Mechanical, Dielectric, and Microwave-Absorption Properties of … · 2017. 8. 26. · 3 ceramics...

Transcript of Mechanical, Dielectric, and Microwave-Absorption Properties of … · 2017. 8. 26. · 3 ceramics...

Mechanical, Dielectric, and Microwave-Absorption Propertiesof Alumina Ceramic Containing Dispersed Ti3SiC2

YI LIU,1,2 FA LUO,1 JINBU SU,1 WANCHENG ZHOU,1

and DONGMEI ZHU1

1.—State Key Laboratory of Solidification Processing, Northwestern Polytechnical University,Xi’an 710072, People’s Republic of China. 2.—e-mail: [email protected]

Dense Al2O3 ceramics containing dispersed Ti3SiC2 were fabricated by hot-pressed sintering. Effects of Ti3SiC2 content on the mechanical, dielectric, andmicrowave-absorption properties of the ceramics were investigated. The bulkdensity, flexural strength, and dielectric constant were enhanced by increas-ing the Ti3SiC2 content. The complex permittivity increased dramaticallywhen the Ti3SiC2 content was above the percolation threshold. The dielectricperformance of the ceramics at high temperatures was also studied. Theresults revealed increases in both the real and imaginary parts withincreasing temperature. Ceramic 2.2 mm thick containing 10% (w/w) Ti3SiC2

had the optimum microwave-absorption properties. The absorption bandwidthbelow �5 dB was in the range 8.2–12.4 GHz with a minimum value of �20 dBat 9.56 GHz. Although the reflection loss increased with the increasing tem-perature, the ceramic still had favorable microwave-absorption propertiesthroughout the X-band. This study contributes to the development of themicrowave absorption materials for high-temperature application.

Key words: Ti3SiC2–Al2O3 ceramics, dielectric properties, microwaveabsorption, high-temperature application

INTRODUCTION

In recent years, electromagnetic (EM) waves havebeen widely used in military and civilian applica-tions, for example in broadcasting, communication,and personal digital assistants, among others.Although use of EM waves can be a convenience,problems with EM wave radiation and pollution alsooccur. To solve these problems, microwave absorbingmaterials which can be used not only at room tem-perature but also at high temperatures haveattracted much attention. Traditional microwave-absorbing materials consist of insulating matrixeswith conducting fillers. Choosing absorbents andinsulating matrixes with high-temperature stabilityand oxidation resistance are crucial to developingmicrowave-absorption materials for high-tempera-ture application. Although microwave-absorbingmaterials containing iron carbonyl,1,2 carbonblack,3,4 and carbon nanotubes5,6 have excellent

absorption properties at room temperature, theycannot be used at high temperatures because of theirlow Curie temperatures or poor oxidation resistance.

Ti3SiC2 is a novel, readily machinable, ternarycompound with both metallic and ceramic proper-ties, for example excellent electrical conductivity,high melting point, and high-temperature oxidationresistance.7–9 These advantages make it a promis-ing absorbent for use at high temperature.

Alumina should be an excellent candidate as theinsulating matrix. Alumina, an important electro-ceramic material with ultra-low dielectric loss andexcellent chemical stability, has been used as aninsulating matrix in the GHz frequency range. Cho-jnacki et al. studied the microwave-absorbing proper-ties of alumina multiwall CNT ceramics.6 The resultsindicatedthematerialhadattractiveproperties foruseas a robust broadband microwave absorber in the 1–40 GHz frequency range. The EM wave-absorptionperformance of plasma-sprayed alumina coatingscontaining absorbents were investigated by Zhouet al.10 Their results revealed favorable absorption by

(Received August 21, 2014; accepted December 17, 2014;published online January 9, 2015)

Journal of ELECTRONIC MATERIALS, Vol. 44, No. 3, 2015

DOI: 10.1007/s11664-014-3607-2� 2015 The Minerals, Metals & Materials Society

867

the coating in the X-band. In addition, the thermalexpansion coefficient of Al2O3 (8.8 9 10�6 K�1) is closeto that of Ti3SiC2 (9.2 9 10�6 K�1), so the residualstress is expected to be small. This indicates aluminacould be a suitable host matrix for Ti3SiC2. However, thedielectric and microwave absorption properties of theseceramics have rarely been reported.

In this study, Ti3SiC2 dispersed in aluminaceramics were fabricated by hot-pressed sintering.Effects of Ti3SiC2 content on the mechanical,dielectric, and microwave absorption propertieswere investigated. The dielectric and microwave-absorption properties of the ceramics at high tem-perature were also studied.

EXPERIMENTAL

Preparation of Ti3SiC2/Al2O3 Composites

Ti3SiC2 powder was synthesized by a solid reactionmethod reported elsewhere.11 The as-prepared Ti3-

SiC2 powder and a-Al2O3 (d50 = 2 lm, purchasedfrom Ultrafine Powders, Zhejiang Province) were wetmixed with alcohol as medium, the Ti3SiC2 contentwas 0, 5, 10, 15, or 20% (w/w). After the slurries hadbeen dried and passed through a 100-mesh sieve, thepowder mixtures were sintered at 1450�C for 2 hunder vacuum (20 MPa). The chamber was evacu-ated to<6 Pa before starting the sintering process.

Characterization

The phase compositions of the samples were identi-fied by XRD with Cu Ka radiation (X-Pert diffractom-eter; Philips, the Netherlands). The morphology wascharacterized by scanning electron microscopy (Jeol,Tokyo, Japan; model JSM-6360). The bulk densities ofthe sintered ceramics were measured by the Archime-des method. Flexural strength was tested by use of thethree-point bending method with samples of size3 mm 9 4 mm 9 40 mm. Complex permittivity weremeasured by use of a vector network analyzer (AgilentTechnologies E8362B; 10 MHz–20 GHz), in the fre-quency range 8.2–12.4 GHz, with use of a heatingdevice. The composite ceramics were cut into rectan-gular blocks of size 22.86 mm (length) 9 10.16 mm(width) 9 2.58 mm (thickness). The reflection loss(RL) of the samples was calculated by use of trans-mission line theory on the basis of measured dielectricconstants (Eqs. 1–3).12–14:

RLðdBÞ ¼ 20log ðZin � Z0Þ=ðZin þ Z0Þ���

��� (1)

Z0 ¼ffiffiffiffiffiffiffiffiffiffil0=e0

q

(2)

Zin ¼ Z0

ffiffiffiffiffiffiffiffiffilr=er

q

tanh j2pc

ffiffiffiffiffiffiffiffilrerp

fd

� �

; (3)

where Zin and Z0 are the input impedances ofabsorber and free space, respectively, er and lr are

the relative complex permittivity and the perme-ability of the absorber (lr = 1 for nonmagnetic Ti3-

SiC2), f is the EM wave frequency, d is the thicknessof the absorber, and c is the velocity of light.

RESULTS AND DISCUSSION

Phase Analysis

Figure 1 shows the x-ray diffraction (XRD) pat-terns of the mixed powders and the ceramics sin-tered at 1450�C.

It is apparent that Al2O3 and Ti3SiC2 are the twomain phases in the mixed powders. Diffractionpeaks of TiC are detected and the intensitiesincrease with increasing Ti3SiC2 content of thesintered ceramics. The main reason is that a part ofTi3SiC2 powders are decomposed during the sin-tering process, as follows15:

Ti3SiC2ðs)! TiCxðs) + Si(l): (4)

Diffraction peaks of Si are not detected in thesamples because of the small amount present. First,only a small amount of the Ti3SiC2 powder decom-poses during the sintering process, so the amount ofSi is low. Also, Si(l) will evaporate at such a hightemperature (the melting point of Si is 1410�C).Evaporation will be promoted under the high-vac-uum environment of a rotary pump. There are no

Fig. 1. XRD patterns of (a) the mixed powders and (b) the ceramicssintered at 1450�C.

Liu, Luo, Su, Zhou, and Zhu868

other new phases in the ceramics, which indicatesthat no chemical reactions occur between the Ti3-

SiC2 and Al2O3 powders during sintering.

Mechanical Properties

Figure 2 shows the bulk density and flexuralstrength of the Ti3SiC2–Al2O3 ceramics.

The theoretical densities of the multiphaseceramics are calculated by use of the equation16:

q ¼P

MiPMi=qi

; (5)

where q is the theoretical density of the ceramic,and Mi and qi are the weight and density of phase i.The theoretical density increases with increasingTi3SiC2 content, because the density of Ti3SiC2

(4.53 g/cm3) is higher than that of Al2O3 (3.98 g/cm3). When the Ti3SiC2 content is increased from 0to 20% (w/w), the bulk density increases from3.425 g/cm3 to 4.017 g/cm3 and the porositydecreases from 13.9% to 1.5%. As discussed above,decomposition of Ti3SiC2 results in the presence ofSi(l) in the ceramics; this acts as a sintering aid andpromotes densification.

The flexural strengths of the ceramics are illus-trated in Fig. 2b. It is apparent that flexuralstrength increases from 260 MPa to 360 MPa as theTi3SiC2 content is increased from 0% to 20% (w/w).The results indicate that addition of Ti3SiC2 has abeneficial effect on the flexural strength of theceramics. There are three reasons for this. First, thebulk density increases with increasing Ti3SiC2

content, which contributes to improvement of flex-ural strength by reducing the number of pores,defects, and cracks in the ceramics. Second, thedispersed Ti3SiC2 powder restricts the growth ofalumina grains. This helps improve the flexuralstrength because of the fine-grain strengtheningmechanism. Third, the Ti3SiC2 filler effectivelytransfers load from the Al2O3 matrix to Ti3SiC2

particles, because of Al2O3/Ti3SiC2 interfacialbonding, i.e. the Ti3SiC2 acts as a reinforcementphase which also contributes to enhancement offlexural strength.

Microstructure

Figure 3 shows SEM images of the fracture sur-faces of ceramics with different Ti3SiC2 content. It isapparent that the number of pores in the ceramicsdecrease with increasing Ti3SiC2 content. Solidsolutions are also observed in the sample withincreasing Ti3SiC2 content, because of the appear-ance of Si(l), as shown in Fig. 3b and c. Energy-dispersive spectroscopic (EDS) analysis shows thatthe columnar grains in the ceramics are Ti3SiC2

powder, which are not only uniformly distributed inthe alumina matrix but also easily distinguished. Itis apparent from Fig. 3a–c that the grain size ofAl2O3 of the composite ceramics is smaller than thatof the pure alumina ceramic, which indicates thatthe presence of Ti3SiC2 hinders growth of aluminagrains during the sintering process. The results arein accordance with the above discussion.

Dielectric Properties

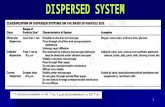

Effect of Ti3SiC2 Content on Dielectric Properties

Complex permittivity (e = e¢ � je¢¢) is a valuecharacterizing the dielectric properties of materials.The dielectric performance of ceramics with differentTi3SiC2 content in the 8.2–12.4 GHz frequency rangeis shown in Fig. 4. It is apparent that both the realand imaginary parts are enhanced with increasingTi3SiC2 content, and that the complex permittivitysurges substantially as the Ti3SiC2 content is in-creased from 15 to 20% (w/w). The real part indicatesthe storage capacity of the material, which is mainlyattributed to polarization (relaxation and interfacialpolarization) of the free charges which accumulate atthe interfaces between the insulating matrix andconducting filler. In this materials, more interfaceswill be formed between Al2O3 and Ti3SiC2 withincreasing Ti3SiC2 content. So the polarization(especially interfacial polarization) ability of the

Fig. 2. Bulk density (a) and flexural strength (b) of the Ti3SiC2–Al2O3

ceramics.

Mechanical, Dielectric, and Microwave-Absorption Properties of Alumina CeramicContaining Dispersed Ti3SiC2

869

ceramic is reinforced under an external alternatingelectronic field, which contributes to the increase ofthe real part.

The imaginary part (e¢¢), which represents thelossy capacity, is also related to the Ti3SiC2 content.e¢¢ is mainly dominated by the electric conductivityof the materials which, according to free-electrontheory, can be expressed as11:

e00 ¼ r=xe0¼ r=2pf e0

; (6)Fig. 3. SEM images of the fracture surfaces of ceramics with dif-ferent Ti3SiC2 contents: (a) 0, (b) 10, and (c) 20% (w/w).

Fig. 4. Dielectric performance of ceramics with different Ti3SiC2

content in the 8.2–12.4 GHz frequency range: (a) real part, (b)imaginary part, and (c) dielectric loss.

Liu, Luo, Su, Zhou, and Zhu870

where r is the electrical conductivity, e0 is the freespace permittivity and f is the frequency. It is clearthat the increase of e¢¢ with increasing Ti3SiC2 con-tent is attributed to the increase of electrical con-ductivity. The conductivity of the ceramic consistingof insulating matrix (Al2O3) and conducting filler(Ti3SiC2) is dominated by the interparticle distanceof the filler, as expressed by17:

d ¼ D ðp=6uÞ1=3 � 1

h i

; (7)

where d is the average interparticle distance, D isthe particle diameter, and u is the volume fractionof the fillers. The interparticle distance of the fillersdecreases with increasing Ti3SiC2 content, as shownin Fig. 3. So free electrons can hop between fillerparticles which form a conducting network; thishelps improve the conductivity and the imaginarypart. When the Ti3SiC2 content is increased from 15to 20% (w/w), the surge of the complex permittivityis attributed to the percolation effect. The electricconductivity will increase abruptly as the Ti3SiC2

content is close to the percolation threshold, whichresults in the surge of the complex permittivity.

The dielectric loss of the ceramic is analyzed byuse of the equation tan d = e¢¢/e¢. The value for thepure Al2O3 ceramic is close to 0, implying Al2O3

ceramic is a low lossy material for EM waves. Thedielectric loss first increases then decreases as theTi3SiC2 content rises from 0 to 20% (w/w). The valueis highest for ceramic doped with 10% (w/w) Ti3SiC2.The impedances of microwave-absorbing materialsare required to match the impedance free space, sothe EM wave can enter and subsequently be atten-uated inside the material.

Effects of Temperature on Dielectric Properties

To understand the effects of temperature ondielectric properties, the complex permittivity of theceramics in the X-band was tested at 25–400�C. Thereal and imaginary parts of the complex permittiv-ity of the ceramic containing 10% (w/w) Ti3SiC2 atfive different temperatures are shown in Fig. 5. Thedielectric constants of ceramics with other Ti3SiC2

content are not shown here because the complexpermittivity has a similar trend with increasingtemperature. It is observed that both the real andimaginary part increase with the increasing tem-perature. The real part increases from 15.29 to20.36 and the imaginary part increases from 7.83 to9.53 as the temperature increases from 25 to 400�C.The temperature dependence of the real part can beillustrated by the Debye theory18,19:

e0 ¼ e1 þ ðes � e1Þ.

1þ x2sðTÞ2h i

; (8)

where x is the angular frequency, es is thestatic (zero frequency), e1 is the relative dielectric

permittivity at the frequency limit, and s(T) is therelaxation time. As shown in Eqs. 6 and 8, the realand imaginary parts of the complex permittivity aredetermined by the relaxation time s(T) and theelectric conductivity r, respectively, which dependon the temperature. The relaxation time is givenby20:

sðTÞ ¼ s0 exp E0=RT

� �

; (9)

where s0 is the prefactor, R is the Boltzmann con-stant, and Ea is the activation energy. The conduc-tivity is expressed by use of the Arrheniusformula21:

rðTÞ ¼ r0 exp �Eg�

2RT

� �

; (10)

where r0 is a prefactor for migrating behavior andEg is the band gap. From Eqs. 9 and 10 it isapparent that relaxation time will decrease and theelectric conductivity will increase with increasingtemperature. Therefore, both the real and imagi-nary parts of the complex permittivity increase withincreasing temperature.

Fig. 5. Complex permittivity of the ceramic containing 10% (w/w)Ti3SiC2 in the temperature range 25–400�C: (a) real part, (b) imag-inary part.

Mechanical, Dielectric, and Microwave-Absorption Properties of Alumina CeramicContaining Dispersed Ti3SiC2

871

Microwave Absorption Property

RL was calculated to further investigate themicrowave absorption properties of the ceramic.This is defined as22:

RL ¼ 10 log PR=PIdBð Þ; (11)

where PI and PR are, respectively, the incidentpower and reflected power of the microwaves. Forexample, when RL is �5 dB, 70% of the microwavesare absorbed and 30% are reflected.

Microwave-Absorption Properties of Ceramicswith Different Ti3SiC2 Contents

The RL calculated for 2.2 mm thick Ti3SiC2–Al2O3 ceramics with different Ti3SiC2 contents areshown in Fig. 6. The RL value first decreases thenincreases when the Ti3SiC2 content increases from 0to 20% (w/w). The ceramic doped with 10% (w/w)Ti3SiC2 has the optimum microwave-absorbingperformance. RL values <�5 dB are obtainedthroughout the frequency range, with a minimumvalue of �20 dB at 9.56 GHz. As discussed above,the dielectric loss value is highest for the ceramicdoped with 10% (w/w) Ti3SiC2, which demonstratesit can turn more EM wave energy into heat.Although high e¢¢ is necessary for good microwave-absorbing properties, permittivity which is too highis detrimental to impendence matching, which leadsto strong reflection of the incident EM wave andpoor absorption.

The normalized input impedances (Z = Zin/Z0) ofTi3SiC2–Al2O3 ceramics 2.2 mm thick are shown inFig. 7. Both the real and imaginary parts of theinput impedance are first enhanced then decreaseas the Ti3SiC2 content increases from 0 to 20% (w/w). The impedance of the ceramic doped with 10%(w/w) Ti3SiC2 is closest to the optimum normalizedinput impedance value, which is Z¢ = 1 and Z¢¢ = 0.Ceramics with low or high Ti3SiC2 content deviatefrom the matching condition, which results in poorabsorption properties. When the amount of Ti3SiC2

added is low the ceramic cannot convert EM waveenergy completely to heat whereas a high Ti3SiC2

content leads to strong reflection of the incidentwave. Ceramic doped with 10% (w/w) Ti3SiC2 fitsthe matching condition well, which results in themost favorable microwave absorption.

The effect of thickness on microwave absorptionwas investigated; results for ceramic of differentthickness containing 10% (w/w) Ti3SiC2 are shownin Fig. 8. It is apparent that the minimum RL peak

Fig. 6. RL of 2.2 mm thick Ti3SiC2–Al2O3 ceramics.

Fig. 7. Normalized input impedances of 2.2 mm thick Ti3SiC2–Al2O3

ceramics: (a) real part, (b) imaginary part.

Fig. 8. RL of ceramic of different thickness containing 10% (w/w)Ti3SiC2.

Liu, Luo, Su, Zhou, and Zhu872

shifts toward the lower-frequency range with theincreasing thickness, which is in accordance withthe relationship between the matching frequencyand thickness, expressed as23:

fm ¼ c=4dm� 1.ffiffiffiffiffiffiffie0l0p � 1þ tan2 d�

8

� ��1

; (12)

where fm and dm are the matching frequency andthickness, respectively, tand is the dielectric loss,and c is the velocity of light. It is clear that thematching frequency decreases with increasingthickness because

ffiffiffiffiffiffiffie0l0p

is constant.

High Temperature Microwave-AbsorptionProperties

The RL of ceramic 2.2 mm thick containing 10%(w/w) Ti3SiC2 in the temperature range 25–400�C ispresented in Fig. 9. It is apparent that RL increasesslightly with the increasing temperature but theceramic still has favorable microwave-absorptionperformance throughout the X-band. These resultsindicate that the Ti3SiC2–Al2O3 ceramic is a poten-tial microwave absorption material for high-tem-perature application.

CONCLUSIONS

Ti3SiC2 powder was added to Al2O3 ceramic tofabricate a microwave-absorption material for high-temperature application. The mechanical, dielec-tric, and microwave absorption properties of theceramics are affected by Ti3SiC2 content. The com-posite ceramic containing 10% (w/w) Ti3SiC2 has theoptimum microwave absorption properties. Anabsorption peak at 9.56 GHz with a minimum RLvalue of �20 dB is obtained for a sample 2.2 mm

thick. An absorption bandwidth below �5 dB isobtained throughout the frequency range 8.2–12.4 GHz. As the temperature is increased from 25to 400�C, the ceramic still has favorable microwave-absorption properties throughout the X-band. Theseresults indicate that the Ti3SiC2–Al2O3 ceramic is apotential microwave absorption material for high-temperature application.

ACKNOWLEDGEMENT

This work was supported by National NaturalScience Foundation of China, no. 51072165. Thiswork was financially supported by the fund of theStates Key Laboratory of the Solidification Pro-cessing in NWPU, no. KP201307.

REFERENCES

1. Y.B. Feng, T. Qiu, and C.Y. Shen, J. Magn. Magn. Mater.318, 12 (2007).

2. B.C. Wang, J.Q. Wei, L. Qiao, T. Wang, and F.S. Li, J. Magn.Magn. Mater. 324, 763 (2012).

3. X.X. Liu, Z.Y. Zhang, and Y.P. Wu, Comp Part B 42, 328(2011).

4. Y.W. Dai, M.Q. Sun, C.G. Liu, and Z.Q. Li, Cem. Concr.Compos. 32, 510 (2010).

5. D.A. Makeiff and T. Huber, Synth. Met. 156, 500 (2006).6. E. Chojnacki, Q. Huang, A.K. Mukherjee, T.B. Holland, M.

Tigner, and K. Cherian, Nucl. Instrum. Methods Phys. Res.Sect. A 659, 52 (2011).

7. M.W. Barsoum and T. El-Raghy, J. Am. Ceram. Soc. 79,1954 (1996).

8. Z.M. Sun, S.L. Yang, and H. Hashimoto, Ceram. Int. 30,1875 (2004).

9. B.Y. Liang, S.Z. Jin, and M.Z. Wang, J. Alloys Compd. 460,442 (2008).

10. L. Zhou, W.C. Zhou, J.B. Su, F. Luo, D.M. Zhu, and Y.L.Dong, Appl. Surf. Sci. 258, 2694 (2012).

11. Y. Liu, F. Luo, W.C. Zhou, and D.M. Zhu, J. Alloys Compd.576, 45 (2013).

12. B. Music, M. Drofenik, P. Venturini, and A. Znidarsic,Ceram. Int. 38, 2696 (2012).

13. L.D. Liu, Y.P. Duan, L.X. Ma, S.H. Liu, and Z. Yu, Appl.Surf. Sci. 257, 844 (2010).

14. Y.K. Liu, Y.J. Feng, X.W. Wu, and X.G. Han, J. AlloysCompd. 472, 443 (2009).

15. C. Racult, F. Langlais, and R. Naslain, J. Mater. Sci. 29,3388 (1994).

16. S.H. Wu, X.S. Wei, X.Y. Wang, H.X. Yang, and S.Q. Gao,J. Mater. Sci. Technol. 26, 474 (2010).

17. Z.B. Huang, W.C. Zhou, X.F. Tang, and J.K. Zhu, J. AlloysCompd. 509, 1922 (2011).

18. H.T. Guan, Y.D. Wang, G. Chen, and J. Zhu, PowderTechnol. 224, 357 (2012).

19. J. Yuan, W.L. Song, X.Y. Fang, X.L. Shi, Z.L. Hou, and M.S.Cao, Solid State Commun. 154, 66 (2013).

20. H.T. Guan, G. Chen, J. Zhu, and Y.D. Wang, J. AlloysCompd. 507, 129 (2010).

21. S.A. Ansari, A. Nisar, B. Fatma, W. Khan, M. Chaman, A.Azam, and A.H. Naqvi, Mater. Res. Bull. 47, 4166 (2012).

22. X. Hao, X.W. Yin, L.T. Zhang, and L.F. Cheng, J. Mater. Sci.Technol. 29, 253 (2013).

23. J. Sun, H.L. Xu, Y. Shen, H. Bi, W.F. Liang, and R.B. Yang,J. Alloys Compd. 548, 20 (2013).

Fig. 9. RL of ceramic containing 10% (w/w) Ti3SiC2 at differenttemperatures.

Mechanical, Dielectric, and Microwave-Absorption Properties of Alumina CeramicContaining Dispersed Ti3SiC2

873