Modal Testing of a Rotating . Wind Turbine -...

Transcript of Modal Testing of a Rotating . Wind Turbine -...

SANDIA REPORT SAND82-0631 ● Revised. Unlimited Release

Printed June 1983

Reprinted September 1983

Modal Testing of a Rotating. Wind Turbine

Thomas G. Carrie, Arlo R. Nord

Prepared bySandia National LaboratoriesAlbuquerque, New Mexico 87185 and Livermore, California 94550for the United Sitatea Department of Energyunder Contract DE-AC04-76QPO0789

Supersedes SAND82-0631 Dated November 1982

SF 2900 -Q(6-S2)

*

4

Ieeuedby Sendm National Laboratories,operatadfor the United StateeDepartmentof Energyby Sadie Corporation.NOTICE Thinreportwaa raperadaeanaccountof workEponeoradby en~en~oftieUtitiStib&vewenL NeithertheUnitedStatea Govern-ment nor any agencythereof,nor auy of their employaae,nor any of theircontrac@a,dcontract.era, orthe$ ernployeen,mak~ NY warranty,expreeeor im had, or aseumeeany 1 al ~bfity or.ranponwbfityfor tbe accuracy,

r 7competeneee,or ueafulneeeo any urformation,apparatus,producLor pro-ceaediacloeed,or rapr~nte thet ite ~ wouldnot infringeprivatelyownedrights. Reference herein to any spade commercialprodu~ proceae,orsaMca by trade name, trademark,manufacturer,or otherwise,doee notneceamrif conetitutaorimplyitaendorsement,recommendation,orfavoring

d“by the mtad Statea Governrnen&.aoy ~cy thereof or any of theirmntractoraor subcontractors.The mewnen opmioneexpraaaadhereindonot neceeeady state or reflectthoeeof the United StateaGovernment,anyagencythereofor any of their contractorsor subcontractor.

Printed in the United Statee of AmericeAvailablefromNationalTacbnicnlInformationserviceU.S. Departmentof Commerce5265 port Ro d Road

?’Sprin#leld, A 22161

NTIS pricecodeePrinted copy A02Microfichecopy AO1

II

.

-1

SAND82 –0631 RevisedUnlimited ReleasePrinted June 1983

Modal Testing of a Rotating Wind Turbine

Thomas G. CarrieArlo R. Nord

Vibration and Modal Testing Division 7542Sandia National Laboratories

Albuquerque, NM 87185

AbstractA testing technique has been developed to measure the modes of vibration of a rotating

vertical axis wind turbine. This technique has been applied to the Sandia 2-m turbine, where thechanges in individual modal frequencies as a function of the rotational speed have been trackedfrom 0rpm (parked) to 600 rpm. During rotational testing, the structural response was measuredusing a combination of strain gages and accelerometers, passing the signals through slip rings.Excitation of the turbine structure was provided by a scheme that suddenly released a preten-sioned cable, thus plucking the turbine as it was rotating at a set speed. In addition to calculatingthe real modes of the parked turbine, the modes of the rotating turbine were also determined atseveral rotational speeds. The modes of the rotating system proved to be complex because ofcentrifugal and Coriolis effects. The modal data for the parked turbine were used to update a fi-nite element model. Also, the measured modal parameters for the rotating turbine were comparedto the analytical results, thus verifying the analytical procedures used to incorporate the effects ofthe rotating coordinate system.

AcknowledgmentsThe authors wish to acknowledge W. N. Sullivan’s

impetus to do the rotating modal test. C. M. Grasshammade invaluable contributions in the design of thesnap-release device and in the planning and mainte-nance of the signal processing system. Others whomade significant contributions in the testing and datareduction are R. A. Watson, P. H. Adams, B. K. Cloer,and M. R. Weber.

.

.

ContentsIntroduction ............................................................................................................................................ ....... 7

Mathematics Model ................................................................................................................................ ........ 9

Modal Testing of the Parked Turbine ....................................................................................................... 11

Modal Testing of the Rotating Turbine .................................................................................................... 17

Conclusions ..................................................................................................................................................... 22

References ................................................................................................................................ ....................... 22

Figures12

345

678

9

10

11

12

The Sandia 17-m Vertical Axis Wind Turbine ................................................................................ 7

Predicted Variation in Modal Frequencies for the2-m Turbine .......................................................................................................................................... 10

The Sardia 2-m Turbine With Instrumentation ............................................................................. 11Measurement Locations for the Parked 2-m Turbine .................................................................... 12Typical Frequency Response Function From the ParkedModal Test ............................................................................................................................................ 12

Measured Mode Shapes for the Parked 2-m Turbine .................................................................... 14The Snap-Release Device .................................................................................................................... 18

A Typical Filtered Force History Produced by theSnap-Release Device ............................................................................................................................ 19

The Magnitude of the Frequency Response Function forthe Filter Used in the Rotating Modal Test .................................................................................... 19

The Frequency Response Function for the In-Plane TowerAccelerometer at a Rotational Speed of 600 rpm ............................................................................ 19The Frequency Response Function for the Out-of-PlaneTower Accelerometer at a Rotational Speed of 600 rpm ................................................................ 20A Comparison of Predicted and Measured Modal Frequencies -.for the 2-m Turbine as a Function of rpm ....................................................................................... 21

Tables1 Modal Frequencies and Damping Factors for the Parked

Turbine .................................................................................................................................... ............ .. 13

2 Parked Frequency Comparison .......................................................................................................... 17

3 Modal Frequencies and Damping Factors for theRotating Turbine .................................................................................................................................. 21

5-6

.

,

.

Modal Testing of a Rotating Wind Turbine

IntroductionWind turbines have received attention as a possi-

ble device for producing electric power from a renew-able energy source. In general there are two types ofwind turbines currently involved in major develop-ment programs. The horizontal axis (or propeller)turbine and the vertical axis turbine. Figure 1 showsthe Sandia 17-m turbine, an example of a vertical axiswind turbine, which is the subject of this work. Whenthe turbine is operating, both the tower and the bladesrotate at a constant speed; the aerodynamic forceswhich are applied to the blades are transmittedthrough the tower as a torque to the electric generator.Since the orientation of the blades in the wind repeatsitself at the constant rotation speed, the aerodynamicforces are periodic. These forces then have large spec-tral components at integral multiples of the rotationspeed. There are broad band random forces caused bywind variability, but these are generally small com-pared to the discrete frequency forces. Because of thediscrete frequency nature of this applied force, it is ofparamount importance to understand the completemodal vibration characteristics of a turbine design sothat operating the machine at a resonant frequency isavoided. Understanding the modal parameters is com-plicated since the frequencies, damping, and modeshapes are functions of the rotation speed and mayvary over a wide range. Consequently, determining themodal characteristics of a parked turbine is not suffi-cient; it is necessary to know how the parameters haveshifted at the proposed operating speed of the turbine.

This paper describes a technique for identifyingthe modal parameters of a rotating turbine and em-phasizes the experimental details of work described inReference 1. There were two objectives for developingthis modal testing capability. (1) experimental data onrepresentative hardware were required to verify theaccuracy of an analysis technique based on finiteelement theory, and (2) a need existed for an estab-lished experimental technique for the measurement ofrotating modal frequencies.

Figure 1. The Sandia 17-m Vertical Axis Wind Turbine

Correct identification of modal parameters usingexperimental data is a challenging task for any struc-ture. It is further complicated for a rotating structurebecause (1) a mechanism must be devised to excite thestructure while it is rotating; (2) the response datamust be transmitted from the rotating system bymeans of slip rings or telemetry; and (3) unless thesystem can be tested in an evacuated chamber, aero-dynamic excitation will cause undesired responses atintegral multiples of the rotation speed.

Manufacturers of rotating structures (includinghelicopters, gas and steam turbines, rotary saws, com-puter disks, and wind turbines) have been interestedin predicting the modal parameters of their struc-tures. This interest is evidenced by the large numberof papers that discuss analytical procedures for pre-dicting modal parameters during rotation. References2 through 10 are representative of some of the analyti-cal approaches; Reference 1 briefly describes thesetechniques.

Reported analytical studies greatly outnumberexperimental investigations. This is partly the resultof previously mentioned experimental difficulties.Reference 11 discusses measuring the modes of arotating model propeller blade by means of electro-magnetic excitation. The test was performed in anevacuated chamber to reduce aerodynamic forces. Atechnique using small piezoelectric crystals as excita-tion devices, with an application to turbine blades, isreported in References 12 and 13; the crystals aredriven by an applied voltage passed through slip rings.Reference 14 describes excitation by piezoelectriccrystals with application to rotating saw blades. Sawblades are also examined in Reference 15, but a sta-tionary electromagnet is used for excitation and astationary, noncontacting displacement transducer isused for response measurements.

Use of either stationary excitation or stationaryresponse transducers creates problems since both theexcitation frequencies and the response measure-ments are explicitly dependent on rotation speed. Theexcitation force reported in Reference 16 partiallyavoids this difficulty using stationary air jets to exciteturbine blades. In this application, blade frequencieswere much higher than rotational frequencies, and thesixth multiple of the rotation frequency was used forexcitation. Consequently, the problem of blade fre-quencies shifting rapidly with the changing rotationfrequency was avoided. An evacuated chamber wasused to reduce the other aerodynamic input, and avery small air gap between the air jet and the turbinedisk was also required. Reference 17 describes a simi-lar technique applied to a steam turbine, using steamnozzles and a vacuum chamber.

In each investigation involving rotating transduc-ers, slip rings transmitted the signals from the rotat-ing system. Some use has been made of optical orholographic techniques in an attempt to measure theresponse without using rotating instrumentation. Therotational frequency must be removed from those

signals, causing further difficulty. In Reference 18 anovel approach for applying the excitation force isdescribed. A force is imposed at the tQp bearing of avertical-axis wind turbine, using a leaf spring; then thespring and resulting force are rotated with a separatemotor and speed controller. The objective was tosimulate the operational aerodynamic forces and mea-sure impedance rather than modal properties, but thistype of excitation could also be used for a modalinvestigation. In many of these applications it wasdifficult to limit unwanted aerodynamic excitation ofthe. bladed systems; consequently, evacuated testchambers were used. Evacuated chambers and otherspecial test equipment used by these investigators areunsuitable for field or on-site testing.

All of these references have attempted to producesingle frequency or sine excitation, measuring fre-quency response functions one point at a time. Thismethod requires long test times, and modes can bemissed completely if there is not sufficient frequencyresolution. The modal frequencies were then deter-mined by picking peaks from the frequency responsefunctions. The peak-picking technique can have se-vere shortcomings if the modes are closely spaced orcoupled. Also, modal damping factors can be difficultto measure directly from the frequency response func-tions for closely spaced modes.

This paper examines a new procedure for experi-mentally determining the modal parameters of a ro-tating wind turbine. The testing technique incorpo-rates an excitation force that is applied by using aninternal quick-release device that operates while thestructure is rotating. This excitation concept hasmany distinct advantages. Large structures can bemuch more easily excited with a quick-release devicethan with piezoelectric crystals or gas jets. Further,the excitation device is field compatible, allowingtesting to be done on site if the test items cannot bebrought into a lab. Finally, the quick-release devicewill excite all frequencies simultaneously, so that allmodes can be excited by a single input, eliminating theneed for a swept-frequency excitation.

Because of its variable speed capability and itsconvenient size, the Sandia 2-m turbine was used forthe tests. First, a detailed modal test of the parkedturbine was required so that modal characteristicswould be well understood before starting the rotatingtest. The resulting modal parameters were then usedto update a finite element model of the parked tur-bine. After the parked test, modal testing continued

8

on the rotating turbine at rotation speeds from 100 to600 rpm. Mode shape data, modal frequencies, andmodal damping factors were extracted from the ex-perimental data. These modal frequencies were com-pared to predictions from a finite element analysis inwhich the effects of the rotation were taken intoaccount [1].*

Mathematics ModeIWhen performing a modal analysis of a rotating

structure, the motion is most conveniently measuredrelative to a coordinate system that is rotating withthe structure. This permits the displacements to besmall by eliminating the large rigid-body rotation. Toaccurately model a rotating vertical axis turbine, theeffects induced by the rotation that include tensionstiffening, and the centrifugal and Coriolis terms mustbe included.

The tension stiffening that primarily affects theblades is induced from the steady centrifugal andgravity forces. The centrifugal and Coriolis terms areadirect result of using a rotating coordinate system.The total acceleration can be represented in terms ofthe acceleration in the rotating coordinate system by

~=kt2&x&+~x[Q_x (L+Q)I , (1)

where

g = the total acceleration vector, ex-cluding gravitational acceleration

1$, g, Jl, & = the original position, the displace-ment, velocity, and accelerationvectors, respectively, as observedin the rotating coordinate system

~ = the fixed angular velocity vector ofthat system.

Using this expression for the acceleration in the equa-tion of motion for a structure, the usual damping andstiffness matrices are altered. The resulting differen-tial equations are represented by

*Numbers in brackets refer to references listed at the end ofthe paper.

Here M is the normal mass matrix; C is the skew-symmetric Coriolis matrix, resulting from the secondterm on the right side of Eq (l); K is usual structuralstiffness matrix; S is the centrifugal softening matrixthat comes from the variable portion (dependent on u)of the last term of Eq (l); F. is a static load vectorrepresenting the steady centrifugal forces that alsocomes from the last term of Eq (l); and, F~ representsthe gravitational force that is also steady because ofthe vertical axis of rotation. Here we have ignored thestructural damping, so the C matrix is totally due tothe .Coriolis effects. To obtain the modes and frequen-cies of the turbine as observed in the rotating system,Eq (2) is reduced to the following form:

Mu+ Cu+(K+K~– S)u=O , (3)

where KG is the geometric stiffness matrix resultingfrom the steady centrifugal and gravitational loads.Thus, the solutions correspond to small motions abouta prestressed state.

To find the eigenvalues of the system of equationrepresented by Eq (3), it is more convenient to usestate vectors. Hence, introducing the state vector

-’H&

v=–––, (4)

g

and the matrices

where

K= K+ K~– S ;

then Eq (3) can be written as

(5)

Here A is real symmetric, and B is real skew symmet-ric. Seeking a solution for Eq (6) in the form~(t) = ~ ei”t, the resulting eigenvalue problem is

[B+iw A]~=O . (7)

Defining ~ = A-% ~ (assuming that A is now positivedefinite), Eq (7) maybe transformed into a standardeigenvalue form

[G–(.o I]~=O , (8)

9

where

G=i A-% BA-fi .

Because of the skew-symmetry of the matrix B,the matrix G is Hermitian. Consequently, it can beshown [19] that the eigenvectors are, in general, com-plex; but the eigenvalues are real.* If structural damp-ing is included, the system loses its Hermetian charac-ter and the eigenvalues as well as the eigenvectors arecomplex. For the present work, structural dampinghas been ignored because most vertical axis windturbines are lightly damped.

The Hermitian character of the eigenvalue systemhas important ramifications to the rotating modaltest. Even if the modes of the parked structure areperfectly real, the modes of the rotating structure willbe complex.

The important role of the rotation speed alsobecomes apparent by examining Eq (3). The overallstiffness matrix K is dependent on the rotation speedthrough the & and S matrices. The modal frequen-cies can vary tremendously with the rotation speed(see Fig. 2). This figure shows the variation in themodal frequencies of 10 modes for the $andia 2-mturbine, as predicted by the finite element analysis[1].

*If A is not positive definite, then G is no longer Hermetianand the eigenvalues are not necessarily real. This conditioncan lead to instability.

I 1 I 1 1 I I I

OL I I I 1 I 1 10 100 200 300 400 500 600 700

Rotor rpm

Figure 2. Predicted Variation in Modal Frequencies for the2-m Turbine

10

Modal Testing of theParked Turbine

We will present a brief overview of the generaltechnique of modal testing with a minicomputer-based Fast Fourier Transform (FFT). The FFT tech-nique, which involves exciting the structure with aforce having a linear spectrum containing the frequen-cy band of interest, is generally faster and more versa-tile than the classical swept-sine technique. The ap-plied force and responses are measured in the timedomain amd transformed to the frequency domainusing the FFT. The frequency response functions arethen computed from the cross-spectral and auto-spectral densities of the applied force and the respons-es. Typically, several measurements are averaged toreduce the effects of uncorrelated noise. A more com-plete description of FFT modal testing is contained inReference 20. The greater versatility of this techniqueis a result of more relaxed requirements on the excita-tion. For example, the technique is equally applicableto shaker-driven structures or structures excited by aninstrume:nted hammer.

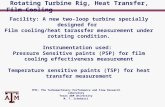

To develop and evaluate the modal testing tech-nique for a rotating turbine, the Sandia 2-m turbinewas chosen as the test vehicle because of its conve-nient size and variable speed capability. Fig. 3 showssome of its special features. The turbine is equippedwith a motor and speed controller so that it can beoperated in the absence of wind and at chosen speeds.

The parked modal test of the 2-m turbine actuallyconsisted of two separate tests. In the first test, theturbine pedestal was supported on top of a 4-ft steelchannel stand originally configured so that therewould be more ground clearance for the blades. Thestand was thought to be stiff compared to the turbine.However, it was later determined from the data thatthe stand contributed to much of the tower motionand greatly complicated the analytical model. Afterthe modes were extracted from the data, two conclu-sions were drawn: (1) excessive base motion couldcause complications in the understanding of the tower

modes, and (2) the pedestal needed to be fully instru-mented. A decision was made to remove the stand andretake the data. Some of the modal data reported hereis from this first test, particularly that for the blademodes. Since their modes were not influenced byremoving the base, the additional instrumentation onthe blades in the first test provided a better represen-tation of these mode shapes. The remainder of theparked modal data and all rotating data is from thesecond configuration with the stand removed and thepedestal attached directly to the concrete pad.

The turbine was instrumented for the secondparked test (Fig. 4) with 18 accelerometers on theblades, 10 on the tower, 20 on the pedestal, and 6 onthe driveline. The structure was excited by strikingthe tower both in-plane and out-of-plane of the rotorat location 10; also by striking the blade flatwise andedgewise at location 6. Data taken from four differentdriving points gave assurance that alI the tower andblade modes would be excited in at least one of thefour test inputs.

1

4

5

6

.0

3

B

Figure 4.bine

Measurement Locations for the Parked 2-m Tur-

Excitation for the parked modal test was providedby an instrumented 3-lb PCB hammer. The tip wasselected to excite frequencies up to 60 Hz. All responsemonitoring for the parked tests was taken with En-devco 2221M2 piezoelectric accelerometers, condi-tioned through Endevco 2721B charge amplifiers. Allinput and response signals were low-passed at 100 Hz.They were amplified as necessary with Vishay 2310signal conditioning amplifiers and recorded on anAmpex 2200 14-channel tape recorder.

Prior to the test, a two-channel analyzer had beenused to determine the frequency range of interest, theresolution required, and the best locations for thedriving points. From this procedure it was determinedthat all the modes of interest were between 10 and 60Hz. The input force spectrum was tailored for thisrange, and the time histories were zoomed between itsextremes to give a desirable frequency resolution(-o.i Hz).

Fig. 5 shows a typical frequency response function ‘derived from six samples of data with the magnitudeplotted versus frequency. This response function isthe response of a blade in the flatwise direction (per-pendicular to the blade chord) resulting from a forceinput on the tower. The sharp resonant peaks clearlyindicate modal frequencies and, because of theirsharpness, corresponding low modal damping. Usingadditional minicomputer-based software [21] with acomplete set of frequency response functions as input(one for each measurement point and direction), themodal frequencies, damping, and mode shapes werecomputed.

0.010.0 Frequency (Hz) 60.0

Figure 5. Typical Frequency Response Function From theParked Modal Test

.Table 1 shows the values of the modal frequency

and damping for the lowest 14 modes with an identify-ing description of each mode. In conjunction with thistable, Fig. 6 shows the three orthogonal views of eachof these mode shapes, with the undeformed shape insolid lines and the ‘deformed shape in dashed lines.

12

Table 1. Modal Frequencies and Damping Factors for the ParkedTurbine

Measured MeasuredMode Modal Modal Damping

No. Mode Name Frequency (Hz) (% of Critical)

1 1st antisymmetric flatwise 12.3 1.62 1st symmetric flatwise 12.5 1.63 1st rotor out-of-plane 15.3 0.74 1st rotor in-plane 15,8 0.75 Dumbbell 24.4 1.86 2nd rotor out-of-plane 26.2 0.57 2nd rotor in-plane 28.3 0.58 2nd symmetric flatwise 29.7 0.59 2nd antisymmetric flatwise 31.5 0.9

10 3rd rotor out-of-plane 36.5 1.111 3rd rotor in-plane 42.0 0.412 Pedestal mode 47.8 1.013 3rd antisymmetric flatwise 49.1 0.414 3rd symmetric flatwise 49.5 0.5

These modes were analyzed as real modes, so all thedisplacements are either in phase or out-of-phase withno phase shifts. Examining the first two modes of Fig.6, one can see that they area symmetric/antisymmet-ric pair of first flatwise blade modes. The next twomodes (3 and 4) are the first two rotor modes, an out-of-plane and an in-plane. Mode 3 contains motion inboth directions, while Mode 4 is purely in-plane. Thefifth mod[e,a twisting of the rotor, appears shaped likea dumbbell from the side view. The sixth and seventhmodes are the second rotor out-of-plane and in-planemodes, ahowing much greater blade deformationsthan the first rotor modes. Modes 8 and 9 are anotherpair of symmetric/antisymmetric blade modes. Modes10 and 11 are the third pair of rotor modes. Examiningthe three rotor out-of-plane modes (3, 6, and 10), onecan see some interesting comparisons by looking at theside views. In mode 3, the blades follow the tower with

somewhat less deformation. For mode 6, the bladesmove in the same direction as the tower, but with anamplified motion. By contrast, in mode 10, the bladesmove in the opposite direction of the tower. Mode 12 issimilar to the rotor in-plane modes, but with moremotion coming from the base and drive train. Modes13 and 14 are the third pair of symmetric/antisymmet-ric blade modes.

The primary purpose for this parked modal testwas to understand the modes of the parked turbineand to use this information to evaluate the acurracy ofthe finite element model before using this model topredict modes of the rotating turbine. Table 2 com-pares the measured modes and the analytical modesfor the first 10 modes both before and after modifyingthe model. From the data, it is easy to see the value ofmodal testing for correcting and tuning the finiteelement model.

13

#-----r;III

MODE 1: FREQ = 12.3 HZ

. —

C/-.-.-

<“I:

1I

8\

‘\‘.

‘.‘.

\8

[

L

LMODE 3: FREQ = 15.3 HZ

(/

/“’/’

)’

<“\\\\

.$

>

,, \\

\\

/’ ‘,1’ \# \

I \\i

tf

MODE 2: FREQ = 12.5 HZ MODE 4 FREQ = 15.8 HZ

Figure 6. Measured Mode Shapes for the Parked 2-m Turbine

14

(/’”

\

NIODE 5: FREQ

\

B= 24.4 HZ MODE 7: FREQ

MODE 6: FREQ

IJv

= 28.3 HZ

<

,/#/

/“,

(“\\\‘.

‘.‘.

\?

I

IIIII, I

1

l!?l)‘\,\

.\ \\\>

~~#

.“.’

,/”

= 26.2 HZ MODE 8: FREQ = 29.7 HZ

Figure 6. (Continued)

15

MODE 9: FREQ = 31.5 HZ

MODE 10 FREQ

Figure 6. (Continued)

= 36.5 HZ

-----

AI

MODE 11: FREQ = 42.0 HZ

-lIEi3-

MODE 12: FREQ = 47.7 HZ

16

-+IZZ!E

i!!!

Table 2. Parked Frequency Comparison

Measured Initial ModifiedModal Analytical Analytical

Mode Frequency Frequency FrequencyNo. (Hz) (Hz) (Hz)

1 12.3 12.5 12.32 12.5 12.6 12.43 15.3 17.1 15.24 15.8 17.2 15.9

5 24.4 22.6 24.46 26.2 30.5 26.27 28.3 30.6 28.08 29.7 30.9 30.69 31.5 39.7 31.7

10 36.5 42.3 36.5

Modal Testing of theMODE 13: FREQ = 49.1 HZ

—ili31-Rotating Turbine

It was more difficult to obtain frequency responsefunctions from the rotating turbine than from theparked configuration. A proper excitation was the firstobstacle to overcome; the collecting of ample responsedata required for adequate determination of themodes was the second.

The proper excitation device had constraints: (1)the input force should be measured and the excitationshould be repeatable; (2) it must excite all the modesof interesb (3) it must not produce secondary hits orbanging after being energized; and (4) it must operateat high rotor speeds. In addition, the turbine must beoperated in very low winds to reduce aerodynamicinput at the discrete frequencies, thus eliminatingwind gusting as an excitation source. Since samplesshould be averaged in order to improve the quality ofthe frequency response functions, it was importantthat the samples be similar in excitation location andamplitude level. This constraint tends to eliminatemany ideas of throwing or shooting something into therotating blades as excitation. The excitation must alsoexcite both the rotor and the blade modes. It wasobserved in the parked test that some of the modesincluded both blade and tower motion, while others

1 \ had only one component involved. There was little

MODE 14 FREQ = 49.5 HZreason to believe that a shaker attached to the station-ary portion of the umer or lower part of the turbine or

Figure 6. (Continued) plu~king a guy cab~~ would exci~e the blade modes.

17

The technique that was devised for exciting theturbine used a pretensioned cable between the towerand one of the blades. The cable that imposed en-forced displacements on both the blade and the towerwas suddenly released while the turbine was rotating,thus plucking the turbine. The release device con-tained a burn wire that was activated remotely at theappropriate operating speed and a force transducerthat measured the force applied to the turbine. Thisexcitation technique enjoyed the advantage of modalcoupling created by the Coriolis effects so that all ofthe modes of interest were excited. Fig. 7 shows adiagram of the snap-release device used to excite theturbine while rotating. The cable was adjusted by aturnbuckle located above the quick adjustment come-along, so that after the nylon cord and burn wire wereinstalled, the come-along would put the proper ten-sion on the cable.

For the parked modal, accelerometers were usedto measure the response. In the rotating modal test,however, the high steady centrifugal acceleration pre-vented the use of accelerometers except on the tower.Because strain gages are normally installed on newly

designed turbines undergoing initial evaluation (suchgages will probably be available on future turbines),the rotating modal test depended primarily on straingages as response transducers. Strain gages wereplaced on the blades and tower, using a double activegage in the bridge so that a single axis of bendingwould be measured. Gages were placed on the leadingand trailing edges of the blades to measure edgewisebending, and on inside and outside at maximum bladethickness for flatwise bending. Besides their use ininstrumenting the roots of the blades, gages were alsoinstalled on the upper and lower tower to read in-plane and out-of-plane bending. Seven of the nine on-board amplifiers boosted the strain signal to 2000 psi/V for all gages to give an adequate level for passingthrough the slip rings and the long lines to the instru-mentation trailer. Because of the projected difficultiesin understanding the tower modes, two piezoresistiveEndevco 2265-25 accelerometers were placed on theupper tower to record in-plane and out-of-plane mo-tion. These seven strain gages and two accelerometerswere wired through the nine on-board amplifiers andto the slip rings.

DTF

3

TO TURBINEBLADE

\

L

1-1” IT

Figure 7. The Snap-Release Device

18

The performance of the rotating test was fairlystraightforward after all the instrumentation hadbeen connected and checked out. The turbine wasbrought up to the desired speed (100 to 600 rpm) withthe electrilc motov a remotely controlled power supplyprovided current through the slip rings to the burnwire; and the preloaded cable was released but stillconstrained at its ends to prevent random banging.The initiall preload gave a dc voltage offset on the forcegage; the sudden release caused it to go to zero. Whenthis signal~was passed through a high-pass filter, theresulting pulse was typical of the one displayed in Fig.8. The low-level oscillation prior to the pulse is thethree-per-revolution response seen by the force gageresulting from aerodynamic input.

45.0

0.0-0;4 0.0 0.4 0.0

TIME (sOC)

Figure 8. A Typical Filtered Force History Produced by theSnap-Release Device

The high-pass filter used in this test is the accoupling circuit of a set of amplifiers that amplifiedthe signals before recording them on FM tape. Theresponse signals must also pass through matched fil-ters to avoid relative phase shifts between the re-sponse and the excitation. Fig. 9 shows the magni-tudes “of the frequency response function for thelow- and high-pass filters used here, with the 3.O-dBpoints at approximately 2 and 100 Hz.

o

m -lou

it

3 dB line

-201.9 Hz

-30 1, I I1 I1.0 10.0 100.0

Frequency (Hz)

Figure 9. The Magnitude of the Frequency Response Func-tion for the Filter Used in the Rotating Modal Test

Fig. 10 and 11 show typical frequency responsefunctions from the rotating test at 600 rpm. Thesefunctions were obtained from data taken by the in-plane and out-of-plane accelerometers located nearthe top of the tower. Taking into account the scalefactors on the two plots, we found that the magnitudesof the two response functions were approximatelyequal. This indicates that the Coriolis coupling hasindeed produced out-of-plane response, even thoughthe initial excitation was strictly in-plane.

21rev

L!__J1I rev

0.0 Frequency (Hz)

4/rev

Jl_3 I rev

50.0

Figure 10. The Frequency Response Function for the In-Plane Tower Accelerometer at a Rotational Speed of 600rpm

19

0.0._&_J_1/rev

41 rev

3 I rev

1

0.0Frequency (Hz) 50.0

Figure 11. The Frequency Response Function for the Out-of-Plane Tower Accelerometer at a Rotational Speed of 600rpm

Although the general data quality is representedby that in Fig. 10 and 11, at higher rotational speedsthe aerodynamic excitation of the turbine becamemore prevalent in spite of the low-wind environment.This increase was indicated in the frequency responseby the high levels at integral multiples of the rotation-al frequency.

At each rotational speed, frequency responsefunctions were computed from the data taken with theseven strain gages and the two accelerometers. Ignor-ing those peaks associated with the aerodynamic exci-tation, we extracted and tabulated the frequencies ofthe remaining peaks on each of the response functions.Small variations in the frequency of some of themodes did occur; in those cases an average value wasused. Since the mode shapes are complex, magnitudedata were used rather than the imaginary componentto obtain these modal frequencies.

In view of the small number of transducers on theturbine, a full description of the mode shape is impos-sible. However, eigenvectors can still be computedwith nine components in each vector. One typicaleigenvector, corresponding to the second rotor out-of-plane mode and a rotational speed of 300 rpm, isshown below. The magnitude and phase are separatedby commas in the vector. The first two componentsare the accelerations with units of mini-G’s, and thelast seven are stresses with units of psi.

tower out-of-plane ‘

tower in-plane

tower out-of-plane

tower in-plane

blade 1, lower edgewise

blade 1, upper edgewise

blade 2, lower edgewise

blade 2, upper edgewise

blade 2, lower flatwise

1.00,90

L28, 166

7.57,279

4.25, 178

1.06,249

10.83, 275

1.12, 256

0.80, 255

0.00, ---

This eigenvector has been normalized so that the firstcomponent has a unit magnitude and a phase of 90degrees. Observe the large phase variations that arenormally not seen when nonrotating structures areanalyzed for their complex modes. The out-of-planeacceleration has a phase of 76 degrees (nearly 90degrees) greater than the in-plane acceleration. Like-wise, the out-of-plane tower strain gage is advanced by101 degrees over the in-plane gage. The four edgewisestrain gages are basically in phase with the out-of-plane deformation of the tower. These phase relation-ships are caused primarily by rotating coordinatesystem effects. Structural damping, errors from noisein the initial data, and approximations in the extrac-tion algorithms also contribute. However, from thephase components in the vector, it is clear that the in-plane and out-of-plane motion is approximately 90degrees out of phase.

The modal frequency versus rpm plot of Fig. 3,generated by finite element analysis, is reproduced inFig. 12. The experimentally determined modal fre-quencies from O to 600 rpm are superimposed on thisfigure. The agreement between the predicted and themeasured values is excellent, with an average devi-ation of only 2.2 %. This fine correlation is due in partto the close agreement that existed for the parkedmodal frequencies. Although the deviation does notappear to be dependent on the rpm, the agreement isnot as good at the higher frequencies—generally thecase when finite element methods are employed. An-other facet of Fig. 12 that should be noted is theoccasional jump in the measured frequency from theparked value to the value at 100 rpm. The ratherabrupt change in frequency is more prevalent in thehigher modes than the lower modes and is probablycaused by changing joint interface conditions whenthe turbine is rotating.

20

I I I T I I I

40’_4++’

;=s!2:‘a 0

920 -k 4

32

).

10 -

0 ExparknantalData— Arratytkal Pradktkns 1

I.1- 1 I I 1 I I

-0’ 100 200 300 400 500 600 700Roto8 rprn

Figure 12. A Comparison of Predicted and Measured Mod-al Frequencies for the 2-m Turbine as a Function of rpm

Because of the small number of transducers on the

turbine, the experimental mode shapes are coarse, and

quantitative comparisons to those predicted are diffi-

cult. However, as indicated in the theory section, the

measure modes are definitely complex rather than

real; the in-plane and out-of-plane motions are cou-

pled. These motions are approximately 90 degrees out

of phase, consistent with the predicted results.

Modal damping factors were computed at a num-ber of rotational speeds, using minicomputer-basedsoftware [21], but it is fairly difficult to compare thedamping values for a particular mode shape since theshapes change so drastically with the rotation speed.For example, mode 1 on Fig. 12 is the antisymmetricflatwise mode at O rpm. However, that modal degree-of-freedom haa a shape that appears to be rotor out-of-plane at 600 rpm, where as the rotor out-of-plane,mode 3, has become more like the antisymmetricflatwise mode. The predominant mode shape associat-ed with a particular modal degree-of-freedom tends tochange as the rpm is increased. This modal identifica-tion is further complicated by the in-plane and out-of-plane coupling that also exists when the turbine isrotating.

Table 3 tabulates the damping factors and fre-quencies of the 10 modes shown on Fig. 12 for O, 300,and 600 rpm. For this table, the modal parametershave been grouped according to a mode shape descrip-tion rather than to an analytical modal curve as in Fig.12. This approach may cause some confusion; howev-er, it is the best way to examine trends in the dampingfactors. Examining the table, observe how the modaldamping varies with the rotation speed. In particular,the damping of the first symmetric flatwise and thedumbbell modes steadily declines with increasingrpm, with the damping of the dumbbell mode drop-ping from 1.8 to 0.16%. The damping of these twomodes is particularly important since these are themodes that can cause the turbine to flutter, if thedamping becomes negative.

Table <3. Modal Frequencies and Damping Factors for the Rotating Turbine

O rpm 300 rpm 600 rpm

Mode Frequency Damping Frequency Damping Frequency DarnpingDescription (Hz) (% of Critical) (Hz) (% of Critical) (Hz) (% of Critical)

1st antisymmetric flatwise 12.3 1.6 14.8 1.2 18.5 1.81st symmetric flatwise 12.5 1.6 14.2 1.4 17.7 0.41st rotor out-of-plane 15.3 0.7 10.8 1.7 5.9 2.91st rotor in-plane 15.8 0.6 21.0 0.4 25.7 0.3Dumbbell 24.4 1.8 26.5 0.5 30.7 0.162nd rotor out-of-plane 26.2 0.5 24.2 1.0 19.6 0.72nd rotm in-plane 28.3 0.5 30.6 1.3 30.9 0.62nd symmetric flatwise 29.7 0.5 32.6 2.0 39.2 0.52nd antisymmetric flatwise 31.5 0.9 33.8 0.5 40.0 0.93rd rotor out-of-plane 36.5 1.1 38.2 1.1 41.4 1.5

21

ConclusionsA newly developed modal testing technique for a

rotating vertical axis wind turbine has been demon-strated. Modal frequencies, damping factors, andmode shape data have been measured on a 2-m tur-bine. The agreement with frequencies from a finiteelement prediction is excellent. The mode shape datarevealed the complex modes as predicted by the ana-lytical theory. This technique is applicable to large aswell as small turbines and, further, cm-ibe adapted foruse on other rotating systems.

ReferenceslT. G. Carrieet al, “Finite Element Analysis and Modal

Testing of a Rotating Wind Turbine,” AIAA Paper 82-0697,23rd Structures, Structural Dynamics, and Material Con-ference, Part 2, New Orleans, May 1982, pp 335-347.

2S. V. Hoa, “Vibration of a Rotating Beam With TipMass,” J Sound and Vibration 67(3):369-381 (1979).

3P. P. Friedmann and F. Straub, “Application of theFinite Element Method to Rotary Wing Aeroelasticity,” JAm Helicopter Soc 25:36-44 (January 1980).

‘D. H. Hodges and M. J. Rutkowski, “Free-VibrationAnalysis of Rotating Beams by a Variable-Order Finite-Element Methodv AAIA J 19:1459-1466 (November 1981).

‘G. L. Nigh and M. D. Olson, “Finite Element Analysisof Rotating Disks,” J Sound and Vibration 77(1):61-78(1981).

8J. S. Patel and S. M. Seltzer, “Complex EigenvalueSolution to a Spinning Skylab Problem? NASA TMX-2378,Vol. II (September 1971).

‘J. W. Klahs, Jr., and J. H. Ginsberg, “Resonant Excita-tion of a Spinning, Nutating Plate,” J App Mech 46:132-138(March 1979).

‘W. Warmbrodt and P. Friedmann, “Coupled Rotor/Tower Aeroelastic Analysis of Large Horizontal Axis WindTurbines,” AIAA J 18(9):1118-1124 (1980).

‘W. F. Hunter, “Integrating-Matrix Method for Deter-mining the Natural Vibration Characteristics of PropellerBlades,” NASA TN D-6064 (December 1970).

10DOJ, Ewins ~d Y. V. K. Sadaeiva Rae, “A Theoretic~

Study of the Damped Forced Vibration Response of BladedDiscs,” (Am Soc ME Winter Annual Meeting, 1976).

llJ. E. Carpentir and E. M. Sullivan, “Structural ~d

Vibrational Characteristics of WADC S-5 Model PropellerBlades,” WADC Tech Rpt 56-298, DDC AD 130787, US AirForce (June 1957).

“M. Swaminadham, ‘Study of the Vibrations of Rotat-ing Blades,” Am Soc ME Paper 77-DET-147(1977).

13M Swminadham et ~, “Identification of Resonant

Frequencies of Rotating Beams With the Use of PZT Crys-tals,” Exper Mech, February 1979, pp 76-80.

14D.G. Gormm et al, “Experimental Analysis of Trms-verse Vibration in Thermally Stressed Rotating Discs,” JSound and Vibration, 73(2):221-223 (1980).

15E. MOller ad U. Ringh, “A Method to Observe and

Record Vibration Modes of Rotating Circular Objects,”Exper Mech, June 1982, pp 226-230.

16D J Ewins, “An Experimental Investigation of the. .Forced Vibration of Bladed Discs Due to AerodynamicExcitation,” Structural Dynamic Aspects of Bladed DiskAssemblies (New York: Am Soc ME, 1976).

17L, I. Walker and F. Kushner, “Experimental Investi-

gation of the Vibratory Characteristics of an Exhaust EndSteam Turbine Rotating Blade and Wheel Assembly,” AmSoc ME Paper 74-PET-38 (September 1974).

16D. U. Noiseux and J. B61anger, “Vibration Study of aVertical Axis Wind Turbine,” Institut de recherche de l’hy-dro-Qu6bec (October 1978).

“J. N. Franklin, Matrix Theory (Englewood Cliffs, NJ:Prentice-Hall Inc., 1968) p 99.

‘A. L. Klosterman and R. Zimmerman, “Modal SurveyActivity Via Frequency Response Functions,” SAE PaperNo. 751068, National Aerospace Engineering and Manufac-turing Meeting, Culver City, November 1975.

21Modal-Plus Reference Manual, Version 6 (Milford,OH: The SDRC Corporation 1981).

.

22

DISTRIBIJTION:

7540T. Church7542 D. R. Schafer7542 T. G. Carrie (20)7542 A. R. Nerd

SECOND DISTRIBUTION:

6225 R. H. Braasch - 50

23