Modeling of Liquid-Liquid Taylor Flow in Mini-Scales ...

Transcript of Modeling of Liquid-Liquid Taylor Flow in Mini-Scales ...

RESEARCH POSTER PRESENTATION DESIGN © 2015

www.PosterPresentations.com

(—THIS SIDEBAR DOES NOT PRINT—) DES I G N G U I DE

This PowerPoint 2007 template produces a 36”x48” presentation poster. You can use it to create your research poster and save valuable time placing titles, subtitles, text, and graphics. We provide a series of online tutorials that will guide you through the poster design process and answer your poster production questions. To view our template tutorials, go online to PosterPresentations.com and click on HELP DESK. When you are ready to print your poster, go online to PosterPresentations.com Need assistance? Call us at 1.510.649.3001

QU ICK START

Zoom in and out As you work on your poster zoom in and out to the level that is more comfortable to you.

Go to VIEW > ZOOM.

Title, Authors, and Affiliations Start designing your poster by adding the title, the names of the authors, and the affiliated institutions. You can type or paste text into the provided boxes. The template will automatically adjust the size of your text to fit the title box. You can manually override this feature and change the size of your text. TIP: The font size of your title should be bigger than your name(s) and institution name(s).

Adding Logos / Seals Most often, logos are added on each side of the title. You can insert a logo by dragging and dropping it from your desktop, copy and paste or by going to INSERT > PICTURES. Logos taken from web sites are likely to be low quality when printed. Zoom it at 100% to see what the logo will look like on the final poster and make any necessary adjustments. TIP: See if your school’s logo is available on our free poster templates page.

Photographs / Graphics You can add images by dragging and dropping from your desktop, copy and paste, or by going to INSERT > PICTURES. Resize images proportionally by holding down the SHIFT key and dragging one of the corner handles. For a professional-looking poster, do not distort your images by enlarging them disproportionally.

Image Quality Check Zoom in and look at your images at 100% magnification. If they look good they will print well.

ORIGINAL DISTORTED

Cornerhandles

Good

prin

/ngqu

ality

Badprin/n

gqu

ality

QU ICK START ( con t . )

How to change the template color theme You can easily change the color theme of your poster by going to the DESIGN menu, click on COLORS, and choose the color theme of your choice. You can also create your own color theme. You can also manually change the color of your background by going to VIEW > SLIDE MASTER. After you finish working on the master be sure to go to VIEW > NORMAL to continue working on your poster.

How to add Text The template comes with a number of pre-formatted placeholders for headers and text blocks. You can add more blocks by copying and pasting the existing ones or by adding a text box from the HOME menu.

Text size

Adjust the size of your text based on how much content you have to present. The default template text offers a good starting point. Follow the conference requirements.

How to add Tables To add a table from scratch go to the INSERT menu and click on TABLE. A drop-down box will help you select rows and columns.

You can also copy and a paste a table from Word or another PowerPoint document. A pasted table may need to be re-formatted by RIGHT-CLICK > FORMAT SHAPE, TEXT BOX, Margins.

Graphs / Charts You can simply copy and paste charts and graphs from Excel or Word. Some reformatting may be required depending on how the original document has been created.

How to change the column configuration RIGHT-CLICK on the poster background and select LAYOUT to see the column options available for this template. The poster columns can also be customized on the Master. VIEW > MASTER.

How to remove the info bars

If you are working in PowerPoint for Windows and have finished your poster, save as PDF and the bars will not be included. You can also delete them by going to VIEW > MASTER. On the Mac adjust the Page-Setup to match the Page-Setup in PowerPoint before you create a PDF. You can also delete them from the Slide Master.

Save your work Save your template as a PowerPoint document. For printing, save as PowerPoint or “Print-quality” PDF.

Print your poster When you are ready to have your poster printed go online to PosterPresentations.com and click on the “Order Your Poster” button. Choose the poster type the best suits your needs and submit your order. If you submit a PowerPoint document you will be receiving a PDF proof for your approval prior to printing. If your order is placed and paid for before noon, Pacific, Monday through Friday, your order will ship out that same day. Next day, Second day, Third day, and Free Ground services are offered. Go to PosterPresentations.com for more information.

Student discounts are available on our Facebook page. Go to PosterPresentations.com and click on the FB icon.

©2015PosterPresenta/ons.com2117FourthStreet,[email protected]

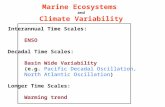

Two phase Taylor flow is a flow patterns that has been examined extensively over the past ten years. It is characterised by splitting the fluid stream up into a series of shorter elements or plus. Researchers refer to Taylor flow as plug or segmented flow. A two phase Taylor flow of low viscosity silicone oil-water is illustrated in figure (1). Heat transfer is an important characteristic of liquid-liquid Taylor flow. It has been known that within liquid plugs of segmented flow, internal circulation arise as a results of gas-liquid, or liquid-liquid interfaces. It has been proven by Muzychka et al. (2009) that theses internal circulation explain the thermal enhancement resulting from Taylor flow. Therefore, the application of liquid-liquid Taylor flow in the heat transfer in mini-scale tubes is a promising technique for process optimization due to both fluid segments participating.

INTRODUCTION

OBJECTIVES

Ø Experimental Facilities and Setup An experimental facility for heat transfer and pressure drop characteristics has been assembled in the Micro-fluidics lab at Memorial University, as shown in Fig. (4).

METHODOLOGY

Ø Benchmark Test

RESULTS CONCLUSIONS

In this application liquid-liquid Taylor flow are studied the thermal performances of these flows, which can be helpful in understanding the whole process better, including pressure drop and film thickness in this flow regime. The working fluids are water and low viscosity silicone oils. The experimental data is presented using the dimensionless variables for heat transfer, and pressure drop. The results of single-phase flow in a mini-scale tube are used as a reference point to the new two-phase Taylor flow data. The new experimental data for liquid-liquid Taylor flow in straight and curved mini-scale tubes is compared to a model proposed for Poiseuille and slug Graetz flow in a circular tube. The comparison provides validation for the model for predicting convective heat transfer rate and pressure drop in liquid-liquid Taylor flow in mini-scale tubes with different geometries.

REFERENCES

[1] Adrugi M. A., Muzychka Y. S., and Pope K., “Heat Transfer in Liquid-Liquid Taylor Flow in a Mini-Scale Tube with Constant Wall Temperature”, ASME 2015 13th Int. Conference on Nanochannels, Microchannels, and Minichannels, July 6-9, 2015, CA.,USA . [2] Asthana A., Zinovik I., Weinmueller C., and Poulikakos D., “Significant Nusselt number increase in microchannels with a segmented flow of two immiscible liquids: An experimental study”, Int. J. of Heat and Mass Transfer, 54, p. 1456– 1464, (2011). [3] Eain M. G, Egan V., Punch J. “Review and extension of pressure drop models applied to Taylor flow regimes”, Int. J. of Heat and Mass Transfer, 68, pp. 1-9, (2015). [4] Fischer M., Juric D., Poulikakos D.,. “Large Convective Heat Transfer Enhancement in Microchannels With a Train of Coflowing Immiscible or Colloidal Droplets”, Int. J. of Heat Transfer, 132, 112402-1, (2010). [5] Eain M. G, Egan V., Punch J. “Local Nusselt number enhancements in liquid-liquid Taylor flow”, Int. J. of Heat and Mass Transfer, 80, pp. 85-97, (2015). [6] Muzychka Y. S., Walsh E., Walsh P., “Heat transfer enhancement using laminar gas-liquid segmented fluid stream”, Proceedings of Inter Pack 2009, San Francisco, July 19-23, (2009). [7] Ghobadi M., Muzychka Y.S., Measurement and Analysis of Laminar Heat Transfer Coefficients in Micro and Mini-Scale Ducts and Channels, ASME 2014 4th, Chicago, Illinois, USA, August 3–7 , (2014). [8] Janes N., Muzychka Y. S., Guy B., Walsh E. J., and Walsh P., Heat transfer in gas-liquid and liquid-liquid two-phase plug flow systems. Proceedings of 12th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems, (2010). [9] Malsch D., Kielpinski M., Merthan R., Albert J., K¨ohler J., S¨uße H., Stahl M., Henkel T., “PIV-Analysis of Taylor flow in micro channels”, Chemical Engineering Journal 135S (2008).

ACKNOWLEDGEMENTSandCONTACTThe authors acknowledge the support of the Natural Sciences and Engineering Research Council of Canada (NSERC) for providing financial assistance under the discovery grants program. The first author acknowledges the financial support of the Libyan Ministry of Higher Education and Scientific Research. Corresponding author. : Tel:+1 709 864 2050 E-mail addresses: [email protected] (W. Adrugi), [email protected] (Y. S. Muzychka), [email protected] (K. Pope)

The main focus in the present research is on modeling of liquid-liquid Taylor flows using experimental method based on the concept of the internal fluid flow and using a dimensionless analysis for reduce experimental data.

Ø The following subjects in modeling liquid-liquid Taylor flow will be

addressed in this research :

ü Measurement of heat transfer in a small scales with types of geometries

ü Measurement of pressure drop

ü Measurement of film thickness

ü Measurements of streaming velocities in plugs using a PIV

FacultyofEngineeringandAppliedScience,MemorialUniversityofNewfoundland,St.John’s,NL,Canada,A1B3X5

WesamAdrugi,YuriMuzychka,KevinPopeDepartmentofMechanicalEngineering

ModelingofLiquid-LiquidTaylorFlowinMini-ScalesChannels

Fig. 1 - Two-phase Taylor flow of water- 1 cSt oil in mini-channel (Dh=1.65 mm) with the water is dyed red for visibility.

DischargeTank

PumpA

PumpB

Camera

PressureTransducer

Isotemp.Bath

DAQ CPU

Ø Create Liquid-Liquid Taylor Flow Two-phase liquid-liquid Taylor flow has been obtained by using T, Y, and X junctions, and junction boxes/segmenters have already been designed, manufactured and examined.

Fig 5 - Illustration of segmented flow for (a) variable flow rates of water and constant flow rate of 1 cSt oil (right column), and (b) variable flow

rates of 1 cSt oil and constant flow rate of water (left column).

Fig. 4 - Schematic of experimental apparatus.

Fluid Prandtl# Reynolds# Peclet# Water DispersedPhase 5.4 50-935 270-5049

0.65cStOil Con/nuousPhase

8.4 59-1188 496-9979 1cStOil 13.8 38-737 524-10,171 3cStOil 38.5 41-705 1578-27,142

Ø Fluid Test Water and three low viscosity silicone oils were used.

Ø Analytical Model of Taylor Flow The following expressions are used to validate the results for dimensionless mean heat flux for constant wall temperature, Muzychka et al. (2009) and pressure drop. q For Graetz - Poiseuille flow in a circular tube:

q For Graetz - Plug flow in a circular tube:

q Pressure drop of liquid-liquid Taylor flow:

qPlug* =

1.128L*1/2

!

"#

$

%&−2

+14L*!

"#

$

%&−2(

)**

+

,--

−12

qPois* =

1.614L*1/3

⎛

⎝⎜

⎞

⎠⎟−32

+14L*⎛

⎝⎜

⎞

⎠⎟−32⎡

⎣⎢⎢

⎤

⎦⎥⎥

−23

,

Le** =

LeD

Ca2cosθ

ΔPT* =16+ 1

Le*

⎛

⎝⎜

⎞

⎠⎟,

L* = LD

1Pe⎛

⎝⎜

⎞

⎠⎟

1

10

0.005 0.05

q*

L*

Water/3cStOilTaylorFlow

Water/1cStOilTaylorFlow

StraightTube

0.1

1

10

0.01 0.1 1

q*

L*

Water

0.65cStSiliconeOil

1cStSiliconeOil

GraetzModel

1/4L*

0.01

0.1

1

50 500

f

Re

Exp.

Theory

1

10

0.005 0.05

q*

L*

R=2cm,θ=360°

R=4cm,θ=180°

StraightTube

1

10

0.01 0.1

q*

L*

Longtube(3cStoil)

Mediumtube(3cStoil)

Shorttube(3cStoil)

1/4L*

Graetz-PlugFlow

Graetz-PoiseuilleFlow

10

100

1000

0.001 0.01

ΔP*

Le*

ProposedModel

Exp.(α=0.5-0.16)

Exp.(α=0.5-0.83)

Exp.(α=0.5)

Ø Heat Transfer in a Straight Tube

Ø Heat Transfer in a Curved Tube

Ø Pressure Drop in a Straight Tube

Fig. 7 - Comparison of Taylor flow heat transfer data at various flow rates with various lengths channels .

Fig. 9 - Non-dimensional total pressure drop, as a function of dimensionless slug length and Capillary numbers compared with the theoretical solution.

Fig. 8 - Comparison of Taylor flow heat transfer data in curved tubes with straight tubes at various flow rates with various lengths and curvatures.

Fig. 6 - Benchmarking results for heat transfer and pressure drop with 10% & 15% error bar.

Ø Mechanism of Heat Transfer Enhancement in Taylor Flow § Using a Taylor flow is another passive way to enhance single-phase heat

transfer in small scale tubing. § The internal circulation in Taylor flow effect on heat transfer in a

moving slugs.

Fig. 3 – Instantaneous velocity vector and streamline in liquid plugs for (a) straight micro-channel, and (b) curved micro-channel (Malsch et al. 2008)

Fig. 2 –Temperature field for liquid-liquid Plug flow (Fischer et al. 2010).

![HANGING SCALES/CRANE SCALES - Aviga HFO 159 page 166 1020,-from € Hanging scales/Crane scales Lisa Mayer Product specialist Hanging scales/Crane scales Tel. +49 [0] 7433 9933 - 219](https://static.fdocuments.net/doc/165x107/5afd22507f8b9a68498c727e/hanging-scalescrane-scales-hfo-159-page-166-1020-from-hanging-scalescrane.jpg)