MECH 3582 A01: MANUFACTURING PLANNING AND ......MECH 3582 A01: MANUFACTURING PLANNING AND QUALITY...

Transcript of MECH 3582 A01: MANUFACTURING PLANNING AND ......MECH 3582 A01: MANUFACTURING PLANNING AND QUALITY...

MECH 3582 A01: MANUFACTURING PLANNING AND QUALITY CONTROL

C.A.P.P. – PROCESS PLANNINGREPORT IV - (DUE FEBRUARY 9, 2011)JASEN FULLANTE (#6842437) JUSTIN ALBO (#6842375) ARJUN KAUSHAL (#7668240)

DOCUMENT PREPARED FOR: PROFESSOR Q.PENG

DEPARTMENT OF MECHANICAL ENGINEERING

UNIVERSITY OF MANITOBA

12

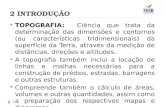

X4’

Z1’

Z2’

Z3’

X5’

X6’ X7’

Z3’’

Since the part is cylindrical we use pin and hole locating method. One end can be held in a three jaw chuck as it centers automatically. The other end can be held with a pin specially when machining the longer end

We first machine the end 1 holding it from face till X4. The detailed process is discussed in third part of the

assignment. Once end 1 is finished the Part is flipped to machine the other end i.e.

Thus in the whole machining process the part is only flipped once. While machining the end we can hold it by Z1 till T. The reason for so is discussed in the later part of the assignment.

For most surfaces the tolerance is default i.e. IT 10. However for face Z1 and the linear dimension X1 to X4 the tolerance grade is IT 5 since the tolerance is + 0.2. This has been deduced from the following table.

The shapes of the tools used can be decided from the table shown.

2)Process plans:

As we decided we would start manufacturing the part from so the process plan for this would be as follows.

Also the datum planes would be

and X7 as these are the edges already available to us.

Process PlanSet up Sequence ID: Datum plane ID: X7(linear dimensions) Z ( radial dimensions)

Clamping Face ID: Machine: Lathe

1

FaceCut of Depth

(mm)

feed

(mm/rev)

speed

(m/min)Xstart Xend Zstart Zend

Tool

Semi rough turning

X7 4mm 0.4 95 X7X4’

(226mm)200mm

Z1’ D

Diamond turning X4’ 2mm .05 135 X4’X4

(230mm)200mm

Z1’ D

Diamond turning Z1’ 2mm .05 135 X4X5

(132mm)

Z1’

144mm

Z1

140mmD

Semi rough Turning

X7 2mm .4 95X5

(132mm)

X7

(0mm)

Z1’

144mm

Z2’

120mmD

Rough turning for

Functional grooveX5’ 5mm .4 105

X5’

(122mm)

X5

(132mm)

Z2’

120mm

Z2

100mmR

Semi Rough turning

X5’ 2mm .4 95X5’

(122mm)

X6

(82mm)

Z2’

120mm

Z2

100mmD

Semi rough turning

X6 2mm .4 95X6

(82mm)

X7

(0mm)

Z2’

120mm

Z3’

80mmD

Semi rough turning for

Functional groove

X6 5mm .4 95X6

(82mm)

X6’

(72mm)

Z3’

80mm

Z3

60mmR

Semi rough turning

X6’ 2mm .4 95X6’

(72mm)

X7

(0mm)

Z3’

80mm

Z3

60mmD

Semi rough turning

For chamfering

X7

2mm .4 95 X7

(0mm)

X7’

(10mm)

Z3 Z3’’ S

Process plan

Set up Sequence ID: Datum plane ID: X1(linear dimensions) Z ( radial dimensions)Clamping Face ID: Z1 till Machine: Lathe

2 T

Z1

T

Z1”

X1”

Z6”

FaceCut of Depth

(mm)

feed

(mm/rev)

speed

(m/min)

Xstart Xend Zstart Zend

Tool

Semi Rough turning

3mm .4 95 X1 X3

200mm

Z1’’

140mmD

Semi Rough turning Z1’’

2mm .4 95 X1 X2’Z1’’

140mm

Z4

120mmD

Drilling X1 40mm X1 D 0Just

enough for boring tool

to enter

Drill bit

The hole on face X1 would be generated by boring or reaming but for either process we need to drill the face first. The diameter of the drilled hole has to be large enough so that the boring tool can enter it. We drill to a depth of D instead of X2. This gives us a clearance of 4mm for creating a perfect flat at X2. Same clearance also needs to left at X1’. Let’s call it D’.Drilling gives us a rough finish as per the chart mentioned below (class notes),

According to the drill bit specifications

DD’

FaceCut of Depth

(mm)

feed

(mm/rev)

speed

(m/min)

Xstart Xend Zstart Zend

Tool

Diamond Boring

X1 36mm 0.2 130X1

(0mm)

D

(36mm)

From drilled hole

Z5 V

Counter boring

X1 16mm 0.2 130X1

(0mm)

D’

(16mm)Z5 Z6 V

ReamingInternal of X2

4mm 0.4D

(36mm)

X2

(40mm)Z5 Z5

Reaming bit

The hole on face X1 would be generated by boring or reaming but for either process we need to drill the face first. The diameter of the drilled hole has to be large enough so that the boring tool can enter it. We drill to a depth of D instead of X2. This gives us a clearance of 4mm for creating a perfect flat at X2. Same clearance also needs to left at X1’. Let’s call it D’.Drilling gives us a rough finish as per the chart mentioned below (class notes),

According to the reaming bit specifications

ReamingInternal of

X1’4mm

D’

(16mm)

X1

(0mm)Z6 Z6

Reaming Bit

Semi rough turning

for chamfering

X2’ 2mm 0.4 95X2’

(30mm)

X2

(40mm)Z1” Z4 S

Semi rough turning

for chamfering

X1 2mm 0.4 95X1

(0mm)

X1”

(10mm)Z4 Z6” S

Rough Chamfering

X3 10mm X3 X3’

200mm

-10

190mm

New tool

Rough Chamfering

X4 10mm X4 X4’

200mm

-10

190mm

New tool

According to the reaming bit specifications

According to the new tool specifications

According to the new tool specifications

According to us there is no tool in the given tools which can create a convex radial surface. We may have to use a new tool shape somewhat like what is given in the image below. The specifications could be same as the concave radial tool as R given.

3) Reason for selecting the above Parameters

Now since the material is given as Heat resistant steel we choose MI for the material specification from

Material classifications according to ISO 513

R 10.00

New tool Proposed

Since the default tolerance grade is IT 10 we have an option of choosing either of the two processes here:

Apart from face Z1 and length X1-X4 where the tolerance is of grade IT 5

E xp laining the sequence for

The clamping face for this sequence would be

. The datum for linear dimensions is selected

as X7 as this end is going to be exposed while

machining. For radial dimensions datum would be

Z i.e. the central axis. It can be held in a three jaw

chuck at face from X1 to X4. We have to

create a tolerance of IT 5 grade at X4 so we can

use the semi rough cutting from X7 till let’s say

4mm before X4 i.e. X4’. From X4’ till X4 we turn

and remove material using diamond turning and

1

thus achieving the required tolerance grade. Similarly we can use a rough cut from 200 till 144 mm diameter

(Z1’). The last 4 mm from face X4 till X5 can be done by diamond turning to achieve the required tolerance

grade IT 5. So now the diameter is Z1 i.e. 140. After that the face from X5 till X7 can be turned and cut using the

rough turning till 120 mm is achieved. Then the functional grove of r 10 can be created on face X5 generating a

new surface X5’. The rest of cutting from X5’ to X6 can be done by again using rough or semi rough cutting. The

final diameter will now be Z2. Using the same

process the diameter will be brought to 80 mm

for X6 to X7. Again a functional grove of r 10 can

be created on face X6 generating a new surface

X6’. The remaining length of X6’ to X7 would be

turned and cut using the same rough or semi

rough turning. The final diameter would now be

Z3 i.e. 60 mm. At the end we would make the

chamfers at X7 using S tool by holding it inclined

at 45o. Thus the part is complete from one side.

E xplaining the sequence for

The part is now flipped to machine . The part

can now be held from Z1 till T. This is to allow some

clearance to machine the concave fillet at X4. Now

2

2

we begin by reducing to Z1” from X1 till X3. This is done by semi rough cutting. Similarly from X1 till X2’ the diameter

is reduced from Z1” till Z4. Now the process of creating the hole starts. For boring the holes we need to first drill a small

hole for boring tool to enter. We drill it only till D since some clearance has to be left for generating a perfect flat through

reaming since Boring can only finish the side walls not the base (shown in figure)

Thus first we enlarge the drilled hole to a diameter of Z5. Then we counter bore till D’( again for the same reason for

generating a flat. At the end We ream the flat surfaces to the required or better tolerance grade.

At the end we create the fillets at X3 and X4. The reason for suing a new tool has already been introduced earlier.