METAL DETECTOR - SIGMA Equipment · 2016. 5. 7. · Metal detector duw Series The ultimate mission...

Transcript of METAL DETECTOR - SIGMA Equipment · 2016. 5. 7. · Metal detector duw Series The ultimate mission...

-

METAL DETECTOR

-

2

Metal detector that supports safety and securein the food business

METAL DETECTOR duw Series

Dual Wave &Easy Setting

High sensitivity and stabilityanyone can achieve

Simultaneous 2-frequency magnetization detectionmethod allows high-sensitivity detection both offerrous and non-ferrous metal contamination.

• Auto setting algorithm equipped with our uniquesensing technologyAnyone can make the setting optimum for products to bechecked, including dry, wet, and aluminum-evaporatedfilm products, with the automatic setting function allowedby auto setting algorithm.

• Simultaneous 2-frequency magnetization detectionmethod adoptedHighly sensitive detection of both ferrous and non-ferrousmetals is allowed.The auto setting algorithm and the detection method haveimproved detection sensitivity by 1 to 3 ranks comparedwith conventional metal detectors (test piece size, ourcompany ratio).

• Phase tracking functionFor frozen or wet products as well as bulk products, thetracking (phase tracking) function provided works onindividual i tem, thus maintaining stable detectingoperation.

Metal detector duw SeriesThe ultimate mission of a metal detector is to detect and eliminateminute metal contamination without fail. we have analyzed theconcept comprehensively, and reengineered the series from scratch.The Metal detector duw series are our proud products thusdeveloped to allow anyone to obtain highly sensitive and stablebasic performance in production line.The duw series, which adopt the industry’s first simultaneous 2-frequency magnetic field detecting method, dual wave, areprovided with our unique sensing technology such as auto settingalgorithm and tracking functions. Enhanced sensitivity both toferrous and non-ferrous metals achieves stable detectionperformance.

-

3

Superior adaptability to production line

• The speed of the conveyor belt can be individuallyselected by product type. Change of belt speed, whichmay be required because of increase of production, etc.,is allowed without making modification. Setting change toadapt the flow direction resulting from relocation orchange of production line layout can also be made easily.

• The range of supply voltage from 100 to 120 V/220 to 240V (AC) allows the installation at any place.

Easy maintenance• Auto balancing function provided to correct losing balance

eliminates the need of adjustment work.

• Adopted one-touch attaching/detaching system and directdrive system (AW model only), which does not require adrive belt, facilitate maintenance work.

• Adopted auto tension mechanism, which eliminates theneed of tension adjustment, and meander-less transferbelt (AW model only) facilitate belt adjustment.

Estimated detection sensitivitydisplay

• Provided with a function of displaying estimateddetection sensitivity.Once auto setting is completed, estimated sensitivity toferrous and stainless steel is displayed, which allows youto check detection sensitivity to the test piece.

Note: The estimated detection sensitivity display does not assure the size of atest piece that can be detected. Check the detection sensitivity with the

test piece.

Compliance with HACCPSubstantial waterproof design for easy cleaning

• IP66-compliant (AW model only) dustproof and waterproofperformance allows easy cleaning with jet water.Possibility of propagation of bacteria due to entering ofwater into the equipment has thus been eliminated.

• Stainless steel exterior, waterproof stainless steel motor,and open frame structure that prevents dust fromaccumulating have been adopted with consideration givento maintenance of sanitary conditions and easy cleaning.

• Transfer belt can be cleaned by boiling (W type), which isideal for hygienic management.

Auto tension mechanism

One-touch attachment/detachment of the conveyor

Example of estimated detection sensitivity display

Open frame structure Transfer belt can be cleaned by boiling

-

4

Easy operation and substantialfunctions

• Simple operation based on interactive systemAdoption of interactive menu screen system allows simpleand easy operation. Product type registration, autosetting, and rejecting setting in wizard system, inparticular, prevent omission and mistakes in setting.

• History recording functionNG history, which displays when and with which itemmetal contamination was detected, and operationhistory, which displays when product type or detectionsensitivity was changed, are automatically recorded.

• Statistical functionTotal number of checked items, number of OK or NGitems, NG ratio, etc. can be displayed.

• Operation check functionEfficient automatic manual operation check with test pieceand automatic result recording.

• Monitoring the sensitivity to contained objectThe level of the effect of contained objects on checkeditems viewed from the metal detector is graphicallydisplayed in chronological order.

• Access level control functionAccess level controlled with password prevents unwantedsetting change.

• Missing component checking functionMetallic products with missing components are checkedand removed as NG items.

• Rejection confirmation function (Option)Whether rejecting operation was performed securely withthe rejecting machine is monitored.

Expandability and options that assure further enhanced production line

Abundant expansion functions and options such asinterlock with our Checkweighers are available. Contact our sales representatives for details.

Example of wizard system menu

Example of monitoring of effect on an item

Example of change of operator level

-

Co

nta

mi

na

nt

Ins

pe

cti

on

Sy

ste

m

5

Co

ntam

inan

t Insp

ection

System

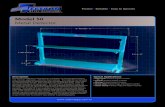

KD8113AW

External Dimensions

402

213

800160

M20 47060 dia.

H2

H1

300

376 110

220

Bel

t wid

th

IndicatorDetector head

Flow direction

Photocell

30 dia. Roller

Conveyor

700

to 8

50P

assl

ine

heig

htPa

ss h

eigh

t

Max. pass widthMax. detection width

KD8113AKD8115AKD8116A

Units: mm

402

213

800160

M20 47060 dia.

300

376 110

220

Bel

t wid

th

700

to 8

50P

assl

ine

heig

ht H2

H1

Pass

hei

ght

IndicatorDetector head

Flow directionPhotocell

33 dia. Roller

Conveyor

Max. pass widthMax. detection width

KD8113AWKD8115AWKD8116AW

Units: mm

KD811X type KD8113A/KD8113AW/KD8115A/KD8115AW/KD8116A/KD8116AWThis is a high-sensitivity type for small individually packaged productsand products in containers like glass or plastic bottles, etc.

duw Series

Metal Detector

H1 H2

KD8113A 80 1100+100

KD8115A 120 1140+100

KD8116A 180 1200+100

-50

-50

-50

H1 H2

KD8113AW 75 1095+105

KD8115AW 115 1135+105

KD8116AW 175 1195+105

-45

-45

-45

Model KD8113A KD8113AW KD8115A KD8115AW KD8116A KD8116AW

Pass height 80 mm 75 mm 120 mm 115 mm 180 mm 175 mm

Max. pass width 300 mm

Belt width 220 mm

Display STN LCD

Operation method Flat panel key

Preset memory Max. 100

Product packaging Both general and aluminum-evaporated film packaged products

Belt speed 10 to 90 m/min (variable speed depending on Product No.)

Max. product weight 5 o (A types can support up to 10 o as an option. AW types can support up to 15 o. However, the belt speed is 5 to 49 m/min)

Metal detection Rejection signal output and beep, or belt stop and beep

Power requirements 100 to 120 Vac +10 % -15 % or 200 to 240 Vac +10 % -15 %, single phase, 50/60 Hz, 150 VA, rush current 62 A (typ.) (20 ms min)

Weight 72 o 75 o 77 o

Environmental conditions 0° to 40 °C, relative humidity 30 % to 85 %, no condensation

Protection class IP30 compliance IP66 compliance IP30 compliance IP66 compliance IP30 compliance IP66 compliance

External finish A type: painted [Indicator and detector head: stainless steel (SUS304)] W type: stainless steel (SUS304)

Specifications

Dust and waterproof protection class(only W type)

Interactive guidance

.

Printer(option)

LISTStatistical functions

NG History

NG

Operation history

Online interface

Supports flow direction change

Variable belt speed

BELT SPEED

LOW HIGH

Variable passline height

Simple cleaning

Rejection confirmation

function(option)

NG

DSP

Analog

Digital

Automatic power

switching

Automatic power switching

100V 200V

HACCP Support

(only W type)

HACCPSupport

CE Marking(option)

MD with coaxial

detection coils

Coaxial Type

Dual frequency

Estimatedsensitivity

Estimated sensitivity display

-

Co

ta

min

nt

ns

ec

on

ys

em

6

Co

ntam

inan

t Insp

ection

System

450

350

477

288

470 526M20

800160

700

to 8

50Pa

sslin

e he

ight H2

H1

Pass

hei

ght

Conveyor

60 dia.

Bel

t wid

th

IndicatorDetector headPhotocell

33 dia. Roller

Max. pass widthMax. detection width

Flow direction

M20

160800

470 526

450

350

288

477

H2

H1

Pas

s he

ight

Pas

slin

e he

ight

Conveyor

60 dia.

700

to 8

50B

elt w

idth

IndicatorDetector head

Photocell

30 dia. Roller

Max. pass widthMax. detection width

Flow direction

KD8124AW

External Dimensions

Units: mm

Units: mm

KD8124AKD8125AKD8126A

KD8124AWKD8125AWKD8126AW

duw Series

Metal Detector

KD812X type KD8124A/KD8124AW/KD8125A/KD8125AW/KD8126A/KD8126AWHigh-sensitivity and medium size type Suitable for bulk products and bag products for commercial use

H1 H2

KD8124A 100 1100+100

KD8125A 130 1140+100

KD8126A 180 1200+100

-50

-50

-50

H1 H2

KD8124AW 75 1095+105

KD8125AW 115 1135+105

KD8126AW 175 1195+105

-45

-45

-45

Model KD8124A KD8124AW KD8125A KD8125AW KD8126A KD8126AW

Pass height 100 mm 95 mm 130 mm 125 mm 180 mm 175 mm

Max. pass width 450 mm

Belt width 350 mm

Display STN LCD

Operation method Flat panel key

Preset memory Max. 100

Product packaging Both general and aluminum-evaporated film packaged products

Belt speed 10 to 73 m/min (variable speed depending on Product No.)

Max. product weight 5 o (A types can support up to 10 o as an option. AW types can support up to 15 o. However, the belt speed is 5 to 49 m/min)

Metal detection Rejection signal output and beep, or belt stop and beep

Power requirements 100 to 120 Vac +10 % -15 % or 200 to 240 Vac +10 % -15 %, single phase, 50/60 Hz, 200 VA, rush current 62 A (typ.) (20 ms min)

Weight 82 o 84 o 86 o

Environmental conditions 0° to 40 °C, relative humidity 30 % to 85 %, no condensation

Protection class IP30 compliance IP66 compliance IP30 compliance IP66 compliance IP30 compliance IP66 compliance

External finish A type: painted [Indicator and detector head: stainless steel (SUS304)] W type: stainless steel (SUS304)

Specifications

Dust and waterproof protection class(only W type)

Interactive guidance

.

Printer(option)

LISTStatistical functions

NG History

NG

Operation history

Online interface

Supports flow direction change

Variable belt speed

BELT SPEED

LOW HIGH

Variable passline height

Simple cleaning

Rejection confirmation

function(option)

NG

DSP

Analog

Digital

Automatic power

switching

Automatic power switching

100V 200V

HACCP Support

(only W type)

HACCPSupport

CE Marking(option)

MD with coaxial

detection coils

Coaxial Type

Dual frequency

Estimatedsensitivity

Estimated sensitivity display

-

Co

nta

mi

na

nt

Ins

pe

cti

on

Sy

ste

m

7

Co

ntam

inan

t Insp

ection

System

KD823A

Dust and waterproof protection class(only W type)

Printer(option)

LISTOnline

interface(option)

Variable passline height

DSP

Analog

Digital

CE Marking(option)

MD with opposed

detection coils

Opposing Type

780

Max

. pas

s w

idth

550

Bel

t wid

th67

0Le

g sp

acin

g46

046

7

1800/1500/ (1200)

340Indicator

Photocell

Liner

Detector head

Emergency switch

Flow direction

Conveyor

79 dia. Roller

1155

M24

191

Pass

height

Protector

460

to 5

50Pa

sslin

e he

ight

308

550

Effect

ive de

tection

width

(1200) : KD823AW, KD823ADW

KD823AKD823AWKD823ADKD823ADW

Units: mm

KD823A/KD823AWFor both general and aluminum-evaporated film packaged products

KD823AD/KD823ADWFor general packaged productsKD823 type

Wide large and general-use typeSuitable for large products in bags or cartons.

External Dimensions

Metal Detector

Model KD823A KD823AW KD823AD KD823ADW

Pass height 150 mm,300 mm,400 mm (The pass height is available in 50-mm pitch within the range from 100 to 400 mm.)

Max. pass width 780 mm

Belt width 550 mm

Display LED

Operation method Flat panel key

Preset memory Max. 50

Product packaging both general and aluminum-evaporated film packaged products only dry products

Belt speed 27.6 m/ min (50 Hz), 33.2 m/ min (60 Hz) 26.8 m/ min (50 Hz), 32.2 m/ min (60 Hz) 27.6 m/ min (50 Hz), 33.2 m/ min (60 Hz) 26.8 m / min (50 Hz), 32.2 m/ min (60 Hz)

Max. product weight 50 o

Metal detection Rejection signal output and beep, or belt stop and beep

Power requirements 100 Vac ±10 %, single phase, 50/60 Hz, 400 VA

Weight 160 o (Pass height: 150 mm)

Environmental conditions 0° to 40 °C, relative humidity 30 % to 85 %, no condensation

Protection class IP30 compliance IP65 compliance IP30 compliance IP65 compliance

External finish Painted Conveyor: stainless steel (SUS304) Painted Conveyor: stainless steel(SUS304)

Specifications

-

Co

ta

min

nt

ns

ec

on

ys

em

8

Co

ntam

inan

t Insp

ection

System

KD803AUW

KD803AD/KD803ADWFor dry general packagedproducts

KD803AU/KD803AUWFor wet general packagedproducts

650

550

670

490

415

Max

. pas

s w

idth

Max

. det

ectio

n wi

dth

M24

Indicator

Conveyor

79 dia. Roller

300

1800/1500/ (1200)

1155

191

460

to 5

50

850

to 9

40

100

Pass

heigh

tPa

sslin

e heig

ht

Bel

t wid

th

Leg

spac

ing

Detector head

Emergency switch

Photocell

Flow direction

(1200) : KD803ADW, KD803AUW

KD803ADKD803ADWKD803AUKD803AUW

Units: mm

KD803 typeHigh-sensitivity type for wide large and bulk products. External Dimensions

Metal Detector

Model KD803AD KD803ADW KD803AU KD803AUW

Pass height 100 mm

Max. pass width 650 mm

Belt width 550 mm

Display LED

Operation method Flat panel key

Preset memory Max. 50

Product packaging dry products wet products

Belt speed 27.6 m/ min (50 Hz), 33.2 m/ min (60 Hz) 26.8 m/ min (50 Hz), 32.2 m/ min (60 Hz) 27.6 m/ min (50 Hz), 33.2 m/ min (60 Hz) 26.8 m / min (50 Hz), 32.2 m/ min (60 Hz)

Max. product weight 50 o

Metal detection Rejection signal output and beep, or belt stop and beep

Power requirements 100 Vac ±10 %, single phase, 50/60 Hz, 400 VA

Weight 160 o 170 o

Environmental conditions 0° to 40 °C, relative humidity 30 % to 85 %, no condensation

Protection class IP30 compliance IP65 compliance IP30 compliance IP65 compliance

External finish Painted Conveyor: stainless steel (SUS304) Detector head: stainless steel (SUS304) Detector head, conveyor: stainless steel (SUS304)

Specifications

Dust and waterproof protection class(only W type)

Printer(option)

LISTOnline

interface(option)

Variable passline height

DSP

Analog

Digital

CE Marking(option)

MD with coaxial

detection coils

Coaxial Type

-

Co

nta

mi

na

nt

Ins

pe

cti

on

Sy

ste

m

9

Co

ntam

inan

t Insp

ection

System

800174

Indicator

Detector head

Liner

Flow direction52 dia. Roller

Photocell

Conveyor

Pass

heig

ht

47068 dia.

M24

Max

. pas

s wi

dth

Effectiv

e dete

ction w

idth 275

270

220

304

Leg

spac

ing

Bel

t wid

th

300

250

350

Pas

slin

e he

ight

700

to 8

00

KD821AHKD821AHW

Units: mm

KD821AH/KD821AHWEspecially for aluminum foil packaged productssuch as retort pouches and snack foods

External Dimensions

especially for Aluminum foil packaged products

Metal Detector

Model KD821AH KD821AHW

Pass height 30 mm, 55 mm, 80 mm, 105 mm, 130 mm

Max. pass width 300 mm

Belt width 220 mm

Display LED

Operation method Flat panel key

Preset memory Max. 50

Product packaging Aluminum foil packaged products

Belt speed 39 m/min

Max. product weight 5 o

Metal detection Rejection signal output and beep, or belt stop and beep

Power requirements 100 Vac ±10 %, single phase, 50/60 Hz, 200 VA

Weight 75 o

Environmental conditions 0° to 40 °C, relative humidity 30 % to 85 %, no condensation

Protection class IP30 compliance IP65 compliance

External finish Painted Conveyor leg: stainless steel (SUS304)

Specifications

KD821AH

Dust and waterproof protection class(only W type)

Printer(option)

LISTOnline

interface(option)

Variable passline height

Simple cleaning

DSP

Analog

Digital

CE Marking(option)

MD with opposed

detection coils

Opposing Type

-

10

400

270 1

60250 67

0

Belt

widt

h

H Model

KW6205XX3R

KW6205XX5R

KW6205XX6R

80

120

180

XX: AF, AP, BF or BP

18 dia. Roller

700

to 8

50

H

Pas

slin

e he

ight

60 dia.

130 105540

30 dia. Roller

300

775270

Indicator

Flow directionMetal detector

M20

670

495

Leg

spac

ing

H

480

340

350

Bel

t wid

th

820

645

Leg

spac

ing

1300495

33 dia. Roller

33 dia. Roller

915 105280

750

to 8

50P

assl

ine

heig

ht

M2060 dia.

670

300 Indicator

Metal detector

H ModelKW5476AW4RKW5476BW4RKW5476AW5RKW5476BW5RKW5476AW6RKW5476BW6R

75

115

175

Flow direction

H ModelKW5412AF3RKW5412AP3RKW5412BF3RKW5412BP3RKW5412AF5RKW5412AP5RKW5412BF5RKW5412BP5RKW5412AF6RKW5412AP6RKW5412BF6RKW5412BP6R

80

120

180

300

850

M20

105

345

130 615

H

670

25 dia. RollerMetal detector

30 dia. Roller

60 dia.

Indicator

700

to 8

50P

assl

ine

heig

ht40

027

0

495

Leg

spac

ing

250

Belt

widt

h

670

Flow direction

SVh Series Checkweigher with Metal DetectorKW6205 type

SVi Series Checkweigher with Metal DetectorKW5476 type

SVf Series Checkweigher with Metal DetectorKW5412 type

ModelKW6205AFXR KW6205BFXRKW6205APXR KW6205BPXR

Weight range 2 to 600nMax. accuracy (3σ) Note 1 ±0.02nMax. speed Note 1 400 products / minDisplay 10.4-inch color TFT LCD FDM panel displayOperation method Touch panel Flat panel keyIndication range 600.9nScale interval 0.02n/600n, 0.01n/300nLimit range Within indication rangePreset memory Max. 100Classification 2 or 3

Width W 20 to 160 mmLength L 58 to 230 mmHeight H 3R:5 to 80 mm 5R:5 to120 mm 6R:5 to180 mm

Belt speed 15 to 120 m/min

Power requirements100 to 120 Vac +10 % -15 % or 200 to 240 Vac +10 %-15 %, singlephase, 50/60 Hz, 300 VA, rush current 62 A (typ.) (20 ms min)

Weight 3R:96 o 5R:98 o 6R:99 o

Environmental conditions0 to 40°C (variation not to exceed 5°C/h to maintainaccuracy), relative humidity 30 to 85 %, no condensation

Protection class IP30 complianceExternal finish F type: painted, P type: stainless steel (SUS304) excluding some parts

Note 1: The speed and accuracy may change depending on the checked product type and rejector type.Note 2: The checked product size depends on the rejector type; select the rejector in line with your needs—consult us about semi-transparent and transparent products.Note 3: Functions in [ ] are optional. The upper limit of the weight range changes according to the operating environment.

Note 1: The speed and accuracy may change depending on the checked product type and rejector type.Note 2: The checked product size depends on the rejector type; select the rejector in line with your needs—consult us about semi-transparent and transparent products.

Specifications External Dimensions

Note 1: The speed and accuracy may change depending on the checked product type and rejector type.Note 2: The checked product size depends on the rejector type; select the rejector in line with your needs—consult us about semi-transparent and transparent products.

Units: mm

Units: mm

Units: mm

KW6205AP3R

KW5476BW4R

KW5412AF3R

Productsize Note2

Model KW5476XWYRWeight range 30 to 3000nMax. accuracy (3σ) Note 1 ±0.5nMax. speed Note 1 120[155] products / min Note 3

DisplayX=Atype: 10.4-inch color TFT LCDX=Btype: FDM panel display

Operation methodX=Atype: Touch panelX=Btype: Flat panel key

Indication range 3009nScale interval 0.2n/3000n, 0.1n/1200nLimit range Within indication rangePreset memory Max. 100Classification 2 or 3

Width W 20 to 350 mmLength L 76 to 400 mm

Height HYR= 4R: 5 to 95 mm, YR= 5R: 5 to 125 mm,YR= 6R: 5 to 175 mm

Belt speed 7 to 65[9 to 83] m/min Note 3

Power requirements100 to 120 Vac +10 % -15 % or 200 to 240 Vac +10 %-15 %, singlephase, 50/60 Hz, 300 VA, rush current 62 A (typ.) (20 ms min)

Weight YR= 4R:133 o YR= 5R:135 o YR= 6R:137 o

Environmental conditions0 to 40°C (variation not to exceed 5°C/h to maintainaccuracy), relative humidity 30 to 85 %, no condensation

Protection class IP66 complianceExternal finish stainless steel (SUS304)

Specifications External Dimensions

Specifications External Dimensions

Productsize Note2

KW5412AF3R/KW5412AF5R/KW5412AF6R

modelKW5412AP3R/KW5412AP5R/KW5412AP6RKW5412BF3R/KW5412BF5R/KW5412BF6RKW5412BP3R/KW5412BP5R/KW5412BP6R

Weight range 12 to 3000nMax. accuracy (3σ) Note 1 ±0.2nMax. speed Note 1 320 products / minDisplay Atype: 10.4-inch color TFT LCD, Btype: FDM panel displayOperation method Atype: Touch panel, Btype:Flat panel keyIndication range 3009nScale interval 0.2n/3000n, 0.1n/1200nLimit range Within indication rangePreset memory Max. 100Classification 2 or 3

Width W 20 to 250 mmLength L 65 to 300 mm

Height H3R: 5 to 80 mm, 5R: 5 to 120 mm,6R: 5 to 180 mm

Belt speed 15 to 120 m/min

Power requirements100 to 120 Vac +10 % -15 % or 200 to 240 Vac +10 %-15 %, singlephase, 50/60 Hz, 300 VA, rush current 62 A (typ.) (20 ms min)

Weight 3R: 99 o 5R: 101 o 6R: 102 o

Environmental conditions0 to 40°C (variation not to exceed 5°C/h to maintainaccuracy), relative humidity 30 to 85 %, no condensation

Protection class IP30 complianceExternal finish F type: painted, P type: stainless steel (SUS304) excluding some parts

Productsize Note2

-

11

RejectorAir jet type

Model KW483BW

Classification 2

Max. product 220 W�180 H�300 L mm, 300nsize and weight

Max. speed 220 products/min

Power requirements Supplied from Metal detector, 50 VA

Air requirements 0.49 MPa, 16r/min [A.N.R.]

Air supply inlet Nylon tube having external 10 mm dia.

Protection class IP66 compliance

Weight 3 oApplicable model KD811X type, KD812X type

Dropout typeModel KW465BW KW466BW

Classification 2

Max. product Bulk products Products with certain interval Bulk products Products with certain interval

size and weight 220 W�30 H�200 L mm, 220 W�100 H�200 L mm, 350 W�30 H�200 L mm, 350 W�100 H�200 L mm, 500n 500n 500n 500nMax. speed —— 80 products/min —— 80 products/min

Power requirements Supplied from Metal detector, 50 VA

Air requirements 0.39 to 9 MPa, 2r/min [A.N.R.]

Air supply inlet Nylon tube having external 10 mm dia.

Protection class IP66 compliance

Weight 8 o 10 oApplicable model KD811X type KD812X type

Dropout typeModel KW4672DW KW4676DW

Classification 2

Max. product 230 W�130 H�300 L mm, 350 W�210 H�450 L mm, size and weight 3000n 3000nMax. speed 70 products/min 30 products/min

Belt speed 7 to 36 m/min 7 to 26 m/min

Power 100 to 120 Vac +10%, –15%,

requirements200 to 240 Vac single phase, 50/60 Hz, 200 VA

Air requirements 0.4 to 0.9 MPa, 30r/min [A.N.R.]

Air supply inlet Nylon tube having external 6 mm dia.

Protection class IP66 compliance

Weight 29 o 37 oApplicable model KD8011X type KD8012X type

Dropout typeModel KW4612A KW4612AH

Classification 2

Max. product 220 W�130 H�300 L mm, 220 W�50 H�300 L mm, size and weight 1.2 o 1.2 oMax. speed 70 products/min 120 products/min

Belt speed 24 to 90 m/min

Power requirements 100 Vac ±10%,single phase, 50/60 Hz, 80 VA

Air requirements 0.4 to 0.9 MPa, 3r/min [A.N.R.]

Air supply inlet Nylon tube having external 6 mm dia.

Protection class IP30 compliance

Weight 23 oApplicable model KD811X type

Flipper typeModel KW4103AW KW4104AW

Classification 3

Max. product 230 W�200 H�300 L mm, 230 W�200 H�300 L mm, size and weight 3 o 10 o Note 1

Max. speed 150 products/min 70 products/min

Belt speed 10 to 102 mm/min 10 to 77 mm/min

Power 100 to 120 Vac +10%, –15%,

requirements200 to 240 Vac single phase, 50/60 Hz, 200 VA

Air requirements 0.4 to 0.9 MPa, 4r/min [A.N.R.]

Air supply inlet Nylon tube having external 6 mm dia.

Protection class IP66 compliance

Weight 45 o 70 oApplicable model KD811X type KD812X type

Flipper type

Mount the detection head to the conveyor you are currently using or the one

to be supplied by you by referring to technical data 84W141457, “Metal

Detector Installation Manual.”

Model KW413BA/�KW413BE KW414AClassification 3

Max. product 230 W�200 H�300 L mm, 300 W�500 H�600 L mm, size and weight 3 o/�1.2 o 10 o

Max. speed100 products/min

70 products/min�150 products/min24 to 77 mm/min,

Belt speed 60 to 102 mm/min 24 to 77 mm/min(belt position change)

Power 100 Vac +10%, –15%, 100 Vac +10%, –15%,

requirementssingle phase, 50/60 Hz, single phase, 50/60 Hz, 100 VA/�200 VA 240 VA

Air requirements0.4 to 0.8 MPa, 0.4 to 0.9 MPa, 4r/min [A.N.R.] 4r/min [A.N.R.]

Air supply inlet Nylon tube having external 6 mm dia.

Protection class IP30 compliance

Weight 57 o/�62 o 67 oApplicable model KD811X type KD812X type

Note 1: Max. product weight may change depending on the speed.

-

CAT. NO. K3107-A-1 2004-9 50 (M) Printed in Japan

INTERNATIONAL SALES DEPARTMENT1800, Onna, Atsugi-shi, Kanagawa-Prf., 243-0032, JAPANPHONE +81 46 296 6699FAX +81 46 225 8387E-Mail: [email protected]://www.anritsu.co.jp/E/Industry/

ISO14001 CERTIFICATE No.JQA-EM0210ISO 9001 CERTIFICATE No.JQA-0566

ANRITSU INDUSTRIAL SOLUTIONS CO., LTD.

©ANRITSU INDUSTRIAL SOLUTIONS CO., LTD. 2004

Printed with environment-friendly vegetable soybean oil ink.

Printed on 100% Recycled Paper

Specifications are subject to change without notice. No part of thewhole of this catalog may be reproduced without our permission.

• In addition to daily inspection, an annual maintenance checkshould be carried out.