Mlf 7 1 final

-

Upload

kmi-media-group -

Category

Documents

-

view

233 -

download

2

description

Transcript of Mlf 7 1 final

FOB Power O Intermodal Shipping O JLTV Life Cycle Management Rugged Devices O Vehicle Reset

Capability Provider

Maj. Gen. John R. “Jack” O’ConnorDeputy Chief of Staff, G-4U.S. Army Forces Command Exclusive Interview with:

Arthur “Art”G. DAhl IVDeputy Chief of Staff, G-4TACOM LCMC

www.MLF-kmi.com

February 2013Volume 7, Issue 1

The Publication of Record for the Military Logistics Community

AUSA WINTER ISSUE

OrGAnIzAtIOnAl PrOfIleSpecial pull-out Supplement

At Oshkosh, we have an unwavering commitment to the men and women whose lives rely on our vehicles. Our JLTV solution is no exception.

The Oshkosh® Light Combat Tactical All-Terrain Vehicle (L-ATV) is tested, proven and ready to bring new capabilities to future missions. With an advanced crew protection system, the Oshkosh L-ATV provides MRAP-level protection and the ability to adapt as operating environments change. Its lightweight design and TAK-4i ™ intelligent independent suspension system* deliver unprecedented off-road mobility, maneuverability and speed.

Building for tomorrow’s missions. The Oshkosh L-ATV.

For more than 90 years, Oshkosh Defense has been defi ning the leading edge of light, medium, MRAP and heavy tactical vehicles.

*Patent pending

©2013 OSHKOSH CORPORATION Oshkosh and the Oshkosh logo are registered trademarks and TAK-4i is a trademark of Oshkosh Corporation, Oshkosh, WI, USA JLTV_001_2012-US-1

Supporting today’s missions. And, building for tomorrow’s.

The OSHKOSH® JLTV Solution.

oshkoshdefense.com/jltv

14632_OshD-JLTV_MilitLogForum.indd 1 2/4/13 1:39 PM

Your single-source solution for material and services.

www.SupplyCore.com

Major General john r. “jack” o’connor

Deputy chief of Staff, G-4u.S. army Forces command

14

February 2013Volume 7, Issue 1

Departments Industry Interview2 editor’s PersPective12 suPPly chain23 resource center

Graz GrazianoVice president, combat Support and SustainmentGeneral Dynamics land Systems

MILITARY LOGISTICS FORUM

24

Cover / Q&AFeatures

Major General john r. “jack” o’connor

Deputy chief of Staff, G-4u.S. army Forces command

14

4 vehicle resetthe current environment could represent a perfect opportunity for the u.S. military to grow programs to reset and recapitalize military vehicles. the prospect of significant cuts to the defense budget has placed a greater emphasis on cost control.By Peter BuxBaum

7interModalHauling freight more efficiently across the transportation chain. efficiency translates to cost savings and security.By Hank Hogan

9touGh by desiGnRugged laptop providers have begun to introduce light, thin, rugged tablets and small docking stations that can fit into tight spaces when mounted inside military vehicles and rotary wing aircraft.By CHeryl gerBer

21Power onthe options available for electrical power at forward operating bases are growing in both numbers and capabilities.By Hank Hogan

u.S. Army tACOm lCmC SPeCIAl Pull-Out SuPPlement

exclusive interview with arthur “art” G. Dahl iVDeputy chief of Staff, G-4

doinG it riGhtplanning for the life cycle management of the JltV is part of the development—not an afterthought.By marC Selinger1 7

There are times when the visible application of U.S. foreign policy is displayed by projecting an armed force somewhere in the world. This exten-sion of U.S. capability is designed to reinforce U.S. interests, lend support to an ally or as part of an international force against a common threat.

However, there are other times where the best interests of the U.S. are not served by being the one delivering the force, but by serving as a facilitator. Logistics as an extension of foreign policy continues to be a strong and posi-tive use of U.S. military strength.

The ungoverned areas of northern Mali have long been a cause of concern, as they are—except for geography—a mirror image of what was found in Afghanistan that allowed it to become a haven for terrorist groups. Not being easily accessible has never been a deterrent for militants and has always proved more of a chal-lenge to those opposed to the militants than to the militants themselves.

Logistics, therefore, much like direct action, is an extension of U.S. capability, designed to reinforce U.S. interests, lend support to an ally or to be a part of an international force against a common threat.

Defense budgets are under threat in the U.S., but we still possess so much more capability than any of our coalition partners. Our ability to maintain our mission requirements in support of U.S. operations, yet still have the capacity to divert resources to support other requests, is another testament to the logistician. It is also a reflection of a core capability that needs to be understood. France took the lead in Mali but lacked the strategic depth to project their forces without help from partners, such as the U.S., and by contracting with commercial cargo haulers. In fact, a reflection of U.S. industry capability is that much of the partner airlift support came from other countries operating the C-17 into Mali!

Whether direct combat action, responding to an international disaster or crisis, or working with a partner nation, logistics is the common thread that makes the execution and sustainment of foreign policy possible.

Jeffrey D. McKaughaneditor-in-CHieF

EDITOR’S PERSPECTIVE

Publication of Record for the Military Logistics Community

EditorialEditor-In-ChiefJeff McKaughan [email protected] EditorHarrison Donnelly [email protected] Editorial ManagerLaura Davis [email protected] EditorsSean Carmichael [email protected] Hobbes [email protected] Baldwin • Christian Bourge Peter Buxbaum • Henry Canaday Cheryl Gerber • Hank Hogan • Marc Selinger Leslie Shaver • Karen Thuermer

art & dEsignArt DirectorJennifer Owers [email protected] Graphic DesignerJittima Saiwongnuan [email protected] Designers Scott Morris [email protected] Papineau [email protected] Paquette [email protected] Waring [email protected]

advErtisingAssociate PublisherJane Engel [email protected]

KMi MEdia groupPublisherKirk Brown [email protected] Executive OfficerJack Kerrigan [email protected] Financial OfficerConstance Kerrigan [email protected] Vice PresidentDavid Leaf [email protected] McKaughan [email protected] Castro [email protected] & Communications ManagerHolly Winzler [email protected] AssistantCasandra Jones [email protected] Show CoordinatorHolly Foster [email protected]

opErations, CirCulation & produCtion

Circulation & Marketing AdministratorDuane Ebanks [email protected] SpecialistsTuesday Johnson [email protected] Walker [email protected] Villanueva [email protected]

a proud MEMbEr of:

subsCription inforMation

Military Logistics Forum ISSN 1937-9315

is published 10 times a year by KMI Media Group. All Rights Reserved.

Reproduction without permission is strictly forbidden. © Copyright 2013.

Military Logistics Forum is free to qualified members of the U.S. military, employees of the U.S. government and non-U.S. foreign service

based in the U.S. All others: $65 per year. Foreign: $149 per year.

CorporatE offiCEsKMI Media Group

15800 Crabbs Branch Way, Suite 300 Rockville, MD 20855-2604 USA

Telephone: (301) 670-5700 Fax: (301) 670-5701

Web: www.MLF-kmi.com

Military logistiCs foruM

Volume 7, Issue 1 • February 2013

www.GIF-kmi.com

Geospatial Intelligence

Forum

www.BCD-kmi.com

June 2012Volume 1, Issue 1

www.BCD-kmi.com

Border Threat Prevention and CBRNE Response

Border Protector

Michael J. Fisher

ChiefU.S. Border PatrolU.S. Customs and Border Protection

Wide Area Aerial Surveillance O Hazmat Disaster ResponseTactical Communications O P-3 Program

Integrated Fixed Towers

Leadership Insight:Robert S. BrayAssistant Administrator for Law EnforcementDirector of the Federal Air Marshal Service Transportation Security Administration

SPECIAL SECTION:

Border & CBRNE Defense

www.MAE-kmi.com

Military AdvancedEducation

www.MIT-kmi.com

Military Information Technology

www.GCT-kmi.com

Ground Combat

Technology

www.MLF-kmi.com

Military Logistics Forum

www.M2VA-kmi.com

Military Medical & Veterans

Affairs Forum

www.MT2-kmi.com

Military Training Technology

www.SOTECH-kmi.com

Special Operations Technology

www.TISR-kmi.com

Tactical ISR Technology

www.CGF-kmi.com

U.S. Coast Guard Forum

KMI MedIa Group LeadershIp MaGazInes and WebsItes

For more than 160 years, APL has been working to ensure our service men and women always

have what they need to get the job done. Our unparalleled experience in ocean transportation

and in-country logistics sets us apart from the competition. APL’s successful, long-standing

relationship with the military proves that we have the resources and know-how to deliver when

it counts. We won’t let you down, and more importantly, we won’t let down the troops who

rely on the supply chain. We pride ourselves on being the mission critical link to success for our

military yesterday and today, and we’ll be there for our troops tomorrow.

To learn more about how we serve those who serve, visit www.apl.com/usflag.

Steaming jungles, blazing deserts, frozen mountaintops. No matter where the dinner order comes from, we’re the reason MREs are never MIA.

U.S. FlagServices

The current environment could repre-sent a perfect opportunity for the United States military to grow programs to reset and recapitalize military vehicles. The prospect of significant cuts to the defense budget has placed a greater emphasis on cost control. It’s less expensive to reset or recapitalize a vehicle than to buy new. In addition, given the adver-saries the U.S. expects to face in the foresee-able future, investments in new technologies may not be absolutely necessary.

Whether current trends dictate a strengthening of the armed forces’ vehicle reset and recapitalization programs remains to be seen, however. Part of the outcome will be dictated by politics. Another big part of it will be whether policymakers will be willing to make decisions that look toward the long haul.

In the meantime, the U.S. Army con-tinues with a robust program of resetting and recapitalizing military vehicles. In places like the Red River Army Depot in Texarkana, Texas, the Army is recapitalizing fleets of military vehicles and is always trying to figure out better ways to do so. The Army also turns to the original equipment manufactures to reset and recapitalize vehicles that they have supplied.

“We have been given the mission of recapitalizing a fleet of 6,200 up-armored HMMWV vehicles,” said Colonel Doyle

Lassitter, commander of the Red River Army Depot. “When we first started, we were turn-ing out about 17 vehicles a day. By con-tinually reviewing the process, we are now producing 42 vehicles per day.”

Red River managed to achieve these results by benchmarking the Army’s manu-facturing process with those of commercial industry and incorporating lean manufacturing pro-cesses into its practices. “We have an office of continuous improvement that looks into our processes and evaluates and modifies them,” said Las-sitter.

Recapitalization and resetting of military equip-ment refer to two different processes. “Recapitalization tears equipment down to its basic components and introduces to it any updated system engineering changes that have come about since it was first manu-factured,” said Lassitter. “Once it is recon-structed it is like a brand-new vehicle with zero miles and zero hours and provides a longer life expectancy.”

In other words, recapitalization updates a platform to its newest variant. Resetting brings a vehicle back to its original configu-ration.

Red River has been designated by the Sec-retary of the Army as the Center for Industrial and Technical Excellence for tactical wheeled vehicles, the Bradley fighting vehicle and others. The depot is the 2011 recipient of the Army Award for Maintenance Excellence as well as the two-time recipient of the Robert T. Mason Award for Depot Maintenance Excel-

lence. Red River’s continuous

improvement process works by examining the minutiae of how the refurbishment work is performed. “We look at specific workstations and the tasks that mechanics perform,” said Lassitter. “We look at the sequences in which items are done and eliminate waste in movement. For example we reduced the number of items

assembled on a vehicle before painting it. We reduced the number of men assigned to mount tires from two to one. This made the process quicker and improved quality as well.”

Oshkosh Defense has been active in recapitalizing the military vehicles it sup-plies the Army, including the Palletized Load System (PLS) and Heavy Expanded Mobil-ity Tactical Truck (HEMTT). HEMTTs haul troops, supplies and equipment in severe

It’s all about lIfe extensIon and mIssIon readIness.

Col. Doyle lassitter

by Peter buxbaum

mlf CorresPondent

www.MLF-kmi.com4 | MLF 7.1

environments. The Oshkosh PLS is built to carry ammunition and other critical supplies needed in battle. Oshkosh also supplies the family of medium tactical vehicles for which there is no current recap or reset program.

In the case HEMTT, Oshkosh upgrades A0 and A2 configurations of the vehicle to the A4 variant, a process which includes installing improved suspension systems, an air-conditioned and armor-ready cab and a more powerful drive train. Oshkosh Defense has also reset vehicles from the Army’s family of heavy tactical vehicles and line-haul fleets.

Oshkosh’s recapitalization contract runs through fiscal year 2014. Recapitalized vehi-cles are dialed back to zero hours and zero miles and come with a new vehicle warranty.

“The real strength of our recap program is in our logistics engineering and the knowl-edge of the platform,” said Jeff Koga, senior director for integrated product support at Oshkosh Defense. “We focus on modernizing the right elements of the vehicle to improve reliability in the long run. We lower the vehi-cle’s life cycle costs and extend the service life while respecting the customer’s budget.”

Oshkosh performs these ser-vices at its plants in the U.S. as well as in the field when called upon to do so. Between 2007 and 2012, Oshkosh reset over 2,000 vehicles for the Southwest Asia theater in Kuwait. “We are pre-pared to do this work where it is most cost effective while meet-ing readiness requirements,” said Koga. “We employ many lean practices to keep quality high at the least cost.”

Under the HEMTT recapi-talization contract, Oshkosh installs new armored cabs, LED marker lights, two-piece wheels, and air-ride seats and upgrades the transmission and engine. The Cat 15C engine, which has been in service since the 1980s, is replaced with a Detroit Diesel AV92 engine that increases the vehicle’s horsepower. The tires and all electronics are replaced with new parts. Recapped vehicles cost an average of

15 percent less than new Oshkosh vehicles, according to Mike Ivy, vice president and general manager for Army Programs at Oshkosh Defense.

“It is a good idea for the Army because it is getting like-new vehicles with a new truck warranty for less than the cost of new truck,” said Ivy. “It’s good for us because it improves the volumes going through our produc-tion facilities.” The level of savings depends on the spe-cific truck variant, Ivy added.

The current recap at Red River of the HMMWV is the second of two such programs on the tactical wheeled vehicle, considered to be one of the most versa-tile, dependable and mobile

in the world. Over 65 combat and combat sup-port systems have been fielded on HMMWVs.

DLA, TACOM, LEAD, RRAD AND MMA WANTED A SURE-FIRE PARTS DELIVERY SYSTEM,DLA, TACOM, LEAD, RRAD AND MMA WANTED A SURE-FIRE PARTS DELIVERY SYSTEM,WHENDLA, TACOM, LEAD, RRAD AND MMA WANTED A SURE-FIRE PARTS DELIVERY SYSTEM,

WE HAD AN ANSWER.

www.wwwilliams.com

DLA, TACOM, LEAD, RRAD AND MMA WANTED A SURE-FIRE PARTS DELIVERY SYSTEM,DLA, TACOM, LEAD, RRAD AND MMA WANTED A SURE-FIRE PARTS DELIVERY SYSTEM,WE HAD AN ANSWER.WE HAD AN ANSWER.In fact, we helped drive the development of a Customer Pay program that mandates the only

time our OEM gets paid is when a part is delivered to the military assembly line. The following results speak for themselves: No G-coded vehicles coming off the lines • Parts inventories reduced from $100 million to $25 million • 28 million parts for 25,000 Humvees were delivered with only 52 misses • Named 2008 LEAD supplier of the year

For Warehousing & Logistics, Technical Services, Products, or Kitting and Packaging, choose Williams Logistics and Consider It Done.

Albany, GA | Chambersburg, PA | Scranton, PA | New Boston, TX

Call 1-800-999-0933

Jeff Koga

mike Ivy

www.MLF-kmi.com MLF 7.1 | 5

AM General has produced more than 281,000 HMMWVs for the U.S. and more than 50 friendly international forces. The HMMWV is in its sixth generation and continues to evolve.

“AM General proudly supports the Army depots as they recapitalize and reset HMMWVs,” said Jeff Adams, an AM General spokesperson. “The company has the exper-tise and capability to leverage its significant production experience to conduct HMMWV recapitalization in its facilities if requested.”

Through reset and recap initiatives, the company has provided its cus-tomers improved and updated engines, transmissions and chassis, as well as steering and other components to maintain performance and durability. “We have decades of engineer-ing and integration capabili-ties as [a] prime contractor for light tactical vehicles,” said Adams. “More than 25 years building and evolving the HMMWV gives us intimate knowledge of what can and can’t be done to modernize the platform. We have the further advantage of using existing and well-established HMMWV logistics support, training and rapid production through the active HMMWV production line.”

Although recapitaliza-tion involves a more elaborate process than resetting, the logistics of the reset can be more complex, according to Lassitter. “It is easier for us to predict the parts needed to support the recapi-talization process and to establish production lines that flow very efficiently,” he said. “With reset, the supply chain becomes much more complex because each vehicle is unique. We still try to use lean manufacturing processes for resets but it is much more challenging.”

Red River uses historical databases to manage the complexities of both resets and recapitalizations. “We use these to track the types of parts used in the past to support like programs,” said Lassitter. “As we bring new programs into Red River, we reference those historical data to anticipate the parts we need.”

A related type of technology and ser-vice is provided by ISO Group. ISO main-tains a proprietary database of over 120 million national stock numbers along with information on companies that maintain

inventories of those parts and the levels of inventories they maintain. ISO can also advise depots and their contractors on com-panies that can design and manufacture parts that have become obsolete.

“When there are requirements for depots or contractors,” said Alex Techoueyres, ISO’s co-founder and senior vice president of global sales, “we can tie those requirements to inventories that may be maintained by the original manufacturer or another company that may have that part in stock. We have

done this kind of work for the HMMWV and the FMTV, as well as other platforms.”

The ISO Group maintains a live feed on parts inventories maintained by 13,000 sup-pliers. “They provide us with their inventory status and we can tie that inventory status to platforms,” said Techouey-res. “Their incentive is that we have 12,000 active buyers around the world. We have 150 buyers registering with us every day looking for 20,000 line items every month. With this information, we provide our customers with an instant availability picture of parts needed for a given program.”

Another approach to the logistics of recapitalizations and resets that has already been applied to vehicle repairs involves having the Army or

a contractor actually manufacture a needed part. “The tendency has been to buy a lot of parts and put them on a shelf,” said Major General (Ret.) Charles Fletcher, former direc-tor of operations and plans at the U.S. Trans-portation Command and now a senior vice president at Alion Science & Technology.

An alternative is to establish a fabrication capability that can produce parts which can-not be stocked cost effectively. Alion helped establish such a facility at a repair location in Afghanistan. Alion is now in talks with the Defense Logistics Agency on how this concept could work for resets and recapitalizations.

“The DLA is interested in business prac-tices that could reduce distribution costs,” said Fletcher. “Savings on transportation and warehousing costs should go into the reset or recap calculation.”

How might the prospect of an aus-tere defense budget impact the Army’s recapitalization and reset programs? The

Army could save on fleet modernization efforts with recaps and resets instead of acquiring new vehicles. But the end result may not be that simple.

“Even as budgets come down we will see efforts to sustain recapitalizations,” said Ivy. “That is where the military gets the best value for the dollar and it is the best way to continue fleet modernization in an austere budget environment.”

Techoueyres is concerned that if Congress decides on an across-the-board budget cuts, recapitalization and reset will suffer most. “Seventy percent of 2013 dollars are being spent on maintenance, repair and opera-tions versus 20 percent on procurement and 10 percent on research and development,” he said. “That means that in the case of an across-the-board budget cut, sustainment and MRO will be hit the most.”

“I think that from a national security strategy point of view and from a fiscal expen-diture point of view it makes more sense to emphasize recapitalizations and resets over investing in new vehicles,” said Fletcher. “The scenarios in which the U.S. will be engaged in the foreseeable future call into question whether we need to invest in technical supe-riority given our potential adversaries.”

But political pressures may dictate dif-ferent results. For one thing, manufacturing new equipment creates more jobs and there may be members of Congress who will want to push in that direction.

Also, Fletcher asserted, some decision makers might prefer cutting sustainment budgets because its impacts would not be felt immediately. “When you cut investments in parts and maintenance you may not see the result right away, but you may suffer the results later,” he said. “Policymakers need to look past expeditious budget decisions and look toward the readiness that will help the military meet its missions in the future.”

“Our mission is to support readiness,” said Lassitter. “If there were a reduced budget I would assume there to be a reduction in the numbers of vehicles the Army decided to reset and we would adjust from there. But that wouldn’t affect the quality of the equipment we turn out.” O

Charlie fletcher

Alex techoueyres

For more information, contact Editor-in-Chief Jeff McKaughan at [email protected] or search our online archives for related stories

at www.mlf-kmi.com.

www.MLF-kmi.com6 | MLF 7.1

Behind the tip of the spear lies a long shaft, which, in the case of support for the U.S. military, stretches around the world. Get-ting warfighters what they need when they need it involves a com-plicated coordination of trucks, trains, ships and planes. Advances in processes and technologies such as fewer port calls and better scheduling software promise to make that effort smoother and more cost effective.

Just how big that supply chain is can be seen in some figures from the Army’s Military Surface Deployment and Distribution Command (SDDC). The agency moved more than 7.3 million measurement tons of cargo in 2012, the equivalent of almost 124,000 20-foot containers full of cargo. That’s about 90 percent of all cargo the Defense Department shipped last year, said Peter Soule, SDDC chief of future operations.

“Our responsibility is for global surface cargo movement, which has morphed into a multimodal land/sea/air mission,” Soule said.

In general, the preference for cargo going in or out of the-ater is to use a standard 20-foot ISO container or something even smaller, he added. Doing so eliminates the need to unpack, transfer and repack freight, as those sizes can be handled by the widest array of carriers and transport methods. Shipping via a larger, 40-foot container is somewhat more economical for the surface segment of a journey, but the airframes that can handle such containers are expensive. Thus, any savings from the surface leg would likely be wiped out by the extra cost of using larger aircraft, Soule said.

That isn’t to say that 40-foot containers are never used. When that’s done, the contractor will unstuff the container when needed and load it onto pallets for air shipment. The contractor provides pallet level manual in-transit visibility so that the cargo can be tracked. Only a small percentage of total cargo ever goes through this process, however.

Shipments by air face simultaneous volume and weight con-straints. For that reason, vehicles traveling by air are not put into

a container. Doing so saves cubic inches that can be used for other cargo, Soule noted.

In general the SDDC is trying to minimize any air leg, as sur-face travel is much cheaper, he said. As of October 2012, less than 30 percent of the traffic into Afghanistan was by air. About half the cargo traveled by land over the northern distribution network that snakes through Russia and Central Asia. About a sixth moved in a multimodal fashion.

Avoiding shipment by air is not always possible, as land or sea routes can be cut off. Also, using only surface methods does require higher stocking levels because transit times are longer.

As for the future, the SDDC is constantly on the prowl for new shipping hubs. Today it has one in Jordan and another in Dubai, with the latter a better fit for current missions but unable to accommodate all the needed volume. Any new hub would have to be on existing major shipping lines and have the needed infra-structure. The hub would also have to reside in a country willing to allow the U.S. to conduct military operations in exchange for the benefits they bring.

“They provide dollars to the various countries willing to allow us to conduct them,” Soule said of the SDDC’s transport activities.

Moving military cargo around is similar to commercial trans-port in many respects, but there are some special requirements. For instance, transporting arms, ammunition, explosives and other sensitive cargo demands a certain level of security be in place. The SDDC has a team that looks into how best to satisfy these require-ments while holding down costs. By doing this, the group found a way to save $2.7 million in transportation costs in 2012 alone.

Some of that military cargo moves over the country’s second-largest freight rail network, which is operated by Fort Worth, Texas-based BNSF Railway. To increase efficiency, the railroad often groups military freight together, said Denis Smith, industrial marketing vice president.

In practice, this means that, for instance, tanks being shipped do not travel on individual cars interspersed among a group of

HaulIng freIgHt more effICIently aCross tHe transPortatIon CHaIn.

by Hank Hogan

mlf CorresPondent

www.MLF-kmi.com MLF 7.1 | 7

other goods, Smith said. “A lot of what we do is unit train stuff. We’ll ship a bunch of tanks in flatcars and all in one train.”

Thus, there may be 45 to 80 cars in a single, dedicated unit train shipment, carrying everything from tanks to ammunition and a myriad of commodities. For ammunition and gear that requires security and special handling, this approach improves efficiency and makes it easier to guard the cargo. Done properly, bunching up equipment and supplies in this way can also help the military execute its missions, Smith said.

Movement by rail can be highly efficient, particularly when it comes to shipment of goods by containers. In BNSF’s lingo, this falls under the intermodal heading. Cami Large, the railroad’s assistant vice president of industrial product sales, noted that a single train loaded with containers can get 280 trucks off the road. Since trains are three or more times as fuel efficient as trucks, that translates into significant savings in transportation costs.

The company adjusts the spacing and configuration of cars, as well as the length of the overall train, so as to improve efficiency. One innovation has involved double stacking containers, an arrangement that has required BNSF to upgrade infrastructure, as not all tunnels, bridges and overpasses can accommodate the greater height of stacked containers.

“That’s the investment that we’ve made in adding tracks and making sure we can handle the double stack all along our network. We’ve done the same in maintenance. All of that makes us more efficient, so we can run the trains at optimal speeds. We don’t have to stop. We don’t have to reroute,” Large said.

While efforts continue to make trains more efficient, other areas are also being targeted. For instance, BSNF is paying con-siderable attention to the queuing at terminals, the hubs where containers are moved between trains and trucks or between trains, trucks and ships. Automated systems are used, with bio-metrics employed to rapidly authenticate drivers for quick entry and exit of a freight facility. Cameras and other technology are used to identify and track containers so that freight operations run more smoothly. Technology in the form of sensors and the like ensures that a sealed container is not breached without detec-tion during transit.

For overseas operations, cargo may start out or end up on a truck or train but in between, most of it travels by sea on ships. Some of these come from Maersk Line, a global operation head-quartered in Copenhagen that comprises about 550 vessels. Its U.S. flagged ships are owned and operated by Maersk Line, Limited.

Kevin Speers, senior director of marketing and communica-tions for the U.S. operation, noted that by law the military must use 100 percent U.S. flagged ships. While meeting this requirement, carriers design their services to maximize cargo volume and profit-ability, competing on transit time, schedule reliability and other factors. In all of this, they must accommodate the demands of the U.S. military and other customers.

In Maersk’s case, it has a facility in Portsmith, Va., where rail lines allow freight to come right into the terminal to be loaded onto a ship. From the U.S., these long-haul vessels will travel to their destination. If that is in the Middle East, Maersk Line, Limited offers two options. One involves a trip without making port calls along the way, while the second does include minimal stops during transit, Speers said.

He likened the operation to that of a bus running on a regular route. Weather anywhere along the way and port congestion at

either end, however, can cause delays. As a result, scheduling is not a simple affair.

“It is complex. You start getting into a pattern and a rhythm. It’s something that has to be actively managed. You can’t put it on autopilot,” Speers said.

For example, through tracking en route, it may be known when a long-haul ship is due to arrive at a port in the Persian Gulf with cargo bound for Iraq or elsewhere. What also will be known is how long it will take to unload the ship. That information can be derived from the nature of the cargo and the port facilities, as well as expected demands on those capabilities.

Armed with that information, operations planners can schedule a short-haul feeder to arrive after the long-haul ship has docked and been unloaded. If the timing is correct, the cargo can be picked up immediately. Once loaded, the short-haul ship can then head northbound into Persian Gulf or in another direction, if that is what’s needed.

If the cargo is traveling by air, then the situation is different. Because the freight constraints differ between sea and air, there necessarily is some repacking of the cargo when moving between the two. This can be a complicated affair, a task made somewhat easier by technology and procedure changes. For instance, track-ing of cargo has to be done by pallet or a smaller-than-a-container parcel basis. That’s the only way to achieve the necessary visibility and control of the cargo. It also helps in creating the paperwork to document the proper chain of custody.

As for the future, general advances in shipping technology and services will benefit the military. This is by design. In order to cap-ture any part of the military’s cargo business, carriers are required to function just like any other commercial concern.

As Speers said of the shipping business that Maersk runs for the military, “It’s a commercial service. These ships are U.S.-flagged but the preponderance of their cargo is commercial. In fact these ships are required to be in international trade and com-mercially viable.” O

For more information, contact Editor-in-Chief Jeff McKaughan at [email protected] or search our online archives for related stories

at www.mlf-kmi.com.

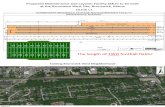

Most equipment items travel across various modes of transport including air, land and sea, and the easier that equipment—or the container that it is packed in—can transition from one mode to the other, the quicker and cheaper the entire transit will be. [Photo courtesy of DoD]

www.MLF-kmi.com8 | MLF 7.1

Rugged laptop providers have begun to introduce light, thin, rugged tablets and small docking stations that can fit into tight spaces when mounted inside military vehicles and rotary wing aircraft. The tablets can’t match the more power-ful, fully rugged laptops, often functioning as mobile servers, but the smaller size, lighter weight and lower power draw can provide advantages.

A growth in BYOD—bring your own device—has boosted the appeal of rug-ged tablets in the military. “Soldiers in the field today are also consumers in the BYOD evolution, showing up with an Android tablet or smartphone of their own,” noted Jim Rimay, president of Getac Inc.

Arriving familiar with such devices means soldiers need less—if any—time to adjust when they encounter tablets in theater. Soldiers can download only the information they need from a rugged laptop server in a vehicle, then go mobile with a light but rugged tablet worn with a shoulder strap.

Getac, Panasonic and other rugged laptop providers began releasing light but rugged tablets on Windows 8 and Android 4 last year. “We’ve seen an increased level of interest in rugged tablets and iPads lately. It’s safe to assume that every branch of the military is field-testing this form factor now,” noted Tim Collins, senior director, federal, Panasonic Systems Com-munications Co.

The tablet SWaP—smaller size, lighter weight and lower power—can facilitate lean mobility and logistics. A lighter tablet can have less chance of damage than a heavier laptop. They can also be easier to read. “A tablet can be mounted closer to the operator’s field of view,” said Donald McCook, vice president of business devel-opment, The ProCustom Group, which manufactures mounting racks and dock-ing stations for Getac, among others.

Last year both Getac and Panasonic released light, rugged tablets to comple-ment their rugged laptop lines. Getac launched its Z710 rugged Android tab-let, weighing less than 2 pounds. The Z710 offers a 7-inch, scratch-resistant Gorilla glass display, MIL STD 810/IP65

beIng rugged Is Part of tHe equatIon, beIng useful Is tHe otHer PIeCe.by CHeryl gerber

mlf CorresPondent

www.MLF-kmi.com MLF 7.1 | 9

certification and advanced communica-tions features, including WiFi and an RF-pass-through GPS sensor. Photo/video capabilities are accessed via the glove-friendly touchscreen display. The Z710 includes barcode scanning and RFID (radio frequency identification) configurations for data capture.

Panasonic began launching its Tough-pad family of rugged tablets with the A1 last year, which weighs only 2.1 pounds. “We built the A1 with the same form factor as the iPad, but the A1 is MIL STD 810G and IP65 certified,” Collins said. “Every-thing we learned from the CF 31 and CF 19 we translated into the 10-inch Toughpad A1,” he said.

The company continued to expand its Toughpad line early this year with the release of the Toughpad G1, a 10.1-inch tablet running Windows 8 Pro with Intel i5 vPro processors. The G1 has a sunlight-viewable touchscreen, an 8-hour battery, wireless with Bluetooth V4, 802.11 a/b/g/n WiFi, and for I/O it’s got USB 3.0, HDMI, wired LAN and true serial port or dedicated GPS.

Panasonic followed with the Tough-pad B1 running Android 4.0, also MIL STD 810G-tested. The A1 and B1 include security features such as encryption, IPsec VPN, trusted boot, root protection and FIPS compliance.

The rugged tablet family took lessons learned from Panasonic’s most rugged products: the CF 31, a 13.1-inch laptop now running Windows 8, and the CF19, a convertible laptop/tablet with a sunlight-viewable LCD touchscreen. Both have Intel i5 vPro processors, many communications options and are MIL-STD 810G- and IP65-certified.

As with Panasonic, Getac’s new tab-let arrived informed by Getac’s existing

installed base of rugged laptops, such as the V100 fully rugged convertible. The V100 is used in Black Hawk helicopters by the Unit Level Logistics System–Aviation-Enhanced (ULLS-A E) Army program at Fort Lee, Va.

The ProCustom Group developed an unusual way to mount the V100 convert-ible in a large truck where there was no space for a traditional mount or dock. “They created a foam insert for the com-puter to go into the map pocket next to the console while the computer continues to run. It’s ventilated with a Velco strap to secure it at a fraction of the cost of other mounts,” Rimay said.

Getac collaborates with mount and dock providers early in the development of their rugged mobile products to arrive at a synchronized solution. “We integrate the overall design from the earliest stages. These mounts have got the computer clamped down securely in military vehi-cles but they have floating capability so the connectors inside the docks are float-ing and do not allow damage vibration to pass through into the motherboard,” said Rimay. “We want to make sure there is good mechanical alignment of the dock so nothing gets damaged,” he said.

Mounting racks, docking stations and rugged mobile products are all manufac-tured with devices that mitigate vibration and shock. “Vibration can be transferred into any and all of the pieces in a laptop and mounting rack. All that shock and vibration can transfer up the stalk of a mounting rack which is bolted to the floorboard, mounting bracket and plat-form through the devices that hold the laptop in place,” Collins said.

“In the event of a collision, rollover or IED explosion, the mount becomes a point

from which the laptop can jettison. If the casing of a laptop has not been built to withstand that, the mounting points can cause the case to break off and all of a sud-den, you’ve got a jettisoned laptop in the cockpit of the vehicle,” said Collins.

Vibrations are specific to particular vehicles. “There are different vibrations on a small vehicle, large truck or tracked vehicle. Sensors determine the degrees of vibration. We take that data, add data from MIL STD 810G, and from the customer to determine the category and degree of shock and vibration to arrive at a number and a procedure for designing it,” said McCook.

“There’s very little real estate inside of them,” noted Rimay. “Tracked vehicles, the bulldozer type, are not standard. They create a completely different type of vibra-tion. So we work with the Pro Custom Group to design vibration dampeners and customized docking stations,” he said. “If you don’t work directly with the mount-ing companies, then you are relying on a third party to do it after the fact,” he added.

The Pro-Custom Group makes wire rope isolators that, as the name suggests, isolate the impact of shock and vibration from the computer. “The weight of the computer on wire rope isolators varies. The isolators are made of stainless steel fibers from heavy to light. They can have two, six or eight coils. It’s a mathematical formula to determine the calculations tuned for the specific weight and type of computer,” McCook said.

Last year Havis Inc. worked with Pan-asonic to develop a rugged mounting and docking solution for the Toughpad A1. The Havis Docking Station lets users charge the tablet and connect to periph-erals such as printers and keyboards. It provides a full range of motion with a tilt-swivel device that rotates the Toughpad from portrait to landscape yet includes a barrel lock for tablet security. Havis soon will release a docking station for the Toughpad B1 as well.

Havis designed the Toughpad dock to withstand vehicle crash simulations and pass MIL STD 810G vibration testing as well as environmental and extreme dura-bility testing. The company then expanded on its Toughpad docking station to offer a thin, universal tablet mount that is com-patible with most 10-inch tablets and can be used with or without protective cases

Multi-FunctionalTried-and-true rugged laptops

remain the predominant workhorses in the field today. For example, VT Miltope provides its RCLC-1 (Rugged Convert-ible Laptop Computer) to the Army for maintenance and support of Army vehicles. VT Miltope also provides the RTCS-2 rugged tablet with a 10.4-inch screen mounted in vehicles to provide troops with situational awareness. “It’s

used for air and ground blue force tracking applications,” said Wes Keph-ard, VT Miltope vice president of rug-ged systems program development.

Mounted on a shelf in the rear of the Stryker, the RCLC-1 is also used as a diagnostic tool for maintenance. For BFT, the RCLC-1 is used on the move in various mounting configurations in both fixed wing and rotor wing aircraft.

www.MLF-kmi.com10 | MLF 7.1

and skins. The tablet tray was tested to withstand in-vehicle crash simulations and is compliant with RoHS (Restriction of Hazardous Substances, a U.K. Direc-tive) regulations. The latch handle and barrel lock mount the tablet in such a way as to act as a theft deterrent and to prevent it from becoming a potentially dangerous projectile in a crash.

The demand for rugged laptops with strong communications capability and processing power has driven a full range of options for the military. Dell’s XFR fully rugged clamshell meets MIL STD 810G and F for drop and extreme temperatures as well as IP 65 for ingress protection. “We have the XFR in a lot of Stryker vehicles and for that, we partner with First Mobile Technologies for the customized docking stations and mounting racks used in the Army Strykers,” said Jeffrey Hill, Dell rug-ged mobile account executive.

The ruggedized docking stations provide port replication and Internet connection. “The electronic piece expands the XFR connectivity to peripheral items like GPS or satellite,” said Hill. “But the mounting rack is separate and consists of the product, vehicle dock and mounting solution. The plate is designed to mount to the floor of the Stryker and pedestal mounts it with different swivel technolo-gies that take it to the right or left and allow flexibility, depending on how it needs to be used in the vehicle,” said Hill.

The goal is to provide the Army with quick and easy installation out of the box. “We provide IKs—installation kits—for the Army to install the Dell E6420 XFR fully rugged Dell clamshell in Strykers and HMMWVs,” said Jeff Rosen, strategic alliance manager, First Mobile Technolo-gies. “The Army wants the entire IK pre-assembled so it’s user-installable within 10-15 minutes in the field.”

First Mobile takes an off-the-shelf docking station and modifies it to meet Army requirements. “We custom-build the IK for the vehicle. One of our biggest challenges is to fit the solution into the vehicles without blocking the visibility of the driver and passengers,” he said. “We have to make it as small as possible since there is very little room in these vehicles,” he said.

Ridgeline Technology also noticed increased military interest in the rugged tablet form factor in the past year. “The tablet generation is really starting to

change the way that UAV and other sensor data gets quickly to the soldier,” noted Jan O’Hara, Ridgeline senior vice president of sales. “Rugged tablets are a perfect fit for mounting in rotary wing aircraft, espe-cially helicopters. As a result, Ridgeline is now working closely with the Army to determine tablet and mounting require-ments,” she said.

Ridgeline works with Getac and Pana-sonic, among others, to integrate rugged mobile systems in various military appli-cations. Ridgeline’s N2 division manufac-tures rugged external hard drives, called Databooks, for secure data storage with USB interfaces for use in extreme environ-ments with rugged laptops, tablets and convertibles. Ridgeline provides the Data-book to iGov under the Special Operations Command Tactical Local Area Network contract.

Companies such as DRS Technologies and Motorola have also been producing mounted rugged mobile products to meet international demand. The DRS Scorpion line of rugged notebooks is mounted in various wheeled and tracked military vehicles for both the U.S. and U.K. armies. DRS designed and manufactured rug-ged tablets with keyboards and docking stations for the Army Movement Track-ing System program for use in logistics vehicles to track battlefield assets.

DRS is under contract to provide IKs to the Army for its Force Battle Command Brigade and Below/Blue Force Tracking (FBCB2/BFT) program. The $248 million IDIQ contract includes IKs, engineering technical services and mounting plates for the FBCB2 computer and display system.

The growing interest in light but rug-ged tablets did not escape DRS, which released its Armor X7et and Armor X7ad, multi-touch, 7-inch tablets. The X7et runs Windows 7 Professional, weighs less than 1.5 pounds, meets MIL STD 810G and provides six hours of battery life. Its X7ad, Android-based, 7-inch counterpart is MIL STD 810G certified, contains an outdoor-readable multi-touch screen dis-play, weighs only 1.3 pounds and operates for up to eight hours.

DRS also pays attention early in the development process to the design of both rugged mobile systems as well as mounts and docks. One notable upgrade is from spinning disk to solid-state hard drives. “The same knowledge we use to design rugged systems is applicable when

designing mounts and docks for these systems. The availability of lower-cost, solid-state hard drives has helped to miti-gate one of the greatest environmental challenges for on-the move computing, because rotating hard drives do not han-dle military shock or vibration require-ments well without additional isolation,” said Bill Guyan, DRS vice president of strategy.

DRS has provided its Scorpion and MRT (Mobile Rugged Tablet) products to the British Ministry of Defense for Bowman, the tactical communications systems used by the British armed forces. “We have fielded more than 13,000 Scor-pions to the British MoD for the Bowman program. These units are used in their command posts as well as their wheeled and tracked vehicles to include the British Army’s Challenger 2,” said Guyan.

The AES Group works with Motorola Solutions, Federal and various mount-ing companies to integrate the Motorola MW810 into various military vehicles. The mobile workstation running Windows 7 Professional has a three-piece design comprised of a CPU, display and keyboard to allow for ease of use and installation flexibility in space-limited vehicles. It meets MILSTD 810G specifications and offers either an 8.4-inch or 12.1-inch dis-play. Motorola also just released the VC70, which was designed for rugged, in-vehicle logistics applications.

“Motorola works with several in-vehi-cle mounting designs that include cen-ter console, in-dash pedestal and mobile workstation mounts. The center console mount is secured horizontally while in-dash mounts attach to the vertical surface of the dashboard,” said Jean Flanagan, director of portfolio management, Motor-ola Solutions Federal Markets Division.

“Some mounting designs allow the display to fold down and be placed out of the way to [provide] access to dashboard controls. Pedestal mounting systems are generally used in vehicles that have a single bench seat or separate seats and are mounted to the floor, typically on the pas-senger’s side of the vehicle,” he said. O

For more information, contact Editor-in-Chief Jeff McKaughan at [email protected] or search our online archives for related stories

at www.mlf-kmi.com.

www.MLF-kmi.com MLF 7.1 | 11

Lithium Battery Contract

Saft, a designer and manufacturer of high-technology batteries for industry, has been awarded a one-year, $1.2 million contract by the Defense Logistics Agency (DLA) to make manufacturing improvements to the advanced lithium power source (ALPS) battery, the compact energy storage unit with integrated charger developed as a portable energy source in the field.

The funding will advance the technical and manufac-turing readiness of the ALPS battery for use in a variety of applications, including the Long-Range Advanced Scout Surveillance System (LRAS3).

Saft will provide a total of 10 ALPS batteries to the U.S. Army Communications-Electronics Research, Development and Engineering Center. Some units will be supplied to the U.S. Army Product Manager, Ground Sensors, for field testing. Improvements to the ALPS will enable Saft to manufacture and market the battery for additional defense applications.

Compared to the current LRAS3 power sources, the improved ALPS system will be lighter by 187 pounds, provide a 200-percent increase in silent watch time and reduce recharging time by 300 percent. The system will be capable of serving as a remote energy source and will be able to power critical sighting and communications equipment and recharge from tactical vehicles.

CENTCOM Medical LogisticsAAR has been awarded a medical logistics contract for the U.S. Army Medical Material

Center–Southwest Asia, located at Camp As Sayliya, Qatar. AAR’s Defense Systems and Logistics business will provide inventory management support to the U.S. Central Command in Iraq, Afghanistan, Kuwait, Qatar and the United Arab Emirates. The one-year agreement includes two renewal options.

This program marks the first time AAR’s Defense Systems and Logistics business will manage inventories of medical supplies for a defense customer. To date, its programs have focused exclusively on parts and logistics in support of various aircraft platforms and ground equipment.

“We appreciate the confidence the U.S. Army has in AAR Defense Systems and Logistics to run this important program in support of the warfighter,” said John Holmes, Aviation Services Group vice president, inventory, management and distribution.

Compiled by kmi media group staffSUPPLY CHAIN

JMR Future Vertical Lift

Sikorsky Aircraft Corp., a subsidiary of United Technologies Corp., and Boeing have signed a teaming agreement to submit a joint proposal in response to the U.S. Army Aviation Applied Technology Directorate solici-tation for the Army’s Joint Multi-Role ( JMR) Technology Demonstrator (TD) Phase 1 program.

The JMR TD supports the Department of Defense’s Future Vertical Lift program to deliver the next generation of vertical lift aircraft with greater performance, reliability and affordability.

“We are excited about this opportunity and for our customer. The Sikorsky and Boeing team brings together exceptional technical expertise,” said Mick Maurer, presi-dent of Sikorsky Aircraft Corp.

“Our teaming agreement is the continuation of a long-standing relationship between Boeing and Sikorsky and reflects a common vision for the future of Army aviation,” said Chris Chadwick, president of Boeing Military Aircraft.

The Sikorsky and Boeing team will compete to build and fly one or more demonstrator aircraft in 2017 to be evaluated for next-generation vertical lift performance in a medium-lift-sized aircraft.

Dismantling is Only Solution

After running aground on Tubbataha Reef near the Philippines on January 17, the Navy has deter-mined that the 23-year old USS Guardian will be dismantled and safely removed from the reef in sections.

Naval architecture and salvage experts have assessed that attempts to remove Guardian intact, such as by towing or pulling it off the reef, could possibly cause more damage to the reef and the ship’s hull, and most likely result in the vessel breaking up or sinking.

“Guardian is badly damaged and with the deteriorating integ-rity of the ship, the weight involved, and where it is grounded on the reef, dismantling in sections is the only supportable option,” said Captain Darryn James, U.S. Pacific Fleet spokesman. “We have the right team of experienced professionals to conduct this complex operation and to ensure that it is done safely while minimizing damage to the surrounding marine environment.”

No fuel has leaked since the grounding and all of the approxi-mately 15,000 gallons aboard Guardian were safely transferred off the ship during two days of controlled de-fueling operations last week.

Since Guardian’s grounding, the Navy has been working metic-ulously to salvage any reusable

equipment, retrieve the crew’s personal effects, and remove any potentially harmful materials including petroleum-based products and human wastewater. USS Mustin, USNS Bowditch, M/V Trabajador, USNS Salvor and the Malaysian tug VOS Apollo remain on scene supporting the salvage operation.

It is expected that the first Navy contracted floating crane from Singapore will arrive in the next several days and that the disman-tling operation will take more than one month. The Navy has presented a dismantling plan to the Philippine Coast Guard that main-tains the floating cranes necessary for this operation in deeper water in order to minimize coral damage to Tubbataha Reef.

www.MLF-kmi.com12 | MLF 7.1

Compiled by kmi media group staffSUPPLY CHAIN

New Power for an Old Workhorse

Some decades-old KC-135 tanker aircraft are getting to drink from the fountain of youth.Or at least the engines are.The first of 1,440 new upgraded engines for the venerable Stratotanker aircraft was installed at

MacDill Air Force Base, Fla., on January 15. Upgrading 1970s engine parts with modern technology, the engines will burn less fuel and run for longer without repairs, officials say.

“We expect the engine to stay on wing for 20-plus years and take the KC-135 into retirement,” said Senior Master Sergeant Dong Kim, Air Mobility Command’s propulsion branch chief.

Mounting the CFM Propulsion Upgrade Program, or C-PUP, on an airplane culminates almost three years of work between Air Mobility Command, Air Force Material Command, the Navy and the original equipment manufacturer, CFM International.

The engine upgrade will allow the KC-135 and the Navy’s E-6B aircraft to fly longer and at less cost by improving fuel efficiency and increasing engine time-on-wing.

The C-PUP engine delivered to MacDill is the first of 15 that will be delivered by General Electric Aviation under an F108 engine augmentation contract.

The engine depot at Oklahoma City Air Logistics Complex expects to deliver the first organically produced C-PUP engine later this year and is planning to produce 120 annually. Affecting 1,440 Air Force engines, the upgrade effort is projected to take 12 years to complete, according to officials.

Article by Major Mark Blumke, Air Mobility Command Directorate of Logistics

F-35s Drink from KC-130Two F-35 Lightning II carrier variants completed an aerial refueling for the first time

January 18. Test pilots Navy Lieutenant Christopher Tabert and Dan Canin of Lockheed Martin flew CF-1 and CF-2 respectively, with a KC-130 from Air Test and Evaluation Squadron (VX) 20 at Naval Air Station Patuxent River.

The F-35C carrier variant of the Lightning II is distinct from the F-35A and F-35B variants with its larger wing surfaces and reinforced landing gear to withstand catapult launches and deck landing impacts associated with the demanding aircraft carrier environment. Initial carrier trials for the F-35C are scheduled for 2014. The F-35C is undergoing flight testing and evaluation at NAS Patuxent River prior to delivery to the fleet.

Sub Work

General Dynamics Electric Boat has received an $11.5 million contract modification from the U.S. Navy to provide on-board repair parts for Virginia-class submarines. Electric Boat is a wholly owned subsidiary of General Dynamics.

The modification was exercised under the $14 billion contract awarded to Electric Boat in December 2008 for the construction of eight Virginia-class submarines, and has a potential value of $85 million.

C-46 Basing Possibilities

The Air Force announced Altus Air Force Base, Okla., and McConnell AFB, Kan., as candidate bases for the KC-46A formal training unit (FTU).

Altus AFB; Fairchild AFB, Wash.; Grand Forks AFB, N.D.; and McConnell AFB are candidate bases for the first active-duty led KC-46A main operating base (MOB 1).

Forbes Air Guard Station, Kan.; Joint-Base McGuire-Dix-Lakehurst, N.J.; Pease Air Guard Station, N.H.; Pittsburgh International Airport Air Guard Station, Pa.; and Rickenbacker Air Guard Station, Ohio, are candidate bases for the first Air National Guard-led KC-46A main operating base (MOB 2).

The major commands will conduct detailed, on-the-ground site surveys of each candidate base. The Air Force plans to announce KC-46A preferred and reasonable alternatives and begin the environmental impact analysis process in spring 2013.

“Bringing the KC-46A online is an important step in recapitalizing a tanker fleet that has been a leader in air refu-eling for more than five decades,” said General Mark Welsh III, Air Force chief of staff. “This new-age aircraft will achieve better mission-capable rates with less main-tenance downtime, improving our ability to respond with rapid, global capability to assist U.S. joint, allied and coalition forces and better support humanitarian missions.”

Welsh went on to explain that the 179 planned KC-46A aircraft are just the first phase of a three-phase effort to replace more than 400 KC-135 and 59 KC-10 aircraft. The first phase of tanker recapitalization will complete deliveries in fiscal 2028. He went on to emphasize the importance of continuing KC-135 modernization efforts.

“I want to stress that the KC-135 units not replaced with the KC-46A will continue to fly the KC-135R for the foreseeable future,” Welsh said. “Throughout tanker recapitalization, the Air Force is committed to ensuring continued support of combatant commander requirements.”

The FTU and MOB 1 will begin receiving aircraft in fiscal year 2016. MOB 2 will receive aircraft in FY18.

www.MLF-kmi.com MLF 7.1 | 13

Major General John R. O’Connor became the Deputy Chief of Staff, G-4, U.S. Army Forces Command, on July 11, 2011. In this position, he ensures FORSCOM can provide fully equipped logistically sustainable and ready forces to meet combatant com-mander requirements across the spectrum of current and future operations.

O’Connor graduated from the University of Miami, Florida in 1984, with a Bachelor of Science degree in business administra-tion and was commissioned in the Transportation Corps through the Reserve Officers Training Corps. He holds a Master of Logistics Management degree from the Florida Institute of Technology and a Master of Strategic Studies degree from the United States Army War College. His military education includes the Transporta-tion Officer Basic and Advanced Courses, the Logistics Executive Development Course, the United States Army Command and Gen-eral Staff College, the Armed Forces Staff College and the United States Army War College.

He has served in a variety of multifunctional logistics assign-ments to include: platoon leader, executive officer, 590th Trans-portation Company; 181st Transportation Battalion, Mannheim, Germany; aide-de-camp to the commanding general, 3rd Corps Support Command; V Corps, Wiesbaden, Germany; assistant battalion S2/3 and commander, Delta Company, 407th Supply and Transportation Battalion; 82nd Airborne Division Support Command, Fort Bragg, N.C.; battalion S2/3 operations officer [Operation Desert Shield/Storm—Saudi Arabia], 7th Transporta-tion Battalion; assistant S3 [operations] officer, 507th Corps Sup-port Group, 1st Corps Support Command, Fort Bragg; division transportation officer, G-4, 82nd Airborne Division, Fort Bragg; logistics plans officer, J4, United States Pacific Command, Camp Smith, Hawaii; commander, Troop Support Battalion, Opera-tion Enduring Freedom—Uzbekistan; Transportation Branch chief, Human Resources Command, Alexandria, Va.; commander, 402nd Army Field Support Brigade, Army Sustainment Command [Operation Iraqi Freedom—Kuwait/Iraq]; executive officer to the Army Materiel Command Executive Deputy to the Commanding General, Fort Belvoir, Va.; deputy commanding general, Military Surface Deployment and Distribution Command, Fort Eustis, Va.; commanding general, Army Materiel Command-Southwest Asia/G-4, United States Army Central [Kuwait]; and most recently director, G-43, Operations and Logistics Readiness Division, Deputy Chief of Staff, G-4, Department of the Army.

His personal awards and decorations include the Legion of Merit [two Oak Leaf Clusters], Bronze Star Medal [two Oak Leaf Clusters], the Department of Defense Meritorious Service Medal, the Meritorious Service Medal [five Oak Leaf Clusters], the Army Commendation Medal [six Oak Leaf Clusters], Joint Service Achievement Medal, Army Achievement Medal, Joint Meritorious Unit Award, Meritorious Unit Commendation, the Master Para-chutist Badge, and numerous campaign and service medals.

Q: As a matter of operational processes, how has the Army changed the way deploying units are equipped, with their vehicles and major equipment items?

A: U.S. Army Forces Command [FORSCOM] is aggressively using lessons and insight from the last 11 years to develop processes and partnerships that generate more effective fielding and oversight. FORSCOM is fully committed to providing our soldiers and the global combatant commands the necessary training, equipment and capabilities needed to transition from the previous decade of conflict. We strive to forge a balance of readiness, resourcing, risk and reporting supporting Army equipping strategy, Army modern-ization and Army force generation [ARFORGEN].

As the Army’s force provider, understanding the theater require-ment builds the foundation to operational success. As operational

Major General John R. “Jack” O’ConnorDeputy Chief of Staff, G-4

U.S. Army Forces Command

Capability ProviderCommitted to Providing the Necessary Training, Equipment and Capabilities

Q&AQ&A

www.MLF-kmi.com14 | MLF 7.1

AviAtion Supply ChAin

MAintenAnCe RepAiR &

oveRhAul

StRuCtuReS & SySteMS

GoveRnMent & DefenSe

SeRviCeS

AAR has more of what government and defense organizations worldwide require — for

airlift support, maintenance and modifications, logistics, mobility products and integrated

communications. AAR solutions improve readiness and efficiency for critical missions

ranging from defense to humanitarian relief.

Agile, reliable and proven, AAR is a trusted supplier to government and defense customers.

AAR 1P MLF.indd 7 2/5/13 9:38 AM

environments change, so must enabling processes and capabilities. Initially, our focus was to deliver as much as we could with speed and precision. Now with presidential guidance to end combat opera-tions in Afghanistan by December 2014, our Army adapted its sus-tainment and distribution strategy to meet this guidance.

I use the analogy of being a pit crew at a NASCAR race. Our job is to ensure that the driver has everything he needs regarding safety, performances, endurance and the ability to win. At the end of the race, the driver must slow down, avoid collision, come into the pit, make repairs and get packed into their moving vans for final delivery to the garage. It is a very deliberate, safe and well-synchronized operation. This is where we are now in Afghanistan. Like our responsible drawdown in Iraq, we are adjusting systems, processes and procedures to consume what we have in theater, decrease the amount of equipment stocks, reduce deliveries and return excess with increased velocity to the right place at the right time. We call this back-end campaign success.

To do this, FORSCOM, in coordination with the Headquarters, Department of the Army [HQDA], U.S. Army Central [ARCENT], U.S. Forces-Afghanistan [USFOR-A], and Army Materiel Command [AMC] instituted an equipment deployment/redeployment review board [EDR2B] to review and validate theater equipping require-ments. The EDR2B ensures deploying units bring the correct types and amounts of equipment. This process involves months of rehearsal and planning.

Additionally, the new Army Redistribution, Redeployment, Reset, Return and Disposal [R4D] process is how FORSCOM part-ners with HQDA, AMC, ARCENT, USFOR-A, the Defense Logistics Agency and U.S. Central Command come across the finish line and set the conditions for future responsible recovery operations. The R4D process will use units, like pit crews, to facilitate equipment flow out of Afghanistan. Once at home station, the equipment will be redistributed to units for reset, training or other engagements. The process maximizes effective and efficient use of resources to support Army equipping requirements and assist with equipment redeployment and enhance combatant commanders’ readiness in a resource-constrained environment. Like NASCAR, the business of deployment and redeployment is a team support and FORSCOM is part of a great Army pit crew.

Q: What is your role in implementing, maintaining and support-ing the Global Combat Support System-Army? As the system becomes more deeply embedded in the Army’s logistics system, how is the system evolving to meet the real world needs of a global supply chain?

A: FORSCOM is no stranger to GCSS-A as we have leveraged over two years of feedback from both the 1st Armored Division’s 2nd Brigade Combat Team [Fort Bliss, Texas] and the 11th Armored Cavalry Regiment at Fort Irwin, California’s National Training with system employment and experimentation. As a result, we have developed fielding schedules in coordination with the GCSS-Army program manager and our units to ensure ARFORGEN impacts are minimized, soldiers are properly trained and ongoing warfighter support is met.

The GCSS-Army conversion will be accomplished in two waves. Our first wave includes converting 81 units that provide Supply Support Activity [SSA] support to all FORSCOM units and their associated financial management.

Wave two will include converting every supply room and motor pool. We have partnered with the Enterprise Data Management Office at the Army Logistics Support Activity to ensure our data is cleansed in preparation for the conversion. We have also estab-lished a training program at our two GCSS-Army activities [Fort Irwin and Fort Bliss] to provide sustainment training and award a personnel development skill identifier to our trained soldiers.

GCSS-Army allows universal, permission-governed access via internet that is one system used by all in order to simplify train-ing and facilitate sustainment. The GCSS-Army provides unprec-edented organizational asset visibility and status information that provides only one version of the logistics truth in real-time access to transaction status. This system shortens processing timeframes and eliminates uncertainty. It enables task organization capabili-ties that will benefit log planners and commanders at all levels.

It also supports split-based operations and removes man/machine chokepoints, which ultimately saves sustainers process-ing time. GCSS-Army is being developed by leveraging the state-of-the-art Enterprise Resource Planning software known as SAP. Enterprise represents the entire Army organizational structure. The resources are all equipment, personnel, facilities and funds, while the planning represents the systematic planning, coordina-tion and execution of all Army logistics business using one single software system and common hardware.

GCSS-Army will incorporate the General Fund Enterprise Business System [GFEBS] financial solution creating a feder-ated financial system of record. Under the federated approach to accounting, GCSS-Army will leverage the GFEBS core design template to provide a single business process that will allow the Army to integrate logistics, finance, maintenance and property accountability of assets and accounting data. GCSS-Army has re-engineered current business processes to achieve end-to-end logistics execution and provide unclassified feeder data to appli-cable C2/Joint systems. The next target installation of units for FORSCOM fielding is the 82nd Airborne Division and 18th Air-borne Corps at Fort Bragg.

Q: The Government Accountability Office recently issued a report on preparation for equipment drawdown from Afghanistan. What is Forces Command’s role in drawdown preparation and in par-ticular what responsibilities are you and your staff managing?

A: As the GAO report indicated, the 10-year inflow of equipment without corresponding outflow created an abundance of equip-ment in Afghanistan. Existing processes will ensure proper equip-ment disposition. FORSCOM is closely nested with theater’s three equipment options to redistribute, demilitarize and return as the majority of combat formations return back to FORSCOM and other Army installations.

Not only does FORSCOM man, equip and train forces deploy-ing to theater, but we play an active role in synchronizing unit activities coming home. There are numerous B2C2WG [boards, bureaus, cells, centers working groups] to synchronize equipment reset, future training, and most importantly, compliance to the Army’s Campaign on Property Accountability.

An important aspect of FORSCOM’s mission is sustaining equipment readiness. The process is very complex and involves multiple agencies and partnerships. HQDA and Army commands decided to create a single source document used to establish

www.MLF-kmi.com16 | MLF 7.1

retrograde priorities and sourcing decisions called the reset, redistribution and retrograde task force [R3TF]. The R3TF mis-sion is to alleviate equipment-on-hand [EOH] shortages, increase pre-deployment training equipment inventory and improve over-all unit readiness.

The intent is to have visibility on planned predictable retro-grade and reset quantities to fill FORSCOM and Army EOH short-ages and improve readiness. The process sequence starts with retrograding rolling and non-rolling stock class VII items from the theater redistribution property accountability team [RPAT] yards. Equipment then moves onward to the port of embarkation and shipment to specific AMC depots or field reset locations for induction into funded reset/recap production.

FORSCOM sends its demand signal with a prioritized list of critical short line items [LINs], which is passed to HQDA G-8 and included with the Army’s top 200 readiness LINs and the Chief of Staff of the Army’s AIM Point LINs to establish a retrograde, reset and redistribution [R3] priority list for theater provided equip-ment [TPE] disposition. These pieces will arrive at the depot and once repaired, will be ready for unit distribution per Department of the Army priority list.

Additionally, FORSCOM is identifying MTOE equipment shortages by installation by pinpointing TPE excess that may not require sustainment repair. FORSCOM will then transfer the TPE to organizational property books. This will rapidly improve unit’s readiness and also increase pre-deployment training equipment inventory. This is accomplished by maintaining close linkages to theater with our FORSCOM LNO and units. All serve as contributing methods we use to build retrograde velocity and visibility.

Finally, in line with the 2005 RPAT concept I helped jumpstart in Iraq that is now functioning extremely well in Afghanistan: FORSCOM recently responded to a USFOR-A and CENTCOM requirement for an additional logistics command structure to facilitate equipment redistribution and base closure. This organization is called the CENTCOM materiel recovery element [CMRE]. FORSCOM identified the 593rd Sustainment Brigade [SB] for the CMRE mission and ensured they were trained and ready to engage in this new demanding capability. Early reports from their commander, Colonel Douglas McBride, indicate the soldiers, airmen, sailors, Marines and DoD contractors are focused, vigilant and relentless in their pursuit of excellence on the battlefield in spite of multiple units executing reliefs in place and transfers of authority within 593rd SB’s CMRE.

Virtually all equipment coming out of Afghanistan requires either field- or sustainment-level maintenance support. Even after the drawdowns from Afghanistan are complete, the Army will require funding for several more years to reset our equipment from the harsh demands of war.

Q: As an example, I’ve seen estimates that the Army has identi-fied more than 50,000 vehicles and more than 90,000 containers of materiel in Afghanistan requiring disposition. I’ve also seen estimates that, depending on the mode of transportation out of Afghanistan, a single vehicle could cost anywhere from $19,000 to $153,000 to relocate. How do Army requirements, capabili-ties and the budget come together to decide on the disposition of individual major equipment items? What to keep, what to fix and what to dispose of?

A: There are four concepts that FORSCOM uses to ensure proper equipment disposition. First, using R3TF processes, we synchro-nize multiple headquarters to prioritize R3 decisions and develop a single source document to inform equipment sourcing deci-sions.

ARCENT, as the Army’s title 10 service component, is respon-sible for theater-level implementation and redeployment orders to ensure all theater requirements are met before equipment release.

Second, FORSCOM is the lead agent for the UERC and ensures return of reset items, new materiel in briefs, new equipment training, new equipment fielding and other equipping actions in support of a unit’s long-range training calendar. FORSCOM will adjust the conduct of future UERCs to effect more efficiencies and support unit requirements as we transform to the 24-month ARFORGEN model.

Third, the AMC Lead Materiel Integration [LMI] Decision Support Tool [DST] implementation will optimize equipping solutions to support the ARFORGEN cycle and streamline the distribution and redistribution of assets across the Army. Forces Command G-4 will continue to support the LMI-DST implemen-tation and link with AMC’s Army Sustainment Command for col-lective training to 6,000 users across our formations. We recently successfully executed 10th Sustainment Brigade, 10th Mountain Division, Fort Drum, N.Y., UERC in January 2013 using DST. The Fort Riley 4-1 Brigade Combat Team will receive DST training in April 2013 to execute a BCT level pilot DST proof of principle.

Last, from my time as the ARCENT G4 from 2009 to 2010, I leveraged the commercial concept of reverse logistics, which was the nexus of drawing down out of Iraq. Reverse logistics is a team sport to ensure processes are efficient and effective through deliberate planning, implementing and controlling materiel from point of use to a point of recovery. Reverse logistics standards leverage all the tools available to us to get rapid disposition to our forces as we manage the multitude and magnitude of all of this equipment moving both in and out of theater.

By using reverse logistics principles, we are attempting to consume what is in Afghanistan, fill units’ critically short items to return to home station, support depot maintenance, and turn equipment over to the Defense Logistics Agency for reutilization. Our intent is to keep equipment in motion now until its final destination, which is in the hands of our soldiers.

Q: Where can the Army Forces’ Command logistician have the most impact to push greater efficiencies and generate more effective outcomes in the supply chain?

A: In April 2012, FORSCOM implemented new initiatives to estab-lish sustainment operations centers [SOC] that have recently expanded to the Sustainment Mission Command Capability [SMCC]. The SMCC enables commanders at each respective level to integrate sustainment planning and execution, while establish-ing enabling internal and external partnerships. Output is unity of effort and trust through sustainment fusion. A unity of effort in a time of diminishing resources is imperative to leveraging the sustainment community at large and optimizing complex supply chains. Per the Secretary of the Army’s top priorities, we are to ‘ensure a highly capable force within evolving budgetary constraints.’ This effort simplifies field-level sustainment through

www.MLF-kmi.com MLF 7.1 | 17

a single organizational construct that collects requirements and either satisfies them or coordinates for resources and solutions across the sustainment spectrum.