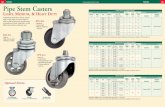

Mrbt 075 Cw d Specifications

-

Upload

jorge-bravo -

Category

Documents

-

view

222 -

download

0

Transcript of Mrbt 075 Cw d Specifications

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 1/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

Contents1. Model Number Nomenclature …...………………………………....…2

2. External Appearance…………………………………………………....3

3. Feature & Benefits………………………………………………….…...4

4. List of Functions…………………………………………………….…..5

5. Specifications…………………………………………………….……...7

6. Dimensional Drawings……………………….………………….….….9

7. Wiring Diagrams………………………………………………….……10

8. Performance Data……………………………………………….……..11

9. Electrical Data……………..……………………………………..….…12

10. Parameter & Pressure Chart for Air Volume………………….…13

11. Refrigerant Cycle Diagram...…………………………………….…14

12. Installation…………..…………………………………………….…..15

13. Wired Controller…………..…………………………………….……15

14. Error Code…………..…………………………………………….…..17

15. Maintenance and Upkeep…………………………………………..18

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 2/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

1. Model Number Nomenclature.

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 3/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

2. External Appearance 7.5 Ton.

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 4/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

3. Feature & Benefits

1. The adoption of anticorrosive-boxThe reinforced anticorrosion by using galvanization armor plate and coated with man-composedpaint.The appearance is stylish and be easy for maintenance. (Has been 1000 hours salt spray test)

2. The adoption of credible protection system2.1 The protection of compressorHigh-pressure protection, low-pressure protection, compressor current protection and so on theseries’ protectors can ensure compressor operating normally.Adopts independent system, except for protections of sequence and wire control output, anyprotection relate to its corresponding compressor. Once a compressor protection energized, thecorresponding compressor will stop, as others working still.

2.2 Fan motorThe fan motors for evaporator have over-heat protection and over-current protection function. Thefan motors for condenser have the temperature controller protection function.

3. Energy saving design3.1 High Efficiency CompressorUsing professional compressor, heat exchanger and optimum connection pipe, the compressor canstartup under low power input.

3.2 CondenserBy using high-efficient thin wing, the condenser has high-efficient heat exchanger, the energy waste

decreases greatly.

3.3 EvaporatorBy using the high-efficient, super thin wing and inner-whorl copper pipe, the evaporators get thehigher capacity and the lower noise level.

3.4 The Heat Insulation of indoor unitThe heat insulation of indoor unit can availably decrease heat loss.

4. Optional collocation4.1 Operation in High TemperatureThe air-conditioner designed for high temperature can run despite the ambient temperature reaches

up to 52℃(125℉).

4.2 Strong Air FlowThe wind is sent off by exterior high static pressure produced by condenser fan.

4.3 Minimum Installation ArrangementThe installation is fast and low cost with the easy installation and ready operation

4.4 Pre-Drilled Duct FlangeFlanges are prepared at the supply and return duct connections so that they can reduce ductconnectionwork at site.

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 5/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

4.5 Quiet OperationNoise and vibration have been effectively reduced by adopting new style hermetic compressor. The

centrifugal fan and fan casing are optimum shaped for efficient and low noise operation.

5. Cabinet5.1 Sloped drain pan and drain pipe

5.2 Cabinets have forklift and lifting holes for easy transportation

5.3 Cabinets have fresh air function, and the filter can be washable.

6. Optional supply/return airflow design, from side or bottom, It could be flexiblyapplied to multi-position.

4. List of Functions4.1 STANDARD SPECIFICATIONSA. GeneralPackaged cooling or combination heating and cooling units suitable for mounting on the roof orground. The packaged unit consists of scroll compressors, cooling coil, condenser coil, control wiringand interconnecting piping- all factory assembled and mounted on heavy gauge G-90 galvanizedsteel sheet press formed base, ready for field connection to utilities and ducts. The packaged unit isof rigid construction with holes provided in the base rails for overhead rigging. The unit is providedwith an integral weather resistant control panel.These units are rated and tested in accordance with ARI standard 210/ARI 360.

B. Unit Enclosure

Panels are of heavy gauge, G-90 galvanized steel sheet with removable access panels, completelyweatherized for outdoor installation and properly reinforced and brazed. Panels and access door areprovided for inspection and access for all internal parts. Enclosures are provided with adequatelyreinforced points of support for setting in the unit. Steel sheet panels are zinc-coated and galvanizedby the hot dip process of lock forming quality conforming to ASTM A 653 commercial weight G-90,followed by baked on electrostatic polyester dry powder coat paint, on all external panel.

C. CompressorCompressors are scroll for all the models. They are provided with all the standard controls andaccessories necessary for safe operation. These are equipped with internal motor protector; factoryinstalled crank case heater and rubber vibration isolator for quiet and efficient operation.

D. Air-cooled Condensing Section1. The air-cooled condensing section is enclosed within the unit housing and consists of condensercoil, fan(s) electric motor(s) and inherently protected compressor(s). Inner grooved copper tubeswith wall thickness of 0.3mm, mechanically bonded to enhanced louvered aluminum fins arestandard for all condenser coils. Return bends have 0.022 inch thickness (0.56mm). As an option,enhanced coated aluminum fins may be provided. Tube support sheets are galvanized steel, formedto provide structural strength.

2. Fans are propeller type, direct driven, upward discharge and provided with fan grille mounted onthe casing.

3. Motors are totally enclosed air-over type with class F insulation. Inherent thermal protection isautomatic reset type.

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 6/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

E. Evaporator Coil Section1. All cooling coils are of enhanced louvered fins and inner grooved copper tubes with wall thickness

of 0.3mm, mechanically bonded to aluminum fins. Return bend has 0.022 inch thickness (0.56mm).As option, enhanced coated aluminum fins may be provided. Tube support sheets are galvanizedsteel, formed to provide structural strength.

2. Drain Pan: An insulated drain Pan made of G-90 galvanized steel is provided, for additionalcorrosion protection.

3. Insulation: Insulation is supplied in adequate density and thickness for all units to preventcondensation from forming on the unit casing. Insulation meets the requirements of NFPA 90A andis protected against deterioration and erosion from air currents.

F. Evaporator FanEvaporator fan is of centrifugal forward-curved blade design capable of handling total required CFM

and static pressure in the low and the medium ranges. Casings are made of galvanized steel.Blower motors are of open drip proof type (totally enclosed types are optional) and conform to NEMAMG-1 and MG-2. Fan drive is through adjustable pitch pulleys and belt driven. Blower motor ismounted on adjustable base and secured by locking device. Fan wheels shafts and bearing areselected to operate at 25% below first critical speed. Pillow block bearing are selected for at 200,000hours average life at design operating conditions.Shaft is turned, ground and polished from solid steel. Fans and pulleys are keyed to shaft anddesigned forcontinuous operation at maximum motor horse power and fan speed. All rotating components andassemblies are statically and dynamically balanced and every unit is vibration tested beforeshipment fromthe factory.

G. Electronic ThermostatsGeneral information: A dedicated electronic thermostat is supplied with unit controls as standard.This thermostat controls one or two stage heating and cooling applications. The thermostat normallydisplays room temperature and mode of operation.The temperature can be set by up/down buttons for both cooling and heating cycles. The thermostatalso allows you to select continuous fan operation, or have the fan on intermittent operation with theequipment. It also displays the status of unit, thus providing maximum information for the end user.

4.2 OPTIONS AND ACCESSORIESA. Electric HeatersElectric heaters are of the resistance open coil type and conform to the requirements of UL 573 orequivalent. Electrical characteristics, kW capacities and number of stages are as indicated. Airflow

switches, fusible links and overheat limit thermostats are provided to shut-off power in case of airflowfailure/overheat. Electric heater kit is installed as an externally mounted kit at the supply opening.

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 7/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

4.3 STANDARD FEATURES/OPTIONS/ACCESSORIES

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 8/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

5 Specifications

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 9/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

6. Dimensional Drawings

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 10/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

7. Wiring Diagrams

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 11/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

8. Performance Data

Cooling capacity for 7.5Ton:

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 12/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

9. Electrical Data

VOL: Unit Power Supply Rated (plated) Voltage (V)Hz: Frequency (Hz)

STC: Starting Current (A)RNC: Running Current (A)IPT: Input (kW)

Note:1. These data are based on the following conditions:Evaporator Air Input Temperature 85 F DB, 66 F WB.Condenser Air Input Temperature 115 F DB.2. The starting current is indicated for each compressor motor.3. The maximum currents of the compressor can be estimated as follows.

Max. IPT×: Compressor power input from the performance table at the expected maximum conditionSTC, IPT, RNC: Compressor data from the above table

4. The data in the compressor motor column shall indicate the respective values of the refrigerationcycle.

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 13/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

10. Parameter & Pressure Chart for Air Volume

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 14/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

11. Refrigerant Cycle Diagram

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 15/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

12. Installation12.1 Service Space1. The recommended clearances for single-unit installations are illustrated in following Fig.These minimum requirements are not only an important consideration when determining unitplacement, but they are also essential to ensure adequate serviceability, maximum capacity, andpeak operating efficiency.

2. Any reduction of the unit clearances indicated in these illustrations may result in condenser coilstarvation or the recirculation of warm condenser air. Actual clearances which appear to beinadequate should be reviewed with a local engineer.

13. Wired Controller1. Standard unit with Midea’s wired controller: KJR-12B/DP (T)-E

KJR-12B/DP (T)-E

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 16/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

2. Optional well-known brand thermostat controller:KJR-23B: For cooling only and cooling with auxiliary heater

KJR-25B: For Cooling and heating

KJR-23B

KJR-25B

Note:When select KJR-12B wire controller, please make sure SW3 have been set at“ON”,

otherwise it should be set at “1”.

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 17/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

14. Error Code

8/3/2019 Mrbt 075 Cw d Specifications

http://slidepdf.com/reader/full/mrbt-075-cw-d-specifications 18/19

MRBT-075-CW-D T3 Condition Rooftop Package

Climate Solution for Green Environment www.mideacac.com

15. Maintenance and UpkeepRegular maintenance and upkeep

Some regular maintenance and upkeep have been carry on by user, includes: change the one-timedust filter, clean casing, wash condenser and replace a new belt, as well as do some test for theequipment.

Regulating belt of rate of tension, inner fan Refer to the following Fig. fixed bolt of electric motor’ssupporting slide was loosened, following electric motor was droved, belt of rate of tension will beginchange.

Method of belt tensioning using belt tension indicatorCalculate the deflection in mm on a basis of 16mm per meter of center distanceCenter distance (m) ×16=deflection (mm).