Technology And Innovation Special Supplier - Yizumi Rubber Machinery

Modular Design - YIZUMI-HPM Corporation

Transcript of Modular Design - YIZUMI-HPM Corporation

地:广东省佛山市顺德区大良顺昌路12号 TEL:86-757-2921 9800 86-757-2926 5150(overseas) www.yizumi.com

DP-N(550-3500 US Tons)

DP-N Series Two-platen Injection Molding Machine

YIZUMI-HPM Corporation

3424 State Route 309 Iberia, Ohio 43325TEL: 740-382-5600 www.yizumi-hpm.com Email: [email protected]

DP-N Series Two-platen Injection Molding Machine

DP-N Series Two-platen Injection Molding MachineWe Walk Alongside The World

01 02

Yizumi-HPM Corporation is a manufacturer of high quality hybrid injection molding machinery from 60 to 3500 tons, and hot and cold chamber die casting machinery from 200 to 4500 tons. HPM has been supplying injection molding machinery and support services to the plastic industry since 1931, and has thousands of Injection Molding and Die Casting Machines in operation throughout North America.

HPM Company was incorporated in 1877 as the Hydraulic Press Manufacturing Company in Mount Gilead, Ohio, with the purpose to design and build hydraulic presses for the extraction of apple cider. Through the sales efforts of its founders, the company marketed its products to most fruit-growing areas in the United States and Canada, gaining credibility primarily through word-of-mouth advertising. HPM started to manufacture hydraulic presses that were used in a number of markets, including textiles, railroads, and food processing.

In March of 2011, YIZUMI Precision Machinery Co., Ltd, located in China, acquired all HPM intellectual properties. Shortly after the purchase, HPM North America Corporation was set up in Marion, Ohio. In 2017 HPM North America changed its name to Yizumi-HPM Corporation to be representative of the formidable international company that we are a part of today.

Yizumi-HPM Corporation sells and manufactures injection molding machines and die casting machines based upon the HPM designs but utilizing the engineering, manufacturing and financial strengths of YIZUMI. It is not only the service and technical center of YIZUMI in North America; it’s also a very important step of the globalization strategy of the company. I hope with further global operation of HPM and YIZUMI brands, we can provide our customers worldwide with our best products and services. - Richard Yan, CEO of Yizumi

About Yizumi-HPM Corporation

Precision & Stability High Efficiency & Energy Saving

Special Processes◆ Based on Germany modular design and excellent equipment structure, a variety of special processes solutions, such as injection compression molding (ICM) technology, FoamPro microcellular foam technology, precision mold-open technology, secondary mold-close technology, carbon fiber-based lightweighting technology, long glass fiber (LGF) injection molding technology and multi-material micro injection molding technology are available.

High-response servo valve control technology and ultrasonic displacement sensor are applied to mold closing and opening, with accurate position control and mold-open repeatability up to ±0.1mm.

Clamping unit is highly rigid. There is no contact and frictional resistance between the movable platen and tie bars so that motion becomes faster. With the diagonally-positioned high-speed cylinders, four short-stroke high-pressure cylinders and synchronous locking nut mechanism, mold closing and closing and generation of clamping force happen in less time and dry cycle becomes very short, reducing cycle time and improving productive efficiency by 22%.

The high-performance Ecoservo drive and piston variable pump system can provide pressure and flow as needed and has merits of strong power and fast response, consuming 56% less energy than traditional drive systems.

Three Value Propositions

Fully-closed-loop control of the injection and h o l d ( p r e s s u r e a n d v e l o c i t y ) s t a g e s , numerically-controlled proportional back pressure and part repeatability ≤ 3‰.

Yizumi-HPM's cost-effective two-platen injection molding machine not only brings high productivity for injection molding production, but also higher return on use value to customers through stable performance and high product quality. DP-N series is your trustworthy better choice in the long term.

Yizumi-HPM Corporation

Yizumi-HPM Team Yizumi Shunde (Wusha) Production Base Yizumi Suzhou (Wujiang) Production Base

Yizumi Headquarters

DP-N Series Two-platen Injection Molding MachineWe Walk Alongside The World

Modular Design

Precise, Efficient, Energy-saving

※ Data above are reference criteria for factory test.

03 04

High-rigidity platen and precise mold openingBox-shape platen is designed for high rigidity and high parallelism. Mold closing and opening are controlled by high-response servo valve with mold-open repeatability up to ±0.1mm.

Steadier mold supportThe moving platen is supported by extended rigid sliding shoes with the function of tilt adjustment and L-shape guide design, providing steady support and precise guidance for the mold.

More accurate position controlMeasurement of stroke is performed by the ultrasonic displacement sensor which is resistant to interference and durable, with accuracy up to 0.001%/F.S.

Lower energy consumptionHigh-performance Ecoservo drive technology, a standard feature for the DP series, is integrated with the piston variable pump system to offer strong power and fast response, resulting in 56% less energy consumption.

Higher efficiencyWith further optimized clamping unit, mold closing and opening and generation of clamping force happen in shorter time and dry cycle time (EUROMAP 6, dry cycle time of UN1000DP up to 4.1sec) is reduced, with productive efficiency up by 22%.

More reliable and stable clamping unitThe high-pressure clamping cylinder, parallel locking nut mechanism and tie bars are made of high-quality materials and subject to special technical processing so that they are durable and reliable. Tie bars are designed with uniform stress distribution, which ensures the clamping unit works reliably and stably.

Better injection precisionDouble parallel cylinders and patented dual proportional closed-loop control technology are applied to injection, with high injection repeatability and repeatability of part weight ≤ 3‰.

Professional control systemAustria s KEBA controller works faster and it is powerful enough to offer a variety of control software solutions for special processes.

’

DP-N Series Two-platen Injection Molding MachineWe Walk Alongside The World

Injection Unit

DP-N Series Two-platen Injection Molding Machine

Offer You Multiple Solutions

05 06

Car grille Bumper TV frameWashing machine tub Air conditioner panel Plastic pallet Rubbish binCar light

Application Examples

*Calculation of injection unit model based on international standards: shot volume [cm ] × max. injection pressure [bar]/1000

*Larger platens are optional (see specifications).

3

Model

UN550DP-N

UN770DP-N

UN1200DP-N

UN1650DP-N

UN2000DP-N

UN2500DP-N

UN3000DP-N

UN3500DP-N

UN990DP-N

5450048001885 2695 6150

2.362 2.677 2.992 2.677 2.992 3.307

3330

2.992 3.307 3.622

2.992 3.307 3.622

3.307 3.622 4.252

3.307 3.622 4.252 3.622 3.937 4.5672.677 2.992 3.307

3.307 3.622 3.937

3.9373.622 4.252

3.9373.622 4.252

6800

3.9373.622 4.252

3.9373.622 4.252

9000 12050 18500 23750 31750 44500 54500 75500 100000

4.2523.937 4.567

4.2523.937 4.567

4.2523.937 4.567

4.2523.937 4.567

4.9214.567 5.315

4.9214.567 5.315

4.9214.567 5.315

4.9214.567 5.315

4.9214.567 5.315

5.7095.315 6.102

5.7095.315 6.102

5.7095.315 6.102

5.7095.315 6.102

5.7095.315 6.102

5.7095.315 6.102

6.1025.709 6.496

6.1025.709 6.496

6.1025.709 6.496

6.1025.709 6.496

6.1025.709 6.496

6.4766.102 7.087

6.4766.102 7.087

6.4766.102 7.087

6.4766.102 7.087

7.487.087 7.874

7.487.087 7.874

7.487.087 7.874

7.8747.48 8.465 9.0558.465 9.646 9.6469.055 10.236

7.8747.48 8.465 9.0558.465 9.646 9.6469.055 10.236

Clamping Unit

④

⑤

⑥

⑦

⑥ ⑦

⑤④③

②①

07 08

DP-N Series Two-platen Injection Molding MachineWe Walk Alongside The World

Highly-rigid extended platen supports

Safety foot plates

Open ejector mechanism

Automatic tie bar retraction

High-rigidity platens are designed as box structures with high degree of parallelism, large space between tie bars, large mold thickness and long mold-open stroke.

Mold closing and opening are controlled by high-response and high-speed proportional valves, with mold opening repeatability up to ±0.1mm.

Diagonally-positioned high-speed cylinders enable mold closing and opening to be faster and effectively shorten dry cycle.

Clamping force is quickly generated thanks to the synchronous locking nut mechanism and four short-stroke high-pressure cylinders.

Compact two-platen clamp unit saves space by 20%.

Large areas of safety foot plates that harbor no oil or water are mounted in the areas of front and rear safety gates and mold. Separate safety switches are connected to the control ler for safety, completely conforming to GB22530-2008 national safety standard.

The automatic tie bar retraction function is optional and designed with stability and reliability. It can remove the restriction of factory ceiling height.

The open double-cylinder ejector mechanism is easy to install and maintain. Ejection synchronized with mold opening and forced ejector-backward are available.

The moving platen is supported by exceptionally long, rigid sliding shoes with the function of tilt adjustment and L-shape guide design, providing steady support and precise guidance for large molds.

①No frictional resistance, faster mold opening and closing, no need of tie bar lubrication and clean mold area without oil stain.

No contact between tie bars and movable platen

②High-pressure cylinders offer large mold opening force, which solves the problem of difficult mold opening in the production of deep-cavity parts.

High-pressure mold opening

③The fast, reliable and durable synchronous locking nut mechanism is driven by patented impact-cushioning cylinders and performs movements accurately.

Synchronous locking nut mechanism

UN2500DP-N

DP-N Series Two-platen Injection Molding MachineWe Walk Alongside The World

③

④

②

①

◆

◆

◆

◆

◆

Injection Unit ①

②

③

④

Carriage supports and linear guide rails

09 10

Thanks to modular design, each clamping unit can be combined with different injection units to meet diversified needs of injection molding applications.

Combination of advanced drive technology and further optimized plasticizing unit brings better plasticizing effect, so that molding of precision parts is no longer difficult.

Double-parallel-cylinder injection, fully-closed-loop control of the injection and hold (pressure and velocity) stages, numerically-controlled proportional back pressure and stable injection end position ensure part repeatability is less than or equal to 3‰.

Ceramic heater bands are used for barrel heating and it is under self-tuning PID temperature control performed by Austria s KEBA controller, with control accuracy up to±0.5℃. The heater bands have long service life and low energy consumption.

Specialized bi-metallic barrel assembly resistant to wear and corrosion is optional to meet requirements of different materials.

High-rigidity carriage supports and double-deck guide rails are designed with low resistance and ensure high injection precision.

Injection and injection carriages are equipped with ultrasonic displacement sensors which are resistant to interference and durable, with measurement accuracy up to 0.001%/F.S.

Barrel is mounted with a press plate. The injection unit and barrel assembly are detachable as a whole, which greatly shortens the barrel unit replacement time.

Two injection carriages are parallel located. The universal coupling used for connection ensures stable nozzle contact and no plastic leak.

Ultrasonic digital displacement sensor

Quick barrel change mechanism

Injection carriage cylinder

’

Hydraulic System ◆

◆

◆

11 12

Data above are reference criterions for factory tests.

① Precision filtration and cooling system

② Humanized designThe cabinet of the drive unit is designed with L-shape covers available to opened, which is maintenance-friendly.

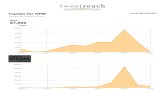

③ Fast responseWith the use of advanced Ecoservo drive technology, the system response time is only 50ms.

④ Strong powerThe power system employs Italy s branded servo motor and imported piston variable pump, with fast response, high overload capacity, double energy savings and energy consumption reduction up to 56%.

’

39Set speed(rpm)-200.0

-150.0

-100.0

-50.0

0.0

50.0

100.0

150.0

200.0

250.0

300.0

-2500

-2000

-1500

-1000

-500

0

500

1000

1500

2000

2500

-2500

-2000

-1500

-1000

-500

0

500

1000

1500

2000

2500

-200.0

-150.0

-100.0

-50.0

0.0

50.0

100.0

150.0

200.0

250.0

300.0

37Given oil pressure 38Oil pressure feedback

40Set speed(rpm)0.0 400.0 800.0 1200.0 1600.0 2000.0

③

④

②

①

The excellent performance of DP -N series benefits from the high-performance Ecoservo drive technology and the piston variable pump, which has strong power, fast response, little internal leak and significant energy savings.

The drive system and injection unit will be matched in the form of modules so as to customize the power for machine and minimize energy loss.

Mold opening during plasticizing, ejection or core pulling is a standard feature that reduces cycle time.

T h e h y d ra u l i c s y st e m i n c l u d e s G e r m a n y s H Y D A C low-pressure oil filter and cooling system, with separate filtration and cooling. Filter fineness up to 5μm ensures clean hydraulic circuit, stable oil temperature and reliable, durable hydraulic components.

’

DP-N Series Two-platen Injection Molding MachineWe Walk Alongside The World

Professional control system Powerful and accurate in controlQuick process parameters setting and easy operation

◆ Stable, fast and accurate control

◆ Easy to operate

◆ Data and safety

Control System

Sequence of machine movementsProduction process data control

Mold closing settings Injection curve

13 14

Double-CPU control, 1ms of scan cycle, faster response and high reliability Real-time accurate control of mold closing and opening and injection by the intelligent high-response closed-loop controller

Storage of process data without limit Memory of alarm and process parameter change Process quality control (PDP), statistical process control (SPC) and data export Multi-level user access ensuring data safety, multiple protections of equipment and operator through software and hardware Networked remote control

Online conversion of multiple languages and units Multiple means of quick input, such as graph and virtual keyboard Easy and convenient process parameter setting

● ●

●

●

●

●

●

●

●

●

DP-N series employs Austria s KEBA control system with user-friendly interface and higher processing speed. It is also powerful and capable of providing multiple control software solutions for special processes.12'' TFT color touch screen, visualized graphic parameter setting, actual parameter values recorded and displayed with curves, more accurate online process analysis Free programming is available to meet the needs of special molds and processes. The sequence of machine movements also can be freely edited. Extensible I/O modules can integrate with more functions, including temperature control and sequence valve as needed. Communication ports for printer, auxiliary equipment and automation.

◆

◆

◆

◆

◆

’

◆ Mold closing for the second time with larger pressure ◆ Effectively prevent possible internal stress in molded parts and air trap◆ Improve the accuracy and appearance quality of molded parts for higher QC passing rate

Secondary mold closing

Part

qua

lity/

g

Molded part repeatability 934932930928926924922920

Test part: automotive lampshadeRepeatabilityWithout secondary mold closing :0.725%With secondary mold closing:0.715%

TimesWithout secondary mold closing With secondary mold closing

1 2 3 4 5 6 7 8 9 10

◆ Mold opening driven by high-pressure cylinders with large opening force ◆ Solution to difficult mold-open in the manufacture of deep-cavity parts

High-pressure mold opening

FoamPro microcellular foam technology

Technical points:

● Injection compression molding (ICM) function● SmartClamp technology realizes automatic calibration of platen parallelism, with response accuracy up to ±0.015mm/2ms.

Low-pressure injection molding technology

。

Technical points:

● SmartClamp technology ● Aircraft aluminum mold technology● Alternative temperature technology (ATT) ● FLEXflow servo-driven hot runner system

※Data above are reference criteria for factory test.

With the use of rigorous and innovative Germany processes, DP-N series gives every material distinctive properties and provides new ideas of application and efficient, intelligent material combinations.

Yizumi-Hpm is committed to becoming a leader in China’s injection molding machine industry and provide you with cost-saving injection molding solutions and the best investment return.

Applied to production of deep-cavity parts, including washing machine

drum, rubbish bin and storage box

For automotive applications, such as car lights and applications in household appliances industry

15 16

Special Processes DP-N Series Two-platen Injection Molding Machine

DP-N Series Two-platen Injection Molding MachineWe Walk Alongside The World

Carbon fiber molding

Carbon fiber has been widely used in passenger cars. The greatest advantage of carbon fiber as an automotive material is light and strong, which will facilitate breakthroughs in automotive lightweighting and bring a social benefit: energy saving. In the future, “high carbon fiber” will become increasingly popular.

HP-RTM (high-pressure resin transfer molding), completed with the use of preform, steel mold, vacuum-aided exhaust, high-pressure injection and high pressure, thermoset composites impregnation and solidification technologies Insitu polymerization technology

◆

◆

Reaction technology

Carbon fiber composite preform Processes such as heating, press forming, back injection and trimming of preform

◆◆

Injection molding technology

◆ Higher added value of molded part ◆ Enhanced mechanical property of molded part ◆ Better appearance of molded part ◆ Improved productive efficiency◆ Less investment cost

Technology of multi-material micro injection molding via second injection unit

◆ Accurate horizontal rotator positioning and control technology ◆ Spray painted part surface replaced by high-gloss appearance

Technical points:

17 18

DP-N Series Two-platen Injection Molding MachineWe Walk Alongside The World

Main Part List (Standard) Part Name

Control system

Servo motor

Piston variable pump

Servo valve

Proportional valve

Key control valve

Pressure sensor

Seal

Hydraulic motor

Low-pressure oil filter

Oil cooler

Suction filter

Barrel assembly

Tie bar

Tie bar locking nut

Clamping piston

Servo drive

Solid-state relay

Automatic switch

Air switch

Position limit switch

Proximity switch

AC contactor

DTFLOCK self-locking nut

KEBA

PHASE

Rexroth/YUKEN

Rexroth

Rexroth

Rexroth/YUKEN

Danfoss

MTS

SKF

STAFFA/HAGGLUNDS

HYDAC

HYDAC

Rexroth

TAN STAR/Huaye

GENERAL&GENESIS

GENERAL&GENESIS

GENERAL&GENESIS

Inovance

KUDOM

ABB

FUJI

SCHMERSAL/Schneider/Panasonic

AUTONICS

FUJI

DTF

Austria

Italy

Germany / Japan

Germany

Germany

Germany / Japan

Germany / Italy

America

Sweden

Britain / Sweden

Germany

Germany

Germany

Taiwan / China

Taiwan

Taiwan

Taiwan

China

Britain

Switzerland

Japan

Germany/ France/ Japan

Korea

Japan

America

Brand / Specifications Place of Brand

Standard and Optional FeaturesStandard Optional Standard Optional

- 8 sets of hydraulic sequence valve (bi-directional)

Optional feature

- High-performance servo pump system- Real-time display of the pressure of power unit via pressure sensor

- High-precision low-pressure oil filter

- Imported-brand hydraulic valve - Low-noise energy-saving hydraulic circuit- Proportional back pressure control for plasticizing - Proportional pressure control of injection

- Reliable hydraulic piping- Modular combination of power- Oil pre-heating system

- Oil level monitoring and alarm - Openable protective cover of pump motor- 4 sets of electrical connectors of core puller/ unscrewing devices. 2 sets each on the fixed platen and moveable platen - Differential mold opening circuit- Injection and mold-close pressure protection- High-pressure mold opening

- Precision independent filtration and cooling systems - Automatic pressure and flow calibration

- Imported branded seal- Automatic oil temperature inspection and alarm- Panel cooler and automatic cooling pump - 6 sets of sequence (injection ) valve interface- Closed-loop proportional variable displacement pump system

- Variable displacement pump system- High-response accumulating servo injection system- Enlarged oil cooler- Enlarged multi-capacity pump motor - Closed loop servo control of injection, plasticizing, holding pressure and back pressure

- Plasticizing during mold opening (quick plasticizing)- Multiple sets of electrical connectors of core puller or unscrewing devices (optional, increasable )

- Core puller pressure relief - Gate pressure relief - Quick connector for core puller and hydraulic gate - Independent hydraulic gate control system

● Other- Operation Manual- Adjustable leveling pad

- 4 sets of lifting rings- Stainless steel hopper - Glass-tube cooling water flowmeter- Mold clamp- Mold temperature controller- Automatic loader - Dehumidification dryer

- Other auxiliary equipment

Standard feature

19 20

- Clamping mechanism with tie bars independent of moving platen

- Simultaneous ejector or core-pull movements - SPI ejector pin hole

- High-rigidity clamping frame

- Quantitative volumetric automatic lubrication system

- Open ejection mechanism hydraulically-driven by double parallel cylinders

- High-accuracy ultrasonic displacement sensor measuring stroke of tie bars, mold opening and closing and ejection

- High-rigidity box-shape platen

- Low-pressure mold protection

- Electrically-protected safety foot plates of mold area and safety gates

-One-button automatic mold adjustment

- Clamping force adjustment as needed

- Ejection/ tie bar reset/ plasticizing/ core pulling during mold opening

- Robot mounting hole as per EUROMAP 18- Fixed platen with solid sliding bearing

- Platen with T-slot and mold mounting hole- Sliding support with steel-base copper alloy lubricating bearing- Hardened spring steel strips and guide rails- Four platens made of high-rigidity ductile iron- Hydraulic and electrical safety devices- Secondary mold closing- Low-pressure injection molding - Forced return of main ejector pin- Protective plate in mold area- SPI mold locating ring - Quick mold change system- Hydraulic mold clamp- Magnetic platen - Safety mechanical lock device - Heat insulating plate of mold- Special mold mounting hole- Increased mold opening stroke- Increased mold thickness - Increased ejector stroke- Larger ejection force- Mold-open cylinders exchange - Automatic tie bar retraction (upper tie bars optional)- Ejector-backward protection switch- Ladder for maintenance of fixed platen - Central water pan - Stainless steel material receiving pan- (Rear, lower) mold-open cylinder safety cover

● Electrical Control System- CE certified- Voltage: 460V/3Ph/60Hz - 16 sets of input/output points reserved- PID closed-loop control of barrel and nozzle temperature- Manual, semi-auto and fully-auto operating mode - Input and output inspection interface- Automatic display of alarm messages and acousto-optic alarm system

- Built-in software with the oscilloscope function- Unlimited technical parameter storage

- Chinese and English operating system- Safety gate emergency stop function- Online cycle monitoring

- 12"TFT color touch screen- Visualized graphic programming- PDP interface- Auto-protection of injection monitoring

- Auto-protection of mold closing monitoring- Statistical process control (SPC) interface- Electrical enclosure rated IP54- Screw speed detecting device- Time/ position/ time + position control modes for switchover to holding pressure

- 3 sets of 380V 32A socket - 1 set of 380V 16A socket - 1 set of multi-function 220V socket - 16-level password security- EUROMAP 12 robot interfaces - Automatic heat preserving, automatic heating and group heating settings

- Phase sequence protection- Oil cleanliness monitoring- Warning or motor switch-off due to stepping on safety foot plate

- Electric unscrewing device- Hot runner control system- Auxiliary emergency stop

- Air blast (one set on fixed platen and one set on moving platen)

- Electric unscrewing device interface

- Central (networked) monitoring system- Protective light grid of safety gates- Opto-electronic safety switch of front and rear safety gates- Protective light grid of central safety foot plate- Safety switch for front safety door edge

- Robot interfaces based on EUROMAP 67

- KEBA 5000 control system

● Injection Unit- Double-cylinder injection system- Low-speed high-torque hydraulic motor

- Hopper loading platform

- 5-stage plasticizing speed/ pressure/ position control- Selectable suck-back before or after plasticizing

- Linear guides for injection carriage- Linear guides for injection - Double-deck injection unit - Double carriage cylinders - Protective cover of injection unit - Screw cold start protection- Suck back function- Automatic material cleaning

- Manual central lubrication system of injection unit- Dual-cycle cooling water for feed opening - Ceramic heater band- Screw rotation measuring device

- Lifting and change of the whole barrel assembly- Mounting interface for hopper loading platform

- Mixing screw - Bi-metallic screw

- Swivel injection unit

- Extended nozzle (50/100/150/200mm longer)

- Special screw components- Barrel heat-retaining energy-saving device (silicone cover)- Spring shut-off nozzle- Increased injection stroke- Servo injection system - Nitrogen injection system

- Special low-pressure injection molding system - MuCell system - System dedicated to UPVC pipe fitting- Accumulator system for large shot volume production

- Auxiliary ladder -Hopper sliding device - Enlarged plasticizing motor

- Second injection unit for micro injection molding

- 10-stage injection speed/ pressure/ position control

- 10-stage holding pressure speed/ pressure/ position/ time control

● Hydraulic System

- Bi-alloy barrel- Heat preservation cover for barrel and safety nozzle cover (with electrical protection)

- High-accuracy ultrasonic displacement sensor measuring stroke of injection, plasticizing and carriage

- 10-stage injection speed/ pressure/ position control

- High-response servo control of pressure and flow for mold opening and closing

Ultrasonic digital displacement sensor (non-contact)

We Walk Alongside The World

● Clamping Unit

Technical Specifications of UN550DP-N

63.0047

1.Dry cycle time accords with EUROMAP 6.2.The load-bearing capacity of the moving platen is 2/3 of the total mold weight.3.The shot weight is calculated by GPPS and it is 0.92 times of the theoretical shot volume.4.The injection unit data are in international units and calculated as follows: theoretical shot volume[㎝³]×injection pressure [Mpa]/1005.Plasticizing capacity is calculated by GPPS ( for the injection unit model 18500 and smaller ones ) or PP ( for injection unit above model 18500 ).6.Because of constant technical improvement, the machine specifications are subject to change without notice.

UN550DP-N

2.36260

50.903834 27

767 32779226 22.6

19.651322

2.67768

65.3821071

35 986

25527176 20

25.265414

4.488114

11.61295250

278729.8022.2

514.84131.9

2.99276

81.6711338

431231

20450141 20

31.551517

29.80 22.2

33.0024.6

1885 2695 3330 4800UNITDESCRIPTION

inmmcu incm3

ozg

psiMPa

cu in/scm3/sin/s

mm/sin

mmr/min

NmhpkWPCS

US tonskN

Screw L:D ratio

Screw diameter

Theoretical shot volume

Shot weight

Injection pressure

Injection rate

Max. injection speed

Screw stroke

Max. screw speedScrew torque

Heating capacity

Nozzle contact force

Barrel heating zone number

2.67768

73.1391198

391103 32633

22522.3

23.374383

2.992 76

91.361497

491377

2610718020

29.171478

4.134105

12.99330184

445935.4026.4

614.83131.9

3.30784

111.6061829

591683

2132114720

35.640584

2.99276

102.4341678

551544

2886319922.1

26.242430

3.30784

125.1352050

671886

23496162 20

32.101526

3.74095

14.57370147

5573

3.62292

150.1052460

802263

1972513620

38.570632

3.30784

135.2812217

722039

31618218 21.9

31.490516

3.62292

162.2752659

86 2446 26252181 20

37.776619

3.66193

15.75400154

6967

4.252108

223.6273664119

337119000131 20

52.057853

35.4026.4

41.4030.9

44.4033.1

614.83131.9

44.4033.1

48.5036.2

50.7037.82

627.81247.3

50.7037.82

Injection Unit

.

Clamping force

Opening stroke

Platen size

Space between tie-bars

Mold thickness

Max.opening stroke

Max.daylight

Ejector force

Ejector stroke

Ejector number

System pressure

Motor

Total power

Clamping Unit

Electrical & Hydraulic Units

General

US tonskN

US tonskNin

mmin

mmin

mmin

mmin

mmUS tons

kNin

mmPCS

psiMPahpkWhpkW

galL

S/inS/mm

lbmT

lbmTinm

Oil tank capacity

Dry cycle

Max.mold weight

Machine dimensions

Machine weight (clamping+injection units, no oil)

5625000

44390

50x49.61270x1260

35.83x32.68910x830

13.78-35.43350-900

51.18130064.961650

121109.8425021

2538, 435117.5,30

52.84+21.99+10.0639.4+16.4+7.5

171.6650

5/25.085/63717600

826400+8800

12+4307.09x94.49x102.36

7.8×2.4×2.6

198750

4.4/25.084.4/63717600

826400+11000

12+5307.09x94.49x102.36

7.8×2.4×2.6

198750

4.4/25.084.4/63717600

826400+12100

12+5.5 307.09x94.49x102.36

7.8×2.4×2.6

2641000

4.2/25.084.2/63717600

826400+14300

12+6.5342.52x94.49x102.36

8.7×2.4×2.6

114.6685.5

114.6685.5

117.8787.9

2538, 435117.5,30

52.84+38.49+10.0639.4+28.7+7.5

136.78102

136.78102

142.82106.5

2538, 435117.5,30

52.84+38.49+10.0639.4+28.7+7.5

145.77108.7

145.77108.7

149.92111.8

2538, 453117.5,30

74.56+38.49+10.0655.6+28.7+7.5

173.79129.6

173.79129.6

186.13138.8

Model

UN550DP-N-IU1885

UN550DP-N-IU2695

UN550DP-N-IU3330

UN550DP-N-IU4800

L H1 H2 W

mm in

7751

7751

7751

8681

305.157

305.157

305.157

341.772

mm in

1617

1677

1555

1565

63.661

66.024

61.220

61.614

mm in

2360

2542

2420

2430

92.913

100.079

95.276

95.669

mm in

2198

2198

2198

2333

86.535

86.535

86.535

91.850

mm2

70

70

70

70

Full-loadcurrent

A

169

181.7

210.4

250.4

in2

0.109

0.109

0.109

0.109

Sectional area of main power cord

Bearing capacity of foundation

Number of cooling water line port

Cooling water flow (mold excluded)

t/m2

7.5

lbm/in2 n×L/min n×gal/min

16500 (10+10)×11 (10+10)×2.90

L/min gal/min

160 42.24

Cooling water pressure

bar psi

3~4 43.5~58

Cooling water pressure

bar psi

5~6 72.5~87

UN550DP-N Machine Dimensions

UN550DP-N Platen Dimensions

21 22

Cooling water inlet/outlet for moving mold halvesCooling water inlet/outlet for fixed mold halves Water inlet/outlet for oil cooler

Power port

Robot mounting holes according to Euromap 18/E14

Model

UN770DP-N-IU2695

UN770DP-N-IU3330

UN770DP-N-IU4800

UN770DP-N-IU6800

L H1 H2 W

mm in

8128

8128

9058

9058

320

320

356.614

356.614

mm in

1757

1635

1818

1645

69.173

64.370

71.575

64.764

mm in

2622

2500

2510

2510

103.228

98.425

98.819

98.819

mm in

2198

2198

2333

2711

86.535

86.535

91.850

106.732

mm2

70

70

70

95

Full-loadcurrent

A

200.2

210.4

247.9

261.4

in2

0.109

0.109

0.109

0.147

Sectional area of main power cord

Bearing capacity of foundation

Number of cooling water line port

Cooling water flow (mold excluded)

t/m2

7.5

lbm/in2 n×L/min n×gal/min

16500 (10+10)×11 (10+10)×2.90

L/min gal/min

160 42.24

Cooling water pressure

bar psi

3~4 43.5~58

Cooling water pressure

bar psi

5~6 72.5~87

UN770DP-N Machine Dimensions

UN770DP-N Platen Dimensions

23 24

Technical Specifications of UN770DP-N

1.Dry cycle time accords with EUROMAP 6.2.The load-bearing capacity of the moving platen is 2/3 of the total mold weight.3.The shot weight is calculated by GPPS and it is 0.92 times of the theoretical shot volume.4.The injection unit data are in international units and calculated as follows: theoretical shot volume[㎝³]×injection pressure [Mpa]/1005.Plasticizing capacity is calculated by GPPS ( for the injection unit model 18500 and smaller ones ) or PP ( for injection unit above model 18500 ).6.Because of constant technical improvement, the machine specifications are subject to change without notice.

.

Clamping force

Opening stroke

Platen size

Space between tie-bars

Mold thickness

Max.opening stroke

Max.daylight

Ejector force

Ejector stroke

Ejector number

System pressure

Motor

Total power

Oil tank capacity

Dry cycle

Max.mold weight

Machine dimensions

Clamping Unit

Electrical & Hydraulic Units

General

US tonskN

US tonskNin

mmin

mmin

mmin

mmin

mmUS tons

kNin

mmPCS

psiMPahpkWhpkW

galL

S/inS/mm

lbmT

lbmTinm

Machine weight (clamping+injection units,no oil)

787.4700056.24500

59.45x56.691510x1440

43.30x37.801100x960

17.72-37.40450-950

57.09145074.81900

121109.8425021

2538, 435117.5,30

52.84+38.49+10.0639.4+28.7+7.5

198750

5.8/30.315.8/77024200

1135200+11000

16+5322.83x106.30x106.30

8.2×2.7×2.7

198750

5.8/30.315.8/77024200

1135200+12100

16+5.5322.83x106.30x106.30

8.2×2.7×2.7

2641000

4.8/30.314.8/77024200

1135200+14300

16+6.5358.27x106.3x106.3

9.1×2.7×2.7

303.61150

4.5/30.314.5/77024200

1135200+18700

16+8.5358.27x106.3x106.3

9.1×2.7×2.7

136.78102

136.78102

142.82106.5

2538, 435117.5,30

52.84+38.49+10.0639.4+28.7+7.5

145.77108.7

145.77108.7

149.92111.8

2538, 435117.5,30

74.56+38.49+10.0655.6+28.7+7.5

173.79129.6

173.79129.6

186.13138.8

2538, 453117.5,30

80.46+52.84+10.0660+39.4+7.5

199.67148.9

199.67148.9

211.74157.9

Cooling water inlet/outlet for fixed mold halvesCooling water inlet/outlet for moving mold halves Water inlet/outlet for oil cooler

Power port

Robot mounting holes according to Euromap 18/E14

UN770DP-N

2.67768

73.1391198

391103

3263322522.3

23.374383

3.30784

111.6061829

591683

2132114720

35.640 584

2695 3330 4800 6800UNITDESCRIPTION

Screw L:D ratio

Screw diameter

Theoretical shot volume

Shot weight

Injection pressure

Injection rate

Max. injection speed

Screw stroke

Max. screw speedScrew torque

2.99276

102.4341678

551544

2886319922.1

35.274578

3.62292

150.1052460

802263

1972513620

48.639797

3.30784

135.2812217

722039

3161821821.9

31.490516

4.252108

223.6273664 119

337119000131 20

52.057853

3.62292

194.733191104

293630893

21321.7

37.532615

4.567116

309.5815073165

466719435

13420

59.807980

35.4026.4

41.4030.9

Heating capacity

Nozzle contact force

Barrel heating zone number

44.4033.1

48.5036.2

50.7037.82

63.0047

56.3042

69.5051.82

Injection Unit2.992

7691.361497

491377

2610718020

29.171478

4.134105

12.99330184 445935.4026.4

614.83131.9

3.30784

125.1352050

671886

2349616220

41.682683

3.74095

14.57370147

557344.4033.1

614.83131.9

3.62292

162.2752659

862446

2625218120

37.776619

3.66193

15.75400154

696750.7037.82

627.81247.3

3.937100

230.0693770122

346826107

18020

44.306726

3.64292.5

18.90480145

877856.30

427

27.81247.3

inmmcu incm3

ozg

psiMPa

cu in/scm3/sin/s

mm/sin

mmr/min

NmhpkWPCS

US tonskN

Technical Specifications of UN990DP-N

UN990DP-N

3.50489.0

15.75400154

6688

620.09178.6

3.30784

135.2812217

722039

3156021821.9

28.500467

3.62292

162.2752659

862446

2631018120

34.176560

3.937100

191.7243142102

289022278

15420

40.400662

51.2038.16

51.2038.16

55.9041.66

4800 6150 9000 12050UNITDESCRIPTION

inmmcu incm3

ozg

psiMPa

cu in/scm3/sin/s

mm/sin

mmr/min

NmhpkWPCS

US tonskN

Screw L:D ratio

Screw diameter

Theoretical shot volume

Shot weight

Injection pressure

Injection rate

Max. injection speed

Screw stroke

Max. screw speedScrew torque

Heating capacity

Nozzle contact force

Barrel heating zone number 720.09178.6

720.09178.6

820.09178.6

3.62292

176.4742892

942660

3086421321.7

35.274578

3.937100

208.53416111

314326136

18020

41.682683

4.252108

243.1943985129

366622408

15520

48.639797

3.937100

263.6214320140

397430284

20921.6

46.759766

4.252108

307.4875038164

463625976

17920

54.540894

4.567116

354.7285813189

534722510

15520

62.9201031

4.567116

386.9766341206

583327572

19022.1

55.694913

3.42386.9

17.13435139

8639

3.84197.6

21.65550128

11982

3.40086.4

23.62600113

14769

4.921125

449.3547363239

677423743

16420

64.6891060

5.315135

524.1268588279

790120363

14020

75.4301236

63.8047.56

63.8047.56

69.7051.96

62.4046.52

62.4046.52

68.8051.32

89.0066.39

89.0066.39

94.7070.65

Injection Unit

1.Dry cycle time accords with EUROMAP 6.2.The load-bearing capacity of the moving platen is 2/3 of the total mold weight.3.The shot weight is calculated by GPPS and it is 0.92 times of the theoretical shot volume.4.The injection unit data are in international units and calculated as follows: theoretical shot volume[㎝³]×injection pressure [Mpa]/1005.Plasticizing capacity is calculated by GPPS ( for the injection unit model 18500 and smaller ones ) or PP ( for injection unit above model 18500 ).6.Because of constant technical improvement, the machine specifications are subject to change without notice.

.

Oil tank capacity

Dry cycle

Max.mold weight

Machine dimensions

General

machine weight (clamping+injection units,no oil)

316.81200

4.8/32.514.8/82630800

1470400+22000

32+10413.39×129.92×114.17

10.5×3.3×2.9

316.81200

4.8/32.514.8/82630800

1470400+24200

32+11413.39×129.92×114.17

10.5×3.3×2.9

3961500

4.5/32.514.5/82630800

1470400+26400

32+12413.39×129.92×114.17

10.5×3.3×2.9

3961500

4.5/32.514.5/82630800

1470400+30800

32+14413.39×129.92×122.05

10.5×3.3×3.1

180.5134.6

180.5134.6

185.19138.1

199.76149

199.76149

205.66153.4

231.32172.5

231.32172.5

237.76177.3

291217

291217

296.63221.2

Clamping force

Opening stroke

Platen size

Space between tie-bars

Mold thickness

Max.opening stroke

Max.daylight

Ejector force

Ejector stroke

Ejector number

System pressure

Motor

Total power

Clamping Unit

Electrical & Hydraulic Units

US tonskN

US tonskNin

mmin

mmin

mmin

mmin

mmUS tons

kNin

mmPCS

psiMPahpkWhpkW

galL

S/inS/mm

lbmT

lbmTinm

900/10128000/9000

85760

69.09x65.161755x1655

46.45x40.161180x102018.90-44.09

480-112064.96165083.862130

2522012.632017

2538,362617.5,25

38.49×2+52.8428.7×2+39.4

2538,362617.5,25

41.57×2+52.8431×2+39.4

2538,362617.5,25

74.56+52.84+41.5755.6+39.4+31

2538,362617.5,25

74.56×2+52.8455.6×2+39.4

126.9

3

166.71

W

61

.69

215.45

5.33194.65

L

6.5

113

.56

5.9

89

.45

H1

H2

Cooling water inlet/outlet for moving mold halves

Cooling water inlet/outlet for fixed mold halves Water inlet/outlet

for oil cooler

Power port

UN990DP-N Machine Dimensions

UN990DP-N Platen Dimensions

63.4663.46

89.4

5

27

.56

40

.16

65

.16

5.9

3.93

46.45

17.2

6

24

.8

15

.74

5.9

3.9

3

57.0757.07

15.7527.56

2 2

.9

961

.69

Ø2.28

69.09

40.9

4

Ø1.18

8.2705.51

16.5422.0527.56

12.6

13.7

8

22.0

4

16.5

4

11.0

2

8.2

7

5.5

1

0

26.7

7

31.02

27.5

6

10.43

94

.67

Ø9

.84

H7

0.98

Ø9

.84

H7

1.97

MIN.24.4

A

MAX.83.86

MAX.64.96

35.7

12.6

MIN.18.9

MAX.44.09

SR0.59

27.56

16.54

2.7

6

6.9

11

.02

M24, 48 deep(mm)

M24, 48 deep(mm)

Robot mounting holes according to Euromap 18/E16

25 26

Model

UN990DP-N-IU4800

UN990DP-N-IU6150

UN990DP-N-IU9000

UN990DP-N-IU12050

L H1 H2 W

mm in

10591

10591

10553

10553

416.969

416.969

415.472

415.472

mm in

2006

2026

2081

2231

78.976

79.764

81.929

87.835

mm in

2848

2848

2923

3073

112.126

112.9134

115.0787

120.9843

mm in

2789

2789

3145

3145

110.157

110.157

123.819

123.819

mm2

70

95

95

120

Full-loadcurrent

A

230.2

281.4

305.1

347.3

in2

0.109

0.147

0.147

0.186

Sectional area of main power cord

Bearing capacity of foundation

Number of cooling water line port

Cooling water flow (mold excluded)

t/m2

8

lbm/in2 n×L/min n×gal/min

17600 (10+10)×11 (10+10)×2.90

L/min gal/min

160 42.24

Cooling water pressure

bar psi

3~4 43.5~58

Cooling water pressure

bar psi

5~6 72.5~87

Technical Specifications of UN1200DP-N

UN1200DP-N

3.4286.9

17.126435139

8639

720.09178.6

3.62292

176.474289293.82660

3086421321.7

35.274578

3.937100

208.53416110.93143

2613618020

41.682683

4.252108

243.1943985129.33666

2240815520

48.639797

63.7847.56

63.7847.56

69.6851.96

6150 9000 12050 18500UNITDESCRIPTION

inmmcu incm3

ozg

psiMPa

cu in/scm3/sin/s

mm/sin

mmr/min

NmhpkWPCS

US tonskN

Screw L:D ratio

Screw diameter

Theoretical shot volume

Shot weight

Injection pressure

Injection rate

Max. injection speed

Screw stroke

Max. screw speedScrew torque

Heating capacity

Nozzle contact force

Barrel heating zone number 720.09178.6

820.09178.6

833.38296.7

3.937100

263.6214320140.23974

3029820921.6

46.757766

4.252108

307.5495040163.54636

2597617920

54.537894

4.567116

354.6695812188.65347

2251015520

62.9161031

4.567116

386.9776341205.75833

2757219022.1

55.696913

4.921125

449.3537363238.96774

2374316420

64.6741060

5.315135

524.1248588278.77901

2036314020

75.4361236

5.315135

611.4810020325.19218

2673018423.6

76.3461251

3.8497.6

21.654550128

11982

3.4086.4

23.622600113

14769

3.4487.4

27.559700118

18949

5.709145

705.42511559375.11063423177

16022

88.1241444

6.102155

806.0813208428.61215220276

14020

100.6961650

62.3846.52

62.3846.52

68.8251.32

89.0366.39

89.0366.39

94.7470.65

10.41295

Injection Unit

1.Dry cycle time accords with EUROMAP 6.2.The load-bearing capacity of the moving platen is 2/3 of the total mold weight.3.The shot weight is calculated by GPPS and it is 0.92 times of the theoretical shot volume.4.The injection unit data are in international units and calculated as follows: theoretical shot volume[㎝³]×injection pressure [Mpa]/1005.Plasticizing capacity is calculated by GPPS ( for the injection unit model 18500 and smaller ones ) or PP ( for injection unit above model 18500 ).6.Because of constant technical improvement, the machine specifications are subject to change without notice.

2538,362617.5,25

80.46×360×3

374278.9

Clamping force

Opening stroke

Platen size

Space between tie-bars

Mold thickness

Max.opening stroke

Max.daylight

Ejector force

Ejector stroke

Ejector number

System pressure

Motor

Total power

Oil tank capacity

Dry cycle

Max.mold weight

Machine dimensions

Clamping Unit

Electrical & Hydraulic Units

General

US tonskN

US tonskNin

mmin

mmin

mmin

mmin

mmUS tons

kNin

mmPCS

psiMPahpkWhpkW

galL

S/inS/mm

lbmT

lbmTinm

Machine weight (clamping+injection units,no oil)

1124/123710000/11000

98875

74.8x72.831900x1850

51.57x47.241310x120019.69-47.24

500-120072.84185092.522350

31274

14.1736025

2538,362617.5,25

41.57×2+52.8331×2+39.4

316.81200

6/36.16/91744000

2088000+24200

40+11429.13×133.86×118.11

10.9×3.4×3.0

3961500

5.8/36.15.8/91744000

2088000+26400

40+12429.13×133.86×118.11

10.9×3.4×3.0

3961500

5.6/36.15.6/91744000

2088000+30800

40+14429.13×133.86×122.05

10.9×3.4×3.1

633.62400

5.5/36.15.5/91744000

2088000+48400

40+22468.5×141.73×133.86

11.9×3.6×3.4

199.76149

199.76149

205.66153.4

2538,362617.5,25

74.55+52.83+41.5755.6+39.4+31

231.32172.5

231.32172.5

237.76177.3

2538,362617.5,25

74.55×2+52.8355.6×2+39.4

291217

291217

296.63221.2

Model

UN1200DP-N-IU6150

UN1200DP-N-IU9000

UN1200DP-N-IU12050

UN1200DP-N-IU18500

L H1 H2 W

mm in

10878

10878

10878

11878

428.268

428.268

428.268

467.638

mm in

2086

2141

2291

2431

82.126

84.291

90.197

95.709

mm in

2928

2983

3133

3418

115.276

177.441

123.346

134.567

mm in

2798

3145

3145

3546

110.157

123.819

123.819

139.609

mm2

95

95

120

150

Full-loadcurrent

A

281.4

305.1

347.3

517.6

in2

0.147

0.147

0.186

0.233

Sectional area of main power cord

Bearing capacity of foundation

Number of cooling water line port

Cooling water flow (mold excluded)

t/m2

8

lbm/in2 n×L/min n×gal/min

17600 (10+10)×11 (10+10)×2.90

L/min gal/min

160 42.24

Cooling water pressure

bar psi

3~4 43.5~58

bar psi

5~6 72.5~87

UN1200DP-N Machine Dimensions

UN1200DP-N Platen Dimensions

202.28

224.74

L

6.38

64.

06

119.

76

5.33

5.9

95.9

4

H1

H2

133

.93

175.98

W

5 .5113.78

13.7

8

5.5

1

27.5

6

22.0

4

33.0

7

16.5

4

9.6

5

0

33 .0727.5622.05

16.549.650

47.2

4

72.8

3

51.57

9.84

3.9

3

22.04

4.3

3

33.07

45

.51

20.6

264

.05

62.09

66.81

62.09

66.81

15.75

27.56

39.37

74.8

95.9

4

5.9

31.5

34.4

Ø2.28

Ø1.18

8.4

6

12.6

16.5

4

16 .54

100.

87

14.17

1.97

Φ9.

84H7

Φ9.

84H7

0.98

MAX.92.52

MAX.72.83 MIN.19.68

39.25 MAX.47.24

MIN.28.74

R0.59

A

M24, 48 deep(mm)

Cooling water inlet/outlet for moving mold halves

Cooling water inlet/outlet for fixed mold halves Water inlet/outlet

for oil cooler

Power port

M24, 48 deep(mm)Robot mounting holes according to Euromap 18/E17

27 28

Compressed air pressure

Technical Specifications of UN1650DP-N

UN1650DP-N

3.8497.621.7550128

11982

720.09178.6

3.937100

263.6274320140

397430284

20921.6

46.759766

4.252108

307.5435039164

463625976

17920

54.5554894

4.567116

354.6755812189

534722510

15520

62.90961031

62.3846.52

62.3846.52

68.8251.32

9000 12050 18500 23750UNITDESCRIPTION

inmmcu incm3

ozg

psiMPa

cu in/scm3/sin/s

mm/sin

mmr/min

NmhpkWPCS

US tonskN

Screw L:D ratio

Screw diameter

Theoretical shot volume

Shot weight

Injection pressure

Injection rate

Max. injection speed

Screw stroke

Max. screw speedScrew torque

Heating capacity

Nozzle contact force

Barrel heating zone number 820.09178.6

833.38296.7

1033.38296.7

4.567116

386.9766341206

583327572

19022.1

55.6905913

4.921125

449.3547363239

677423743

16420

64.68541060

5.315135

524.1268588279

790120363

14020

75.48671237

5.315135

611.4810020

3259218

2673018423.6

76.3411251

5.709145

705.42511559

3751063423177

16022

88.11861444

6.102155

806.0813208

4291215220276

14020

100.691650

5.709145

755.81312385

4021139427847

19223.5

91.84111505

3.4086.423.6600113

14769

3.4487.427.6700118

18949

3.5991.129.5750114

24522

6.102155

863.65814152

4591302024366

16822

104.6561715

6.496165

978.69216037

5211475621466

14820.1

118.9971950

89.0366.39

89.0366.39

94.7470.65

150.71112.39

132.6298.9

Injection Unit

1.Dry cycle time accords with EUROMAP 6.2.The load-bearing capacity of the moving platen is 2/3 of the total mold weight.3.The shot weight is calculated by GPPS and it is 0.92 times of the theoretical shot volume.4.The injection unit data are in international units and calculated as follows: theoretical shot volume[㎝³]×injection pressure [Mpa]/1005.Plasticizing capacity is calculated by GPPS ( for the injection unit model 18500 and smaller ones ) or PP ( for injection unit above model 18500 ).6.Because of constant technical improvement, the machine specifications are subject to change without notice.

Clamping force

Opening stroke

Platen size

Space between tie-bars

Mold thickness

Max.opening stroke

Max.daylight

Ejector force

Ejector stroke

Ejector number

System pressure

Motor

Total power

Oil tank capacity

Dry cycle

Max.mold weight

Machine dimensions

Clamping Unit

Electrical & Hydraulic Units

General

US tonskN

US tonskNin

mmin

mmin

mmin

mmin

mmUS tons

kNin

mmPCS

psiMPahpkWhpkW

galL

S/inS/mm

lbmT

lbmTinm

Machine weight (clamping+injection units,no oil)

1462/168713000/15000

1381230

92.13x80.312340x2040

60.63x50.391540x1280

27.17x57.48690-1460

94.882410

122.053100

34300

14.9638025

2538,362617.5,25

74.55+52.83+41.5755.6+39.4+31

3961500

7.2/42.447.2/1078

6600030

125400+2640057+12

464.57×149.61×137.8011.8×3.8×3.5

3961500

6.8/42.446.8/1078

6600030

125400+3080057+14

464.57×149.61×137.8011.8×3.8×3.5

633.62400

6.7/42.446.7/1078

6600030

125400+4840057+22

503.94×149.61×137.8012.8×3.8×3.5

686.42600

6.4/42.446.4/1078

6600030

125400+5060057+23

527.56×149.61×141.7313.4×3.8×3.6

231.32172.5

231.32172.5

237.76177.3

2538,362617.5,25

74.55×2+52.8355.6×2+39.4

291217

291217

296.63221.2

2538,362617.5,25

80.46×360×3

374278.9

2538,362617.5,25

80.46×3+74.5560×3+55.6

466.67348

Model

UN1650DP-N-IU9000

UN1650DP-N-IU12050

UN1650DP-N-IU18500

UN1650DP-N-IU23750

L H1 H2 W

mm in

11794

11794

12794

13394

464.331

464.331

503.701

527.323

mm in

2264

2414

2554

2574

89.134

95.039

100.551

101.339

mm in

3106

3265

3541

3580

122.283

128.543

139.409

140.945

mm in

3145

3145

3546

3434

123.819

123.819

139.606

135.197

mm2

95

120

150

150

Full-loadcurrent

A

305.1

347.3

517.6

627.3

in2

0.147

0.186

0.233

0.233

Sectional area of main power cord

Bearing capacity of foundation

Number of cooling water line port

Cooling water flow (mold excluded)

t/m2

10.5

lbm/in2 n×L/min n×gal/min

23100 (10+10)×11

L/min gal/min

160 42.24

Cooling water pressure

bar psi

3~4 43.5~58

bar psi

5~6 72.5~87

Compressed air pressure

(10+10)×2.90

UN1650DP-N Machine Dimensions

UN1650DP-N Platen Dimensions

5.33

68.9

216.18

145

.59

268.66

L

243.746.5

103.9

4128

.35

5.9

H1

H2

W

5.5

1

016.5

4

22.0

5

27.5

6

33.0

7

38.5

8

11.0

2

5 . 5 1

1 7.919.650

13 .7 81 6.542 2.052 7.5633 .07

40.43

33.6

2

22.0

5

19.2

9

22.05

3.7

4

14.7

6

9.2

5

33.07

3.94

5.9

66.31 66.31

72.8 72.8

9.8

4

3.9

45.9

50.3

9

106.6

9

16.1 24.2

5

80

.31

39.3

7

27.5

6

15.7

5

15.75

39.3727.56

60.63

9.84

92.13

15.4

368

.9

48

.23

Ø2.28

Ø1.18 14.96

42.2

MIN.27.17

MAX.122.05

MAX.94.88

109.4

5

MAX.57.48

R0.79

9.8

4H7

1 .97

9.8

4H7

M IN.29.92

0.98

A

Cooling water inlet/outlet for moving mold halves

Cooling water inlet/outlet for fixed mold halves Water inlet/outlet

for oil cooler

Power port

M30, 60 deep(mm)

M24, 48 deep(mm)Robot mounting holes according to Euromap 18/E18

29 30

Model

UN2000DP-N-IU9000

UN2000DP-N-IU12050

UN2000DP-N-IU18500

UN2000DP-N-IU23750

UN2000DP-N-IU31750

L H1 H2 W

mm in

12384

12384

13384

13984

14484

487.559

487.559

526.929

550.551

570.236

mm in

2364

2514

2654

2674

2709

93.071

98.976

104.488

105.276

106.654

mm in

3206

3365

3641

3680

3715

126.22

132.48

143.346

144.882

146.26

mm in

3145

3145

3546

3434

3702

123.819

123.819

139.606

135.197

145.748

mm2

95

120

150

150

185

Full-loadcurrent

A

305.1

347.3

517.6

627.3

780.9

in2

0.147

0.186

0.233

0.233

0.287

Sectional area of main power cord

Bearing capacity of foundation

Number of cooling water line port

Cooling water flow (mold excluded)

t/m2

10.5

lbm/in2 n×L/min n×gal/min

23100 (10+10)×11 (10+10)×2.90

L/min gal/min

160 42.24

Cooling water pressure

bar psi

3~4 43.5~58

bar psi

5~6 72.5~87

Compressed air pressure

UN2000DP-N

Technical Specifications of UN2000DP-N

3.84197.621.7550128

11982

720.09178.6

3.937100

263.6274320140

397430284

20921.6

46.759766

4.252108

307.5435039164

463625976

17920

54.559894

4.567116

354.6755812189

534722510

15520

62.9131031

62.3846.52

62.3846.52

68.8251.32

9000 12050 18500 23750 31750UNITDESCRIPTION

inmmcu incm3

ozg

psiMPa

cu in/scm3/sin/s

mm/sin

mmr/min

NmhpkWPCS

US tonskN

Screw L:D ratio

Screw diameter

Theoretical shot volume

Shot weight

Injection pressure

Injection rate

Max. injection speed

Screw stroke

Max. screw speedScrew torque

Heating capacity

Nozzle contact force

Barrel heating zone number 820.09178.6

132.6298.9

833.38296.7

150.71112.39

1033.38296.7

193.25144.63

1033.38296.7

4.567116

386.9766341206

583327572

19022

55.718913

4.921125

449.3547363239

677423743

16420

64.6891060

5.315135

524.1268588279

790120363

14020

75.4911237

5.315135

611.4810020

3259218

2673018423.6

76.3461251

5.709145

705.42511559

3751063423177

16022

88.1241444

6.102155

806.0813208

4291215220276

14020

100.6961650

5.709145

755.81312385

4021139427847

19223.5

91.8471505

3.40186.423.6600113

14769

3.44187.427.6700118

18949

3.58891.129.5750114

24522

3.48488.532.783098

34833

6.102155

863.65814152

4591302024366

16822

104.6631715

6.496165

978.69216037

5211475621466

14820.1

119.0041950

6.102155

955.78115661

508 14409 31183

21520.8

101.9161670

6.496165

1083.08617747

5761632827557

19022

115.4641892

7.087180

1288.96221121

6851943123061

15922

137.4342252

89.0366.39

89.0366.39

94.7470.65

Injection Unit

1.Dry cycle time accords with EUROMAP 6.2.The load-bearing capacity of the moving platen is 2/3 of the total mold weight.3.The shot weight is calculated by GPPS and it is 0.92 times of the theoretical shot volume.4.The injection unit data are in international units and calculated as follows: theoretical shot volume[㎝³]×injection pressure [Mpa]/1005.Plasticizing capacity is calculated by GPPS ( for the injection unit model 18500 and smaller ones ) or PP ( for injection unit above model 18500 ).6.Because of constant technical improvement, the machine specifications are subject to change without notice.

Clamping force

Opening stroke

Platen size

Space between tie-bars

Mold thickness

Max.opening stroke

Max.daylight

Ejector force

Ejector stroke

Ejector number

System pressure

Motor

Total power

Clamping Unit

Electrical & Hydraulic Units

US tonskN

US tonskNin

mmin

mmin

mmin

mmin

mmUS tons

kNin

mmPCS

psiMPahpkWhpkW

galL

S/inS/mm

lbmT

lbmTinm

1912/208117000/18500

1551380

104.72x88.192660x2240

73.62x56.101870x142529.52-64.96

750-1650106.32700

135.833450

34300

15.7540033

2538,362617.5,25

74.55+52.83+41.5755.6+39.4+31

2538,362617.5,25

74.55×2+52.8355.6×2+39.4

Oil tank capacity

Dry cycle

Max.mold weight

Machine dimensions

General

Machine weight (clamping+injection units, no oil)

396 1500

8.2/51.548.2/1309

9900045

160600+2640073+12

488.19x165.35x137.8012.4x4.2x3.5

396 1500

7.8/51.537.8/1309

9900045

160600+3080073+14

488.19x165.35x137.8012.4x4.2x3.5

633.62400

7.7/51.537.7/1309

9900045

160600+4840073+22

527.56×165.35×141.7313.4×4.2×3.6

786.42600

7.4/51.537.4/1309

9900045

160600+5060073+23

551.18×165.35×145.6714.0×4.2×3.7

897.63400

7.4/51.537.4/1309

9900045

160600+8140073+37

570.87×165.35×145.6714.5×4.2×3.7

231.32172.5

231.32172.5

237.76177.3

291217

291217

296.63221.2

2538,362617.5,25

80.46×360×3

374278.9

2538,362617.5,25

80.46×3+74.5560×3+55.6

466.67348

2538,362617.5,25

80.46×4+74.5560×4+55.6

565.5421.7

UN2000DP-N Machine Dimensions

UN2000DP-N Platen Dimensions

5.33

165.

51

237.22

266.75

293.96

L

72.8

3

6.5

133.

55.

9

111.

32

H1

H2

W1 7.91

9.6505.51

13 .7822.0527.5633.0738.58

11.0

2

22.0

4

5.5

1

16.5

4

27.5

6

33.0

7

38.5

8

44.0

9

0

49.09

37.4

44.09

33.07

2.76

8.2

7

13.78

11.8

5

50.3

9

72.8

3

27.5639.37

51.1873.62

111

.32

13.7

8

27.5

6

39.3

7

51.1

8

56.1

88.1

9

16.7 24

.6

Ø2.28

Ø1.18

82.7682.76

76.2876.28

104.72

13.78

9.84

5.9

3.93

9.84

5.9

3.94

15.75

46.73

MIN.29.53MAX.106.3

MAX.135.83

117.

32

MAX.64.7

9.84

H7

0.98

1.97

R0.79

9.84

H7

MIN.29.92

A

Cooling water inlet/outlet for moving mold halves

Cooling water inlet/outlet for fixed mold halves

Water inlet/outlet for oil cooler

Power port

M24, 48 deep(mm)

M30, 60 deep(mm)

Robot mounting holes according to Euromap 18/E20

31 32

UN2500DP-N

Technical Specifications of UN2500DP-N

3.40186.423.6600113

14769

4.567116

386.9766341206

583327572

19022.1

55.718913

4.921125

449.3547363239

677423743

16420

64.6891060

5.315135

524.1268588279

790120363

14020

75.4911237

89.0366.39

89.0366.39

94.7470.65

12050 18500 23750 31750 44500UNITDESCRIPTION

Screw L:D ratio

Screw diameter

Theoretical shot volume

Shot weight

Injection pressure

Injection rate

Max. injection speed

Screw stroke

Max. screw speedScrew torque

820.09178.6

Heating capacity

Nozzle contact force

Barrel heating zone number

132.6298.9

833.38296.7

150.71112.39

1033.38296.7

193.25144.63

1033.38296.7

833.38296.7

5.315135

611.4810020

3259218

2673018423.6

76.3461251

5.709145

705.42511559

3751063423177

16022

88.1241444

6.102155

806.0813208

4291215220276

14020

100.6961650

5.709145

755.81312385

4021139427847

19223.5

91.8471505

6.102155

863.65814152

4591302024366

16822

104.6631715

6.102155

955.78115661

5081440931183

21520.8

101.9161670

3.44187.427.6700118

18949

3.58891.129.5750114

24522

3.48488.532.783098

34833

3.36585.536.693075

41799

6.496165

1083.08617747

5761632827557

19022

115.4641892

7.087180

1288.96221121

6851943123061

15922

137.4342252

6.496165

978.69216037

5211475621466

14820.1

119.0041950

7.087180

1444.25823666

7602153627412

18923.4

132.7352175

7.48190

1609.18926368

8462399524511

16922.1

147.9922425

7.874200

1783.03529217

9382658822191

15320

163.8592685

227.97170

245.40183

253.45189

Injection Unit

1.Dry cycle time accords with EUROMAP 6.2.The load-bearing capacity of the moving platen is 2/3 of the total mold weight.3.The shot weight is calculated by GPPS and it is 0.92 times of the theoretical shot volume.4.The injection unit data are in international units and calculated as follows: theoretical shot volume[㎝³]×injection pressure [Mpa]/1005.Plasticizing capacity is calculated by GPPS ( for the injection unit model 18500 and smaller ones ) or PP ( for injection unit above model 18500 ).6.Because of constant technical improvement, the machine specifications are subject to change without notice.

Clamping force

Opening stroke

Platen size

Space between tie-bars

Mold thickness

Max.opening stroke

Max.daylight

Ejector force

Ejector stroke

Ejector number

System pressure

Motor

Total power

Oil tank capacity

Dry cycle

Max.mold weight

Machine dimensions

Clamping Unit

Electrical & Hydraulic Units

General

US tonskN

US tonskNin

mmin

mmin

mmin

mmin

mmUS tons

kNin

mmPCS

psiMPahpkWhpkW

galL

S/inS/mm

lbmT

lbmTinm

Machine weight (clamping+injection units,no oil)

2250/258720000/23000

2111880

114.17×96.062900×2440

79.52×63.782020×162029.52-71.26

750-1810120.473060150

381052

46016.9343025

2538,362617.5,25

74.55×2+52.8355.6×2+39.4

633.62400

11.5/55.6711.5/1414

13200060

206800+4840094+22

551.18×173.23×149.6114.0×4.4×3.8

396 1500

12.5/55.6712.5/1414

13200060

206800+3080094+14

511.81×173.23×145.6713.0×4.4×3.7

686.42600

10.5/55.6710.5/1414

13200060

206800+5060094+23

574.80×173.23×149.6114.6×4.4×3.8

897.63400

10/55.6710/1414132000

60206800+81400

94+37594.49×173.23×153.54

15.1×4.4×3.9

10564000

10/55.6710/1414132000

60206800+81400

94+37606.30×181.10×157.48

15.4×4.6×4.0

291217

291217

296.63221.2

2538,362617.5,25

80.46×360×3

374278.9

0 0 466.67348

0 0 565.5421.7

0 0 683.11509.4

700.54522.4

708.58528.4

2538,362617.5,25

80.46×3+74.5560×3+55.6

2538,362617.5,25

80.46×4+74.5560×4+55.6

2538,362617.5,25

80.46×5+52.8360×5+39.4

UN2500DP-N Machine Dimensions

UN2500DP-N Platen Dimensions

174.5

7

258.9

319.69

289.33

L

6.5 5.33

123.0

3

132.8

75.9

H1

H2

W

78.9

3

5.5

1

016.5

4

27.5

6

33.0

7

38.5

8

44.0

9

49.6

1

11.0

2

22.0

5

2 2.0511.02

05 .51

16 .5427.5633.0738 .5844.09

53.03

42.5

2

2.7

6

13.7

8

8.2

7

49.6

38.58

16.93

127.3

6

51.26

MAX.120.47 MIN.29.53

MAX.150

1.97

12.4

H7

1.57

MAX.71.26

R0.98

12.4

H7

MIN.35.43

A5.9

9.84

27.56

5.9

27.5

6

51

.18

9.8

4

56

.26

78

.94

123

.03

13.7

8

25

51.18

79.53

39.37

96

.06

63

.78

80.8180.8187.2887.28

13.78114.17

39

.37

Ø2.28

6.14

39. 61

Model

UN2500DP-N-IU12050

UN2500DP-N-IU18500

UN2500DP-N-IU23750

UN2500DP-N-IU31750

UN2500DP-N-IU44500

L H1 H2 W

mm in

12957

13957

14557

15057

15377

510.118

549.488

573.110

592.795

605.394

mm in

2669

2809

2829

2864

2920

105.079

110.591

111.378

112.756

114.961

mm in

3511

3796

3835

3870

3955

138.228

149.449

150.984

152.362

155.709

mm in

3145

3546

3434

3702

4257

123.819

139.606

135.197

145.748

167.598

mm2

120

150

150

185

185

Full-loadcurrent

A

347.3

517.6

627.3

780.9

991.1

in2

0.186

0.233

0.233

0.287

0.287

Sectional area of main power cord

Bearing capacity of foundation

Number of cooling water line port

Cooling water flow(mold excluded)

t/m2

12.5

lbm/in2 n×L/min n×gal/min

27500 (10+10)×11 (10+10)×2.90

L/min gal/min

200 52.8

Cooling water pressure

bar psi

3~4 43.5~58

bar psi

5~6 72.5~87

Compressed airpressure

Cooling water inlet/outlet for moving mold halves

Cooling water inlet/outlet for fixed mold halves

Water inlet/outlet for oil cooler

Power port

M24, 48 deep(mm)

M30, 60 deep(mm)

Robot mounting holes according to Euromap 18/E21

33 34

inmmcu incm3

ozg

psiMPa

cu in/scm3/sin/s

mm/sin

mmr/min

NmhpkWPCS

US tonskN

Technical Specifications of UN3000DP-N

1.Dry cycle time accords with EUROMAP 6.2.The load-bearing capacity of the moving platen is 2/3 of the total mold weight.3.The shot weight is calculated by GPPS and it is 0.92 times of the theoretical shot volume.4.The injection unit data are in international units and calculated as follows: theoretical shot volume[㎝³]×injection pressure [Mpa]/1005.Plasticizing capacity is calculated by GPPS ( for the injection unit model 18500 and smaller ones ) or PP ( for injection unit above model 18500 ).6.Because of constant technical improvement, the machine specifications are subject to change without notice.

Heating capacity

Nozzle contact force

Barrel heating zone number

132.62

98.9

8

33.38

296.7

150.71

112.39

10

33.38

296.7

193.95

144.63

10

33.38

296.7

33.38

296.7

33.38

296.7

33.38

296.7

33.38

296.7

UN3000DP-N18500 23750 31750 44500 54500 75500 100000UNITDESCRIPTION

inmmcu incm3

ozg

psiMPa

cu in/scm3/sin/s

mm/sin

mmr/min

NmhpkWPCS

US tonskN

Screw L:D ratio

Screw diameter

Theoretical shot volume

Shot weight

Injection pressure

Injection rate

Max. injection speed

Screw stroke

Max. screw speedScrew torque

Injection Unit7.087

180

1444.258

23666

760

21536

27412

189

23.4

132.735

2175

7.48

190

1609.189

26368

846

23995

24511

169

22.1

147.992

2425

7.874

200

1783.035

29217

938

26588

22191

153

20

163.859

2685

227.97

170

8

245.40

183

9

253.45

189

9

5.315

135

611.48

10020

325

9218

26730

184

23.6

76.346

1251

5.709

145

705.43

11559

375

10634

23177

160

22

88.124

1444

6.102

155

806.08

13208

429

12152

20276

140