Mlf 8 3 final2

-

Upload

kmi-media-group -

Category

Documents

-

view

250 -

download

5

description

Transcript of Mlf 8 3 final2

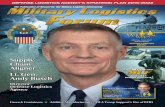

DLA in the Pacific O Managing Life Cycles AFRICOM Logistics O Afghanistan Retrograde

The Publication of Record for the Military Logistics Community

Efficiency Optimizer

Lt. Gen. Judith A. Fedder

Deputy Chief of Staff for Logistics, Installations and Mission SupportU.S. Air Force

Special pull-out Supplement

U.S. Air Force LiFe cycLe

MAnAgeMent center

www.MLF-kmi.com

April 2014Volume 8, Issue 3

Exclusive Interview with:

Lt. gen. c.D. Moore iiCommanderU.S. Air Force Life Cycle Management Center

For those who thrive in the worst.

The real world can be challenging, but you face the challenges head on and so should your computer. Latitude Rugged Extreme provides the tools you need to stand up to adversity.

Learn More at Dell.com/rugged

Cover / Q&AFeatures

Your single-source solution for material and services.

www.SupplyCore.com

Lieutenant GeneraL Judith a. Fedder

Deputy chief of Staff for logistics, installations and mission Support

u.S. air Force

12

April 2014Volume 8, Issue 3

Departments Industry Interview2 editor’s PersPective4 LoG oPs/PeoPLe10 suPPLy chain19 resource center

daLe WinsteadService line Vice president for logistics and Supply chainSaic

MILITARY LOGISTICS FORUM

20

5controLLed retroGrademilitary Surface Deployment and Distribution command experts discuss common issues that can slow movement of u.S. military cargo from afghanistan.By Lieutenant CoLoneL Ryan King

8aFricoM LoGisticsMilitary Logistics Forum recently had the chance to speak with Brigadier General James Johnson, aFRicom’s director for logistics, about building capacity and working with regional partners.

15that’s Where the Money ismanaging life cycle and sustainment issues will, by their nature, drive costs lower.By BRian MCniCoLL

17PaciFic rebaLancethe men and women of the Defense logistics agency positioned throughout the pacific region are directly supporting u.S. efforts to provide a gradual rebalance of u.S. military forces there. By Defense LogistiCs agenCy

u.s. air Force LiFe cycLe ManaGeMent center sPeciaL PuLL-out suPPLeMent

1excLusive intervieW With:

Lieutenant GeneraL c.d. Moore iicommanderu.S. air Force life cycle management center

4aFLcMc transitions to neW acquisition ProGraMin an effort to consolidate and streamline acquisition processes, the air Force life cycle management center is transitioning to the one acquisition Solution for Services (oaSiS) Small Business program, for support in securing professional service needs.

Ghostrider coMPLetes First FLiGht on Way to aFsocthe Strike Systems Branch, working in conjunction with u.S. Special operations command (uSSocom), recently completed the first flight of the ac-130J Ghostrider.

What does it take to get 25,000 cases of meals—about 300,000 meals—to the Ukrainian armed forces? Once you get through the governmental and bureaucratic authorization process that sets the stage and allocates the funding, it takes three elements of the Defense Logistics Agency coming together to make it happen. And it happened quickly!

With the initial request coming from U.S. European Command on March 26 as part of humanitarian support offered by the State Department, DLA Troop Support in Philadelphia, DLA Troop Support Europe and Africa, and DLA Distribution Europe sprung into action. Within 24 hours of receiving the request, the MREs were loaded onto trucks and were on their way, rolling into Ukraine on March 29.

This supply chain effort is an example of how the system should work—whether delivering aid supplies to a friendly partner or ramping up for military action. The process of inventory management, organization and storage, coordination between the services, and the ability to simply get things done are hallmark traits of the U.S. logisticians.

In this issue’s feature Q&A interview, Lieutenant General Judith Fedder reminds us that the 2010 NDAA established a requirement for a comprehensive plan for improving the inventory management systems of the military departments and the Defense Logistics Agency, with the objective of reducing the acquisition and storage of secondary item inventory that is excess to requirements.

An interesting aspect of her comments was on the attention required for “no-demand” items being in held in inventory. No-demand items are described as items with no demand for more than 10 years, yet still required to be held in inventory to support aging weapon systems.

While much of this inventory is still required to support aging weapon systems, we must ensure we are keeping only the assets we need in the quantities needed, helping to minimize storage costs. Through this renewed emphasis on no-demand items we will reduce our inventory, and consequently reduce our storage and handling costs.

Aging systems are more the norm than ever before, and one could make the case that the number of items and the individual counts for each item will increase. Recently it has been rare to hear of the retirement of entire systems, so the number of no-demand items is likely to trend up. I suspect most program/project managers would not want a system failure on their watch ... all for want of a nail!

Jeffrey D. McKaughaneDitoR-in-CHief

EDITOR’S PERSPECTIVE

Publication of Record for the Military Logistics Community

EditorialEditor-In-ChiefJeff McKaughan [email protected] EditorHarrison Donnelly [email protected] Editorial ManagerLaura McNulty [email protected] EditorSean Carmichael [email protected] Baldwin • Christian Bourge Peter Buxbaum • Henry Canaday Cheryl Gerber • Hank Hogan • Marc Selinger Karen Thuermer

art & dEsignArt DirectorJennifer Owers [email protected]

Ads and Materials ManagerJittima Saiwongnuan [email protected]

Senior Graphic DesignerScott Morris [email protected]

Graphic Designers Andrea Herrera [email protected] Paquette [email protected]

advErtisingAssociate PublisherJane Engel [email protected]

KMi MEdia groupChief Executive OfficerJack Kerrigan [email protected] and Chief Financial OfficerConstance Kerrigan [email protected] McKaughan [email protected] Castro [email protected] Show CoordinatorHolly Foster [email protected]

opErations, CirCulation & produCtion

Operations AdministratorBob Lesser [email protected] & Marketing AdministratorDuane Ebanks [email protected] Gill [email protected] Woods [email protected] SpecialistRaymer Villanueva [email protected]

a proud MEMbEr of:

subsCription inforMation

Military Logistics Forum ISSN 1937-9315

is published 10 times a year by KMI Media Group. All Rights Reserved.

Reproduction without permission is strictly forbidden. © Copyright 2014.

Military Logistics Forum is free to qualified members of the U.S. military, employees of the U.S. government and non-U.S. foreign service

based in the U.S. All others: $75 per year. Foreign: $159 per year.

CorporatE offiCEsKMI Media Group

15800 Crabbs Branch Way, Suite 300 Rockville, MD 20855-2604 USA

Telephone: (301) 670-5700 Fax: (301) 670-5701

Web: www.MLF-kmi.com

Military logistiCs foruM

Volume 8, Issue 3 • April 2014

www.GIF-kmi.com

Geospatial Intelligence

Forum

www.BSEP-kmi.com

March 2014Volume 3, Issue 1

www.BSEP-kmi.com

Border Guardian

Michael J. Fisher

ChiefU.S. Border Patrol

Aerostats O CBRN Decon O Responder Comms O DHS NextGen ITNight Vision O Cargo Screening

Border Threat Prevention and CBRNE Response

Border Security & Emergency Preparedness

www.MAE-kmi.com

Military AdvancedEducation

www.MIT-kmi.com

Military Information Technology

www.GCT-kmi.com

Ground Combat

Technology

www.MLF-kmi.com

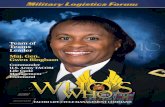

Reverse Auctions O Defense Transportation O Afghanistan RetrogradeILS O Supply Chain Efficiencies O DMSMS O Senior Logisticians

The Publication of Record for the Military Logistics Community

Resource Aligner

Vice Adm. William A. “Andy” Brown Deputy CommanderU.S. Transportation Command

SPECIAL PULL-OUT SUPPLEMENTUSTRANSCOM

www.MLF-kmi.com

November/December 2013Volume 7, Issue 10

Exclusive Interview with:

GAIL JORGENSONAcquisition Director USTRANSCOM

Military Logistics Forum

www.M2VA-kmi.com

Military Medical & Veterans

Affairs Forum

www.MT2-kmi.com www.NPEO-kmi.com

Military Training Technology

Navy Air/Sea PEO Forum

www.SOTECH-kmi.com

Special Operations Technology

www.TISR-kmi.com

Tactical ISR Technology

www.CGF-kmi.com

U.S. Coast Guard Forum

KMI MedIa Group LeadershIp MaGazInes and WebsItes

Compiled by KMi Media group staffLOG OPS

Tunner SupportDRS Technologies, Inc., a

Finmeccanica Company, will continue to provide payload logis-tics support to U.S. Air Force heavy-lift cargo aircraft all over the world.

The Air Force awarded DRS Sustainment Systems, Inc. a 10-year contract valued at more than $390 million for depot-level overhaul,

program engineering support and parts management in support of the DRS Technologies 60K Tunner aircraft cargo loader. The agree-ment between the Air Force and DRS is a performance-based contract.

The work will be performed at DRS Sustainment Systems’ West Plains, Missouri maintenance

facility where the company has overhauled almost 100 Tunner systems for the Air Force.

“The success of the Tunner program is a direct result of our great working relationship with the Air Force customer,” said Joseph Matteoni, vice president and general manager of DRS Sustainment

Systems, Inc. “For well over 20 years, from initial system design and production to system overhaul and field support, DRS has kept the needs of the airmen in the field at the forefront. We look forward to continuing our world-class support throughout the life of the Tunner program,” Matteoni said.

Army Studies Using Technology to Improve LogisticsA National Research Council, or NRC,

committee studying ways to reduce the size of the Army’s logistical demands met with Research, Development and Engineering Command (REECOM) experts recently to look at technologies that may help the Army reach that goal.

Jyuji D. Hewitt, deputy director of RDECOM, led the command’s team of experts who presented in person as well as via video tele-conference from locations across the country.

“The NRC study group’s focus is technolo-gies that have the potential to reduce logistics requirements and meet sustainment require-ments in the Army through 2020 and beyond in support of the joint force commander,” Hewitt said. “If you look at the size of the force, it’s about one-third combat power and two-thirds combat support. If you attack that two-thirds piece, that’s where you’re going to get a lot of return on investment.

“That helps the chief of staff of the Army achieve his 2025 vision of a smaller brigade combat team that’s just as lethal, can move out faster and doesn’t have this huge tail,” Hewitt said.

Retired Brigadier General Dr. Gerald Galloway leads the NRC study group, a divi-sion of the U.S. National Academies. His team of scholars and industry practitioners is conducting the study at the request of Lieutenant General Raymond V. Mason, deputy chief of staff of the Army for Logistics.

“In [recent] wars, the Army moves with fuel. A great deal of food, water and many, many other things causes a very large logis-tics tail for those at the very front lines,” said Galloway, a professor in the University

of Maryland’s Department of Civil and Environmental Engineering. “As we move into the new century, how do we reduce the demand for supplies that need to be moved forward to wherever we happen to be engaged?

“Technology has the opportunity to provide advances—reduce the amount of fuel, reduce the amount of water and to make sure we can obtain it locally. [We need to] figure out ways in which the materiel we do move is lighter and more reliable,” Galloway continued.

RDECOM presented briefings to the NRC committee’s 15-person team on technologies in the areas of condition-based maintenance, fuel delivery and efficiency, water acquisition, ammunition logistics, logistics automation, operational energy, autonomous vehicles, 3-D printing, precision air drop, and combat feeding. Army Communications-Electronics Command, Army Materiel Systems Analysis Activity, Army Public Health Command, and Army Corps of Engineers/Engineer Research and Development Center also provided briefings.

Galloway said his team is focused on evaluating technology areas in those with the greatest potential and providing those recom-mendations to Mason.

“This is an exciting time for the Army—it’s a challenging time. As we go into the next decade, we want to do our part to ensure that the Army is taking with it those technologies that are going to give it the biggest bang for the buck in terms of logistics,” Galloway said. “RDECOM is at the heart of that discussion.”

RDECOM’s briefings proved insightful for the NRC group because they offered an oppor-tunity to interact directly with the Army’s scientists and engineers who are working on

technological solutions to these logistical chal-lenges, Galloway said.

“The Army, in RDECOM, is exploring cutting-edge technologies ranging from autonomous vehicles to methods to increase reliability so we know when we need spare parts—condi-tion-based maintenance. Finding better ways to get water faster and cheaper,” Galloway said. “All of those things are ideas that we heard and explored. We were able to learn from the researcher at RDECOM which ones they saw moving quickly, to answer our questions about why some couldn’t move more quickly, and to help us understand where they thought the real benefits were going to be.”

The committee expects to publish its report this fall.

Hewitt said RDECOM’s challenge is to transi-tion these technologies from the research and development phase to acquisition and into the hands of soldiers.

“The challenge is some of these technologies are mature, and some are a bit further down the road,” Hewitt said. “Can we make them move faster to help this logistics tail so they’re in line with our research and development system moving into the acquisition system and bringing it into the force in a quicker way?

“This is one example of the many things RDECOM is doing to work with the [program executive office] and [program management] communities, the centers of excellence, [Assistant Secretary, Acquisition, Logistics and Technology], [U.S. Army Training and Doctrine Command] and [the Army Capabilities Integration Center], etc., to work together to get things done the Army needs done,” Hewitt said.

By Dan Lafontaine, RDECOM public affairs

www.MLF-kmi.com MLF 8.3 | 3

Compiled by KMi Media group staffLOG OPS

The Secretary of the Army has selected Barbara A. Sisson to become the next Assistant Chief of the Army Reserve in Washington, D.C., effective May 5, 2014. Sisson was the A4/7 for the Air Force Air Education Training Command.

Major General Theresa C. Carter, Air Force civil engineer, Deputy Chief of Staff, Logistics, Installations and Mission Support, Headquarters U.S. Air Force, Pentagon, Washington, D.C., has been assigned as special assis-tant to the commander, Air Force Materiel Command, Joint Base Andrews, Md.

Brigadier General Timothy S. Green, director, installations and mission support, Headquarters Air Combat Command, Joint Base Langley-Eustis, Va., has

been assigned as director, civil engineering, Deputy Chief of Staff, Logistics, Installations and Mission Support, Headquarters U.S. Air Force, Pentagon, Washington, D.C.

Rear Admiral (lower half) David R. Pimpo has been assigned as commander, Naval Supply Systems Command Weapon Systems Support, Philadelphia. Pimpo is currently serving as commander, Defense Logistics Agency Land and Maritime, Columbus.

Rear Admiral (lower half) Donald L. Singleton has been assigned as director of logistics ( J-4), U.S. European Command, Stuttgart, Germany. Singleton is currently serving as deputy chief of staff for logistics, fleet supply and ordnance, N4, commander, Pacific Fleet, Pearl Harbor, Hawaii.

Brigadier General James E. Simpson, commander, Joint Theater Support Contracting Command, U.S. Central Command, Operation Enduring

Freedom, Afghanistan, has been assigned as director for contracting, Office of the Assistant Secretary of the Army for Acquisition, Logistics and Technology, Pentagon, Washington, D.C.

Rear Admiral (lower half) John G. King has been assigned as commander, Defense Logistics Agency Land and Maritime, Columbus. King is currently serving as commander, Naval Supply Systems Command Weapon Systems Support, Philadelphia.

Compiled by KMi Media group staffPEOPLE

Tobyhanna Earns Gray Eagle WorkThe Army, Marine Corps, Air Force and

Navy have named Tobyhanna Army Depot as the depot source of repair for the Gray Eagle (MQ-1C) unmanned aircraft system ground control stations.

The decision by the four services’ main-tenance inter-service support management offices recognizes the depot as the installation best suited for these repairs.

“Through the acquisition process, there is a lot of assessment that takes place, including core logistics analyses that look at our capa-bilities,” said Nick Caprioli, chief of the Business Development Division. “Tobyhanna was selected based on infrastructure, training and technical expertise for this type of work.”

Repairs for the new workload will begin in fiscal year 2016, with 19 ground control stations, or GCSs, scheduled per year, totaling more than 75 systems through fiscal year 2018.

Due to their complexity, Gray Eagle systems and components are currently replaced rather than repaired, exhausting money and resources. Depot personnel are developing cost-effective solutions to repair

GCSs and increase capability. Tobyhanna recognizes that the assignment of this depot source of repair, or DSOR, will enable the depot to be selected for additional DSORs for UAS equipment.

Katlin Edmunds, business development specialist, noted that revamping the DSOR decision process will also help substantially reduce costs and bring more UAS work to the depot.

“DSOR selection helps ensure effective use of commercial and organic depot main-tenance resources,” she said. “We have been aggressively trying to streamline processes, find inefficiencies and figure out the best way to accommodate new UAS workloads.”

“Part of the planning process to bring in this workload is to have our engineers work with the program offices to make sure our capabilities are sufficient to provide the best solution for everybody involved,” said Caprioli. “The depot’s all-hands-on-deck approach to secure this DSOR selection has helped increase our marketability and should open doors for future UAS workloads.”

By Justin Eimers, CECOM

DLA’s COCOM Liaisons

The Defense Logistics Agency’s repre-sentatives to the military’s combatant commands discussed their various assignments at a recent Combatant Command Liaison Officer Summit.

Army Colonel Robert Gagnon, director of the Joint Operations Logistics Center, explained liaison officers, or LNOs, work behind the scenes with the agency’s customers on big-picture issues.

“LNOs serve as the eyes and ears of DLA,” Gagnon said. “We can tailor to commanders’ logistical needs so we’re much more agile and responsive to our customers.” Army Major General Kenneth Dowd, director of DLA Logistics Operations, told the group that they play a crucial role in the agency’s operations.

“We’re really impressed with what you guys are doing out there,” Dowd said. “Back here we may be the nerve center, but out there you guys are really the ones making things happen.”

Barbara A. Sisson

www.MLF-kmi.com4 | MLF 8.3

By Lieutenant CoLoneL Ryan King

MiLitaRy SuRfaCe DepLoyMent anD DiStRiBution CoMManD expeRtS DiSCuSS CoMMon iSSueS that Can SLow MoveMent of u.S. MiLitaRy CaRgo fRoM afghaniStan.

Not since the Red Ball Express of World War II has the Army Transportation Corps played such a large role in a wartime logistics effort as they do in Afghanistan.

The withdrawal of U.S. forces and equip-ment from Afghanistan is one of the most complicated logistics operations in recent history; however, the U.S. military is also no stranger to complicated logistics operations that require innovation and creativity.

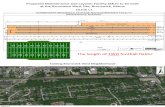

After more than a decade of conflict, there is an iron mountain of retrograde cargo that must be moved from Afghanistan to the continental United States ahead of the president’s approaching December 2014 drawdown deadline.

As the Army service component com-mand to U.S. Transportation Command, Mili-tary Surface Deployment and Distribution Command (SDDC) moves nearly 90 percent of all cargo into and out of Afghanistan via both surface and multimodal, so the respon-sibility to accomplish this formidable task clearly rests on the command’s shoulders.

This massive operation requires innova-tion and creativity, with a focus on increasing the velocity and volume of cargo flow out of

the country, while balancing the efficiency of the transportation network.

With the drawdown deadline loom-ing, along with today’s fiscal constraints, SDDC transportation experts have developed an innovative movement process dubbed Velocity-Volume, Distribution Retrograde, or V2DR. This approach is designed to increase the velocity of retrograde cargo movement by identifying, validating and booking cargo earlier in the movement process, gaining the speed required to remove the hundreds of thousands of pieces of cargo from Afghani-stan that have accumulated over more than a decade of war.

Increasing velocity of movement is key to increasing movement volume. That said, there are three core premises to V2DR: 1) the necessity to move large amount of cargo in a very short time; 2) overcoming mul-tiple impediments, such as political-military, weather and route saturation; and 3) cost-conscious transportation operations.

SDDC leverages three key concepts as part of V2DR: 1) utilizing numerous distribu-tion routes to handle larger volumes while avoiding over saturation of a particular route;

2) drawing upon the established business practices of multiple commercial transporta-tion service providers for effective and cost-efficient movement; and 3) a transportation movement process that continues to gain efficiency as new practices are introduced.

The main route in and out of Afghanistan is the Pakistan ground line of communica-tion (PAKGLOC). As DoD learned in the past, political instability can lead to the near-halt-ing of cargo movements. In 2011, this route was closed to cargo movements for more than nine months, forcing cargo onto alter-nate routes. These routes include the North-ern Distribution Network, which consists of thousands of miles of routes through a dozen countries, and multi-modal routes utilizing air movements to countries within the region for follow on sea movement. These routes are important for increasing cargo volume while eliminating a single point of failure within the transportation network.

While velocity and volume are important for meeting the drawdown timeline, costs are always a concern. V2DR leverages point-to-point movement flow to maximize efficien-cies gained through volume and effectiveness

www.MLF-kmi.com MLF 8.3 | 5

through velocity. As with the transportation networks, avoiding a single point of failure is important for cost efficiency. SDDC relies on multiple commercial transportation service providers to meet cargo movement needs. These providers all have different capabili-ties and leverage their established business practices, infrastructure and distribution network to ensure effective and cost efficient movements.

The V2DR approach synchronizes Joint Operations Planning and Execution System (JOPES) planning with contract acquisition tools to meet operational requirements. SDDC has increased the pickup window and movement timelines to allow carriers to adjust their busi-ness practices, pre-position assets, and adjust vessel schedules to meet movement requirements. There was also an additional 21 days built into the tail end of retrograde movements to allow for the aggregation of cargo at strategic CONUS ports. This addi-tional time generates better cost options using rail during the CONUS lift.

The movement process for retrograde cargo is complex and there are a variety of sequential and concurrent processes required for cargo movements out of Afghanistan. The movement process can be divided into four interrelated areas: transportation planning, procurement, clearance and movement.

First, transportation planning involves forecasting and validating requirements for movement of major end items, including everything from mine resistant ambush pro-tected vehicles and high-mobility multipur-pose wheeled vehicles to unit equipment. As Marisa Bealor, former deputy chief of SDDC’s Command Operations Center, explained, V2DR is designed to balance the volume of cargo against the velocity at which the cargo needs to travel. It does this by identifying early what cargo is being shipped and which routes and modes of transportation will expe-dite moving the cargo out of Afghanistan.

Forecasting needs to be done early in the movement process to ensure transportation shortfalls do not slow movement velocity. Forecasting upcoming cargo requirements involves capturing data through the Theater Provided Equipment, or TPE, Planner up to 180 days prior to the movement require-ment. The key to success is receiving accu-rate data from the unit to determine the scope of the cargo movement for proper fore-casting and planning. If the data is incorrect, the forecast will not accurately capture the true movement requirements, which could

lead to potential transportation shortfalls or delays in movement.

Ensuring the accuracy of the cargo requirement identified for turn in and move-ment is accomplished through an active dia-logue between the 401st Army Field Support Brigade and the outgoing units. At redistri-bution property accountability team yards in Afghanistan, 401st personnel execute deci-sions on retrograde and disposition of equip-ment made by higher headquarters, including accepting equipment from outgoing units; searching vehicles for contaminates, such as biological hazards, ammunition or explosives; and identifying equipment transport destina-tions.

Validating movement requirements asso-ciated with retrograde cargo involves U.S. Central Command verifying the details of each movement requirement in JOPES. As part of the validation process, CENTCOM—through United States Forces-Afghanistan and the 1st Theater Sustainment Command—provides movement requirements to USTRANSCOM, who will then, through SDDC, validate the feasibility of the transportation plan.

SDDC’s traffic management specialists compare the cargo movement requirements against carrier vessel schedules, and CENT-COM or USTRANSCOM published guidelines which provide the transportation community specific timelines and procedures for cargo movement feasibility. If requirements are not transportation feasible, the TMS will make

timeline recommendations that will ensure the movement meets the requirement. If the timelines are not corrected in JOPES, the cargo may be frustrated at its origin or at the RPAT yard, rather than smoothly flowing through the process.

Another important element of the move-ment process is procurement, which involves the transportation requisition process, or TRP, for the transportation assets (i.e., trucks, aircraft, vessels and trains) that are required to meet movement requirements. This means SDDC must provide commercial carriers with accurate transportation requirements to ensure the proper mix of these transporta-tion assets.

The TRP begins with the submission of a valid transportation control movement document to SDDC by the unit or the 401st AFSB. TCMD data is used to generate the movement requirement by providing the data for an export traffic release request (ETRR), so accuracy is paramount. The ETRR is the booking request that is used to request a commercial carrier for the cargo movement. Once accepted by the commercial carrier, this booking is the agreement between the U.S. government and the commercial carrier to dedicate transportation assets for the cargo movement.

The physical preparation and movement involves verifying cargo weights and dimen-sions, as well as meeting approved movement timelines. The cargo movement is adversely

Led by Major General Thomas J. Richardson, SDDC commanding general, SDDC hosted two rehearsals for retrograde operations at SDDC headquarters in 2013. The events included a detailed review of the many tasks involved in quickly and efficiently moving military equipment out of Afghanistan. The ROC drills had support from a number of key military transportation partners, including U.S. Transportation Command, U.S. Army Materiel Command, the U.S. Army TACOM Life Cycle Management Command and the U.S. Air Force Air Mobility Command. [Photo courtesy of U.S. Army, by Mark Diamond, SDDC Public Affairs]

www.MLF-kmi.com6 | MLF 8.3

impacted if the weight and dimensions of the cargo are incorrect. To help decrease the chance of inaccurate data, forecasting and validating early in the movement process allows for cargo bookings adjustment prior to RPAT yard arrival.

As the face to the customer, personnel from SDDC’s 595th Transportation Brigade perform quality assurance checks on TCMD data and ensure customers are aware that inaccurate data (e.g., cargo type, weights, dimensions, etc.) may result in movement delays or increased costs. Errors, especially dimensional discrepancies, have monetary implications later when the carrier processes their invoices.

The arrival of the cargo at the RPAT yard is the first time 401st AFSB and SDDC personnel can physically verify cargo data. To reduce cargo dwell times at the RPAT yard, cargo is being validated and booked prior to its arrival. If any changes must be made to the booking, they must be made as early as possible. If the cargo weight and dimensions are not physically verified on the ground, the carrier can reject the cargo, which would require a new booking or a higher bill to the government upon delivery and could result in delayed movement.

Meeting the approved movement timeline starts with the unit delivering the cargo to the forward operating base/RPAT as required, with accurate paperwork, and ends with the delivery of the cargo at the seaport of embar-kation. The timeliness of the physical move-ment of cargo starts during the planning process, with the close interaction between the 401st AFSB and the unit. Timelines must be understood and documentation accuracy must be enforced to avoid movement delays.

Another critical element of the transpor-tation process involves gaining permission (e.g., customs documentation and border crossing paperwork) to move military cargo through other countries, including Pakistan, Tajikistan, Kyrgyzstan and dozens more, depending on which movement route is used.

Obtaining customs clearance to transit through a country requires approval through various entities, including U.S. embassies and host nation government officials. For transit along the PAKGLOC, SDDC must request a border customs memo, or BCM, that pro-vides specific cargo details associated with commercial carrier trucks for authorization to cross into Pakistan. The BCM request is submitted to the U.S. embassy, which then reviews and forwards the request to the Pakistan Inland Customs Department for

their review and approval. Once the BCM is approved, Pakistan Customs will send the approved BCM to the U.S. embassy and the border crossing point, and when the truck arrives at the border with its cargo, the Pakistani border officials will verify the cargo/truck for clearance into Pakistan. The Port of Karachi, Pakistan, also receives the approved BCM for cargo clearance into the port.

Correcting customs paperwork and dis-seminating the paperwork through various governmental entities is time consuming. If the commercial carrier transloads the cargo (i.e., transfers the cargo from one transpor-tation conveyance to another) at any point along the GLOC, or if the details change in any way, the cargo data will not match the customs paperwork, which may cause delays at the border. These delays could take days or weeks depending on the current workload or other factors, such as holiday schedules. Cargo that misses RPAT arrival dates may also have an effect on BCM processing, or could force a booking cancellation altogether.

In addition to the customs requirements, all Pakistani trucks that transport cargo on the Afghan portion of the PAKGLOC must have a T1 form, which requires the Pakistani trucks to deliver the inbound cargo, pickup the outbound cargo, and arrive back at the border within 21 days. Failure to meet the 21-day timeline results in a cargo delay. A primary issue related to the T1 form includes inconsistent or unclear FOB in-gating procedures that delay cargo delivery and

pickup. If a delay in cargo pickup causes the carrier to miss the 21-day window, it could cause border crossing delays or detained trucks at the border crossing points.

To help mitigate the T1 problem, SDDC coordinates for the establishment of clear, consistent FOB in-gating procedures to expe-dite the movement of carrier vehicles into the RPAT Yards. Additionally, shifting movement timelines to the left (earlier in the process) will reduce RPAT dwell times and ensure cargo is available for immediate pick up, allowing Pakistani trucks to meet the 21-day T1 requirement.

“With a focus on increasing the velocity and flow of cargo out of the country, while balancing the efficiency of multiple trans-portation networks, we will meet the Decem-ber 2014 timeline,” added J.D. Ranbarger, a transportation service provider with SDDC’s CENTCOM team.

The V2DR approach is SDDC’s way to meet the drawdown timeline by achieving the desired balance within the distribution network necessary to maintain the proper movement velocity and cargo volume. O

Lieutenant Colonel Ryan King is the CENTCOM team lead, SDDC Command Operations Center.

For more information, contact Editor-in-Chief Jeff McKaughan at [email protected] or search our online archives for related stories

at www.mlf-kmi.com.

Personnel assigned to Military Surface Deployment and Distribution Command’s command operations center plan, direct, synchronize, coordinate and monitor global surface movements and port operations through subordinate operational commands and strategic seaports. The COC maintains operational oversight of all SDDC operations 24 hours a day, 365 days a year. [Photo courtesy of U.S. Army, by Mark Diamond, Hq. SDDC Public Affairs]

www.MLF-kmi.com MLF 8.3 | 7

As the sixth—and newest—combatant command, AFRICOM covers the geographic continent of Africa with the exception of Egypt. The roughly 2,000 personnel of AFRICOM are a mix of military, federal government civilians and contractors. The command had a budget of about $276 mil-lion in FY12, which was only slightly less than the FY11 level.

Africa covers about 11.67 million square miles, which means you could take the land masses of the U.S., China, Japan, India, and Western and Eastern Europe and put them inside of Africa. The distance from Casa-blanca to Johannesburg is more than 4,700 miles and from Dakar to Djibouti is more than 4,000 miles. The distances are huge and, in general, the infrastructure in must countries is poor. Land and rail traffic is a challenge in all but a few countries, leaving air as the best option in most cases.

Partnering with African countries to build capacity and restrict the movement and growth of terrorist and extremist groups by assisting nations to and regional organi-zations is a key component of AFRICOM’s strategy.

Military Logistics Forum recently had the chance to talk with Brigadier General James Johnson, AFRICOM’s director for logistics, about the mission, opportunities and chal-lenges of AFRICOM in the region.

Q: Distances to and within Africa can be great. In many cases the local transportation infrastructure is weak. What logistical chal-lenges does the continent represent while supporting partnership building exercises and cooperation?

A: Africa’s complex environment presents a myriad of challenges and opportunities for conducting logistics on the continent. That complex environment is affected by a number of factors, including growing econo-mies; Africa’s sheer size; forecasted popula-tion explosion; conflict and instability; and

the variations in-strengths of Africa’s political and democratic institutions.

Logistics in particular is affected by a number of variables, including sub-standard infrastructure to support distribution net-works (both air and ground); lack of military capacity (airlift, sustainment, etc.); and need for a resource strategy to fund sustainment.

AFRICOM is helping to build logistics capacity by working with partners in a num-ber of ways, including programs such as African deployment assistance partnership teams, logistics management assistance teams, vehicle and equipment maintenance assistance teams, etc. We also provide direct support to regional organizations and troop-contributing countries such as the Central African Republic, Mali and African Union Mission in Somalia.

Through our Africa deployment assis-tance partnership team we trained Kenyans, Ugandans and Burundians to more effectively load their equipment and personnel on airlift missions supporting the African Union Mis-sion in Somalia. We also provided critical lifesaving equipment, such as body armor and helmets, to these same partners.

Through our logistics management assistance team, we have conducted regional courses and then followed up with each nation to train their air forces on issues tailored to that nation’s needs. Centered on the “Total Airbase Logistics” concept, this program enhances our partner nation’s airlift capacity with the smallest footprint possible.

We realize, however, that aircraft are not as commonly used as vehicles by Afri-can forces working to secure their borders from extremists. Our vehicle and equipment maintenance assistance team was developed to assist our partners in enhancing preven-tive vehicle maintenance and accountability practices.

Q: Would the creation of a logistics hub in Africa ease logistics operations? What is the current thinking along these lines?

A: U.S. Africa Command, in coordination with our African partners, has established hub operations in Africa, which is one of the two main lines of effort for distribution; the alternate solution is direct delivery. We con-duct hub operations in the east and the west. Many times our hub operations are tempo-rary in nature depending on the operation or exercise we are supporting.

We leverage our hubs for sustainment/resupply; forecasted personnel/equipment rotations; and emergent (short-notice) requirements [that] coincide with sched-uled airlift. For smaller cargo or personnel moves and/or emergent airlift requests out-side scheduled mission lanes, commercial resources or point-to-point airlift is often more expedient and cost effective.

Q: Has AFRICOM’s J-4 office worked with African militaries to help build and strengthen a core group of professional logisticians for those countries?

A: Yes. AFRICOM conducts several pro-grams to help develop logistics capabil-ity. In particular, the peacekeeping logistics (PLOG) course instructs mid-grade officers (and senior non-commissioned enlisted) from African nations that actively partici-pate in peacekeeping operations. The course exposes participants to the specific concepts and practices applied to logistics support within a peace support operations frame-work. The three-week course further aims at enhancing the skills of logisticians by providing them with an overview of some of the nuances particular to a variety of peacekeeping operations (PKO) to include disarmament, demobilization and reinte-gration, civ-mil operations, humanitarian assistance, and disaster relief operations, as well as equipping participants with the tools

heLping to BuiLD LogiStiCS CapaCity By woRKing with RegionaL paRtneRS.

www.MLF-kmi.com8 | MLF 8.3

that will allow them to better plan within the spectrum of possible missions.

To date, over 300 students have gradu-ated from the course. For us, the good news is that program of instruction is delivered in part by previous course graduates. This ensures continuity and builds a pool of experts who we envision going on to actu-ally lead PKOs in the future. Quite frankly, there’s always room for improvement. We’re routinely assessing the course’s effectiveness with respect to content, standardization, delivery and currency. At the end of the day, we answer the question of how effective the course is in meeting its objectives. We will also work with our State Department part-ners to ensure the course is aligned with the UN’s PKO standards.

Q: Have you had ready access to transport assets for operations like the deployments to South Sudan or moving African peace-keepers from their home country to crisis points?

A: We do not have ready access to African air or ground resources, but acquisition and cross-service agreements do exist with a vari-ety of African countries.

As we assess lift requirements on the continent, we do give consideration to those countries with ACSAs [acquisition and cross-servicing agreements] and assess the viability of the request and the risk/return associated with requesting the support.

If I were to speculate on what lift would be most viable for use, it would be linehaul, based on the scrutiny placed on air safety certification procedures.

We also are focusing on leveraging the new Africa Logistics Council to achieve vis-ibility of multinational transportation capa-bility in order to leverage the most effective use of this capability.

Q: Do you have an active planning cell that plots out movements and requirements for those known and planned events and also coordinates operations for more short notice needs in reaction to current events?

A: The AFRICOM Deployment and Distribu-tion Center has designated personnel with airlift tracking and planning capabilities. Doctrinally, tactical level planning for these movements are planned and executed by a service component with reach-back into the higher headquarters, the Combatant Command.

For example, U.S. Army Forces Africa staff planned and managed the airlift opera-tions supporting the Central Africa Republic, and the Combined Joint Task Force-Horn of Africa planned and executed support to South Sudan.

AFRICOM logistics personnel can track and plan these operations, but as the combat-ant command, our main focus is to provide movement priorities to resolve asset decon-fliction; monitor major movements of flow-ing forces; develop, maintain and monitor the effectiveness of our distribution network; and develop/assess strategic policy guidance for distribution.

Q: You recently held an industry day that fea-tured logistics as one of the major themes. Why hold an industry day, what were the objectives and what were the big take-aways from the event?

A: Our industry day and technology exposi-tion had over 700 contractors and 116 exhibi-tors.

We developed this event because U.S. Africa Command could benefit from greater visibility of commercial distribution/logistic capabilities on the African continent that might be able to support our mission.

The goal of the event was to provide an open venue for commercial industry and the Department of Defense community to share information on Africa Command’s unique mission and needs while gaining visibility of the commercial sector’s capabilities and innovations. Additionally, it provided a great networking opportunity for the commercial industry to develop partnerships in support of U.S. Africa Command’s potential future requirements.

Overall, we learned that commercial industry is very interested in supporting us on the continent and we learned about some

resident capabilities in places that were previ-ously unknown to us. We look forward to continued improvement of our relationship with industry to support our requirements while increasing the capability and capacity of our African partners.

The event was a great success and we look forward to hosting a similar event again in the future.

Q: Any closing thoughts on AFRICOM’s logistics accomplishments and challenges?

A: Thank you for the opportunity to respond to questions about logistical challenges across Africa. As I’ve met with logistics lead-ers representing several African partners, the conversation has typically covered the challenge of deploying forces to peacekeep-ing operations, sustaining those forces for a significant amount of time, and maintaining equipment in the field. These challenges have presented opportunities to work together with our African partners to train and equip them for mission success. I mentioned PLOG earlier, which to-date has trained more than 350 senior level logisticians.

AFRICOM’s capability to execute logistics has made great strides when it comes to rapidly moving African forces to points of conflict. Over the past 18 months, we have worked with our African partners to execute multiple operations consisting of troop move-ments for both African and European forces. We look forward to working with the African Union in the future to continue to assist them in developing strategies and approaches to use multi-national resources, to accomplish missions supporting common interests. O

Brigadier General James Johnson is director for Logistics, U.S. Africa Com-mand, Stuttgart, Germany. He is the prin-cipal logistics adviser to the commander, U.S. Africa Command, and is responsible for executing all DoD logistics activities in the U.S. Africa Command area of respon-sibility, with a particular focus on deploy-ment, distribution, supply, medical and engineering matters.

Johnson entered the Air Force through the University of Puget Sound ROTC pro-gram in 1988 with a Bachelor of Arts in

political science. He served in operational positions supporting U.S. Air Forces in Europe and Air Mobility Command and completed numerous leadership assign-ments at the squadron, wing, major com-mand, Headquarters Air Force, as well as Joint Command levels at U.S. Transporta-tion Command, Central Command and Special Operations Command.

Prior to his current position, General Johnson served as the director for Air Force Colonel Management, Headquarters Air Force, the Pentagon, Washington, D.C.

For more information, contact Editor-in-Chief Jeff McKaughan at [email protected] or search our online archives for related stories

at www.mlf-kmi.com.

www.MLF-kmi.com MLF 8.3 | 9

Compiled by KMi Media group staffSUPPLY CHAIN

Special Operational Equipment Tailored Logistics Support

The Defense Logistics Agency (DLA) Troop Support, Philadelphia, recently announced that TSSi (Tactical & Survival Specialties Inc.), Harrisonburg, Va., has been awarded the Special Operational Equipment Tailored Logistics Support (TLS) Program contract. The TLS contract is a five-year contract (two-year base period and three one-year options) that provides logistical support to military commands, federal agencies, and other authorized customers worldwide. TSSi was awarded their original TLS contract in 2009. In addition to TSSi, DLA awarded contracts to five other government contrac-tors. The total estimated contract value to all awardees is $4 billion over the potential five-year contract period.

In order to best serve the end-user, TSSi expanded its workforce and created a department solely dedicated to managing the TLS contract following the initial contract award in February 2009. TSSi President/CEO Bill Strang commented, “We are proud of the support we have provided the Defense Logistics Agency over the past five years on the TLS contract. DLA has an

extremely important mission of providing support to the nation’s warfighters, and they require industry partners who under-stand the daily challenges faced by the DLA team as well as the needs of their customers. These are the same customers TSSi has been supporting since we were founded nearly 35 years ago. Award of this follow-on contract confirms that we have continued to make improvements to our customer service over the past

five years. We have placed an emphasis on going the extra mile to meet the equipment needs and delivery requirements of DLA and our military customers.”

The TLS Program contract expands the procurement options available to federal agencies and military units, streamlines the procurement process, reduces the government’s warehousing and logistics requirements, and provides rapid response to urgent military requirements.

Rebecca Curry, TSSi’s director of contract management for the TLS contract, said, “DLA looks for industry partners who can deliver a quality product, at the best value to the warfighter, on time, every time. With those goals in mind, TSSi has focused on continuous improvement in the service provided to DLA and its customers. This new iteration of the TLS contract will receive the same high level of dedication from the TSSi staff.”

Automated Warehouse SystemsTransbotics, a provider of material handling solutions, has

developed the TJ Series automatic guided cart (AGC), LT Series automated guided vehicle (AGV) Tugger and Kollmorgen traffic management system. The TJ Series AGC is a flexible, small footprint and cost-effective automatic guided vehicle that is ideal for moving products on an assembly line or transporting goods throughout a plant or warehouse. According to the company, it can add flexibility to an order picking operation. Kollmorgen’s traffic management

system is a robust control system for AGVs and AGCs that manages the movement of all vehicles and provides comprehensive reports. Transbotics has demonstrated a tape guided AGC and a laser guided AGV within the same system, towing the same trailers, designed by MMPEX, in a line side delivery system.

Since 1982, Transbotics Corporation has specialized in the design, development, installation and support of automation solu-tions with an emphasis on AGVs and AGCs.

www.MLF-kmi.com10 | MLF 8.3

U.S. Air Force LiFe cycLe MAnAgeMent center

2014

readiness enhancer

Lt. gen. c.D. Moore ii

commanderU.S. Air Force Life cycle Management center

Lieutenant General C.D. Moore II is commander, Air Force Life Cycle Management Center, Wright-Patterson Air Force Base, Ohio. The organization is the single center responsible for total life cycle management covering all aircraft, engines, munitions and elec-tronic systems.

Moore is a distinguished graduate of the U.S. Air Force Academy, as well as the top graduate in engineering. A Guggenheim Fellow, he completed a Master of Science degree in aeronautical engineer-ing at Columbia University before entering flight school in 1981. He served as a T-38 instructor pilot, an operational F-15 pilot and as an experimental test pilot. Moore also served as commander of the first F-22 squadron as well as a group commander at Eglin AFB, Fla., Materiel Wing director of the F-16 System Program Office, Materiel wing commander of the F-22 System Program Office and vice com-mander of the Aeronautical Systems Center.

His staff assignments include director of special programs in the Office of the Under Secretary of Defense for Acquisition, Technology and Logistics, deputy director of the Global Power Directorate in the Office of the Assistant Secretary of the Air Force for Acquisition, and deputy program executive officer of the F-35 Joint Program Office. Moore served as the chief of air operations, Multi-National Forces-Iraq in 2004, and he is a command pilot with more than 3,000 flight hours in 30 types of aircraft.

Prior to assuming his current position, Moore was vice com-mander, Air Force Materiel Command.

His awards and decorations include: Defense Superior Service Medal with oak leaf cluster; Legion of Merit with two oak leaf clus-ters; Defense Meritorious Service Medal; Meritorious Service Medal with three oak leaf clusters; Aerial Achievement Medal with two oak leaf clusters; Joint Service Commendation Medal; Air Force Com-mendation Medal; Air Force Achievement Medal with two oak leaf clusters; Combat Readiness Medal; Iraq Campaign Medal; Global War on Terrorism Service Medal; and Air Force Expeditionary Ser-vice Ribbon with Gold Border.

Q: Do you expect any short-term gains from the budget arrange-ment that the president and Congress signed back in December to restart work that had been on hold? What do you see as your budget priorities for this year?

A: The most valuable benefit of the signed budget is the planning and execution certainty it affords our program teams. This budget certainty and associated program stability allow us to more effectively and efficiently support the AF’s readiness, modernization and recapi-talization priorities. Our key execution objectives remain delivery of cost-effective acquisition solutions and affordable product support for the nearly 3,000 programs and services managed by the center today.

The new budget arrangement allows our program managers to establish firm execution baselines and subsequently higher confi-dence plans for achieving both near- and long-term capability com-mitments to the U.S. services and our international partners.

Q: What do you see as the biggest challenges to Air Force product support in 2014?

A: In this leaner budget environment, the center is laser focused on delivery of product support capability at reduced costs. Capitalizing on the center’s life cycle management and product support enterprise responsibilities, we are working closely with our many program managers and customers to determine the optimum application of resources to achieve a balanced, risk-based level of system availability at the lowest possible cost.

Lieutenant General C.D. Moore IICommander

U.S. Air Force Life Cycle Management Center

Readiness EnhancerEnhancing Performance, Reducing Costs and Improving Operational Readiness

Q&AQ&A

www.MLF-kmi.com U.S. Air Force Life Cycle Management Center | MLF 8.3 | 1

U.S. AIR FORCE LIFE CyCLE MAnAgEMEnt CEntER

2014

Col. Ray LindsayLogistics

Brig. Gen. Shaun MorrisAF Security and Cooperation

Ralph GarciaPropulsion

John ArtusoAcquisition

Col. Keith BeardenProgram Development &

Integration

Lt. Gen. C.D. MooreCommander

Brig. Gen. Peter Sefcik Jr.Mobilization Assistant

Chief Master Sgt. Maxwell Grindstaff

Command Chief

Patsy ReevesExecutive Director

Col. Teresa QuickDirector of Staff

Col. Justin SmithGuard Advisor

Col. James FultomVice Commander

U.S. AIR FORCE LIFE CyCLE MAnAgEMEnt CEntER

Directorates anD support

HeaDquarters

Eric DilworthPersonnel

Col. Peter BaileyIntelligence

Col. Jeffrey DrakeInspector General

Lynn EvistonPlans & Programs

Col. Cassie Barlow88 ABW

Jorge GonzalezEngineering

Col. James PeavySafety

Steve MileyContracting

Col. Franziska ChoppStaff Judge Advocate

Col. Lester A. “JR” Weilacher66 ABG

Kevin BuckleyMobility

John MillerAgile Combat Support

Maj. Gen. Scott W. JanssonWeapons

Maj. Gen. Craig S. OlsonC3I & Networks

Brig. Gen. (S) Eric FickISR/SOF

Steven WertBattle Management

Maj. Gen. Dwyer L. DennisFighters and Bombers

Maj. Gen. John F. ThompsonTanker

Maj. Gen. (S) Daryl HauckStrategic Systems

Robert “Shof” ShofnerBusiness & Enterprise Systems

Carolyn GleasonFinance

Joan ColeSmall Business

U.S. AIR FORCE LIFE CyCLE MAnAgEMEnt CEntER

Directorates anD support

peo

Using a more holistic product support governance process, we are also shaping new support strategies to drive down weapon system sustainment costs while maintaining essential availability objectives.

In short, we are meeting the challenge today through innovation and collaboration as we achieve quality product support results at reduced costs.

Q: Is the Air Force realizing the degree of cost savings and efficien-cies it had expected for this point in time with the creation of the LCMC?

A: The short answer is yes. Over the past year we have forged a more efficient way of operating across our many LCMC locations, employing standardized and improved processes with resultant benefits in cost reduction and enhanced performance.

One of our standard processes involves the application of “should cost” principles to our vast acquisition portfolio. This effort has led to nearly $2 billion in cost savings and avoidance, with much more to come as the process is applied to our product support and services activities.

We are shaping a new life cycle management cost-conscious cul-ture as we systematically and aggressively pursue cost savings while maintaining high quality performance. Early in the center’s life, we talked about LCMC being a “revolution in acquisition and product support.”

We believe the efficiencies achieved to date support that bold asser-tion. The revolution is underway and gaining momentum!

Q: There has long been talk of acquisition reform. Do you think that the way the Air Force PEOs now have a much more defined cradle-to-grave responsibility, is a great step towards looking at total ownership costs as part of the acquisition process?

A: With the standup of LCMC, we elevated life cycle management from a theoretical concept to a day-to-day execution reality for every program within the center’s portfolio, from aircraft and engines to munitions and electronic/cyber systems.

Today we operate in an organization where form and function align ... where cradle-to-grave management is part of our DNA. Our

enterprise-level process standardization and our geo-agnostic operat-ing model harness the full power of the system program manager (SPM) and program executive officer (PEO) concepts.

Each of our systems now has one unified chain of command for program execution, from inception to disposal.

Furthermore, each SPM is supported by one or more product sup-port managers to help build and execute cost-effective life cycle prod-uct support strategies. In this new life cycle management construct, we have introduced the means, mechanisms and motivations for driving down total ownership costs as part of the acquisition process.

This is real acquisition reform!

Q: Is the current education and training pipeline to bring PEOs to the new LCMC processes adequate, or are you making changes to better reflect the new managerial duties the PEO has?

A: Our PEOs have been instrumental in driving a new life cycle management focus as they have fully embraced their cradle-to-grave responsibilities.

Supporting that intent, the center has implemented standardized processes affecting 70-plus locations, which reinforce the PEOs’ efforts to deliver cost-effective acquisition solutions while simultaneously shaping affordable product support strategies.

More importantly, this same life cycle management behavior is being reflected by the many SPMs and program teams across the center.

In short, the implementation of standardized processes forms the core of our ability to effectively and efficiently execute the acquisition and product support mission with positive, repeatable results. These standardized processes institutionalize best practices that ensure suc-cesses are enduring and inherent in future PEO skillsets.

These best practices are intended to outlast personnel turnover and ensure future PEOs are ready and equipped for their life cycle management responsibilities.

Q: What role does the center have in foreign materiel sales (FMS) support?

www.MLF-kmi.com4 | MLF 8.3 | U .S. Air Force Life Cycle Management Center

U.S. AIR FORCE LIFE CyCLE MAnAgEMEnt CEntER

Air Force Life Cycle Management Center’s workforce of nearly 26,000 is charged with true cradle-to-grave life cycle weapon system and sub-system management responsibilities. [Photo courtesy of U.S. Air Force, by Matthew Clouse]

As the Air Force works the new tanker program, AFLCMC is implementing a more agile and responsive strategic resource management process. [Photo courtesy of U.S. Air Force]

A: Today LCMC manages nearly 3,000 programs and services for the USAF, our sister services and our international partners. The organization within the center primarily responsible for oversight of the foreign military sales process is the Air Force Security Assistance Cooperation (AFSAC) Directorate. This directorate has responsibility for managing approximately 2,600 joint and international cases for 100-plus nations.

As the FMS process owner, AFSAC also supports the PEOs and the individual program teams in their execution of more than 1,000 active FMS programs. Working through the PEOs and the program teams, LCMC applies the same level of process rigor and life cycle manage-ment focus to the FMS efforts as we do with all USAF efforts in order to meet each customer’s unique acquisition and product support requirements.

Q: How have the changes here affected the way you do business with small businesses? How significant are small businesses to your overall product support capacity?

A: Building stronger partnerships is one of the key focus areas for the center this year, and central to that tenet is the need to strengthen our relationship with the small business (SB) community. These partnerships are more important than ever in the current resource constrained environment.

In addition to capturing more SB support in our services’ activi-ties, we are making concerted efforts and taking aggressive actions to expand SB involvement in our delivery of new capabilities and associ-ated product support. With that goal in mind, we are working closely with regional and state leaders to identify and expand SB opportunities in support of the LCMC acquisition and product support mission.

Using targeted engagements with industry, we are seeking to capi-talize on SB innovations and subsequently to harness fresh, bold ideas for delivering more cost-effective products and best value services.

Q: When a new project like the KC-46 comes along, how does that alter the structure and size of a directorate—the Tanker Directorate in this case?

A: We like to think about our LCMC enterprise as a factory where we effectively manage over 3,000 programs and services by opti-mally allocating the distributed resources at our 77 LCMC loca-tions. Our 10 execution directorates, each headed by a PEO, have responsibility to manage the programs aligned within their respec-tive portfolios.

As our factory delivers capabilities and takes on new program work such as the KC-46, the resource allocation process adjusts portfolio resources to accommodate the changing workload and program priorities.

In response to expanding program demands and a tighter fiscal environment, the center is developing an even more agile human resource management process to further optimize the allocation of our most precious resource—our LCMC personnel. By doing so, we will maximize productivity while delivering the most cost-effective combat capabilities.

In summary, we are taking life cycle management to a new level of performance, and this improvement starts by implementing a more agile and responsive strategic resource management process.

That initiative is underway as we get better positioned to thrive in a resource constrained environment.

Q: Any closing thoughts on the men and women of the LCMC?

A: The progress we’ve made as a new center is directly attributable to the incredible professionals in the LCMC workforce. Our LCMC team consists of civil servants, active duty military, Guard and Reserve members, and contractor personnel who are all equally committed to the success of our mission—to acquire and support war-winning capabilities. As we move into our second full calendar year as a center, I am more confident than ever that we are on the right track with our life cycle management focus, and that our workforce is absolutely committed to making this new “cradle-to-grave” management concept a huge win for our AF.

The LCMC workforce is comprised of innovative, hardworking airmen who are going the extra mile each day in providing the warfighter’s edge! O

www.MLF-kmi.com

U.S. AIR FORCE LIFE CyCLE MAnAgEMEnt CEntER

U.S. Air Force Life Cycle Management Center | MLF 8.3 | 5

Lieutenant General C.D. Moore has led the Air Force Life Cycle Management Center since its activation, July 9, 2012. [Photo courtesy of U.S. Air Force]

www.MLF-kmi.com

U.S. AIR FORCE LIFE CyCLE MAnAgEMEnt CEntER

6 | MLF 8.3 | U .S. Air Force Life Cycle Management Center

In an effort to consolidate and stream-line acquisition processes, the Air Force Life Cycle Management Center is transi-tioning to the One Acquisition Solution for Services (OASIS) Small Business Pro-gram, for support in securing professional service needs.

OASIS will be used by AFLCMC’s Engi-neering and Professional Administrative Support Services (EPASS) office to hire contractors for services the center needs, including engineering, financial manage-ment, transportation, construction and repair work.

The program, which is administered by the U.S. General Services Adminis-tration, will manage a pool of 40 small businesses, which will compete for up to

$5 billion in AFLCMC contracts at center locations nationwide over the next five years.

OASIS will promote and improve effi-ciency within acquisitions by consoli-dating all of the center’s service needs into fewer and larger task orders and in the process, eliminate redundant require-ments and contracts.

“There are a lot of different options for obtaining the professional services we need to be successful at our jobs,” said Kevin Keck, Strategic Services portfo-lio manager in AFLCMC. “OASIS will be the program used to acquire all AFLCMC services regardless of location. It allows us to effectively manage our resources by reducing the sheer number of service

contracts we have from more than 250 to as few as 30.”

Keck added that other benefits are that OASIS will allow AFLCMC to acquire services faster as well as provide greater flexibility in the movement of contract employees between center offices and organizations spread across multiple locations, all of which can be sup-ported by a single/common contractor team.

According to Patsy Reeves, AFLCMC executive director, the program is a ‘game changer.’

“The award of this contract was part of our six strategic objectives of the year,” said Reeves. “OASIS allows us to obtain the crucial services we need, more efficiently, while partnering with outstanding small businesses nationwide.” O

The Strike Systems Branch, working in conjunction with U.S. Special Operations Command (USSOCOM), recently completed the first flight of the AC-130J Ghostrider.

The branch is part of the Special Operation Forces and Person-nel Recovery Division at Wright-Patterson Air Force Base. Its par-ent organization is the Air Force Life Cycle Management Center, which is headquartered at Wright-Patterson AFB.

The 50-member Strike Systems team, along with Lockheed Martin Missiles Fire Control, began initial modifications in Feb-ruary 2013 at Eglin Air Force Base, Fla. The modification effort took nearly one year from initial cut to first flight in January. The Strike Systems Branch worked closely with airworthiness subject matter experts to ensure all necessary data was received and reviewed to obtain a military flight release for flight test in less than 12 months.

Developmental testing began on January 31 at Eglin and is scheduled to conclude in November. Modifications to the second aircraft will begin in September, with operational tests beginning in the summer of 2015. The first aircraft will be operational in 2017.

The Ghostrider blends the MC-130J Commando II with the combat proven Dragon Spear precision strike package from the AC-130W Stinger II. The precision strike package consists of a mission operator console, dual electro-optical infrared sensors, advanced communication suite, advanced fire control equipment, precision guided munitions, and a trainable 30 mm Bushmaster cannon.

The mission of the AC-130J Ghostrider is to provide close air support, special operations armed airborne reconnaissance, and

ordnance delivery to precise targets in support of ground forces. Additional collateral missions include strike coordination, non-traditional intelligence surveillance and reconnaissance, and command and control.

The next-generation AC-130J is USSOCOM’s number one acquisition priority. A total of 32 MC-130J aircraft will be modi-fied for Air Force Special Operations Command (AFSOC) as part of a $2.4 billion AC-130J program to grow the future fleet and replace AFSOC’s aging fleet of AC-130H/U/W gunships. O

AFLCMC Transitions to New Acquisition Program

Ghostrider Completes First Flight on Way to AFSOC

Compiled by KMi Media group staffSUPPLY CHAIN

Nimbis Services Inc. has been awarded a two-year Air Force Rapid Innovation Fund contract by Air Force Nuclear Weapons Center to develop a Trusted Silicon Stratus–Supply Chain Risk Management (TSS-SCRM) DIACAP-compliant cloud service. The DoD Information Assurance Certification and Accreditation Process (DIACAP) is a process by which information systems are certified for compliance with DoD security requirements and accredited for operation by a designated official.

Nimbis Services will deliver a first-of-its-kind multi-tenancy, inter-organizational, collaborative, trusted microelectronics supply chain risk management (SCRM) ecosystem that provisions a design-to-release-manufacturing, to operational, to life-cycle-management cloud computing infrastructure and enterprise architecture. Electronic

design automation software and integrated circuit data repositories are implemented as a private community cloud computing workflow-as-a-service for DoD research and development teams, contractors and government research laboratories.

“The TSS-SCRM technology is based on prior work funded by the Air Force Research Laboratory and demonstrated at the GOMACTech 2012 conference and in the DARPA Small Business Innovation Research-funded Application Domain Portal Hosting Service project,” said Robert Graybill, Nimbis Services’ president and CEO. The technology’s TSS SCRM capability represents a key milestone in the journey of enabling virtual modeling and simulation design ecosystems for military systems. Additional extensions include smart manufacturing neutral cloud hosting services for large manufacturers and their supply chains.

Army Aviation Field Maintenance

The U.S. Army Aviation and Missile Life Cycle Management Command has awarded DynCorp International (DI) a contract to provide aviation maintenance services throughout the Theater Aviation Sustainment Manager–OCONUS (TASM-O) region under the Army Aviation Field Maintenance contract.

“DynCorp International has decades of experi-ence providing Army Aviation field maintenance through the contract field teams program,” said Jim Myles, DynCorp International senior vice president, DynAviation. “This experience will be invaluable as we continue to provide superior Army Aviation support within the U.S. and internationally.”

DI will provide Army Aviation field and sustain-ment level maintenance services throughout the TASM-O region to include worksites at Camp Humphreys, South Korea, Illesheim Army Airfield, Germany, Landstuhl Army Airfield, Germany, Wiesbaden Army Airfield, Germany, Hohenfels Army Airfield, Germany, Soto Cano Air Base, Honduras, North/South Camp, Sinai, Egypt, and Camp Bondsteel, Kosovo. Services will include reset in accordance with established technical bulletins and directives, installation of modification work orders, support to the installation aviation activities and support to combat aviation brigades.

The competitively-awarded hybrid firm fixed price, cost-plus incentive fee, contract has one base year with four one-year options, and a total esti-mated contract value of $307.1 million if all options are exercised.

Nuclear Supply Chain Risk Management

USS Minnesota Maintenance

The U.S. Navy has awarded Electric Boat a $57.2 million contract to prepare and perform maintenance work on the USS Minnesota (SSN-783), a Virginia-class attack submarine. Electric Boat is a wholly owned subsidiary of General Dynamics.

Under the terms of the contract, Electric Boat will perform a post-shakedown availability on the Minnesota, which consists of maintenance work, repairs, alternations and testing to ensure the submarine is operating at full technical capacity. The work will take place at the Electric Boat shipyard in Groton and is scheduled for completion in February 2015.

www.MLF-kmi.com MLF 8.3 | 11

Lieutenant General Judith A. Fedder is deputy chief of staff for Logistics, Installations and Mission Support, Headquarters U.S. Air Force, Washington, D.C. She is responsible to the chief of staff for leadership, management and integration of Air Force logistics readi-ness, aircraft and missile maintenance, civil engineering and security forces, as well as setting policy and preparing budget estimates that reflect enhancements to productivity, combat readiness and quality of life for Air Force people.

Fedder is a 1980 distinguished graduate of the ROTC program at Michigan State University. A career maintainer, she has served as officer in charge of numerous aircraft maintenance units and as chief of logistics management at the Combined Joint Task Force Headquarters for operations Proven Force and Provide Comfort at Incirlik Air Base, Turkey. Her commands include the 46th Compo-nent Repair Squadron and 46th Equipment Maintenance Squadron at Eglin Air Force Base, Fla.; 31st Logistics Group at Aviano AB, Italy; 65th Air Base Wing at Lajes Field, Portugal, where she also served as the sub-unified commander of U.S. Forces Azores; and the 76th Maintenance Wing at Tinker AFB, Okla. She has served as deputy director in the Office of Legislative Liaison, Secretary of the Air Force; and as the director of logistics for Air Combat Command. Prior to this assignment, she was the director of logistics, deputy chief of staff for Logistics, Installations and Mission Support, Headquarters U.S. Air Force, Washington, D.C.

Her awards and decorations include: Defense Superior Service Medal; Legion of Merit with oak leaf cluster; Meritorious Service Medal with four oak leaf clusters; Joint Service Commendation Medal with oak leaf cluster; Air Force Commendation Medal; and Air Force Achievement Medal.

Q: What are your primary initiatives over the next 12 months to drive as much extra cost from the supply chain as possible?

A: We are continuing to build on successful efficiencies and looking for new ways to impact the cost of logistics. Among the most significant efforts we have underway over the coming year are initiatives impact-ing supply chain costs that will yield the cost-effective logistics we need. These are part of a larger cost effective readiness endeavor that focuses on reducing the cost of doing business while achieving the same business outcome … or readiness.

To that end, we have two major initiatives in work: First, to reas-sess one of our age-old logistics planning factors regarding order and ship time (OS&T) for our mobility readiness spares packages (MRSPs), and second, to optimize our base-level maintenance repair networks within the repair network integration (RNI) construct.

We know that the more spares we keep in our pipeline, the higher our logistics costs will be. For many years the content requirement for some of our MRSPs has been calculated using a planning factor of 30 days OS&T for resupply. While that was a reasonable assump-tion in the past, the efficiencies we’ve gained in our supply chain and transportation over time give us reason to re-evaluate planning factors like this one, and that presents an opportunity for significant savings. While the kit requirements will still be computed to support a 30-day contingency, adjusting the rate of resupply to a more representative O&ST—even tailoring the resupply factor to different commodities—will ultimately drive cost from the total requirement.

Another initiative that is already generating savings and boosting the focus on warfighter readiness is RNI. This effort recognizes that we have some excess capacity in our intermediate level aircraft main-tenance repair capability—what we call our backshops—and seeks the right balance of capability and capacity across the total force of active duty, Air National Guard, and Air Force Reserve. RNI is not just about right-sizing intermediate level repair to target how much capacity and manpower we really need for this support, but equally important, is about networking high performing repair nodes that are flexible, responsive, and integrated into the broader supply chain.

Over the next 12 months we will focus on consolidating hydraulics back shops, evaluating secondary power consolidations and—very importantly—beginning an end-to-end analysis of all segments of the supply chain. Our goal is to fully integrate off-equipment item repair

Lieutenant General Judith A. FedderDeputy Chief of Staff for Logistics, Installations and Mission Support

U.S. Air Force

Efficiency OptimizerCost-Effective Readiness for Product Support and Operational Logistics

Q&AQ&A

www.MLF-kmi.com12 | MLF 8.3

Learn more | 701.231.7938 | [email protected] | http://www.ndsu.edu/transportation/

Managerial LogisticsTransportation & Urban Systems

MASTER’S PROGRAMS IN: