + 77ºF.

N O T EThe multimeter cannot be used to verifyforward and reverse conductance ofsemiconductors because its low outputvoltage is below semiconductorthresholds.

b. Tabulated Data.

1-6. Items Comprising an Operable Equipment

FSN Item Qty Dimensions (in.) Weight (lb)

1 - 2

1/81/8

TM 11-6625-654-14

CHAPTER 2

O P E R A T I N G I N S T R U C T I O N S

Section I. SERVICE UPON RECEIPT AND INSTALLATION

2-1. Unpacking. (b) Slit the top seam of the water-(fig. 2-1) resistant, inner corrugated carton, and open it.

a. Packaging Data. The approximate di- (c) Remove the technical manuals.

mensions, weight, and volume of a multimeter (d) Remove the multimeter set from theset, packed and unpacked, follow: package.

Dimensions (in. ) WeightHeight Width Depth (cu ft.) (lb) (2) Export packaging.

(a) Cut and fold back the metal straps.Unpacked 6 7 3/8 8 ¾ ¼ 5¾ (b) With a nailpuller, remove the nailsPacked 8½ 10-5/16 10-5/8 ½ 6½ from the wooden cover of the wooden packing

case. Do not attempt to pry off the wooden cover;b. Unpacking. the equipment may become damaged.

(1) Domestic packaging. (c) Open the moisture-proof barrier and(a) Slit the seam along the cover of the expose the outer corrugated carton.

outer corrugated carton. Fold back the coverflaps, and open the moisture-vaporproof barrier.

(d) Proceed as described in (1) above.

2-1

Volume

TM 11-6625-654-14

2-2. Checking Unpackaged Equipmenta. Damage Inspection. Inspect the equipment

for damage incurred during shipment. If theequipment has been damaged, report the damageon DD Form 6 (Report of Packaging and Han-dling Deficiencies).

b. Equipment Versus Packing Slip. Make surethat the equipment is complete as listed on thepacking slip. If a packing slip is not available,check the equipment against the Basic IssueItems List (app C). Report all discrepancies inaccordance with TM 38-750. Shortage of a minorassembly or part that does not affect the properfunctioning of the equipment should not preventuse of the equipment.

c. Modified Equipment. If the equipment hasbeen used or reconditioned, examine to see if ithas been changed by a modification work order(MWO). If the equipment has been modified, theMWO number will appear on the front panel nearthe nomenclature plate. If modified, see that anyoperational instruction changes resulting from

the modification have been entered in theequipment manual. Current MWO’S applicable tothe equipment are listed in DA Pam 310-7.

2-3. Battery Installation(fig. 2.2)

Prior. to operation of the multimeter, install thedry cell batteries according to the procedurebelow.

a. Using a screwdriver, remove the two screwswhich retain the battery cover.

b. Install three BA1312 Batteries in each of theoutside clots of the battery compartment.

c. Install a BA42 Battery in the center slot ofthe battery compartment. Use a BA2042 Batteryif the equipment is to be used in ambient tem-perature below 0ºF.

CAUTIONMake certain that correct polarity isobserved when installing the batteries.

d. Replace battery cover, and secure with thetwo screws.

Figure 2-2. View of battery compartment.2-3

TM 11-6625-654-14

Range switch (seven position rotary) Selects the full-scale value of the quantity being measured:

Table 2-1. Operator’s Controls and Function

Control, switch,or jack Function

Function switch (six position rotary) Selects the type of measurement to be made:OFF

AC VOLTSDC MAO H M S

Section II. CONTROLS AND INDICATORS

2-4. Damage From Improper Settingsa. Before making a measurement, be sure that

the function switch is set to the proper position;DC VOLTS, AC VOLTS, DC MA, or OHMS; andthat the range switch is set to the highest range.

b. Before making resistance measurement,

make sure the power on the equipment under test

is turned off. After making resistance mea-surements, switch the function switch tosome other position; preferably OFF.

2-5. Operator’s Controls(fig. 2-3)

Table 2-1 lists the operator’s controls and theirfunction.

OHMS ZERO control . . . . . . . . . .

OHMS INF control . . . . . . . . . . .

COM jack

10A jack . . . . . . . . . . .

Meter . . . . . . . . .

OHMS - X1 to X10,000(25 to 250,000 ohmscenter scale)

Adjusts zero scale setting of the meter pointer when test leads are shorted onOHMS function

Adjusts full scale setting of the meter pointer when test leads are separated onOHMS function.

Connects positive input to function switch.

Connects negative input to multimeter circuits.

Connects positive 5000 vdc input to multiplier resistors.

Connects positive 1000 vdc input to the multiplier resistors.

Connects 1000 vac or positive DC input to the multiplier resistors.Connects 5000 vac or positive DC input to the multiplier resistors.Connects positive 10A DC input to the current shunt.

Indicates the amount of voltage, current or resistance being measured.amount depends on range switch setting.

2-4

DC VOLTS 20K Ω /VDC VOLTS 1K Ω /V

DC MA -0.25 to 2500 mADC V 20ΚΩ/ V - 0.5 to 500 VDC-AC V 1ΚΩ/ V - 2.5 to 500V

V - Ω -A jack

5000V 20,000 Ω / V jack. . . . . . . .

1000V 20,000 Ω / V jack. . . . . . . .

1000V AC-DC 1000 Ω /V jack . . . 5000V AC-DC 1000 Ω /V jack . . .

Actual

TM 11-6625-654-14

Section Ill.

2-6. Initial AdjustmentsInitial adjustments are required only when theequipment is used on the OHMS range. Followthe procedure outlined below.

a. Place the FUNCTION switch in the OHMSposition.

b. Place the RANGE switch to the desiredrange.

c. Short the test leads together and adjust theOHMS ZERO control for zero reading on themeter.

d. Separate the test leads and adjust theOHMS INF control for infinity reading on themeter.

N O T EThis procedure should be done each time adifferent range is selected.

OPERATION

2-7. Operating ProcedureFour sets of meter scales are provided for makingmeasurements with the multimeter; the top scale–printed in green and marked OHMS–isused when making resistance measurements; thesecond scale–printed in black and marked MILSVOLTS– is used when making measurements ofdc volts, direct current, and ac volts greater than10 vac; the bottom two scales– printed in red andmarked 10 vac and 2.5 vac respectively– are usedfor making measurements of voltages of up to 10vac and 2.5 vac respectively. (Refer to figure 2-3).Follow the procedures outlined below to operatethe multimeter:

1331/U) into the COM jack.

2-5

Figure 2-3. Panel controls and jacks.

a. Dc Voltage Measurements – 20,000 (1) Plug the red test lead (CX-1331/U) into

the V - - A jack and the black test lead (CX-

TM 11-6625-654-14

(2) Set the function switch to the DCVOLTS 20K position.

(3) Set the range switch to the desiredvoltage range. If the voltage to be measured isunknown, use the highest range, and reduce therange a step at a time until an upper scaledeflection is obtained on the meter.

W A R N I N GPrior to connecting the test leads andmaking voltage measurements, turn offpower in the equipment whichmeasurements are being made anddischarge any capacitors. Death oncontact may result if safety precautionsare not observed.(4) Connect the red test lead to the positive

source of the voltage to be measured, and connectthe black test lead to the negative source of thevoltage to be measured.

(5) Make voltage measurement. If the meterpointer reads backwards, reverse connections tothe voltage source.

(2) Set the function switch to the ACVOLTS position.

(3) Set the range switch to the desiredvoltage range. If the voltage to be measured isunknown, use the highest range and reduce therange a step at a time until an upper scaledeflection is obtained on the meter.

W A R N I N GPrior to connecting the test leads andmaking voltage measurements, turn offpower in the equipment whichmeasurements are being made anddischarge any capacitors. Death oncontact may result if safety precautionsare not observed.(4) Connect the red and black test leads to

the voltage source to be measured.(5) Make voltage measurement. The meter

scale indicates the RMS value of the AC voltage.

(2) Set the function switch to the DC MAposition.

(3) Set the range switch to the desiredcurrent range. If the current to be measured isunknown, use the highest range and reduce therange a step at a time until an upper scaledeflection is obtained on the meter.

W A R N I N GPrior to connecting the test leads andmaking current measurements, turn offpower in the equipment whichmeasurements are being made anddischarge any capacitors. Death oncontact may result if safety precautionsare not observed.(4) Open the circuit in which the current is to

be measured. If necessary, unsolder a lead to obtain this open circuit.

(5) Connect the red and black test leads toplace the multimeter in series with the circuitwhich current is to be measured. The black testlead shall be towards the negative polarity andthe red test lead shall be towards the positivepolarity.

CAUTIONDo not connect the multimeter directlyacross any source of voltage. Damage tothe circuit under test may result.(6) Make current measurement. If the meter

pointer reads backwards, reverse connections tothe current source.

(7) For currents above 2500 mA, connect redtest lead CX-1331/U to the 10A jack. The rangeswitch does not operate on the 10 ampere range.

e. Resistance Measurements.(1) Plug red test lead CX-1331/U into the V-

(2) Set the function switch to the OHMSposition.

(3) Set the range switch to the desired range.(4) Short the test leads together and adjust

the OHMS ZERO control for ZERO reading on the meter.

(5) Separate the test leads and adjust theOHMS INF control for full scale meter deflection

2-6

(6) For voltages above 500 vdc, connect redtest lead CX-1331/U to the 1000V 20,000 Ω /Vjack or red test lead CX-927/U to the 5000V20,000 Ω /V jack. The range switch does notoperate on these voltage ranges.

b. Dc Voltages Measurements – 1000 Ω /V. DC voltage measurements at 1000 Ω /Vare made in the same manner as thoseat 20,000 Ω /V, except that the function switch isset to the 1K Ω DC VOLTS position.

c. Ac Voltage Measurements.(1) Plug red test lead CX-1331/U into the V-

Ω - A jack and black test lead CX-1331 /U into the COM jack.

(6) For voltages above 500 Vac, connect redtest lead CX-1331/U to the 1000V 1000 Ω /V jackor red test lead CX-927/U to the 500V 1000 Ω /Vjack. The range switch does not operate on thesevoltage ranges.d. Direct Current Measurements.

(1) Plug red test lead CX-1331/U into the V-Ω - A jack and black test lead CX-1331/U into theCOM jack.

Ω -A jack and black test lead CX-1331 into theCOM jack.

TM 11-6625-654-14

(6) Connect the test leads to the resistance to which the resistance is being measured isbe measured and read the value on the ohms turned off.scale. Multipy the value by the factor indicated (7) Disconnect the test leads whenby the position of the range switch. measurement is completed. Place the function

CAUTION switch to OFF or some other position whenMake sure that the power to the circuit in resistance measurements are not being made.

2-7

TM 11-6625-654-14

CHAPTER 3

OPERATOR AND ORGANIZATIONAL MAlNTENANCE INSTRUCTIONS

3-1. Tools and EquipmentNo special tools or equipment are required foroperator and organizational maintenance. Specialtools, special test equipment, and accessoriesissued with or prescribed for use by the operatorand organizational maintenance personnel for theAN/USM-223 are listed in the Basic Issue ItemsList, Item Troop Installed or Authorized List,and Repair Parts and Special Tools List;paragraph 1-6 of this manual.

3-2. Repainting and Refinishing InstructionsRemove rust and corrosion from metal surfacesby lightly sanding with a fine grade sandpaper.Paint bare metal surfaces according to TB 746-10.Use color number 26307, per FED-STD-595. Donot paint nonmetallic surfaces.3-3. Lubrication InstructionsNo lubrication of this equipment is required.3-4. Preventive Maintenance Checks and

ServicesTo insure that the AN/USM-223 is always readyfor operation, it should be inspectedsystematically so that defects may be discoveredand corrected before they result in serious damageor failure. The necessary preventive maintenancechecks and services to be performed are listed anddescribed in table 3-1. The item numbers indicatethe sequence of and minimum inspectionrequired. Defects discovered during operation ofthe unit will be noted for future correction to bemade as soon as operation has ceased. Stopoperation immediately if a deficiency is notedduring operation which would damage theequipment. Record all deficiencies together withthe corrective action taken on DD Form 6. In-structions for performing the required checks arelisted in the reference columns of the table.

a. Operator Preventive Maintenance. Operatorpreventive maintenance is the systematic care,servicing, and inspection of equipment to preventthe occurrence of trouble, to reduce down time,and to maintain the equipment in serviceablecondition. Operator preventive maintenance isperformed daily and weekly; specific proceduresare listed in table 3-1.

b. Organizational Preventive Maintenance.Organizational preventive maintenance is per-

formed monthly and quarterly; specificprocedures are l isted in table 3-1 .Troubleshooting procedures are provided inparagraph 3-6 of this chapter.

c. Preventive Maintenance Checks and Ser-vices. The preventive maintenance checks andservices described in table 3-1 outline inspectionsto be made at specific intervals and are designedto help maintain equipment in serviceable con-dition. They indicate what items should bechecked and how. Also included, are proceduresfor authorized repairs and references to test,illustrations, and other manuals that containsupplementary information.

d. Defective Items. Defective items thatcannot be corrected must be reported to highercategory maintenance personnel. Records andreports of repairs and preventive maintenancemust be made in accordance with the proceduresgiven in TM 38-750.

e. Cleaning.WARNING

The fumes of trichloroethane are toxic.Provide thorough ventilation wheneverused. DO NOT USE NEAR AN OPENFLAME. Trichloroethane is not flam-mable, but exposure of the fumes to anopen flame or a hot metal surface formshighly toxic phosgene gas.(1) Use a dry, clean, lint-free cloth or brush

to remove dust or dirt. If necessary, moisten thecloth or brush with trichloroethane (Federal StockNumber 6810-292-9625). After cleaning, wipe drywith a clean cloth.

WARNINGCompressed air is dangerous and cancause serious bodily harm. It can alsocause mechanical damage to the equip-ment. Do not use compressed air to dryparts where trichloroethane has beenused.(2) Dry compressed air, not to exceed 60 psi,

may be used to remove dirt and dust frominaccessible places.3-5. Preventive Maintenance Checks and Ser-

vices PeriodsPreventive maintenance checks and services foran operating AN/USM-223 are required daily as

3-1

TM 11-6625-654-14

specified in table 3-1. These checks must be a. When the equipment is initially installed.performed during the specified intervals. In b. At least once a week if the equipment is addition, the daily checks and services must be maintained in a standby condition.performed under the following special conditions:

Table 3-1. Preventive Maintenance Checks and Services

123

4

5

6

7

8

9

10

11

12

13

14

15

16

17

Interval

Operator

B

XXX

. . . .

. . . .

. . . .

D

X

X

X

X

X

. . . .

. . . .

. . . .

. . . .

A

. . . .

. . . .

. . . .

. . . .

. . . .

W

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

X

X

X

. . . .

. . . .

M

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

X

. . . .

. . . .

Q

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

x

x

x

B – Before Operation A – After Operation M – MonthlyD – During operation W – Weekly Q – Quarterly

Item to be Inspected

Completeness . . .Meter glass . . . .Cleaning . . . . .

Controls and indi-caters.

20 K/V dc voltagefunction.

1K /V dc voltagefunction.

AC voltage function.

Direct currentfunction.

Ohmmeter function.

Test leads . . . .

Hardware . . . . .

Metal surfaces

Jacks . . . . . .

Bat tery c o m -partment.

Publications

. . . . . . . . . . .

. . . . . . . . . . . . .

Procedure

See that the equipment is complete.Inspect meter glass for cracks.Clean dirt and moisture from exposed surfaces

of case, cover, panel and meter.Observe that the mechanical action of each

knob, control, and switch is smooth and freeof external or internal binding and no ex-cessive looseness is apparent. Check themeter for sticking or loose pointer.

Measure voltage of a 1.5 Vdc flashlightbattery. Reading should be about 1.5 Vdc.

Same as item 5.

Measure voltage of a normal 115 Vac supplyline. Reading should be about 115 Vac.

Measure short circuit current from a flashlightbattery. Reading should be about 1 to 2amperes.

Short test leads; vary OHMS ZERO control.Check that meter pointer can be set toZERO. Separate test leads and vary OHMSINF control. Check to see that meterpointer can be set to full scale

Inspect for breaks, cuts, kinks, strains, orfrayed insulation. Repair or replace asrequired.

Inspect handle and latches for looseness.Replace as necessary.

Inspect exposed metal surfaces for rust andcorrosion. Touch up with paint.

Inspect jacks for snug fit and good contactReplace if necessary.

Remove battery compartment cover andcheck interior for evidence of water leakage,condensation, and corrosion. Clean and dryout is required.

NOTEBattery compartment is not water ormoisture tight.

See that all publications are complete, ser-viceable, and current.

Determine if now applicable MWO'S must beapplied immediately. ALL NORMALMWO’S must be scheduled.

Check all spare parts (operator andorganizational) for general condition andmethod of storage. No overstock should beevident and all shortages must be on validrequisitions.

Reference

App C.

Para 3-4 e.

Para 2-7 a.

Para 2-7 b.

Para 2-7 c.

Para 2-7 d.

Para 2-7 e.

Para 3-2.

Para 2-3.

DA Pam 310-4.

TM 38-750and DAPam 310-4.

App C.

3-2

Org.

Daily

X

. . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . . . . . .

. . . .

. . . .

. . . .

. . . .

. . . .

. . . . . . . .

. . . .

ItemNumber

TM 11-6625-654-14

3-6. Troubleshooting appropriate system in the troubleshooting chart(table 3-2) to find the possible trouble and

Troubleshooting is based on symptoms that may corrective measure. Perform the correctivebe discovered during normal operating measure as authorized in the maintenanceprocedures, or incorrect indications in preventive allocation chart (app B). If the corrective measuremaintenance checks and services (table 3-l). does not correct the trouble, report trouble toWhen a trouble symptom occurs, refer to the higher category maintenance personnel.

Table 3-2. Troubleshooting Chart

Symptom Possible trouble Corrective measure

Unit operates on l0A, 1000V, and 5000V Blown fuse . . . . . . . . . . . . . . . Replace fuse.range(s) only.

Meter cannot be zeroed . . . . . . . . . . Battery BT2 and/or Replace according to paragraph 2-3.BT3 weak. Testleads open.

Meter cannot be set to full scale. Battery BT1 weak . . . . . . . Replace according to paragraph 2-3.

3-3

TM 11-6625-654-14

CHAPTER 4

FUNCTIONING OF MULTIMETER

Section I. GENERAL

4-1. Functional Description(fig. 4-1)

a. Multimeter AN/USM-223 is a multirange acand dc volt-ohm milliammeter using a singlemoving coil, 50-microampere meter of theD’Arsonval type, with appropriate scales markedto indicate ac and dc volts, dc current, andresistance in ohms.

b. The voltmeter circuit is essentially a meterwith series multiplier resistors. The multiplierresistors are the same for ac and dcmeasurements. However, since the meter is a dcmilliammeter, the ac-voltage input must berectified before being applied to the meter.

c. Wafer switches are used in the switchingcircuits to control the functions and ranges of themultimeter. All meter shunt resistors and somemultiplier resistors are selected by the positioningof the contacts in the switching circuits. Theswitching circuits also connect the battery, orbatteries, and appropriate shunt and seriesresistors into the necessary circuit arrangementsfor resistance measurements in the different ohm-meter ranges.

d. All connections between the multimeter andthe equipment under test are made with a pair oftest leads equipped with pin plugs which matewith the jacks (except for the banana jack used inthe high voltage ranges) located on themultimeter panel.

e. Range and function switches and jacksprovide 15 DC voltage ranges, 7 ac voltage ranges, 8 direct current ranges, and 5 resistanceranges without the need for special externalaccessories or shunts. Ranges, functions, andaccuracies are tabulated in paragraph 1-5 b.

EL6625-654-14-TM-5

Figure 4-1. Block diagram of multimeter.

4-2. Special Featuresa. Low Output Voltage. An open circuit

potential of less than 120 millivolts across theprobe terminals allows “safe” measurements insolid state circuitry.

b. Overload Protection System. An overloadprotection system is incorporated on all rangesexcept the 1000- and 5000-volt ranges and 10ampere range. Basically, it consists of a 2.5

a Triac crowbar circuit, and a pair of diodes–back to back–shunting the meter. The fuselimits the amount of current which can flow intothe meter circuitry, the crowbar circuit protectsagainst excessive voltage, and the diodes limitthe voltage drop across the meter to 0.6 volt.Detailed functioning of this circuitry is discussedin section II.

Section Il. CIRCUIT ANALYSIS

4-3. GeneralThe multimeter circuitry is contained on two AC voltage ranges, and the overload protectionprinted circuit boards. Board #1 (closest to front circuitry. Board #2 (farthest from front panel)panel) contains the voltage dividers for the contains the shunts for the direct current ranges

4 -1

ampere fuse in series with the V - Ω -A input jack,

20K Ω /V DC voltage ranges, the 1K Ω /V DC and

Figure 4-2

TM 11-6625-654-14

and resistance ranges.and batteries are also

Connections to the meter circuit loading effects. Each range has a totalmade from this board. resistance of 20,000 ohms per volt. Application of

a full scale value, potential (for the range selected)4-4. DC Voltmeter Circuits allows a current of 50 microampere to flow

through the meter, deflecting the meter to a full scale indication. A fraction of the full scalepotential will result in the same fraction of currentto flow, deflecting the meter the same fraction.

circuitry (resistors R10 through R17) are designedto withstand overloads of twice full scale value or1000 volts, whichever is less, for indefiniteperiods. The meter movement is protected fromoverload damage by diodes CR4 and CR5. Thediodes conduct under overload conditions andlimit the voltage across the meter circuit to about0.6 volt.

voltmeter circuit. This circuit is used formeasuring circuitry where loading effects are not

ohms per volt. Application of a full scale valuepotential (for the range selected) allows a currentof one milliampere to flow through the circuit. Acurrent of 50 microampere will flow through themeter, deflecting the meter to a full scale in-dication. The balance of the current flows throughshunt resistor R23. Fractions of full scale currentwill result in fractions of full scale meterdeflection.

4-2

a. 20 K Ω /V Circuit. Figure 4-2 illustrates asimplified schematic diagram of the 20K Ω /Vvoltmeter circuit. This circuit provides a highimpedance measurement source to minimize

b. 20K Ω /V Overload Protection Circuit. Thecomponent parts which make up the 20K Ω /V

c. 1K Ω /V Circuit. Figure 4-3 illusrates asimplified schematic diagram of the 1K Ω /V

Figure 4-2. Simplified 20K Ω /V Vdc circuit.

critical. Each range has a total resistance of 1000

TM 11-6625-654-14

sine wave ac voltages. During the positive half ofthe sine wave, current passes through rectifierCR3. A portion of this current flows through themeter, resistor R42, and resistor R38 to resistorR40. It then flows through resistors R40 and R41to the COM jack. During the negative half of thesine wave, the current passes through resistorsR41, R40, and R38, and through rectifier CR2 to

through resistors R38, R40, and the meter. Thetotal impedance of the rectifier circuit is 2500ohms. Application of a full scale value potentialto the multimeter (for the range selected) allowsa current of one milliampere to flow through thecircuit. A current of 50 microamperes will flowthrough the meter, deflecting the meter to a fullscale indication. The balance of the current flowsthrough shunting resistor R38 or R39. Fractionsof full scale current will result in fractions of fullscale meter deflection.

overload protection circuit consists of a Triac anda pair of transistors. The Triac is connecteddirectly across the measurement circuit, andremains in a blocking condition until turned on bysufficient gate current from an overload con-dition. The gate current is connected through a100 ohm resistor (for gate current limiting) to apair of transistors used as voltage operatedswitches. When a voltage is applied to the 2.5Vrange which exceeds about 10 volts, the tran-sistors switch ON and trigger the Triac. Theconduction of the Triac places a direct shortacross the test leads and allows the overloadsource to blow the 2.5 ampere fuse.4-5. Ac Voltmeter Circuit

a. Circuit Description. Figure 4-4 illustrates asimplified schematic of the AC voltmeter circuit.Input impedance of all ac voltmeter ranges is 1000ohms per volt. All readings are RMS values of

4-3

Figure 4-. Simplified 1K Ω /V Vdc circuit.

d. 1K /V Overload Protection Circuit. The

the V - Ω -A jack. A portion of this current flows

TM 11-6625-654-14

Figure 4-4. Simpified ac voltmeter circuit.

4-6. Direct Current Circuita. Circuit Description. Figure 4-5 illustrates a

simplified schematic of the direct currentmeasurement circuit. Current flows throughseries resistor R1 and the meter, and shuntresistors (as selected by the range switch) R2through R9. The shunting circuitry is designed sothat 50 microamperes flows through R1 and themeter when a full scale current value is applied tothe appropriate range. The remainder flowsthrough the selected shunt resistors.

EL 6625-654-14-TM-9

Figure 4-5. Simplified direct current circuit.

b. Overload Protection Circuit. Four diodes(CR6, CR7, CR8, and CR9) are used in a gate trigger configuration. The diodes do not conductunless an overload is applied to the multimeter.When the overload potential exceeds three volts,the gate trigger circuit turns ON and triggers theTriac. The conduction of the Triac places a directshort across the test leads and causes theoverload source to blow the 2.5 ampere fuse.4-7. Ohmmeter Circuit

a. Circuit Description. Figure 4-6 illustrates asimplified schematic diagram of the ohmmetercircuit. An open circuit potential of less than 120millivolts for “safe” measurements in solid statecircuitry is provided. This is obtained by dividingdown the 1.5-volt potential of battery BT1 with avoltage divider made up of resistors R30 and R31.The operating potential of 120 millivolts isdeveloped across R30. The positive end of thebattery is connected to the COM terminal. Thenegative end of R30 (negative ohmmeter supply

4-4

described in paragraph 4-4 d.

b. Overload Protection Circuit. The overloadprotection circuit for the ac voltage ranges isidentical to that of the 1k W /V vdc ranges

TM 11-6625-654-14

voltage) is connected to R25, which is the first ofthe ohmmeter standard resistors. The standardresistors are selected by the range switch which is

input. When an unknown resistance is placedacross the test leads, the standard and unknownresistances form a voltage divider, with thevoltage across the unknown fed to the amplifier

input where it is amplified by field effect tran-sistor Q1. Voltage on the drain lead of Q1 is fed tothe base of Q2. The collector of Q2 is connected tothe source of Q1, completing a feedback loop.Meter M1 is connected to the junction of BT2 andBT3 and R37. The meter reads the unbalance ofthe voltage between the battery tap and thesource of Q1.

Figure 4-6. Simplified ohmmeter circuit.

b. Overload Protection Circuit. The overload errors. The Triac protection circuit is not requiredprotection circuit for the ohmmeter ranges is in the X1000 and X 10,000 ranges. The componentidentical to that of the direct current ranges values in these two ranges are sufficiently large todescribed in paragraph 4-6 b. However, the Triac withstand rated overloads. Resistor R32 andcircuit must be disconnected in the X1000 and Zener diode CR1 protect the gate of transistor Q1X 10,000 ranges since worst case leakage at high from overloads.ambient temperatures would cause measurement

4-5

connected to the V - Ω -A jack and to the amplifier

TM 11-6625-654-14

CHAPTER 5

GENERAL SUPPORT MAINTENANCE INSTRUCTIONS

Section I.

5-1. Maintenance Proceduresa. Fault Localization and Isolation. First,

localize the fault by tracing it to a defectivefunction or circuit responsible for the abnormalcondition. Then, isolate the fault by locating thedefective part or parts. Isolation may be ac-complished by visual inspection (burned outresistors) and/or voltage and resistancemeasurements. The troubleshooting chart in table5-2 should be used as an aid in fault localizationand isolation.

b. Operational Tests. The general location andnature of a fault can frequently be determined byoperational testing. The daily preventivemaintenance checks and services listed in table 3-1 are a good guide for operational testing.

c. Voltage and Resistance Measurements. Thisequipment is transistorized. Observe allprecautions given to prevent transistor damage.Make voltage and resistance measurements onthis equipment only as specified. Whenmeasuring voltages, use tape or sleeving to in-

sulate the entire test prod except for the extremetip. A momentary short can destroy a transistor.5-2. Tools and EquipmentTable 5-1 lists the test equipment required fortroubleshooting Multimeter AN/USM-223.

Table 5-1. Tools and Equipment

Item NomenclatureMultimeter . . . . . . . . . . .

TS-682A/GSM-1Decade Resistance Box . . . ZM-16( )/UTool Kit, Electronic Equipment TK-105/G

5-3. TroubleshootingTroubleshooting at the general support levelincludes all of the procedures outlined for operatorand organizational maintenance (ch 3) and thosespecified in table 5-2. They are not necessarily all-inclusive, but do indicate the probable location ofa fault. Use the lists and procedures as a guide inanalyzing symptoms that may not be listed.Figures 5-1 and 5-2 are provided for use incomponent location.

5-1

GENERAL

TS-352AMeter Test Set . . . . . . .

TM 11-6625-654-14

Table 5-2. General Support Troubleshooting Procedures.

SymptomAll or many ranges and functions out

of tolerance.

Ohmmeter will not zero adjust–batteries check good.

Ohmmeter does not function.Ohmmeter does not funct ion–

battery and connecting wiresgood.

No readings on current range(s).

No readings on DC voltage range(s).

No readings on AC voltage range(s).

Possible causeMeter out of calibration.

Defective meter M1Out of calibration . . . . . . .

Open wire to battery terminal.Defective component on circuit

board #2.

Defective component on circuitboard #2.

Defective component on circuitboard #1.

Defective component on circuitboard #1.

Defective resistor(s) R10 throughR17.

Defective resistor(s) R18 throughR22, R43, and/or R55.

Defective resistor(s) R18 throughR22, R43, and/or R55.

Defective resistor(s) R38 throughR42 or diodes CR2 and CR3.

Corrective measureCalibrate accorcding to TB 11-6625-.

654-35 (To be published).Replace meter M1.(Calibrate according to TB 11-6625-

654-35 (To be published).Replace wire.Replace printed circuit board or

defective components (Q1, Q2,R25 thru R37).

Replace printed circuit board ordefective components (R2 - R9.and R51 - R54).

Replace printed circuit board ordefective components (R10through R24, R43, and R55).

Replace printed circuit board ordefective components (R18-R22,R38-R43, R55, CR2 or CR3),

Replace printed circuit board #l ordefective resistors.

Replace printed circuit board #1 ordefective resistors.

Replace printed circuit board #l ordefective resistors.

Replace printed circuit board #1 ordefective components.

Section II. GENERAL SUPPORT TESTING PROCEDURES

5-4. Generala. Testing procedures are prepared for use by

Electronics Field Maintenance Shops andElectronics Service Organizations responsible forgeneral support maintenance of equipment. Theseprocedures set forth specific requirements thatrepaired equipment must meet before it isreturned to the using organization.

b. A chart is provided for each function theequipment can perform plus a chart for physicaltests and inspection. Comply with the in-structions preceding each chart before proceedingto the chart. Perform each step in sequence. Foreach step, perform all actions required in theControl settings column; then perform each

specific test procedure and verify it against itsperformance standard.

5-5. Modification Work Orders (MWO’S)The testing procedures and performance stan-dards (para 5-6 through 5-10) are directly ap-plicable to equipment modified in accordance withthe modification work orders (MWO’s). A listingof current MWO’S will be found in DA Pam 310-7.

5-6. Physical Tests and Inspectiona. Test Equipment and Materials, None.b. Test Connections and Conditions. Remove

multimeter cover.c. Procedure.

5-4

20K Ω /V DC range(s) inoperative orout o f to lerance .1K Ω /V DC range(s) inoperative orout o f to lerance .AC voltage range(s) inoperative orout o f to lerance .All AC ranges inoperative – 1K Ω /VDC ranges good.

TM 11-6625-654-14

StepNo.

1

2

3

N/A

N / A

Equipmentunder test

NA

N/A

N/A

Test procedure

a. Inspect all jacks for looseness or damage.

b. Inspect the case and front panel for damage ormissing parts and inspect condition of the finish.

a. Operate OHMS ZERO control from complete CW to complete CCW

b. Operate FUNCTION and RANGE switches to each position indicated.

a. Remove battery compartment cover and inspect interior for damage, missing parts, or corroded battery contacts.

b. Replace battery compartment cover before proceed-

Performance standards

a. No looseness or damage shall beevident.

b. No damage or missing parts shallbe evident. No surface intended tobe painted shall show bare metal.All lettering shall be legible.

a. Control rotates freely withoutbinding. Knob tight on shaft.

b. Switch action positive–no looseness or binding.

a. No damaged or missing partsshall be evident. There shall be nosigns or corrosion on the batterycontacts or elsewhere in thecompartment.

b. N/A.

5-7. Ohmmeter Function Test b. Test Connections and Conditions. Make noa. Test Equipment and Materials. Decade connections until instructed to do so in procedure.

Resistor ZM-16/U or ZM-16A/U. c. Procedure.

StepNo.

2

3

4

5

Control settings

Testequipment

ZM-16( )/U:X1 switch: 5X10 switch: 2All otherswitches: 0

ZM-16( )/U:X10 switch: 5X100 switch: 2All otherswitches: 0ZM-16( ) / U :X100 switch: 5X1000 switch: 2All otherswitches: 0ZM-16( )/U:X1000 switch: 5X10000 switch: 2All otherswitches: 0ZM-16( ) / U :X10000 switch: 5X100000 switch: 2All otherswitches: 0

Equipmentunder test

FUNCTION switch:OHMSRANGE switch: RX1

RANGE switch: RX10

RANGE switch: RX100

R A N G E s w i t c h :RX1000 . . . .

R A N G E s w i t c h :RX10000 . . . .

Test procedure

a. Install batteries and test leadsinto Multimeter.

b. Short test leads together, andzero the meter.

c. Open test leads and adjust meterto infinity.

d. Connect equipment as shown in- note meter in -figure 5-3, and

dication.Same as step 1

Same as step 1

Same as step 1

Shine as step 1

. . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

Performance standards

a. None.

b. None.

c. None.

d. Meter shall indicate be-tween 22 and 28 ohms.

Meter shall read between 220and 280 ohms.

Meter shall read between 2.2Kand 2.8K ohms.

Meter shall indicate between22K and 28K ohms.

Meter shall indicate between220K and 280K ohms.

5-5

Control settings

Testequipment

ing with tests.

1

. . . . . . . . . .

TM 11-6625-654-14

E L 6 6 2 5 - 6 5 4 - 1 4 - T M - 1 3

Figure 5-3. Ohmmeter function performance test connection.

5-8. Dc Ammeter Function Test b. Test Conditions and Connections.connections when

a. Test Equipment and Materials. Meter Test procedure.Set TS-682A/GSM-1.

Control settings

Step TestNo. equipment

1 TS-682A/GSM-1:AC LINE switch: OFFBATTERY switch: OFFAll OUTPUT controls:Maximum CCWCENTER SELECTORSWITCH: D C M A& µ ΑLEFT-HANDSELECTORswitch: ALL OTHERAC & DC SCALES

Equipmentunder test

FUNCTION switch:DC MARANGE switch: 0.25

c. Procedure.

and

Test procedure

a. Connect the equipment as shownin figure 5-4, with test lead con-nected from Test Set 500 µΑ jackto Multimeter V −Ω−Α jack.

b. AC LINE switch: ON. . . . .c. BATTERY switch: ON. . . .d. Test Set output in a 225 µ A

meter reading.

Makeas instructed in test

Performance standards

a. N/A

b. N/Ac. N/Ad. Multimeter shall read

between 217.5 and232.5 µΑ.

5-6

TM 11-6625-654-14

StepNo.

2

3

4

5

6

7

8

Control settings

Testequipment

Same as step 1 . . . . .

Same as step 1 . . . . .

Same as step 1 . . . . .

Same as step 1 . . . . .

Same as step 1 . . . . .

Same as step 1 except:RIGHT-HANDSELECTOR switch: 5A

Same as step 7 . . . . .

Equipmentunder test

Same as step 1 except:RANGE switch: 2.5

Same as step 1 except:RANGE switch: 10

Same as step 1 except:RANGE switch: 50

Same as step 1 except:RANGE switch: 100

Same as step 1 except:RANGE switch: 500

Same as step 1 except:RANGE switch: 2500

Same as step 1 except:RIGHT-HANDSELECTOR switch:10A

Test procedure

a. Same as step 1 except test leadconnected to Test Set 5 mA jack.

b. AC LINE switch: ON . . . . . . .c. BATTERY switch: ON . . . . . .d. Test Set output to a 2.25 mAmeter reading.

a. Same as step 1 except test leadconnected to Test Set 10 mA jack.

b. AC LINE switch: ON . . . . . .c. BATTERY switch: ON . . . .d. Test Set output to a 9 mA meter

reading.

a. Same as step 1 except test leadconnected to Test Set 50 mA jack.

b. AC LINE switch: ON. . . . . .c. BATTERY switch: ON . . . . . .d. Test Set to a 45 mA meter

reading.a. Same as step 1 except test lead

connected to Test Set 100 mAjack.

b. AC LINE switch: ON . . . . . . . . .c. BATTERY switch: ON . . . . . . .d. Test Set output to a 90 mA meter

reading.a. Same as step 1 except test leadconnected to Test Set 500 mAjack.

b. AC LINE switch: ON . . . . . . . .c. BATTERY switch: ON. . . . . .d. Test Set output to a 450 mA

meter reading.e. Same as step 1 except test lead

connected to Test Set 5A jack.

b. AC LINE switch: ON . . .C. BATTERY switch: ON . . . . . .d. Test Set output to a 2.25A meter

reading.

a. Same as step 1 except test leadconnected to both Test Set andMultimeter 10A jacks.

b. AC LINE switch: ON . . . . . c. BATTERY switch: ON . . . . . .d. Test Set output to a 9A meter

reading.

Performance standards

b. N/Ac. N/Ad. Multimeter shall read between 2.175 and 2.325

a. N/A

b. N/Ac. N/Ad. Multimeter shall read

between 8.7 and 9.3 mA.

a. N/A

b. N/Ac. N/Ad. Multimeter shall read

between 43.5 and 46.5 mA.a. N/A

b. N/Ac. N/Ad. Multimeter shall read ,

between 87 and 93 mA.a. N/A

b. N/Ac. N/Ad. Multimeter shall read

between 435 and 465 mA.a. N/A

b. N/Ac. N/Ad. Multimeter shall read

between 2.175 end 2.325amperes.

a. N/A

b. N/Ac. N/Ad. Multimeter shall read

between 8.7 and 9.3 am-peres.

5-7

a. N/A

TM 11-6625-654-14

—

5-8

Fig

ure

5-4

. D

c a

mm

eter p

erforma

nce

test con

nection

.

EL6625-654-14-TM-14

TM 11-6625-654-14

5-9. Ac Voltmeter Test b. Test Conditions and Connections. Makeconnections when and as instructed in test

a. Test Equipment and Materials. Meter Test procedure.Set TS-682A/GSM-1.

StepNo.

2

3

4

5

6

7

Testequipment

TS-682A/GSM-1:AC LINE switch:OFFBATTERY switch:OFFALL OUTPUT controls:Max CCWCENTER SELECTORswitch: AC VOLTSLEFT-HANDSELECTOR switch:ALL OTHER AC & DCSCALESRIGHT-HANDSELECTOR switch: AC&DC VSame as step 1 . . . . .

Same as step 1 . . . . . .

Same as step 1 . . . . . .

Same as step 1 . . . . . .

Same as step 1 . . . . . .

Same as step 1 . . . . . .

Equipmentunder test

FUNCTION switch: ACVOLTS

Same as step 1 except :RANGE switch: 10

Same as step 1 except:RANGE switch: 50

Same as step 1 except:RANGE switch: 250

Same as step 1 except:RANGE switch: 500

Same as step 5 . . . . . .

Same as step 5. . . . . .

c. Procedure,

Test procedure

a. Connect equipment as shown infigure 5-4, with test lead connectedfrom 5V AC jack of Test Set to V-Ω -A jack of Multimeter.

b. AC LINE switch: ON . . . . . . . . .c. Test Set output to a 2.25 Vac

meter reading.

a. Same as step 1 except test leadconnected to Test Set 10V ACjack.

b. AC LINE switch: ON . . . . . .c. Test Set output to a 9 Vac meter

reading.a. Same as step 1 except test lead

connected to Test Set 50V ACjack.

b. AC LINE switch: ON . . . . . . . . . .c. Test Set output to a 45 Vac meter

reading.a. Same as step 1 except test lead

connected to Test Set 500V ACjack.

b. AC LINE switch: ON . . . . . . .c. Test Set output to a 225 Vac

meter reading.a. Same as step 4. . . . . . . . . . . .b. AC LINE switch: ON . . . . . . . .c. Test Set output to a 450 Vac

meter reading.a. Same as step 1 except test lead

connected to 1000 VAC jack ofboth Test Set and Multimeter.

b. AC LINE switch: ON . . . . . . . . . .c. Test Set output to a 900 Vac

meter reading.a. Same as step 1 except test lead

connected to 2000V AC jack ofTest Set and 5000V AC jack ofMultimeter.

b. AC LINE switch: ON . . . . . .c. Test Set output to a 2000 Vac

meter reading.

Performance standards

a. N/A

b. N/Ac. Multimeter shall readbetween 2.15 and 2.35 Vac.

a. N/A

b. N/Ac. Multimeter shall readbetween 8.6 and 9.4 Vac.a. N/A

b. N/Ac. Multimeter shall readbetween 43 and 47 Vac.a. N/A

b. N/Ac. Multimeter shall readbetween 215 and 235 Vac.a. N/Ab. N/Ac. Multimeter shall readbetween 430 and 470 Vac.a. N/A

b. N/Ac. Multimeter shall readbetween 850 and 950 Vac.a. N/A

b. N/Ac. Multimeter shall readbetween 1650 and 2350 Vac.

5-9

Control settings

1

TM 11-6625-654-14

5-10. Dc Voltmeter Test b. Test Connections and Conditions. Make connections when and as instructed in test

a. Test Equipment and Materials. Meter Test procedure.Set TS-682A/GSM-1.

StepNo.

2

3

4

5

6

7

8

9

.Control settings

Testequipment

TS-682A/GSM-1:AC LINE switch:OFFBATTERY switch:OFFAll OUTPUT controls:Max CCW CENTERSELECTOR switch: DCVOLTS & MVLEFT-HANDSELECTORswitch: 0.1- 500VDCRIGHT-HANDSELECTOR switch:AC & DC VOLTSSame as step 1 . . . . .

Same as step 1 . . . .

Same as step 1 . . . . . .

Same as step 1 . . . . . .

Same as step 1 . . . . . .

Same as step 1 . . . . . .

Same as step 1 . . . . . .

Same as step 9 . . . . . .

Equipmentunder test

s w i t c h : DC VOLTS 20K ΩRANGE switch: 2.5

Same as step 1 except:FUNCTION switch: DCVOLTS 1 K Ω

FUNCTION SWITCH:DC VOLTS 20K ΩRANGE switch: 10

Same as step 3 except:FUNCTION switch: DCVOLTS 1K ΩFUNCTION switch: DCVOLTS 20K ΩRANGE switch: 50

Same as step 5 except:FUNCTION switch: DCVOLTS 1K ΩFUNCTION switch: DCVOLTS 20K Ω .RANGE switch: 250

Same as step 7 except:FUNCTION switch: DCVOLTS 1K Ω .

FUNCTION switch: DCVOLTS 20K ΩRANGE switch: 500

Test procedure

a. Connect equipment as shown infigure 5-4, with test lead connectedfrom Test Set 5V DC jack toMultimeter V − Ω −Α jack.

b. AC LINE switch: ON . . . . . . . .C. Test Set output to a 2.25 Vdc

meter reading.

a. Same as step 1 . . . . . . . . . .b. AC LINE switch: ON . . . . .c. Same as step 1. . . . . . . . .a. Same as step 1 except test lead

connected to Test Set 10V DCjack.

b. AC LINE switch: ON . . . . . . .c. Test Set output to a 9 Vdc meter

reading.a. Same as step 3 . . . . . . . . . .b. AC LINE switch: ON . . . . .c. Same as step 3 . . . . . . . . .a. Same as step 1 except test lead

connected to Test Set 50V DCjack.

b. AC LINE switch: ON . . . . .c. Test Set output to a 45 Vdc meter

reading.a. Same as step 5 . . . . . . . . . .b. AC LINE switch: ON . . . . . . .c. Same as step 5 . . . . . . . . . . . .a. Same as step 1 except test lead

cconnected to Test Set 500V DCjack.

b. AC LINE switch: ON . . . . . .c. Test Set output to a 225 Vdc

meter reading.a. Same as step 7 . . . . . . . . . .

b. AC LINE switch: ON . . . . . . . c. Same as step 7 . . . . . . . .a. Same as step 7 . . . . . . . .b. AC LINE switch: ON. . . . .c. Test Set output to a 450 Vdc

meter reading.

a. N/A

b. N/Ac. Multimeter shall readbetween 2.18 and 2.33 Vdc.

a. N/Ab. N/Ac. Same as step 1.a. N/A

b. N/Ac. Multimeter shall readbetween 8.7 and 9.3 Vdc.a. N/Ab. N/Ac. Same as step 3,a. N/A

b. N/Ac. Multimeter shall readbetween 43.5 and 46.5 Vdc.a. N/Ab. N/Ac. Same as step 5.a. N/A

b. N/Ac. Multimeter shall readbetween 218 and 233 Vdc.a. N/A

b. N/Ac. Same as step 7.a. N/Ab. N/Ac. Multimeter shall readbetween 435 and 465 Vdc.

5-10

1 FUNCTION

Performance standards

c . Procedure.

TM 11-6625-654-14

StepNo.

10

11

12

13

14

Control settings

Same as step 1 . . . . . .

Same as step 1 except:LEFT-HANDSELECTOR switch:1000V DC

Same as step 11 . . . . . . .

Same as step 1 except:LEFT-HANDSELECTOR switch:2000V DC

Same as step 9 except:FUNCTION switch: DCVOLTS lK Ω.Same as step 9 . . . . .

Same as step 10 . . . . .

Same as step 9 . . . . . .

Same as step 9 . . . . .

Test procedure

a. Same as step 9 . . . . . . . . . . .b. AC LINE switch: ON . . . . . .c. Same as step 9 . . . . . . . . . .a. Same as step 1 except test lead

connected to Test Set 1000V DCjack and Multimeter 1000V20K Ω /V jack.

b. AC LINE switch: ON . . . . .c. Test Set output to a 900 Vdc

meter reading.a. Same as step 11 except test lead

connected to Multimeter 1000V1K Ω /V jack.

b. AC LINE switch: ON . . . . . . .c. Same as step 11 . . . . . . . .

a. Same as step 1 except test leadconnected to Test Set 2000V DCjack and Multimeter 5000V20K Ω /V jack.

b. AC LINE switch: ON . . . . .c. Test Set output to a 2000 Vdc

meter reading.a. Same as step 13 except test lead

connected to Multimeter 5000V1K/V jack.

b. AC LINE switch: ON . . . . .c. Same as step 13 . . . . . . . . .

Performance standards

a. N/Ab. N/Ac. Same as step 9.a. N/A

b. N/Ac. Multimeter shall readbetween 860 and 940 Vdc.a. N/A

b. N/Ac. Multimeter shall readbetween 870 and 930 Vdc.a. N/A

b. N/Ac. Multimeter shall readbetween 1700 and 2300 Vdc.a N/A

b. N/Ac. Same as step 13.

5-11

Testequipment

Equipmentunder test

TM 11-6625-654-14

Figure 5-5. Multimeter AN/USM-223, exploded view.

Figure 5-6. Multimeter AN/USM-223, schematic diagram.

(Located in back of manual)

5-12

TM 11-6625-654-14

APPENDIX A

REFERENCES

Following is a list of applicable publications available to the operator,organizational and general support maintenance repairmen of MultimeterAN/USM-223:

DA Form 2028DA Pam 310-4

DA Pam 310-7DD Form 6FED-STD-595TB 11-6625-654-35

TB 746-10

TM 38-750TM 740-90-1

Recommended Changes to Publications and Blank Forms.Index of Technical Manuals, Technical Bulletins, Supply Manuals

(types 7, 8, and 9), Supply Bulletins, and Lubrication Orders.US Army Equipment Index of Modification Work Orders.Report of Packaging and Handling Deficiencies.Colors.Calibration Procedure for Multimeter AN/USM-223. (To be

published).Field Instructions for Painting and Preserving Electronics Command

Equipment.The Army Maintenance Management System (TAMMS).Administrative Storage of Equipment.

A-1

TM 11-6625-654-14

APPENDIX B

MAINTENANCE ALLOCATION

Section I. INTRODUCTION

B-1. GeneralThis appendix provides a summary of themaintenance operations covered in the equipmentliterature for the AN/USM-223. It authorizescategories of maintenance for specific main-tenance functions on repairable items andcomponents and the tools and equipment requiredto perform each function. This appendix may beused as an aid in planning maintenanceoperations.B-2. Maintenance FunctionsMaintenance functions will be limited to anddefined as follows:

a. Inspect. To determine serviceability of anitem by comparing its physical, mechanical, andelectrical characteristics with establishedstandards.

b. Test. To verify serviceability and to detectincipient electrical or mechanical failure by use ofspecial equipment such as gages, meters, etc.This is accomplished with external test equip-ment and does not include operation of theequipment and operator type tests using internalmeters or indicating devices.

c. Service. To clean, to preserve, to charge, andto add fuel, lubricants, cooling agents, and air. Ifit is desired that elements, such as painting andlubricating, be defined separately, they maybe solisted.

d. Adjust. To rectify to the extent necessary tobring into proper operating range.

e. Align. To adjust two or more components orassemblies of an electrical or mechanical systemso that their functions are properly synchronized.This does not include setting the frequencycontrol knob of radio receivers or transmitters tothe desired frequency.

f. Calibrate. To determine the corrections tobe made in the readings of instruments or testequipment used in precise measurement. Consistsof the comparison of two instruments, one ofwhich is a certified standard of known accuracy,to detect and adjust any discrepancy in the ac-

curacy of the instrument being compared with thecertified standard.

g. Install. To set up for use in an operationalenvironment such as an encampment, site, orvehicle.

h. Replace. To replace unserviceable items withserviceable like items.

i. Repair. To restore an item to serviceablecondition through correction of a specific failureor unserviceable condition. This function in-cludes, but is not limited to welding, grinding,riveting, straightening, and replacement of partsother than the trial and error replacement ofrunning spare type items such as fuses, lamps, orelectron tubes.

j. Overhaul. Normally, the highest degree ofmaintenance performed by the Army in order tominimize time work in process is consistent withquality and economy of operation. It consists ofthat maintenance necessary to restore an item tocompletely serviceable condition as prescribed bymaintenance standards in technical publicationsfor each item of equipment. Overhaul normallydoes not return an item to like new, zero mileage,or zero hour condition.

k. Rebuild. The highest degree of materielmaintenance. It consists of restoring equipmentas nearly as possible to new condition in ac-cordance with original manufacturing standards.Rebuild is performed only when required byoperational considerations or other paramountfactors and then only at the depot maintenancecategory. Rebuild reduces to zero the hours ormiles the equipment, or component thereof, hasbeen in use.

l. Symbols. The uppercase letter placed in theappropriate column indicates the lowest level atwhich that particular maintenance function is tobe performed.B-3. Explanation of Format

a. Column 1, Group Number. Column 1 listsgroup numbers, the purpose of which is toidentify components, assemblies, subassembliesand modules with the next higher assembly.

B-1

b. Column 2, Functional Group. Column 2 liststhe noun names of components, assemblies,subassemblies and modules on which main-tenance is authorized.

c. Column 3, Maintenance Functions. Column 3lists the maintenance category at which per-formance of the specific maintenance function isauthorized. Authorization to perform a functionat any category also includes authorization toperform that function at higher categories. Thecodes used represent the various maintenancecategories as follows:

Code Maintenance categoryC . . . . . . . . . . . . . . Operator/crewO . . . . . . . . . . . . . . Organizational maintenanceF . . . . . . . . . . . . . . . . Direct support maintenanceH . . . . . . . . . . . . General support maintenanceD . . . . . . . . . . . . . .Depot maintenance

d. Column 4, Tools and Test Equipment.Column 4 specifies, by code, those tools and testequipment required to perform the designated

function. The numbers appearing in this columnrefer to specific tools and test equipment whichare identified in table I.

e. Column 5, Remarks. Self-explanatory.B-4. Explanation of Format of Table I (Tool

and Test Equipment Requirements)The columns in table I (Tool and Test EquipmentRequirements) are as follows:

a. Tools and Equipment. The numbers in thiscolumn coincide with the numbers used in thetools and equipment column of the maintenanceAllocation Chart. The numbers indicate theapplicable tool for the maintenance function.

b. Maintenance Category. The codes in thiscolumn indicate the maintenance categorynormally allocated the facility.

c. Nomenclature. This column lists tools, test,and maintenance equipment required to performthe maintenance functions.

d. Federal Stock Number. This column lists theFederal stock number of the specific tool or testequipment.

e. Tool Number. Not used.

Section II. MAINTENANCE ALLOCATION CHART

B-2

TM 11-6625-654-14

TM 11-6625-654-14

Table I. TOOL AND TEST EQUIPMENT REQUIREMENTS

TOOL AND TEST EQUIPMENT REQUIREMENTS

Tool or testequipment Maintenance Nomenclature FSN

reference codeTool

category number

1 . . . . . . . H, D. . . . . . . . Meter Test Set, TS-682A/GSM-1. . . . . . . . . . . . . . . . . . . . 6625-669-07472 . . . . . . . . . H, D. . . . . . . . . . Multimeter, AN/USM-223 . . . . . . . .3 . . . . . . . . . H,D. . . . . . . . . Resistor, Decade, ZM-16( )/U . . . . . . . . . . 6625-669-02664 . . . . . . . . . H, D . . . . . . . . . Tool Kit, Electronic Equipment, TK-100G . . . . 5180-605-00795 . . . . . . . . . O . . . . . . . . . . . . . . Tools and test equipment normally supplied to the repairmen

user because of his assigned mission.

B-3

APPENDIX

TM 11-6625-654-14

C

ORGANIZATIONAL, DIRECT SUPPORT, AND GENERAL SUPPORT

MAINTENANCE REPAIR PARTS AND SPECIAL TOOLS LIST

(INCLUDING DEPOT MAINTENANCE REPAIR PARTS AND

SPECIAL TOOLS)

Section I. INTRODUCTION

C-l. ScopeThis manual lists repair parts and special toolsrequired for the performance of organizational,direct support, general support, and depotmaintenance of the AN/USM-223.C-2. GeneralThis Repair Parts and Special Tools List isdivided into the following sections:

a. Organizational Repair Parts List-SectionII. A list of repair parts authorized at theorganizational level for the performance ofmaintenance. The list also includes parts whichmust be removed for replacement of theauthorized parts. Parts lists are composed offunctional groups in ascending numericalsequence, with the parts in each group listed infigure and item number sequence.

b. Organizational Special Tools List–SectionIII. Not applicable.

c. Repair Parts List–Direct Support, GeneralSupport, and Depot Maintenance–Section IV. Alist of repair parts authorized at the direct sup-port, general support, and depot support levelsfor the performance of maintenance. The list alsoincludes parts which must be removed for thereplacement of the authorized parts. Parts listsare composed of functional groups in ascendingnumerical sequence, with parts in each grouplisted in figure and item number sequence.

d. Direct Support, General Support, andDepot Maintenance Special Tools List–SectionV. Not applicable.

e. Index–Federal Stock Number andReference Number to Figure and ItemNumber–Section VI. A list, in ascendingnumerical sequence, of all Federal stock numbersappearing in the listings, followed by a list, inalphanumeric sequence, of all reference numbers

appearing in the listings, Federal stock numberand reference numbers are cross-referenced toeach illustration figure and item number ap-pearance.C-3. Explanation of ColumnsThe following provides an explanation of columnsfound in the tabular listings:

a. Source, Maintenance, and RecoverabilityCodes (SMR).

(1) Source code. Source codes are assigned tosupport items to indicate the manner of acquiringsupport items for maintenance repair, or overhaulof end items. Source codes are entered in the firstand second positions of the Uniform SMR codeformat as follows:Code Definition

P A – Item procured and stocked for an-ticipated or known usage.

P E – Support equipment procured andstocked for initial issue or outfitting tospecified maintenance repair activities.

M D – Item to be manufactured or fabricated atthe depot maintenance level.

A H – Item to be assembled at general supportmaintenance level.

X B – Item is not procured or stocked. If notavailable through salvage, requisition.

NOTECannibalization or salvage may be usedas a source of supply for any items sourcecoded above except those coded XA, XD,and aircraft support items as restrictedby AR 700-42.(2) Maintenance code. Maintenance codes are

assigned to indicate the levels of maintenanceauthorized to USE and REPAIR support items.The maintenance codes are entered in the third

C-1

TM 11-6625-654-14

and fourth positions of theformat as follows:

(a) The maintenance

Uniform SMR Code

code entered in thethird position will indicate the lowest main-tenance level authorized to remove, replace, anduse the support item. The maintenance codeentered in the third position will indicate one ofthe following levels of maintenance:Code Application/Explanation

O – Support item is removed, replaced, usedat the organizational level.

H – Support item is removed, replaced, usedat the general support level.

D – Support items that are removed,replaced, used at depot, mobile depot,specialized repair activity only.

(b) The maintenance code entered in thefourth position indicates whether the item is to berepaired and identifies the lowest maintenancelevel with the capability to perform completerepair (i.e., all authorized maintenance func-tions). This position will contain one of thefollowing maintenance codes:Code Application/Explanation

D – The lowest maintenance level capable ofcomplete repair of the support item isthe depot level, performed by depot.

Z – Nonrepairable. No repair is authorized.

(3) Recoverability code. Recoverabilitycodes are assigned to support items to indicatethe disposition action on unserviceable items. Therecoverability code is entered in the fifth positionof the Uniform SMR Code format as follows:Recoverability

Code Definition

Z – Nonrepairable item. When un-serviceable, condemn and dispose atthe level indicated in position 3.

D – Repairable item. When beyond lowerlevel repair capability, return to depot.Condemnation and disposal notauthorized below depot level.

b. Federal Stock Number. Indicates theFederal stock number assigned to the item andwill be used for requisitioning purposes.

c. Description. Indicates the Federal itemname and, if required, a minimum description toidentify the item. The last line indicates thereference number followed by the applicableFederal Supply Code for Manufacturer (FSCM) inparentheses. The FSCM is used as an element initem identification to designate manufacturer or

C-2

distributor or Government agency, etc., and is identified in SB 708-42.

d. Unit of Measure (U/M). Indicates thestandard or basic quantity by which the listeditem is used in performing the actual maintenance function. This measure is expressed by a two-character alphabetical abbreviation (e.g., ea, in,pr, etc.). When the unit of measure differs fromthe unit of issue, the lowest unit of issue that willsatisfy the required units of measure will berequisitioned.

e. Quantity Incorporated in Unit. Indicatesthe quantity of the item used in the breakoutshown on the illustration figure, which isprepared for a functional group, subfunctionalgroup, or an assembly. A “V” appearing in thiscolumn in lieu of a quantity indicates no specificquantity is applicable (e.g., shims, spacers, etc.).

f. 15-Day Organizational MaintenanceAllowances.

(1) The repair parts indicated by an asteriskin the allowance columns represent thoseauthorized for use at the organizational categoryand will be requisitioned on an “as required”basis until stockage is based on demand in ac-cordance with AR 710-2.

(2) Major Army commanders are authorizedto approve reduction in range of support itemsauthorized for use in units within their com-mands. Recommendations for increase in range ofitems authorized for use will be forwarded to theCommander, US Army Electronics Command,ATTN: AMSEL-MA-CRA, Fort Monmouth, NJ07703. Any changes approved will be reflected ina revision to the RPSTL.

(3) Allowance quantities are indicated in theSpecial Tools List section for special tools,TMDE, and other support equipment.

g. 30-Day DS/GS Maintenance Allowances.NOTE

Allowances in GS column are for GSMaintenance only.(1) The repair parts indicated by asterick

entries in separate allowance columns for DS andGS represent those authorized for use at thatcategory of maintenance to be requisitioned on an“as required” basis.

(2) Allowance quantities are indicated in theSpecial Tools List section for special tools,TMDE, and other support equipment.

h. 1-Year Allowances Per 100 Equip-ments/Contingency Planning Purposes. Columnintentionally left blank.

i. Depot Maintenance Allowance Per 100Equipments. This column indicates that the

TM 11-6625-654-14

items identified with an asterisk are authorized tobe requisitioned as required.

j. Illustrations. This column is divided asfollows:

(1)numbershown.

(2)number