MOVING TOWARDS MODEL SPECIFICATION GUIDELINES FOR …

Transcript of MOVING TOWARDS MODEL SPECIFICATION GUIDELINES FOR …

MOVING TOWARDS MODEL SPECIFICATION GUIDELINES FOR THE SUPPLY OF READYMIXED CONCRETE IN NEW ZEALAND

JAMES MACKECHNIE

Allied Concrete ABSTRACT Specifications for the supply of concrete to construction projects have a variety of objectives with compliance being either by prescriptive means or specifying performance criteria. Neither approach is without its issues since prescriptive specifications may stifle more creative and practical concrete solutions while performance-based approaches require more testing, can be expensive to check for compliance and the performance criteria targeted may not be relevant to in situ performance required. Specifications for concrete supply are further complicated by the variety of approaches taken by consulting engineers in an attempt to ensure quality concrete is achieved on site. Some of these specifications may be criticised for having unrealistic limits, conflicting requirements, use unreliable surrogate outcomes or specify properties that cannot be objectively measured. The intentions of these disparate construction specifications are well intentioned but these objectives might be better achieved within a more practical framework. This paper presents guidelines for the achievement of concrete performance including workability, compressive strength, dimensional stability and durability. Guidelines are presented on how these properties may best be specified to ensure adequate performance and to provide sufficient confidence that compliance has been achieved during production. A framework is presented where concrete can be specified in a more practical manner with better performance targets that can be measured during production. An alternate approach is also taken to analysing research findings where instead of the normal narrative reviews that may be subjective if not biased by the experience of the author a systematic review or meta-analysis is proposed that is able to more objectively compare the results of different studies to identify patterns and relationships. The approach has the potential to aggregate information providing a clearer assessment of research findings than individual research papers. The benefit of a more systematic approach to reviewing research will be discussed in the context of the Christchurch rebuild where many specifications lag well behind developments in technology and research. Outcomes of this approach are presented that show how prescriptive specifications often stifle progress in optimising concrete properties used in structures. More progressive approaches to specifications are shown to be those where appropriate performance-based specifications are used to ensure compliance of concrete supplied. Graphical methods are used to illustrate these findings, which has the advantage of showing how specified performance may be subject to a range of material, processing and environmental factors and cannot be achieved by mix design alone. James Mackechnie is the South Island plant engineer for Allied Concrete and is also an adjunct research fellow at the University of Canterbury. He is a chartered professional engineer and has a PhD in civil engineering from the University of Cape Town.

INTRODUCTION Specifications for the supply of concrete to construction projects tend to be a combination of prescriptive and performance-based criteria. Prescriptive elements in specifications are generally simple to achieve but sometimes these are in direct conflict with the stated performance required for the project [1]. Internationally there is a movement towards performance-based specifications whereas locally some structural designers appear to favour prescriptive-based approach where recipes need to be followed or specific materials included in concrete mixes such as chemical admixtures or additives [2]. Specification for the supply of concrete to construction projects follow three broad categories:

- Standard specifications where strength grade is specified and practical target slump levels are given or may be nominated by the contractor

- Prescriptive specifications where not only is the strength grade specified but cement content and water/cement ratio is also specified, slump targets are fixed and specific materials or mix design ratios such as sand content are also specified

- Performance specifications are generally only used in challenging projects where high performance is required and while a minimum grade strength is specified the concrete supplier has some latitude to achieve the stated performance required

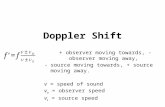

Large infrastructure projects require several properties to be achieved simultaneously in structural concrete as shown in Figure 1. This radar plot provides an indicative idea how the four main cementitious binder systems generally perform when assessing performance in terms of workability, early strength, heat of hydration, 28 day strength, drying shrinkage and durability. This overall performance assessment needs to be considered when finalising concrete rather than focusing on what element such as strength and durability.

Figure 1: Performance factors for infrastructure concrete using different binders

This paper looks at four major performance categories that are commonly specified in construction projects in New Zealand. These are as follows:

- Workability to optimise the placing and compaction of concrete on site - Strength to ensure the structural performance is achieved - Drying shrinkage which may affect service performance and influence cracking - Durability to ensure the structure is able to provide the design service life without

significant amounts of maintenance or repair

WORKABILITY For concrete to be used effective in construction it is important that it is workable enough to allow efficient placement and compaction. Workability of concrete is compromised when using sub-optimal aggregates whether due to shape and/or grading, when using certain binder combinations such as high levels of slag or with high levels of some chemical admixtures such as shrinkage reducing agents or waterproofing agents. Technical mixes that have higher performance targets for hardened properties may therefore require higher slump targets to achieve similar workability to standard concrete produced at a slump of 100mm. Rheological assessment of concrete is able to quantify these differences in workability, which are not seen from simple consistence tests such as slump [3]. Why are lower slump target still specified when use of mid- and high-range water reducing admixtures makes it possible to decouple the traditional relationship between slump and strength? Specifying or nominating a practical slump is still important since it should help the contractor estimate what resources are needed during concrete placing and this can be used to measure the variability in supply, which affects finishing and setting times on site. Slump targets have consistently increased over the last few decades and normal structural concrete is now seldom poured at below 100 mm slump. Structural engineers who revert back to lower slumps such as 80mm are misguided if they think this will result in higher quality. Invariably this causes more problems both in terms of pumping and placing of the concrete due to delays and breakdowns. Specifications should avoid prescriptive slump limits and preferably allow contractors to nominate an appropriate slump, which essentially becomes a performance target. Key messages for workability are summarised in Figure 2 below and require a better understanding of fresh properties of concrete than just a passing knowledge of slump.

Figure 2: Workability issues to be considered in concrete specifications

COMPRESSIVE STRENGTH

Designing concrete mixes relies on the water/cement ratio to predict the compressive strength of the material. A revised version of Abram’s Law provides a good fit for New Zealand materials such that the 28 day strength is determined as follows [4]; 28 day compressive strength fc = 150/(51.5*w/c) MPa …………………….(1)

Typical results measured in New Zealand using different combinations of materials is shown in Figure 3. Equation 1 plots below average and good quality material but does not represent the lower bound limit for all concrete produced. The equation is used to predict actual strength rather than characteristic strength.

Figure 3: Compressive strength versus water/cement ratio

Minimum cementitious contents are regularly specified together with maximum water/cement ratios to hopefully achieve performance such as waterproof or high durability concrete [5]. This prescriptive approach targets the recipe rather than the taste to use a cooking metaphor. Figure 4 shows the problem with this approach since water/cement ratio often does not correlate to the minimum cement contents and neither are these parameters always relevant to the structural grade required for the project. Typical examples of these prescriptive limits are as follows:

- Waterproof concrete requiring a minimum of 300 kg/m3 of cement and maximum water/cement ratio of 0.50, which would mean at least a 35 MPa concrete would need to be supplied with a cement content around 325 kg/m3

- Durable concrete requiring a minimum of 350 kg/m3 of cement and maximum water/cement ratio of 0.40, which would mean at least a 45 MPa concrete would need to be supplied with a cement content of around 400 kg/m3

Figure 4: Minimum binder contents and maximum water/cement ratios

Strength testing using cylinders provides only an index of structural performance since several factors will affect the in situ strength of concrete. Target strengths of concrete are generally 5-10 MPa over grade strength as shown in Figure 5 below [6]. Long-term strength of concrete used in structures may differ from laboratory results at 28 days due to the following factors:

- Compaction difference with test cylinders generally have close to optimum levels of vibration that reduces compaction voids and may increase strength by more than 10% more than standard site compaction

- Curing efficiency of laboratory concrete is optimum both in terms of water retention and curing temperature whereas some site concrete receives little active wet curing and elevated temperature curing will reduce the long-term strength of concrete

Figure 5: Strength limits and ranges for grade 40 MPa concrete in New Zealand

DRYING SHRINKAGE

Drying shrinkage of concrete is relatively easy to determine using AS 1012.13 and effectively measures the free shrinkage of small prismatic test samples over a period of 56 days in a controlled drying environment [7]. Controlling drying shrinkage is seen by many specifiers as a means of reducing the risk of cracking of concrete. The test method was developed in Australia to be able to identify suspect aggregates that significantly increase drying shrinkage of concrete rather than a performance test for crack control. In reality cracking of concrete is caused by multiple factors and in the author’s experience drying shrinkage only accounts for a small percentage of problems as shown in Figure 6.

Figure 6: Summary of causes of cracking in concrete structures around New Zealand

Some concrete structures will be more sensitive to the effects of drying shrinkage and supplying low shrinkage concrete may provide technical benefits (e.g. bridge decks and some flatwork). These shrinkage sensitive structures can be reasonably easily identified by considering the geometry and reinforcing of the structure such that:

- Low shrinkage risk for thick sections such as raft slabs, beams and walls where the surface area to volume ratio is low and the structure is generally heavily reinforced

- Moderate shrinkage risk for industrial floor slabs cast on dpc and medium-sized building elements such as walls and columns

- Higher shrinkage risk for bridge decks exposed on both faces to drying, thinner elements such as panels or where there is significant restraint in topping slabs

A significant number of specifications attempt to limit drying shrinkage by increasing the grade strength of concrete used in specifications. This approach is based on the philosophy that lower strength grades must contain more water and this extra water is what causes higher levels of drying shrinkage in concrete. This rationale is almost 50 years out of date and is no longer relevant when all concrete mixes have significant amounts of chemical admixtures. Modern concrete technology uses water-reducing admixtures to control water demand levels, which are kept relatively constant across all grades. Numerous studies have also shown that increasing the strength of concrete leads to higher levels of drying shrinkage rather than visa versa, since the shrinkage paste fraction increases while the more hygrometrically stable aggregate fraction reduces [8,9]. Water contents are designed to be relatively constant across different structural grades but the actual final water contents in each load will vary due to material, environmental, processing and consistence issues. The concrete production standard NZS304 has an allowable tolerance of ± 2.5% on final water contents but in reality this may vary by as much as 5%, which not only

affects strength but starts to have a significant effect on drying shrinkage of concrete [9]. This is shown in Figure 7 for 30 MPa concrete supplied in Christchurch [10] during 2013 and 2014. Monitoring final water contents or water/cement ratios may therefore be a useful means of controlling drying shrinkage as it done quickly and reliably and at no extra cost to the concrete supplier. Periodic testing of drying shrinkage can then be used to measure actual performance.

Figure 7: Influence of water demand on drying shrinkage of concrete

Setting practical performance limits for shrinkage is also critical since it is only possible to lower shrinkage by 30-40% below normal levels. Aggregate quality varies quite significantly around New Zealand such that some areas might be able to produce concrete with drying shrinkage of 500 microstrain (e.g. dense volcanic aggregates) while other area would have values closer to 900 microstrain (e.g. higher porosity greywacke sandstone). Table 1 shows typical shrinkage values for standard and low shrinkage concrete in Christchurch with the changes in materials, properties and costs. Table 1: Effect of increasing low shrinkage limits on concrete properties (Christchurch)

Shrinkage

(microstrain)

Water

content

Super-

plasticiser

Dose

Shrinkage

Reducer

Dose

Fresh

concrete

properties

Relative

cost

of mix

750 Standard Not required Not required Fine 0%

650 Low Low Not required Ok 2-5%

550 Very low Moderate Moderate Viscous 10-20 %

450 Very low High High Sticky 20-35%

DURABILITY

Concrete structures need to be durable and generally are in most environments. Durability concerns are the result of harsh environmental exposure, modern fast-track construction methods or when dealing with multi-binder systems more common in Europe [11]. Many specifications attempt to deal with these durability concerns using prescriptive limits such as minimum cement contents and/or maximum water/cement ratios. This approach has been shown to have limited value and may not improve the durability performance despite increasing

material costs. A systematic analysis of eight separate research studies is shown in Figure 8, which shows an overwhelming conclusion that increasing binder contents does not improve durability properties for a given water/binder ratio [12].

Figure 8: Meta-analysis showing correlation between paste content and durability properties

Defining appropriate durability tests is complicated by the range of exposure conditions, material interactions and practical testing limitations. Some consensus appears to have been achieved in the area of reinforcing steel corrosion where the resistance of the cover concrete is seen to be the primary factor controlling service life. This is illustrated in Figure 9 where appropriate durability tests for carbonation- and chloride-induced corrosion are shown [13].

Figure 9: Durability test selection for corrosion of steel reinforcement

Marine concrete structures are subject to the most severe exposure conditions whilst often having 100 year service life requirements. Ensuring the concrete has adequate chloride resistance can be done by deemed to satisfy criteria of which NZS 3101 has practical guidelines that acknowledge the superior performance of concrete made with supplementary cementitious materials such as fly ash, slag or silica fume [14]. Increasingly the chloride resistance of concrete needs to be assured by using either resistivity, chloride migration or bulk diffusion techniques. Table 2 shows some of the more common techniques used to measure the chloride resistance of concrete [15,16]. Table 2: Chloride resistance techniques for assessing marine concrete

Test

Method

Standard

reference

Time required

for testing

Reliability

of test

Relative cost

for testing

Resistivity

or conductivity

ASTM 1760

AASHTO TP95 Instant Control test Cheap

Rapid chloride

penetrability

ASTM C1202

AASHTO 277 6 hours Material biases Moderate

Chloride

migration NordTest 492 24 hours Ok Moderate

Bulk diffusion

ASTM C1556

NordTest 443 4-6 weeks Good High

Simple techniques such as resistivity are more appropriate as control tests during construction since these can be done quickly and relatively cheaply. By contrast, techniques such as bulk diffusion that are better able to measure intrinsic properties of concrete such as diffusivity are better specified as final compliance properties. Bulk diffusion test methods take far longer to run and require a significant amount of laboratory testing, which increases costs by as much as $10-20 per cubic metre of concrete. Performance requirements for durability may be consistently achieved if targets are well defined, are practically achievable and have appropriate tolerances. Once these issues are resolved it is possible to provide quality assurance at all stages of the construction cycle as shown in Figure 10.

Figure 10: Performance testing during the design and construction process

MODEL SPECIFICATION GUIDELINES

The US National Readymix Association have developed significant resources to encourage clearer and more progressive specifications for the supply of concrete [17]. These documents could serve as a useful starting point to develop model specification guidelines in New Zealand. There are three main parts to this; general background to the construction standards, performance testing with targets and tolerances and documentation guidelines for specifiers.

Background

Any model specification needs to quote the relevant standards for concrete construction. A brief summary of critical aspects of the concrete production standard (NZS3104) should also be given. The CCANZ guide to specifying concrete for performance (TR10) provides some useful general guidance about major concrete properties but does not provide performance target values [18]. Performance

Details of specified properties required from concrete need to be summarised in terms of acceptable test methods, relevance to in situ performance, typical targets and expected tolerances. Table 4 provides a brief summary of this, which is given to illustrate the approach rather than being an exhaustive review of methods [19].

Table 4: Performance properties of concrete used in New Zealand

Concrete

Property

Test

Method

Relevance to in

situ perform.

Typical

target level

Tolerance for

testing

Workability

Slump

NZS 3112 Pt 1

Spread

NZS 3112 Pt 1

Consistence

target for set

control and

finishing

50-200 mm

500-750 mm

± 20-40 mm

± 50 mm

Compressive

strength

Cylinder strength

NZS 3112 Pt 2

Provides and

index of structural

performance

20-50 MPa

- 3.5 MPa

+ 4.5 – 10 MPa

Dimensional

stability

Drying

Shrinkage

AS 1012.13

Useful to assess

aggregate quality,

does not predict

cracking

500-1000

microstrain

± 75

microstrain

Durability

Chloride

Resistance

NTB 492

NTB443

Quality assurance

for marine

concrete durability

2-5 x 10-12

m2/s

TBA

Documentation

With the advent of electronic documents, details of project concrete properties have become increasingly scattered through specification files. There is more chance that special requirements and conditions for concrete might be overlooked when details are hidden away in drawings and other electronic files. A summary page within the specification outlining all concrete required in structural elements is simple to do and avoids any confusion between contractors and their suppliers. CONCLUSIONS

With the upturn in building and construction surrounding the Christchurch rebuild there has been a shift by some specifiers back towards prescriptive-based specifications. This approach provides less flexibility for concrete suppliers to optimise concrete mixes and may in fact be counter-productive is some cases. Using a performance-based approach to specifying concrete has many benefits but must be well managed to ensure overall structural performance and serviceability are achieved. Summary of findings from this paper are as follows:

- Slump is not a direct measure of workability and practical slump targets need to be set to ensure placing and compaction of concrete is not compromised on site

- When specifying a grade of concrete it is not necessary to prescribe minimum cement contents or maximum water/cement ratios as these are often in conflict with the strength used to design the structure

- Specifying a drying shrinkage limit is only necessary for shrinkage sensitive structures such as bridge decks and toppings and should not be considered as a predictor of cracking risk

- There are a range of durability tests that can be used to measure the resistance of the cover concrete to carbonation or chloride ingress and these need to be carefully considered in terms of speed of measurement, reliability and cost

- Implementing performance-based specifications needs an understanding of the overall framework so that testing is targeted correctly, limits are achievable and there is some allowance for variability

Any framework for establishing performance criteria needs to consider the following:

- Robust quality control tests that can be routinely carried out by laboratory technicians and have both reliability and repeatability as found in cylinder strength testing

- Service life model that is able to relate service performance to the quality control test being used for the concrete

- Allowance for variability and also for difference that are possible between material potential and as built values to allow for construction effects

Understanding the performance of concrete could be improved by agreeing on appropriate methods and developing more local data. This research would then allow for the following:

- Comparing the performance of alternative binders that potentially could be used in New Zealand in the future

- Proving equivalence such as in the debate about the inherent durability of precast concrete where no wet curing is applied after initial thermal curing of concrete that usually has a higher strength grade than specified

- Optimising concrete mixes for sustainability reasons without compromising on other properties such as durability

The way forward in implementing this type of approach should probably be through the technical committee of the NZRMCA with possible involvement by CCANZ and the Concrete Society. Collaboration for Australia and the United States would make sense since this type of approach is already being promoted in these countries. The development of better specification guidelines would also be useful of structural designers as a reference document to better understand concrete as a material. REFERENCES

1. Hover, KC, Bickley, J and Hooton, RD, Guide to specifying concrete performance, NRMCA, RMC Research and Education Foundation, 2008.

2. Beushausen, HD, Alexander MG, Wieland, M and Linsel S, Prescriptive versus performance-based design approaches for concrete durability, Concrete Institute of Australia Conference, Melbourne, August 2015.

3. Mackechnie, JR, Optimising the fresh properties of concrete by understanding rheology, Concrete Institute of Australia Conference, Gold Coast, September 2013.

4. Mackechnie JR, Using high performance concrete in laboratory education of civil engineering students, Ninth High Performance Concrete Conference, NZCS, Rotorua, October 2011.

5. British Standards, BS EN 1992:1-2004, Eurocode 2: Design of concrete structures, 2004

6. Standards New Zealand, NZS 3104: Concrete production, 2003 7. Standards Australia, AS1012:13 – determination of the drying shrinkage of concrete

for samples prepared in the field or the laboratory, 1992.

8. Alexander, MG and Mindess, S, Aggregates in Concrete, Taylor and Francis, 2005. 9. Mackechnie, JR, CCANZ TR11 – Hardened properties of concrete containing New

Zealand aggregates, 2003. 10. Mackechnie, JR, Unpublished laboratory data from Allied Concrete, Christchurch,

2013. 11. RILEM, TC 230-PSC State of the report on performance based specifications and

control of concrete durability, 2014. 12. Angellucci, M, Beushausen, HD, Alexander MG and Mackechnie JR, Specifying

Cement Content for Concrete Durability: Why less is more, FIB Conference, Cape Town, 2016.

13. Salvoldi, BG, Beushausen, H and Alexander MG, Oxygen permeability of concrete and its relation to carbonation, Construction and Building Materials, 85, June 2015, pp 30-37.

14. Standards New Zealand, NZS 3101 – Concrete Structures, Wellington, 2006. 15. Concrete Institute of Australia, Performance tests to assess concrete durability, 2013 16. Concrete Institute of Australia, Durability modelling of reinforcement corrosion in

concrete structures, 2015. 17. RMC Foundation website, www.rmc-foundation.org, 2015 18. Cement and Concrete Association of New Zealand, TR10 – Specifying concrete for

performance, 2005. 19. Bazant, Z, RILERM draft recommendation: TC-242-MDC multi-decade creep and

shrinkage of concrete, Materials and Structures, 48, May 2015, pp 753-770.