MEDIUM VOLTAGE PRODUCT CAPABILITIES OVERVIEW · • Manufactured by Benshaw and supported by...

Transcript of MEDIUM VOLTAGE PRODUCT CAPABILITIES OVERVIEW · • Manufactured by Benshaw and supported by...

3BENSHAW.COM2

MVB SERIES

Standard Breaker Features :

• 1200, 2000, 3000 Amps, 3 phase, 60 Hz, up to 15KV, Metal Enclosed

• Main Bus, Tin-Plated Copper, Insulated

• Wtihstand Ratings to 50kA

• Voltage Transformer

• Current Transformers

• Safety Barriers, Front Access

• Draw-Out Breaker

• Protection Relay

• Switch / Control Options

• 86 Lockout Relay, Breaker Control Switch

• Current / Voltage Test Switch, Shorting Block

• 3 LED Indicating Lights, Green = Open, Red = Closed, Amber = Fault

• Auxiliary Control for Breaker Position

• Capacitor Trip Device

• Ultra Safe Fuse Blocks

• Safe Control Test

• Arrestors

MVB SERIES, CONTINUED

Additional Features :

• Ultrasound Ports

• Thermal Viewing Windows

• Live Line Indication

• Mimic Bus

• Optional Incoming Section

• Remote Breaker Operator

• Lifting Truck, Lifting Yoke

• Arc Mitigation Relays

Key Features :

• Customizable incoming section to meet customer cable entry requirements

• No transition section required to meet Benshaw® Medium Voltage equipment

• Compact and Flexible Design

• Manufactured by Benshaw and Sup-ported by Benshaw

• 2-High Breaker Confi guration

• 2 Year Manufacturer Warranty

Medium Voltage Product Overview

MVRMX SERIES

Standard Softstart Features :

• UP to 30000HP 3 phase, 60 Hz, up to 15KV, Metal Enclosed

• Withstand ratings to 50kA

• 45 / 60 KV BIL

• Metal Enclosed Nema1, 12, 3R enclo-sures

• Benshaw® MX³ controller

• Thermal Capacity 500% for 30 seconds

• Load matched load break and fuses

• Inline and Bypass contactors

• Programmable acceleration and decel-eration ramp profi les

• Programmable starting and stopping modes

• Integrated electronic motor protection

• Real-time metering and diagnostics

• Fiber Optic Gate fi ring

• Motor heater control

• Anti-windmilling

• Slow speed cyclo converter

• Door-mounted LCD keypad

• Built-In Self Test (BIST) for component integrity

• 8 digital programmable inputs

• 6 programmable relay outputs

• 1 programmable analog 0/4-20mA / 0-10VDC input

• 1 programmable analog 0/4-20mA / 0-10VDC output

• Motor PTC input

• Modbus Communication

MVRMX SERIES, CONT.

Additional Features :

• Thermal viewing windows

• Live line indication

• Mimic bus

• Optional incoming section

• Communication protocols, Ethernet, DeviceNet, Profi bus

• Arc mitigation relays

• Full voltage bypass

• Zero sequence ground protection

• Ground balls

• RTD protection

Key Features :

• Customizable to meet customer re-quirements, two speed, reversing, multiple motor, combination and non-combination, mining duty skid mounted, NEMA 1, 12, 3R, 4 and 4X

• Solid State technology for standard induction, synchronous and wound rotor motors

• No transition section required to meet Benshaw® medium voltage equipment

• Compact and fl exible design

• Manufactured by Benshaw and supported by Benshaw

• 3 Year Manufacturer Warranty

MVB SERIES, MEDIUM VOLTAGE DRAW-OUT CIRCUIT BREAKER

MVRMX SERIES, MEDIUM VOLTAGE SOLID STATE SOFTSTART

REMOTE OPERATORS

BENSHAW.COM4 5

MVATL SERIES, MEDIUM VOLTAGE ACROSS THE LINE STARTER MEDIUM VOLTAGE MOTOR CONTROL CENTER

MVATL SERIES

Standard ATL Features :

• 3 phase, 50/60Hz, up to 15kV Metal Enclosed

• Withstand Ratings to 50kA

• 45 / 60 KV BIL

• Metal Enclosed Nema1, 12, 3R enclosures

• Load matched load break and fuses

• HP Rated Bypass contactors

• Integrated electronic motor protection

• Real-time metering and diagnostics

• Isolated 120V Control Section

Motor Protection Option :

• Electronic or Digital Overload

• MX3 Series Control

• Motor Protection Relay

Medium Voltage Product Overview

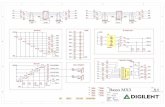

Draw-out Breaker

VFD Feeder

Feeder

Softstart

Tie

Softstart

Feeder

VFD Feeder

Draw-out Breaker

MVRMX SERIES, CONT.

Additional Features :

• Thermal viewing windows

• Live line indication

• Mimic bus

• Optional incoming section

• Communication protocols, Ethernet, DeviceNet, Profi bus, Lon Works

• Arc Flash Mitigation Relays

• Zero sequence ground protection

• Ground balls

• RTD protection

Key Features :

• Customizable to meet customer re-quirements, reversing, multiple motor, combination and non-combination, mining duty skid mounted, NEMA 1, 12, 3R and 4

• Single or Two-high Design

• Solid State technology for, standard induction, synchronous and wound rotor motors

• No transition section required to meet Benshaw® medium voltage equipment

• Compact and fl exible design

• Manufactured by Benshaw and supported by Benshaw

• 3 Year Manufacturer Warranty

BENSHAW.COM6 7

MVMS SERIES, CUSTOMIZABLE UNDERGROUND MINE SKID ADDITIONAL MEDIUM VOLTAGE CAPABILITIES

Medium Voltage Product Overview

MVMS SERIES

Standard Mine Skid Features :

• 1200 or 2000Amps, 3 phase, 60 Hz, up to 15KV, Metal Enclosed

• Fault Make, Load Brake Disconnect Switch

• Vertical Hoist Rated Frame

• High Durability Rails

• Withstand Ratings up to 40kA

• Customizable Line and Load Connections

• Voltage Specifi ed Paneling

• Voltage Transformer

• Current Transformers

• Protection Relay

• Switch / Control Options

• Current:- Voltage Test Switch- Shorting Block

• 3 LED Indicating Lights:- Green = Open, - Red = Closed- Amber = Fault

• Ultra Safe Fuse Blocks

Key Customizable Features :

• Portable Compact Design

• Mine Power Centers

• Power Distribution Centers

• Starter Control Centers

15kV SOFT STARTER WITH CIRCUIT BREAKER BYPASS

LOAD BREAK SWITCH MV JUNCTION BOXES

APPLICATION CONSIDERATIONS

The proper selection and application of soft starters and controls products and components, including the related area of product safety, is the responsibility of the customer. Operating and performance requirements and potential associated issues will vary appreciably depending upon the use and application of such products and components. The scope of the technical and application information included in this publication is necessarily limited. Unusual operating environments and conditions, lubrication requirements, loading supports, and other factors can materially affect the application and operating results of the products and components and the customer should carefully review its requirements. Any technical advice or review furnished by Benshaw, Inc. and/or its affi liates (“Regal”) with respect to the use of products and components is given in good faith and without charge, and Regal assumes no obligation or liability for the advice given, or results obtained, all such advice and review being given and accepted at customer’s risk.

For a copy of our Standard Terms and Conditions of Sale, please visit http://www.regalbeloit.com (please see link at bottom of page to “Standard Terms and Conditions of Sale”). These terms and conditions of sale, disclaimers and limitations of liability apply to any person who may buy, acquire or use a Regal product referred to herein, including any person who buys from a licensed distributor of these branded products.

BENSHAW, Inc.615 Alpha DrivePittsburgh, PA 15238Phone: 412.968.0100 Fax: 412.968.5415

BENSHAW Canada Benshaw Canada Controls, Inc.550 Bright Street East Listowel, Ontario N4W 3W3 Phone: 519.291.5112 Fax: 519.291.2595

benshaw.com andbenshawexpress.com

Regal and Benshaw are trademarks of Regal Beloit Corporation or one of its affi liated companies.

©2017 Regal Beloit Corporation, All Rights Reserved. MCB17013E • Form# 10142E

24 / 7 TECHNICAL SUPPORTBenshaw is dedicated to providing comprehensive 24 –hour-a-day, 7-day-a –week phone support. Benshaw provides repair, spare parts, fi eld engineering, retrofi t and training services, when and where you need us. You can count on our experienced team, backed by the latest diagnostics and repair tools and an extensive parts inventory to support your operations.

24 / 7 Hotline Support from our operation in Pittsburgh and Listowel (Canada):

• Technical phone support

• Overnight parts shipment

• 24-hour service dispatch

• Coordination of all service capabilities

REPAIRSRepairs are made on Benshaw® equipment by trained, experienced personnel using the latest diagnostic and test equipment.

FIELD SERVICESField services are performed on-site by skilled technicians, engineers or complete team if needed. Including :

• Start-up commissioning

• Field repairs

• Field analysis / data collection

• Preventative maintenance

THE BENSHAW® PRODUCT LINE• A wide range of motor controls and variable speed

drives available

• Solid state starters fractional up to 30000HP at 15KV

• Solid state synchronous exciters

• DC injection braking

• LV AC drives to 700 HP

• MV AC drives to 3000 HP

• MV motor control centers

• MV switchgear to 15KV

• Electromechanical controls

Call 1-800-203-2416 for the U.S.

Call 1-877-291-5112 for Canada