Mollier Diagram for R-744 + HFE-170 by use of an Equation ... · Tomoya TSUJI and Toshihiko HIAKI...

Transcript of Mollier Diagram for R-744 + HFE-170 by use of an Equation ... · Tomoya TSUJI and Toshihiko HIAKI...

– 1 –

ISSN 0386-1678

Report of the Research Institute of Industrial Technology, Nihon UniversityNumber 91, 2007

* Associate Professor, Department of Applied Molecular Chemistry, College of Industrial Technology, Nihon University** Professor, Department of Applied Molecular Chemistry, College of Industrial Technology, Nihon University

Mollier Diagram for R-744 + HFE-170 by use of an Equation of State

Tomoya TSUJI* and Toshihiko HIAKI**

( Received June 12, 2007 )

Abstract

Binary interaction parameter in the mixing rule for a van der Waals equation of state was optimized with just one experimental datum of density for a gas mixture, carbon dioxide (R-744) + dimethyl ether (HFE-170), at 377.59 K. Using the parameter, Mollier diagram were drawn in the pressure range from 4 to 20 MPa, and the temperature from 322.04 to 377.59 K. A necessary thrust power was evaluated under the assumption of a refrigerating system repeating isentropic / isothermal compression and expansion in the same range of pressure and temperature.

Keywords: Alternative refrigerant, Mollier diagram, Equation of state, Necessary thrust power

1. Introduction

Mollier diagram is widely used in mechanical engi-neering to design engine, heat exchanger, refrigerating system, and so on. The diagram is generally drawn by equation of state or that of absolute enthalpy based on a huge number of the experimental data. However, the

available diagram is almost for pure substances, and that for mixtures is few except for some refrigerants composed of hydrochlorofluorocarbons. In this study, we proposed a new working fluid, carbon dioxide (R-744) + dimethyl ether (HFE-170), for an earth friendly refrigerating system.

Table 1 show the physical properties1) for a conven-

R-22 R-744 HFE-170

Formula CHClF2 CO2 CH3OCH3

Critical Temperature Tc [K] 369.3 304.1 400.0Critical Pressure Pc [MPa] 4.97 7.38 5.24

Table 1 Physical Properties1) of Refrigerants, R-22, R-744, and HFE-170

Tomoya TSUJI and Toshihiko HIAKI

– 2 –

Fig. 1 Schematic Diagram of the Experimental Apparatus

tional refrigerant, R-22, and alternative ones, R-744, and HFE-170. However, R-744 has the lower critical temperature, and the higher critical pressure. Then, the conventional refrigerating systems should be recon-structed or improved. Otherwise, the critical properties of HFE-170 are similar to those of R-22, and it has been used for an aerosol propellant. Then, the combustibility should be overcome for the refrigerant. Tsang et al.2)

have measured vapor-liquid equilibrium for R-744 + HFE-170. According to the report, the optimized binary interaction parameter, in the mixing rule in equation of state, suggested that a peculiar interaction should be exited between R-744 and HFE-170. Since HFE-170 will be stabilized by addition of R-744, a gas mixture of R-744 + HFE-170 will be widely used as a new working fluid. In this study, The binary interaction parameter, in the mixing rule of equation of state, was optimized from just one datum of density at 377.59 K. Using the parameter, Mollier diagram was drawn for the gas mix-ture, R-744 + HFE-170. A necessary thrust power was also evaluated under the assumption of a refrigerating system repeating isentropic / isothermal compression and expansion in the pressure range from 4 to 20 MPa, and the temperature from 322.04 to 377.59 K.

2. Experimental Section

2.1 Materials

R-744 was purchased from Takachiho Trading Co. Ltd., Tokyo, with the stated purity of 99.99+ %. HFE-170 was purchased from Taiyo Petroleum Gas Co. Ltd., Tokyo, with the stated purity of 99.9+ %. All chemicals were used without further purification.

2.2 Procedure and equipments

Fig. 1 shows a schematic diagram of an apparatus for P-V-T measurement. The apparatus was based on a constant volume method. The equipment and pro-cedure of measurement have been already described elsewhere3), 4). The cell employed was made of stainless steel. The inner volume, and the vacant mass was about 63 cm3 and 0.67 kg, respectively. The precise inner volume was determined with an accuracy of 0.0004 cm3 by weighing the mass of the cell filled with pure water at 298.15 K. The mass was measured with a direct reading balance (EXACT AV 1581, Japan) by a mini-mum capacity of 0.1 mg and a maximum of 1 kg. The

1

2

3

4

5

6

7

8 9

10

11

1: High Pressure Cell 2: Oil Bath 3: Agitator 4: Thermistor Thermometer 5: Heater 6: Air Chamber 7: Vacuum Pump 8: Ribbon Heater 9: Pressure Sensor 10: High Pressure Mercury U-tube 11: Dead Weight Tester:

Mollier Diagram for R-744 + HFE-170 by use of an Equation of State

– 3 –

Fig. 2 P-V-T relationship for R-744 + HFE-170 at 377.59 K (HFE-170: 48.36 mol%)

(2)

was confirmed. Though the P-V-T measurement was carried out for the mixture at a pressure, the precision was thought to be maintained even for the mixture.

In this study, Mollier diagram was drawn by use of equation of state. The equation employed was the van der Waals (vdW) equation.

P = − – –RTv-b

av2

The temperature and molar volume dependences of vdW equation is simple, so the physical properties can be easily evaluated. In eq. (2), a and b is the attractive and the excluded volume parameter, respectively. The parameters, for pure substance, were conventionally evaluated by its critical temperature and pressure.

ai = −27R2T 2c,i

64Pc,i

bi = −RTc,i

8Pc,i(3) (4)

As described before, the critical temperature and the pressure for R-744 and HFE-170 were listed in Table 1.For the mixture, so called conventional type mixing rule, vdW one fluid model, was employed.

a = ∑∑xi xj(1 – ki j )(aiaj)0.5i j

(5)

b = ∑∑xi xj –i j

bi+bj

2(6)

where a binary interaction parameter, kij, was optimized with the experimental data.In Fig. 2, the correlation result was also illustrated. The optimized value was kij = -0.028.The results suggested a strong interaction between a carbon atom of R-744 and an oxygen of HFE-170.

Fig. 3 showed our consideration for the molecular interaction.

experimental temperature was set to 377.59 K, and the precise temperature was measured by a thermistor ther-mometer (Technoseven D461, Yokohama, Japan) within a precision of 0.01 K. The pressure was monitored by a pressure sensor (Erich Brosa EBM 1408-0325, Germany) with an accuracy of 10 kPa. The precise pres-sure was determined by a dead weight tester (Nagano Keiki PD22, Tokyo) with an accuracy of 2 kPa. In the pressure measurement, a mercury U-tube was used to isolate the experimental system, the dead weight tester and its pressure medium, silicon oil.

3. Results and Discussion

3.1 P-V-T relationship and Mollier diagram

Fig. 2 is the experimental result of P-V-T relationship for a gas mixture, R-744 + HFE-170, with the HFE-170 concentration of 48.36% at 377.59 K. Then, the vertical axis, z, indicates compressibility factor given by the following equation.

z = −PvRT

In the figure, the experimental data of pure R-744, and the standard data by Span et al. [5] were also illustrated. As shown in the figure, the experimantal data agreed well with those of literature. Therefore, the reliability

(1)

OC

OO

C

CH

H

H

H

H

H

Fig. 3 Interaction between R-744 and HFE-170

0 2 4 6 8Pressure [MPa]

Com

pres

sibi

lity

fact

or z

[-]

1

0.8

0.6

0.4

0.2

377.59 Kexp. (This work)

std.Span et al.

calc.vdW eq.

[kij = -0.028]

CO2CO2 + CH3OCH3

[CH3 OCH3 48.36 mol%]

Tomoya TSUJI and Toshihiko HIAKI

– 4 –

The thermodynamic relations, for drawing Mollier diagram, were described below:Generally, molar entropy, s, and molar enthalpy, h, were given by ideal and excess ones.

s = sid + sE h = hid + hE(7) (8)

where the entropy and enthalpy in ideal gas state, sid and hid, were calculated from the integration of isobaric molar heat capacity in ideal gas state, Cp

id.

sid (T,P) = sref (Tref ,Pref) + ∫– dT – R ∫–TC id

PdP

Tref

T

Pref

Pp

hid (T ) = href (Tref ) + ∫C dTpid

Tref

T

where, Tref , and Pref is the refference temperature and pressure. In this study, the reference was defined to be 298.15 K and 101.33 kPa. The isobaric molar heat capacity for the gas mixture in ideal gas state was given by the following relation.

C id = ∑ xi C id

ip p,i

where Cp,iid is the isobaric molar heat capacity for pure

substance, and it was given by the following cubic equation with temperature1).

C p,iid = C pa,i + C pb,iT + C pc,iT 2 + C pd,iT 3

The value of these parameters can be available in the literature1).

Table 2 listed the value of the parameters for R-744 and HFE-170. Otherwise, the excess molar entropy and the enthalpy, sE and hE, were given by the following relation.

sE = −hE – g E

T ∂T∂zhE = – RT 2 ∫ − −

Pref

P

P PdP(13) (14)

(9)

(10)

where gE is the excess molar Gibbs free energy given by the following relation similar to that of the enthalpy.

g E = RT ∫ (z–1 ) –Pref

P

PdP

where hE and gE should be converted to hE(v, T ) and gE(v,T) considering the variables in vdW eq. The conver-sion was carried out by using the following relation.

– = – ––PdP

zdz

vdv

Fig. 4 shows the vapor-liquid equilibrium for R-744 + HFE-170 reported by Tsang et al. [1] at 322.04 and 377.59 K, respectively. According to the literature data, a homogeneous gas phase was maintained for the mix-ture with the HFE-170 concentration of 8.00 mol %.

(11)

(12)

(15)

(16)

Substance Cpa,i [J/mol・K] Cpb,i [J/mol・K2] Cpc,i [J/mol・K3] C pd,i [J/mol・K4]

R-744 1.980 x101 7.344x10-2 -5.602x10-5 1.715x10-8

HFE-170 1.702x101 1.791x10-1 -5.234x10-5 -1.918x10-9

Table 2 Coefficient for Isobaric Molar Heat Capacity in ideal gas state1)

Fig. 4 Vapor-Liquid Equilibrium for R-744 + HFE-170 at 322.04 and 377.59 K (Data from Tsang et al.,)

Mollier Diagram for R-744 + HFE-170 by use of an Equation of State

– 5 –

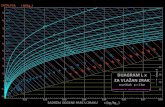

Fig. 5 Mollier Diagram for R-744 + HFE-170 (HFE-170: 8.00 mol%)

Fig. 5 shows the Mollier diagram, the mutual rela-tionship among T, P, s and h, for gas mixture R-744 + HFE-170 in the pressure from 0 to 25 MPa, the tem-perature from 320 to 400 K, and the molar volume from 8x10-5 to 1x10-3 m3/mol.

3.2 Design of Refrigerating System

In this study, a necessary thrust power was evaluated for a hypothetic refrigerating system.

Tomoya TSUJI and Toshihiko HIAKI

– 6 –

Fig. 6 Hypothetic Refrigerating System assumed in this Study

Fig. 7 Temperature Profile and Dimension of Refrigerating Chamber assumed in this Study

Otherwise, a necessary thrust power, W, was given by the following relation.

W = − × −ρVn (TH –TL)∆sη Mw

where n is frequency, and η overall efficiency in the compressor, Mw average molecular weight of work-ing fluid. The value of the efficiency assumed to be 100.0 % for simplicity in the calculation. The exhaust volume of compressor, V, was assumed to be 500 cm3. Under the condition of the exhaust in the compressor, the value of density, ρ, was regarded as that at 4 MPa and 322.04 K. Using eqs. (16)-(18), the frequency was evaluated to be 3432 r.p.m. In case of using a working fluid just composed of pure R-744, the frequency was to be 3501 r.p.m. at the same temperature and the pressure. Therefore, the addition of HFE-170 is slightly effective for decreasing a necessary thrust power.

Acknowledgement

This study was supported by a Grant-in-Aid for Scientific Research (C), No. 1756066, from Japan Society of the Promotion of Science. The authors wish to thank College of Industrial Technology, Nihon University, for an additional financial support of this study. The authors acknowledge Ms. Noriko Hoshi, and Mr. Takeshi Yamaguchi, who were graduated students of master degree, for their assistance of measurements.

Fig. 6 shows the refrigerating system assumed in this study. For the simplicity in the calculations, the work-ing fluid employed was a homogeneous gas mixture of R-744 + HFE-170 with the HFE-170 concentration of 8.00 mol%. In the refrigerating cycle, isentropic / isothermal compression and expansion were repeated in the pressure range from 4 to 20 MPa, and the tempera-ture from 322.04 to 377.59 K. As shown in the Mollier diagram, the cycle can be drawn with bold lines on diagram. The cycle was represent as a rectangle in T-s diagram, because the height and the width correspond to the isothermal and isentropic process, respectively. Therefore, a coefficient of performance (COP), ξ, was given by the following relation.

ξ = − = −TL

TH –TL

qW

where TL and TH are inside and outside temperature of refrigeration chamber, q, heat flow rate, W necessary thrust power for the refrigerating system.

Fig. 7 shows a dimension of refrigerating chamber assumed in this study. The refrigerating chamber was a cube shape with the inner edge of 1 m long. The inside and outside temperature was assumed to be 322.04 and 377.59 K, respectively. Then, the heat flow rate was given by the following relation.

q = UA (TH –TL)

where U is overall coefficient of heat transfer, A effec-tive area of heat transfer. In this study, the value was assumed to be 720 J/m2・s・K.

(17)

(18)

(19)

Mollier Diagram for R-744 + HFE-170 by use of an Equation of State

– 7 –

References

1) Reid, R. C., Prausnitz, J. M. and Poling, B. E., “The Properties of Gases & Liquids 4th ed.”, McGraw-Hill, 1986

2) Tsang, C. Y., Streett, W. B.,Vapor-liquid Equilibrium in the system Carbon dioxide/Dimethyl ether, J. Chem. Eng. Data, 26, 155, 1981

3) Tsuji, T., Honda, S., Hiaki, T., Hongo, M., Measurement of P-V-T Relationship for Carbon Dioxide+n-Butane and Carbon Dioxide+i-Butane

in the vicinity of the critical point, J. Supercritical Fluids, 13, 15, 1998

4) Tsuji T., Tanaka, S., Hiaki, T., P-V-T-x relationship for CO2+C4H10 and CO2+iC4H10 binary gas mixtures and the partial molar volume of C4H10 and iC4H10 at 360.00 K, J. Supercritical Fluids, 29, 215, 2004

5) Span R., Wagner W., A New Equation of State for Carbon Dioxide Covering the Fluid Region from Triple-Toint Temperature to 1100 K at Pressures up to 800 MPa, J. Phys. Chem. Ref. Data, 25, 1509, 1996

Tomoya TSUJI and Toshihiko HIAKI

– 8 –

状態方程式を用いたR-744 + HFE-170系のMollier 線図作成

辻 智也,日秋 俊彦

概 要

地球環境にやさしい冷媒開発を目的として二酸化炭素(R-744)とジメチルエーテル(HFE-170)混合系の密度データ 1点のみから van der Waals状態方程式の2成分系パラメータを最適化して,圧力 4~ 25 MPa,温度 322.04~ 377.59 Kの範囲のMollier線図を作成した。さらにこの温度圧力領域で等温および断熱圧縮・膨張を繰返す仮想的な冷却システムに対して,所要動力計算を行った。

Mollier Diagram for R-744 + HFE-170 by use of an Equation of State

– 9 –

Biographical Sketches of the Authors

Tomoya Tsuji was born on March 1963. He finished Doctor Course, Graduate School of Tohoku University, and then received his Doctor degree of Engineering. After gradu-ation, Dr. Tsuji has been belonging to Department of Applied Molecular Chemistry, College of Industrial Technology, Nihon University. Now, he is an associate professor, and his current work is measurement and prediction of phase equilibrium in chemical engineering, especially research on physical properties of a new energy and refrigerant. He is a member of The Society of Chemical Engineers, Japan (SCEJ), The Japan Society of Mechanical Engineers (JSME), The Society of Separation Process Engineering, Japan (SSPEJ), Japan Society of Thermophysical Properties (JSTP), The Society of Polymer Science, Japan, and The Japan Society of High Pressure Science and Technology. He participates some committees established by Liquified Petroleum Gas Center (LPGC) or The High Pressure Gas Safety Institute of Japan (KHK).

Toshihiko Hiaki was born on February 1955. He graduated from Doctor Course, Graduate School of Nihon University, and received his Doctor degree of Engineering. Dr. Hiaki is a professor of the Department of Applied Molecular Chemistry, College of Industrial Technology, Nihon University. His research topics are measurement, correlation and theoretical interpretation of Physico-Chemical properties, and advanced application of water, for the optimum design and operation of sustainable chemical processes. He is a chairman of the Fundamental Physico-Chemical properties division of the Society of Chemical Engineers, Japan (SCEJ), a general affairs chairman of the Society of Separation Process Engineers, Japan (SSPEJ). He is a member of the American Chemical Society (ACS), the American Institute of Chemical Engineers (AIChE), the Japan Society of Thermophysical Properties, the Japan Petroleum Institute, and the Society of Sea Water Science, Japan.

![The steam-turbine expansion line on the Mollier diagram ... · Buckingham] TheReheatFactor 581 LetTobethekineticenergyperunitmassatAo,oftheaxial component ^ofthevelocity,andTthecorrespondingquantityat](https://static.fdocuments.net/doc/165x107/5c8b2a5809d3f2fa728bdd21/the-steam-turbine-expansion-line-on-the-mollier-diagram-buckingham-thereheatfactor.jpg)