MGM Presentation

-

Upload

lal-kishan -

Category

Documents

-

view

235 -

download

0

Transcript of MGM Presentation

-

8/10/2019 MGM Presentation

1/47

1

MGM Brake Motors

M.G.M. electric motor S.p.A., established in 1950 as a brake motor manufacturer, is now the EuropeanLeader in brake motor production.

Wherever you are in the world it is difficult to see, wear or use anything which was produced without theuse of an MGM brake motor at some stage in the production process.

-

8/10/2019 MGM Presentation

2/47

2

Overview

MGM Electric Motors was established in 1950 as a brake motors manufacturer.

MGM is today a world leading manufacturer of this line of products.

MGM brake motors are designed and assembled as an integral brake motor unit and

not as a mere assembly of a motor with a brake.

The perfect engineering and assembling combined with a strong and safe brake,make these motors very reliable.

MGM is a worldwide organization, having distribution and technical support facilities

in more than 45 countries.

-

8/10/2019 MGM Presentation

3/47

3

The following technical characteristics are used to correctly identify MGM motors:

Series BM, BA

Frames size 56 - 315 mm

Power and poles 0,04 - 136 kW; 2 4 6 8 2-4 4-8 2-6 2-8 4-6 4-12 poles

Mounting B3, B5, B14

Voltage and Frequency According to customer request

Brake Supply AC or DC; Single or double terminal board box

Insulation class F or H

Enclosure IP54, IP55, IP56

Example:

Motor designation

BA 71 B4 IM B5 230/400V 50 Hz AC brake coil, double terminal board box Class F IP54

-

8/10/2019 MGM Presentation

4/47

4

Every motor is provided with an identifying nameplate, on which specific motor information is given.The nameplate shown on the left is used for single speed motors while the nameplate on the right is used fortwo speed motors.

Motor Identification

Duty type

Protection Degree

Insulation Class

Weight (kg)Motor Type Designation

Serial Number

Maximum Static Brake Torque (Nm) Brake Current (A)

Brake Voltage Supply (V)

Electrical Data

Certification Marks

-

8/10/2019 MGM Presentation

5/47

5

The picture below shows the most important types of construction

Type of construction

B5

B14

B3

-

8/10/2019 MGM Presentation

6/47

6

The table below shows the most important types of mounting arrangements according to IEC 34-7 (EN 60034-7) standard.

Two systems of classificatio are provided: code 1 (the alpha-numeric designation) and code 2 (the all numeric designation).

Horizontal Shaft Mounting

Type of construction and Mounting

IM B3 IM 1001 IM B5 IM 3001 IM B35 IM 2001 IM B6 IM 1051

Foot mounted motor, feet down. Flange mounted on D-End side. Foot and flange mounted motor. Foot mounted motor.Feet left (viewed from D-End).

IM B7 IM 1061 IM B8 IM 1071 IM B14 IM 3601 IM B34 IM 2101

Foot mounted motor.Feet right (viewed from D-End).

Foot mounted motor.Feet up (viewed from D-End).

Face mounted. Flange withthreaded holes and spigot.

Face and foot mounted.Flange with threaded holes and spigot.

-

8/10/2019 MGM Presentation

7/47

7

Vertical Shaft Mounting

Type of construction and Mounting

IM V5 IM 1011 IM V6 IM 1031 IM V18 IM 3611 IM V19 IM 3631

Foot mounted motor.Feet right (viewed from D-

End).

Foot mounted motor.Feet up (viewed from D-End).

Face mounted. Flange withthreaded holes and spigot.

Face and foot mounted.Flange with threaded holes

and spigot.

IM V1 IM 3001 IM V15 IM 2011 IM V3 IM 3031 IM V36 IM 2031

Flange mounted. Shaft down. Foot and flange mounted motor.Shaft down.

Flange mounted. Shaft up. Foot and flange mounted motor.Shaft up.

-

8/10/2019 MGM Presentation

8/47

8

Protection Degree

The enclosure rating of the motor has to be suitable to the enviroment conditions the motor operates in. According to the IEC34-

5 (EN 60034-5) standard the designation of the protection degree is expressed by means of a symbol made of two letters (IP)followed by two digit numbers. The first digit indicates the protection degree provided by the motor enclosure in contact withparts in motion, electrically energized, or against the penetration of foreign bodies. The second digit indicates the protectiondegree of the motor enclosure against damages caused by the penetretion of liquids.

First Digit Second Digit

0: No protection 0: No protection

1: The machine is protected against the penetration of solidbodies

greater than 50 mm in diameter (for example against the accidentaltouch of a hand).

1: Vertical dropping of water on the machine will not result in damaging

effects.

2: The machine is protected against the penetration of solidbodiesgreater than 12 mm in diameter.

2: Vertical dropping of water on the machine will not result in damagingeffects when the machine is not inclined more than 15 from its normalposition.

3: The machine is protected against the penetration of solidbodiesgreater than 2,5 mm in diameter.

3: Water or rain dropping on the machine at an angle up to 60 will not resultin damaging effects to the machine.

4: The machine is protected against the penetration of solidbodiesgreater than 1 mm in diameter.

6: Dust tight machine.

7: Immersing the machine in water under specific conditions of pressure andtime will not cause the ingress of a damaging quantity of water.

8: Immersing the machine permanently in water under condition of pressureand time given by the manufacturer will not result in damaging effects.

IP first digit second digit

5: The machine is protected against the penetration of dust. Thepenetration is not completely avoided, but should not compromise thegood functioning of the machine.

4: Water sprayng on the machine from any angle will not result indamaging effects to the machine.

5: Water jets on the machine from any angle will not result in damagingeffects to the machine.

6: Waves of water will not result in damaging effects to the machine.

-

8/10/2019 MGM Presentation

9/47

9

Protection Degree

First Digit Second Digit

5: The machine is protected against the penetration ofdust. The penetration is not completely avoided, but shouldnot compromise the good functioning of the machine

4: Water sprayng on the machine from any angle will not resultin damaging effects to the machine.

5: Water jets on the machine from any angle will not result indamaging effects to the machine.

6: Waves of water will not result in damaging effects to themachine.

MGM brake motors come with standard IP54 enclosure rating. On request, motors can be provided with IP55or IP56 enclosure rating. For use in standard industrial enviroments IP54 is sufficient. For outdoorapplications or for applications that involve contact with water, protection degree IP55 or IP56 is advisable.Itsalways advisable to protect the motor as much as possible.During the installation stage secure the proper tightening of the cable gland and the insertion of the wirefrom the bottom upwards. On request, for outdoor vertical mounting with shaft down, a rain roof (BM series)

or a special brake cover (BA series) are available.

-

8/10/2019 MGM Presentation

10/47

10

Motor Voltage and Frequency Supply

MGM motors are provided with a standard voltage rating of 230/400V 10% 50 Hz (IEC 38, CENELEC HD 472,CEI 8-6)Europeanvoltage. On request they can be provided with different operating voltages.The operating voltages at 50 Hz and 60 Hz are clearly indicated on the motor nameplate. MGM motors aresuitable to work within a voltage variation of 10% on the nameplate voltage.The available rated voltages are shown in the table below under Nameplatevoltageat 50 Hz and 60 Hz,while the corresponding voltages on which the motor is able to run are shown underUsablevoltages.

Nameplate voltage Usable voltage

230/400 50 277/480 60 240/415 50 220/380 50 265/460 60

190/330 50 220/380 60 208/360 60 230/400 60

208/360 50 254/440 60 200/346 50 240/415 60

400/690 50 480/830 60 380/660 50 415/717 50

-

8/10/2019 MGM Presentation

11/47

11

Operating at 60 Hz

MGM motors with rated voltage of 230/400V 50Hz maintein the same rated and starting torque if operating at

277/480V 60Hz while the RPM increase by about 20% (see torque vs. RPM comparing curves 1 and 2 below).The AC brake coil on BA series works equally well if operating either at 230/400V 50Hz or at 277/480V 60Hz.The DC brake coil with nameplate voltage of 110V, 230V or 400V on BM and BA series has to be supplied at110V, 230V or 400V single phase respectively both at 50Hz or 60Hz (i.e. a 230 V brake can be supplied single-phase at 230V 50Hz or at 230V 60Hz).MGM is able to provide motors and brake coils suitable for operating on 220/380V 60Hz power supply. It is notadvisable to run motors designed for 230/400V 50Hz and 277/480V 60Hz on 220/380V 60Hz voltage supply as

the power remains the same, but the starting torque is reduced by 35% (see curves 1 and 3 below).MGM strongly recommends not to use a 277/480V 60Hz (230/400V 50Hz) AC brake coil on 220/380V 60Hzpower system as it results in a significant loss of performance.DC brakes with a rated voltage of 230V 50Hz can be used on 220V 60Hz and those with a rated voltage of400V 50Hz on 380V 60Hz power system.

-

8/10/2019 MGM Presentation

12/47

12

Service Duty Types

The most common duty types are described in this slide. Please contact MGM for different types of duty.

Continuous duty S1The motor operates with constant load for aperiod of time sufficient to achieve the thermalequilibrium.

Limited length duty S2The motor operates with constant load for alimited period of time not sufficient to achieve athermal equilibrium. The remaining period of thecycle is a rest period, during which the motorcools down to the ambient temperature again.

Periodic intermittent duty S3The motors follows a cycle including an operationperiod with constant load (ts) and a rest period(tr). The synthetic indication of the duty is givenby the intermittent percentage ratio related to aperiod of time, which usually is 60 min.(f.e. 15% - 60 min.).

Intermittence Ratio = [ts /(ts + tr)] 100%

-

8/10/2019 MGM Presentation

13/47

13

Service Duty Types

Periodic intermittent duty with start up S4

The motors follows a sequence of identicaloperating cycles, each including a substantialstart-up stage D, a constant-load operating periodN and a rest period R.

Intermittency ratio = (D+N) * 100(%)(D+N+R)

The brief service indication must be accompaniedby the number of starts per hour.

-

8/10/2019 MGM Presentation

14/47

14

Increased Power

A motor designed for S1 duty but running on S2 or S3 duty can provide a power output higher than the ratedone on S1 duty. However, the starting torque remains the same on all duties. The permissible approximateoutput power for single speed motors can be calculated as follows:

Permissible Power =K Nominal power

where K is a coefficient given by the following diagrams:

-

8/10/2019 MGM Presentation

15/47

15

Motor running on Inverter

All MGM motors are designed to be suitable for inverter duty.

The motor speed depends on the power supply frequency. Basically the inverter works converting the powerinput from the line with a fixed amplitude and frequency into a voltage supply with a variable amplitude andfrequency suitable to control the motor speed.Inverter cant generate an output voltage higher than the input voltage, while it can increase the frequencyabove the input rated value.

Constant torque regulation range means a range where the inverter is able to keep the nominal ratio of voltageto frequency constant; in our diagram this range is up to 50 Hz. Constant power (or flow) regulation rangemeans a range where the inverter can increase frequency (and so the motor rotation speed), without voltageincrease to the motor (and consequently the torque); in our diagram this range exceeds 50 Hz.

Operating diagram shows the percent values of the torque available both in continuous and overloadingrunning.

When the motor is running within constant torque regulation range (frequency below 50 Hz), it is necessary to

check that continuous slow running does not cause overheating; in that case servo-fan (see operatingdiagram) is needed.

When the motor is running within constant power regulation range (frequency above 50 Hz), it is necessary tocheck if the torque required by the load does not exceed the torque indicated on the operating diagram,otherwise malfunction and eventual intervention of inverter overload protection devices could occur.

-

8/10/2019 MGM Presentation

16/47

16

Motor running on Inverter

The brake should be supplied separately from the motor on brake motors controlled by inverters, to ensure the

proper working of the brake coil. In this case the double terminal board box option must be requested.On brake motors with AC brake coil, it is also advisable to use a safety overload cutout (MGM type RC04) onthe power supply of the brake coil.The starting torque of a motor running on inverter is different from the one of a motor connected directly online.Be sure to select an inverter with technical specifications suitable for the work load of the machine it isintended to be used on.

An inverter changes the electrical wave pattern to the motorfrom purely sinusoid to switching typical shape. Because ofundesirable harmoniccomponents added to the underlying power supply, a motorcontrolled by an inverter has higher losses, and an increasedvibration and noise level.The efficiency reduction varies according to the type of inverter

used.In the figure the harmonic content on the power supply of amotor under inverter can be seen (blue indicates the underlyingpower supply, grey indicates theharmonics).

-

8/10/2019 MGM Presentation

17/47

17

The standard electrical specifications of the motors are referred to continuous duty (S1), nominal voltage,nominal frequency (50 to 60 Hz), an ambient temperature of max 40 C and installation elevation up to1000m. above sea level.If ambient temperature is higher than 40 C the permissible output power should be reduced by a percentageof the rated value (see the table below).

If ambient temperature is higher than 60 C or lower than -30 C please contact the MGM technical office. Ifthe motor is going to work at an elevation higher than 1000 m. above sea level, the permissible output powershould be reduced by percentage of the rated value (see the table below).

Temperature and Altitude

Elevation above the see level m 1000 1500 2000 2500 3000 3500 4000Permissible Output Power as percentage of the Rated Power 100 97 94.5 92 89 86.5 83.5

Enviroment Temperature C 40 45 50 55 60

Permissible Output Power as percentage of the Rated Power 100 96,5 93 90 86.5

-

8/10/2019 MGM Presentation

18/47

18

If a motor has to be used in an environment where the temperature is lower than -15 C, inhigh moisture or where abrupt temperature changes can occur, it is advisable to use anti-condensation heaters.This recommendation is particularly important where there are long pauses between workingcycles, which may cause abundant condensation on the motor windings. It could permeate thewindings and cause short circuits.

This occurs mostly on larger motors, which contain more air volume inside, allowing morehumidity to condense.Additional protection against moisture may be provided by drain holes on the motor to allowwater drainage.

Motors working in low temperature or high moisture enviroments

-

8/10/2019 MGM Presentation

19/47

19

Anti-Condensation heaters

The application of Anti-condensation heaters helps in preventing water from building up inside the motor, as a

consequence of the condensation effect due to the motor temperature fluctuations.

Anti-condensation heaters application is particularly recommended for those applications with long intervalsbetween two consecutive work cycles.

The condensation could permeate the winding causing a short circuit.

This instance occurs mostly on larger motors, which contain more air volume inside the frame, allowing

more humidity to condensate.

Two anti-condensations heaters are applied on the heads of the motor winding.

Anti-Condensation heaters must be used to keep the motor temperature as steady as possible and they mustbe switched off when the motor is powered to prevent the motor from overheating.

MGM applies three types of heaters according to the motor size.

The anti-condensation heater wires are connected in the terminal box.

The writingSCALDon the nameplate shows that a motor is equipped with space heaters.

Space heaters standard voltage supply is 220/240V.

Any other voltage must be specifically requested and has to be agreed on by MGM.

-

8/10/2019 MGM Presentation

20/47

20

Protection devices

The use of protection devices is advisable for motors used in special working conditions.Use of multiple protection device is recommended for BA series.

The chart below reports the most effective protection devices for the most frequent occurring

problems.

On request MGM is able to supply motors equipped with thermistors (PTC) or bimetallic

(PTO) thermal protectors.

Operation Conditions

Protection Type

Fuses Protective Circuit Breakers Thermal ProtectiveDevice on the Windings

Excess currents 200% In no protection excellent protection excellent protection

Heavy starts, reversing operation no protection partial protection excellent protection

Stalling partial protection partial protection excellent protection

Starting on two phases no protection partial protection excellent protection

Voltage deviations no protection excellent protection excellent protection

Frequency deviations no protection excellent protection excellent protection

Insufficient motor cooling no protection no protection excellent protection

-

8/10/2019 MGM Presentation

21/47

21

Protection devices

Bimetallic Thermal Protectors (PTO): three bimetallic sensors in series with normally closed contacts,fitted on the winding heads. PTO controls a switch (not provided with the motor) that cuts off the powersupply when getting close to the dangerous motor temperature.The nominal voltage and current are respectively 250 V and 2,5 A A.C. while the intervention temperature is140C.The contacts reset to close position once the temperature goes below 35C. The PTO wiring connections arelocated on a terminal board inside the main terminal box. The writing TPon the nameplate shows that themotor is equipped with PTO.

Thermistors(PTC): three thermistors in series (according to DIN standards 44081 and 44802), fitted on thewinding heads. The thermistors resistance changes with the temperature and when getting close to thenominal intervention temperature a sharp increase of resistance guarantees a precise intervention of thesafety devices. Thermistors only sense temperature so a cut-off Device (not provided with the motor) mustbe used to cut off the motor power supply.

The maximum PTC operating voltage is 30 V DC while the intervention temperature is 130C on class Fmotors and 140C on class H motors. The PTC wiring connections are located on a terminal board inside themain terminal box. The writingTMon the nameplate shows that the motor is equipped with PTC.

-

8/10/2019 MGM Presentation

22/47

22

Over-voltage Protection

Low speed motors: when starting motors with a high number of poles (i.e. 8, 12, 16),voltage peaks can be generated damaging the motor insulation materials and contacts. Inthese cases it is advisable to install safety over-voltage protection devices.On request MGM provides over-voltage protection devices such as RC04 for motors up to 4kW and RC10 for motors up to 10 kW. Please note that these devices should not be installed

if the motor is controlled by an inverter.

Brake coil: DC brake coil is supplied as standard with a rectifier fitted with a protectiondevice against over-voltage and with a filter against the radio frequency emissions. The ACbrake coil doesnt generally need this type of protection devices. In case of a very highstart/stop frequency or in case of critical line voltage situation it is recommended the use ofRC04 filter in order to limit the electrical interference on the brake.

-

8/10/2019 MGM Presentation

23/47

23

In the BA series (on the left side figure), the cooling fan located between the motor and the brake.

The air inlet holes are positioned radially along the brake friction surface.

In the BM series (on the right side figure), the cooling fan located at the non-drive end of the motor

shaft and the air is sucked axially and thus the cooling effect doesntaffect the brake friction surface.

Differences between BA and BM series: Cooling

-

8/10/2019 MGM Presentation

24/47

24

BA seriesCooling system

The heat generated by the friction surface during the braking action, is dissipated by theairflow created by the cooling fan located between the motor and the brake.

-

8/10/2019 MGM Presentation

25/47

25

BM seriesCooling system

The heat generated on the friction surface during the braking action is NOTdissipated by thecooling fan and heat is transmitted to the inside motor components (shaft/rotor/winding)

-

8/10/2019 MGM Presentation

26/47

26

Differences in the brake discs dimensions:

Differences between BA and BM: Brake Discs

The BA brake disc diameter is nearly twice as big than the BM one

BA brake disc lifetime is till four times BM brake disc

-

8/10/2019 MGM Presentation

27/47

27

Differences between BA and BM: Motor Shaft

In the BM series between the brakedisc and the shaft is inserted a fithub.

The BA series disc brake directlytransmits the braking torque to themotor shaft.

The main advantages of the first solution is less operating noise when on inverterduty and a more secure design (fewer components).

-

8/10/2019 MGM Presentation

28/47

28

Differences between BA and BM: Brake Coil

The BA series features a rolled steelelectromagnet.Each electromagnet has sixor twelvecoils. It is available with AC or DC power.The BM series features a cast ironelectromagnet.Each electromagnet has a single coil. It is available with DC power.

BA Coil BM Coil

-

8/10/2019 MGM Presentation

29/47

29

AC brake and DC brake reaction time

t1 = release time: time from switching power on

until braking torque begins to decrease

t2 = engaging time: delay time from switchingpower off until braking torque increases.

Ic = Coil Current

Tb= Braking Torque

MotorSize

Release Time t1[ms] Engaging Time t2[ms]

ACBrake

DC BrakeStandard

DC BrakeRapid

ACBrake

DC BrakeStandard

DC BrakeRapid

71 40 100 60 5 80 30

80 60 140 80 6 80 30

90 S 60 140 80 7 80 50

90 L 90 170 100 7 80 50

100 90 170 100 7 80 50

112 120 220 170 9 80 80

132 S 150 150 12 85 100132 M 180 150 12 85 100

160 M 200 200 14 85 120

160 L 350 14 85 120

180 450 14 90 150

200 450 14 90 150

225 S 14 - -

225 M 14 - -

250 14 - -

280 S 14 - -

280 M 14 - -

315 S 16 - -

315 M 16 - -

The table of data shows that the AC brake reacts more quickly (i.e. has shorter response times) for thesame frame size. This gives rise to an important practical consideration:

The AC brake is suited to applications characterised by heavy duty brakingcycles with a great number of inserction per hour.

The AC brake doesntneed the rectifier (reliability advantage)

-

8/10/2019 MGM Presentation

30/47

30

Hand Brake Release

BA series permits a locking or unlocking hand release of the brake.BM series permits the unlocking hand release.

BA Motor series BM Motor series

-

8/10/2019 MGM Presentation

31/47

31

Hand Brake Release

BA SERIES HAND BRAKE RELEASE (LOCKING WAY):

-

8/10/2019 MGM Presentation

32/47

32

Hand Brake Release

BA SERIES HAND BRAKE RELEASE (UNLOCKING WAY):

-

8/10/2019 MGM Presentation

33/47

33

Hand Brake Release

BM SERIES HAND BRAKE RELEASE (UNLOCKING WAY):

-

8/10/2019 MGM Presentation

34/47

34

BA Series Manual Rotation

Both BA and BM series shaft (from 63 to 132 frame size) are prepared as standardwith an hexagonal hole in the non drive end (back of the motor) to allow manualrotation.Attention: make sure that alimentation is down, before using the hexagonal key.

This option is extemely useful in the case of setting or presetting of the machinery,or if a gearbox is coupled with the motor

-

8/10/2019 MGM Presentation

35/47

35

Manual Rotation

Hand release of the brake and manual rotation (BA series)

-

8/10/2019 MGM Presentation

36/47

36

Manual Rotation

Hand release of the brake and manual rotation (BA series)

-

8/10/2019 MGM Presentation

37/47

37

BM Series Manual Rotation

Hand release of the brake and manual rotation (BM series)

-

8/10/2019 MGM Presentation

38/47

38

AC electric motors operating in non standard conditions (low frequency inverter duty, long overcharge periods,

heavy duty cycles) could need additional cooling servo-fan. BASV series motors with forced cooling areprovided with two additional cooling servo-fans fixed on the motor frame. This cooling system is an MGMpatent.SV series motors have the following features:

The standard self cooling fan inside the motor is kept additionally to the two cooling servo-fan.The whole heating surface is increased as the fan fixing system is itself a heat dissipation element

additionally to the exixting fins on the frame.Low noise level.No additional motor lenght compared to standard one.Manual brake release with manual rotation.Uniform winding cooling along the whole motor lenght.The brake friction surface is cooled on the motor side.

Where the forced cooling is used to limit the operating temperature in heavy start/stop duty application, it

should be noted that the efficiency of the forced cooling increases with the number of pole of the motor. Itshard to estimate the amount of hot air removed by the forced cooling fans but it can be roughly said that it isthe same as the air removed by the standard servo-fan of a 4 pole motor operating at 50 Hz.It is advisable to use thermal protectors in heavy operating conditions.The servo-fans can be supplied both at 50Hz or 60Hz. On request forced cooling fans can be provided withdifferent voltage supply.BMAV series motors with forced cooling are provided with single axial servo-fan replacing the standard motorself cooling fan.

Forced Cooling Motors

-

8/10/2019 MGM Presentation

39/47

39

Customers can choose between a DC brake and an AC brake.

The brake terminals are located inside the motors own terminal box in both cases.

BA Brake and BM Brake connection

In the BM version, the brake coil is powered by DCcurrent via an AC/DC conversion performed by arectifier diode bridge. The rectifier block is alsohoused inside the terminal box.

The BA version has a 3-phase coil. This isconnected in parallel to the motor. With this typeof brake, braking torque can be adjusted bymeans of spring pre-load adjustment screws.

AC brake terminal box DC brake terminal box

-

8/10/2019 MGM Presentation

40/47

40

Rectifiers

Motors with a DC brake are provided with a rectifier located inside the terminal box.

The AC/DC converter used to power a DC brake, from a functional point of view, is a block of electricalcomponents, into which alternating voltage is fed and out of which comes direct voltage (single or doublehalf-wave), as shown below:

Half Wave Rectifier

AC Current DC Current

Rectifiers are fitted with an over-voltage and radio frequency emission protection.MGM can provide

Full Wave Rectifier

-

8/10/2019 MGM Presentation

41/47

41

BA Series main features

The BA series consists of three phase, asynchronous brake motors totally

enclosed fan cooled (TEFC).

The BA series range starts from 71 up to 315 frame size.

As standard, the brake power supply is AC 3-phase.

On request DC brake can be provided with a rectifier integrated in the terminal

box. The rectifier is provided with an over-voltage and radio frequency emissionprotection device.

The brake is designed and it is suitable for dynamic braking

All BA series motors are provided with manual brake release.

The BA series cooling fan is fitted between the motor and the braking assembly.

The brake moving element and the brake coil have a laminated magnetic nucleus

to reduce losses and to allow very fast braking.

-

8/10/2019 MGM Presentation

42/47

42

BA series: air gap adjustment

The air gap (60), that is the distance between thetwo magnetic cores, the brake coil (25) and brakemoving element (24), must stay within the valuesexpressed in the table below. The correct air gapadjustment allows the motor to optimally work,without vibrations and noise.It is advisable to check periodically the air gap

because it increases, as a consequences of thebrake disc wear.In order to set the air gap to indicated values,you have to loosen the nuts (21)(22) so to movethe brake coil (25) towards the brake movingelement (24).

Frame Size 71-80 90-100 112-132 160-200 225-315

Air Gap 0.25-0.5 0.3-0.6 0.4-0.8 0.5-1.0 0.6-1.2

-

8/10/2019 MGM Presentation

43/47

43

BA series: brake torque adjustment

The brake torque is proportional to the springs (18)compression, which can be adjusted tightening or loosening thelocknuts (20). The compression of the springs must be as evenas possible. Once the brake is properly supplied, if the brake coil(25) isntable to attract the brake moving element (24) with aquick stroke and to keep it attracted without any vibrations,check the air gap adjustment and, if this inconvenience still

persists, loosen the locknuts (20) by two threads and try againuntil the proper functioning is obtained.Once this operation is completed, check the brake torque tomake sure it is set to the desired value. Never set the braketorque to a higher value than the one indicated on the motornameplate.

Frame Size 71 80 90 100 112 132 160 180 200 225 250 280 315

Max AC Brake Torque 14 18 38 50 80 150 190 300 300 400 700 1000 1400

Max DC Brake Torque 9 15 30 42 60 120 155 180 180 240 - - -

-

8/10/2019 MGM Presentation

44/47

44

Special Features and Options

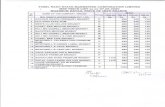

The table below shows the available main special features and the options for MGM motors.

Letters Sstands for Standard, letter R for on Request and the letter Nstands for Unavailable.

Description BM BA

1. Non-standard Flange R R

2. Special motor shaft as per drawing R R

3. Motor with feet and flange (IM B35 and IM B34 with corresponding vertical mounting) R R

4. Balancing for reduced or special vibration level R R

5. Separate brake supply (two different terminal boards) R R6. IP55 or IP56 Enclosure rating (protection degree) R R

7. Special motor/brake voltage or frequency supply R R

8. Insulation Class H R R

9. Brake torque and/or air gap pre-adjustment to desired value R R

10. CSA approval R R

11. CCC approval R R

12. Special pole motors R R13. Standstill heating R R

14. Bimetallic thermal protectors PTO R R

15. Thermistor PTC R R

16. Tropicalization treatment of motor windings R R

17. Over-voltage safety cutout (RC04 and RC10) R R

18. Terminal Box on the right (left) side for IM B3 (BA 80-132) N R

-

8/10/2019 MGM Presentation

45/47

45

Special Features and Options

Description BM BA

19. Double shaft end R R

20. Test certificate R R

21. Rain roof (BM), special fan cover for outside vertical mounting R N

22. Brake cover (BA), special brake cover for outside vertical mounting N R

23. Precise tolerances class R R

24. Fan cover for textile enviroment R S

25. Motor with built-in encoder or tachogenerator R R

26. Motor arranged for manual rotation (shaft fitted with hexagonal hole at non-drive end) S S27. Special finishing (marine enviroments, washdown applications) R R

28. Manual brake release key N S

29. Manual return brake release lever R R

30. T key for manual shaft rotation R R

31. Stainless steel tie rods, bolts,nuts and screws R R

32. Forced cooling motor (SV, AV series) R R

33. Motor with additional cable gland holes R R34. Zinc plated brake surfaces R R

35. Drain holes R R

36. Stainless steel friction surface R R

37. Brake release microswitch R R

38. Microswitch detector of brake disc wear R R

-

8/10/2019 MGM Presentation

46/47

46

MGM brake motors Applications

-

8/10/2019 MGM Presentation

47/47

47

MGM Brake motors

M.G.M. Motori elettrici s.p.a. M.G.M. Electric motors NA Inc.

Thank you for your kind attention.

Please visit our site: www.mgmrestop.com