Master Specs User Guide

Transcript of Master Specs User Guide

-

8/13/2019 Master Specs User Guide

1/43

NBS Educator: Specifications: an introduct ion

NBS Educator

Specifications: an introduction

NBS 1 November 2008

-

8/13/2019 Master Specs User Guide

2/43

NBS Educator: Specifications: an introduct ion

NBS 2 November 2008

0. Content

1. Introduction

2. Definition

3. Consider users

4. Resourcing

5. Planning the process

6. Once and in the right place

7. Structure

8. Management

9. Specification methods

10. Editing

11. Summary

12. References and further reading

-

8/13/2019 Master Specs User Guide

3/43

NBS Educator: Specifications: an introduct ion

NBS 3 November 2008

1. Introduction

1.1 This document

NBS is the producer of the national building specification, and part of RIBA

Enterprises Ltd. This presentation is part of the NBS Educatorsuite. Relatedpresentations in the suite include:

Contract documentation: an introduction.

Briefs: an introduction.

Specifications: problems in practice.

Specifications: product selection process

Schedules of work: an introduction.

The content was developed by John Gelder BArch (Hons) RIBA RAIA CSI.

NBS

The Old Post Office

St Nicholas Street

Newcastle upon Tyne

NE1 1RH

T: 0191 244 5500

F: 0191 244 5623

URL: www.thenbs.com

1.2 Topics

Definition: What is a specification? Specification is both a product and a process,and both are explored in this document. How does a specification differ fromother descriptive documents?

Consider users: If the specification is to be used, then the users needs must beserved. What do they want?

Resourcing: What resources are needed to prepare a specification?

Planning the process: What activities are involved in specifying, and when shouldthey occur?

Once and in the right place: What goes where? For example, what properlybelongs in the specification?

Structure: How is the specification best structured?

Management: What management issues need to be specified?

http://www.thenbs.com/http://www.thenbs.com/http://www.thenbs.com/ -

8/13/2019 Master Specs User Guide

4/43

NBS Educator: Specifications: an introduct ion

NBS 4 November 2008

Specification methods: What are the methods of specifying, and how does onechoose between them?

Editing: If the specification is to be used, then it must be readable. This means itmust be edited.

1.3 Key points

Specification is both a product and a process.

-

8/13/2019 Master Specs User Guide

5/43

NBS Educator: Specifications: an introduct ion

NBS 5 November 2008

2. Definition

2.1 Process

The specification process nests into the contract documentation process.Contract documentation nests, in turn, inside the design process, which nests

inside the building process, which nests inside the facility realisation process. Allthese processes can be project managed, and they can be quality assured, e.g.to BS EN ISO 9001.

2.2 Product

Specifications are written descriptions of the quality of the built product and itscomponent products.

Published definitions often miss the points made here. For example, non-writtendescriptions are not specifications. Likewise, written descriptions of cost andquantity are not specifications, and assembly is best described using drawings orother types of description.

The specification is about deliverables systems and products but notprocesses so it is not about workmanship or tiling or curing, but it is aboutexecuted work, laid tiles, cured concrete. Recipes, not specifications, describeprocesses.

The specification is not about facilities (e.g. the hospital, the school), built entitiesas a whole (the building, the site), activities or spaces. The written description ofthese high level entities is often called the brief. However, briefs andspecifications overlap in practice, the former describing products to some extent,and systems in outline (especially for M&E services).

As a product, the specification can be quality controlled (e.g. certified by first,second or third party as conforming to stated requirements viz. the brief).

2.3 Context

Specifications are one of several potential contract documents. Specifications areused for all projects, but not necessarily in the form of a separate document.

Contract document Definition Clarification

Instructions to tenderers for tender phase

Conditions of contract

Rules of play

for construction phase

Production drawings graphical

Specification incl.Preliminaries

written

Quantities numerical

Schedules of work

Description of work

list

-

8/13/2019 Master Specs User Guide

6/43

NBS Educator: Specifications: an introduct ion

NBS 6 November 2008

The description of work is modular, each module being a particular type ofdescription. The modules can stand alone as documents, or be combined invarious ways to create a range of composite documents, e.g. annotated (i.e.specified) drawings.

Other descriptive modules include photographs, prototypes, and referenceprojects.

Each of the contract documents should complement the others. That is, theproject documents should all be read together, and should not repeat each other

say it once and in the right place.

The specification may be located on the drawings, in the bills or in the schedulesof work, in instructions, and in the specification-proper. This fragmentation ischaracteristic of specifications, and is a common cause of problems, e.g.inconsistency, repetition, omission.

Wherever these written descriptions occur, the same principles apply to their

preparation and use. A tiger in a zoo is still a tiger, after all. Both the tiger and thespecification must have teeth, wherever they are!

2.4 Key points

Specification is one of a nest of projects.

Specifications are written descriptions of the quality of the built product and itscomponent products.

Specifications describe products, not processes.

Fragmentation of the specification across various documents leads to problems.

-

8/13/2019 Master Specs User Guide

7/43

NBS Educator: Specifications: an introduct ion

NBS 7 November 2008

3. Consider users

All users are interested in different aspects of the specification. Each takes a turnas the priority audience.

3.1 DesignersDuring preparation, consider aligning the specification to design disciplines, e.g.acoustics, fire, lighting. To some extent this would be an attribute-basedstructure, roughly parallel to the E&W Building Regulations Approved Documents(BR ADs).

3.2 Building control officers

Structure the compliance specification to parallel the BR ADs rather thanCommon Arrangement of Work Sections (CAWS see Crawford, 1997; Delany,2008). Structuring the specification to match the BR ADs would facilitate cross-checking by the building control officer (BCO) between the specification and the

regulations, as well as similar cross-checking by the designers, and regulationsconsultant if any.

Provide just enough content to demonstrate statutory compliance. The BuildingRegulations are not concerned with aesthetic issues or (usually) maintenanceregimes, for example.

3.3 Estimators and tenderers

Two-part structure: Tendering is done against a very tight program, so anythingwhich helps tenderers will help with equitability, accuracy, and comparing appleswith apples. They particularly need to know about the project variables (funnies)as this is where the cost of this job will differ from the cost of another, similar, job.

Estimators have a similar need. However, conventional specifications roll thestandard and variable stuff together, so it is hard to spot project variables in thetime available. NBS Schedulerisolates the project variables using a two-partstructure, facilitating disassembly, as does the NBS Domestic Specification(Wilson, 2006).

Elemental structure: SMM7 is aligned to CAWS, but estimators and tenderersalso make use of elements (aka systems), e.g. BCIS (Building Cost InformationService), so an elemental structure might help them. NBS Scheduleruses anelemental structure, too, as does NBS Engineering Services.

3.4 Contractors

Contractors need to disassemble the specification, e.g. for compliance and forsubcontracting. They also need room for marking up the spec, e.g. wide margins.

Compliance: Tests, inspections, samples and the like are often describedalongside product and execution requirements, rather than being separated.

Subcontracting: Subcontractors are rarely given all the specification sections(and drawings) they need. The head contractor often splits the specificationpretty crudely, with the result that relevant Preliminaries material and relevant

-

8/13/2019 Master Specs User Guide

8/43

NBS Educator: Specifications: an introduct ion

NBS 8 November 2008

reference sections are not included. Also, irrelevant material will often beincluded if work described in a single section is to be split among more than onesubbie. This compromises pricing and programming. The specification could bedesigned to facilitate such splits, hence the trade-based structure, for example(i.e. CAWS, the norm), and use of small sections.

3.5 Subcontractors

Subbies on-site must be able to read the spec, necessitating, e.g. a big font, andclear English. Convoluted legalese, cryptic or ambiguous phrasing, and unhelpfulsection structures are all too common in specifications. Keep it simple! Keep allrelevant material together, not scattered.

Describe products and execution separately. Ordering of manufactured productsis often done by head office, fabrication by another organisation, execution on-site by other operatives, and commissioning by an independent companyperhaps. It makes sense if the specification reflects this in each section, usingsubsections.

Provide a separable General technical requirements section, rather than whole ofPreliminaries/ General. This is provided in NBS Scheduler, so that trades dontneed to be given the whole of Preliminaries/ General, most of which is of nointerest to them. The section (A90) deals with technical issues of generalapplication, e.g. rules for substitution.

3.6 Contract administrators

CAs need to search the specification for compliance (see 3.4).

3.7 Courts

Their priority is defining obligations of parties to the contract. But specifications

sometimes blur obligations, e.g. by specifying processes, or requiringinappropriate contractor design, or being unclear about the extent of this, andsometimes seek to impose obligations on parties outside the contract, e.g.subcontractors, authorities, tenderers.

Pricing documents take precedence so contracts often state that (specified)bills override the specification.

3.8 Facility managers

FMs need a record spec, but this is almost never provided. Generic specificationcontent in the contract specification will be replaced with suppliers ormanufacturers and their products in the record specification. The contractspecification is as designed. As built is more of a concern for drawings, whereworkers have taken them literally, sometimes with dire consequences, e.g. bydrilling through a slab in the firm belief they were not going to hit live electricalcables. The US court case that resulted led to the suggestion that the documentsbe styled record documents instead. For maintaining the building, it would behandy if the record specification was structured by location, e.g. where a givenproblem has occurred.

-

8/13/2019 Master Specs User Guide

9/43

NBS Educator: Specifications: an introduct ion

NBS 9 November 2008

Operation and maintenance manuals and health and safety files are usually dealtwith in specifications. H&S files are a statutory obligation. Spares, tools, training,manuals, records of commissioning, and other such matters of interest to facilitymanagers, are also routinely covered in specifications.

3.9 Project managers

Their priority is defining quality no other document but the specification willenable them to do this. For quality management, the specification is the keydocument. It is also a critical part of communications management, especially inits role as a nexus between a range of documents, e.g. contract, drawings, bills,standards, regulations (Gelder, 2007).

3.10 Key points

At least 9 different types of user have an interest in the specification:

Designers.

Building control officers. Estimators and tenderers.

Contractors.

Subcontractors.

Contract administrators.

Courts.

Facility managers.

Project managers.

Each is interested in different aspects of the specification, and may requiredifferent content and/or different structures.

-

8/13/2019 Master Specs User Guide

10/43

NBS Educator: Specifications: an introduct ion

NBS 10 November 2008

4. Resourcing

4.1 Time and fees

Specifications are not funded as a separate task. Specification production isusually just rolled into contract documentation (which most people equate with

production drawings), and isnt billed separately. There are no suggested feescales for specification production, and many offices (even larger ones) do nothave specification specialists in house.

The result is that production drawings are prioritised. Designers generally preferdrawn communication, and are well aware of the time taken to produce drawings.Time taken to produce specifications is not so well understood. Accordingly noone actually wants to produce the spec, no one sets aside time for its production,and it gets left to the last minute.

most specifications are pretty poor including ours. You never haveenough time and we are increasingly obliged to use the NBS which means

we have to clear out a whole lot of guff. (Simpson, 2001).Simpsons practice deals with heritage work, so a lot of NBS material doesntapply in his case, an office master based on NBS would be worth setting up.This would certainly save time.

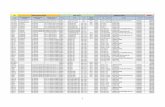

Chart: Specifications cannot be done over a weekend. Appropriate time and feesmust be allocated to their preparation. This chart gives some idea of what mightbe required. Time is in person-weeks, for all disciplines, and includes the wholeprocess of specifying, from information gathering to production. Use of softwaresuch as that built into NBS Buildingwill speed up the process.

-

8/13/2019 Master Specs User Guide

11/43

NBS Educator: Specifications: an introduct ion

NBS 11 November 2008

Specific-ation fees

Specific-ation time(weeks)

20,000 13.5

16,000 10.8

12,000 8.1

8,000 5.4

4,000 2.7

0.4 2 4 20 40

Project value ( million) (based on fee scales for specifying from the AustralianInstitute of Quantity Surveyors [AIQS]).

An Australian survey found that both designers and contractors blame decliningfees for the perceived decline in documentation quality between 1985 and 2000.The lower fees mean, of course, that less time is available to do the work and, inparticular, to check it (Tilley & McFallan, 2000).

4.2 Appropriate staff

Balance experience and charge-out. Is the project time- or cost-critical? Freshyoung graduates will have to re-do their specification several times, taking upsupervisor time. Though they might take a lot of time to get it right, the cost isfairly low. Conversely, a senior partner might take less time to get the

specification right, but the cost will be excessive. The ideal specifier will liebetween these two extremes. But, the ideal specifier may not be available. TheAustralian survey mentioned found that the difficulty of finding good staff,explicitly including specification writers, ranked 13 out of 23 issues affectingdocumentation quality.

Candidate specifiers include:

-

8/13/2019 Master Specs User Guide

12/43

NBS Educator: Specifications: an introduct ion

NBS 12 November 2008

Project architect or engineer: Good for continuity, but may not be up to speedon specifications.

Office specialist specifier: May act as resource for project specifiers, or maywrite project specs, or both.

Quantity surveyor: In the past the (fabric) specification has often been left tothe QS to pull together, though that is changing (but QSs still routinely handlethe Preliminaries and contracts and tendering material). Specifying is adesign process, and should be done by designers.

Consultant specifier: Liability and decisions are still yours. Even so, there arespecifications consultants in the UK offering their services, reflecting theongoing unpopularity of the task with architects and others.

A lead specifier is needed to co-ordinate process and content typically, thearchitect.

Training: Little training is available for specifiers and users (one example is

Daniels, 2007).

Schools of architecture know nothing about specification writing andarent interested. Somebody should set up a working party. Theresno training in specification writing. [Simpson, 2001].

The NVQ in Architectural Technology (Edexcel, 2000) has specifications built intoit, for example, and specifications are taught at some architecture schools, e.g. inthe University of Newcastles Certificate in Architectural Practice. Nevertheless,the subject is definitely under-taught. The NBS Educatormaterial is intended toaddress this need (Gelder, 2006a).

4.3 Software needed

This includes word-processing and databases, such as NBS Specifierand NBSScheduler. Some specifiers create their own databases of clauses, managedusing conventional software. Some even use styles (e.g. in MS Word) to managetheir material. Such systems are unique to the particular office, so training orretraining is needed for newcomers.

4.4 Sources of information

Sources must be current, which means maintenance. New contracts, regulations,standards and amendments are published all the time. Subscription services areavailable to simplify keeping track of them all.

Sources must be reliable, preferably with consensus across industry. Goodexamples are JCT contracts and British Standards. Needless to say, the fact thatthere is consensus does not mean that they are perfect.

The IHS/NBS Construction Information Service (CIS) links to many of them, andis available online or via CD.

Warts and all, get the sources and read them! Specifiers are effectivelysurrounded by standard documents of various kinds they cannot be ignored:

-

8/13/2019 Master Specs User Guide

13/43

NBS Educator: Specifications: an introduct ion

NBS 13 November 2008

Regulations.

Standard specifications.

Tendering procedures.

Contracts.

Conformance.

Quality and environmental management systems.

Technical guidance.

Master specification systems.

Manufacturers literature.

Documentary sources are something the specifier must master. All sources forproject specifications have their advantages and disadvantages. Production of aprofessional quality specification, however, presupposes adequate fees and time,

and so should exclude short-hand approaches.

Many of these sources rely on standard published documents, e.g. from BSIorJCT. Some of these documents are honoured more in the breach.

Master specifications help to make this source material more manageable, byfunctioning as a filter, interface and link.

Standards: These are expensive and wordy, and are continually being amended.British Standards, from BSI, are written by committees with a broadrepresentation from manufacturing, contracting, academia and so on.Negotiations tend to result in the standards defaulting to lowest common

denominator requirements (e.g. limited by the capacity of the less-ablemanufacturers). Nevertheless, manufacturers work to them and regulations relyon them, so specifiers must work with them too.

EuroNorms, from CEN, are limited by the capacity of less-developed economies.Harmonised EuroNorms and the CE Markare intended to address this issue, atleast as far as legal requirements (e.g. Building Regulations) are concerned.

4.5 Specification sources

Proprietary specifications: These are biased, poorly written (e.g. not to BS 4940,unless in Manufacturer Network Keyfiles), and hard to generalise from beware.Relevant standards may not be mentioned in proprietary specifications, and

construction processes are often included. However, they are quick to use andfree.

Project specifications: These are not all relevant, not all there and not current.Even for similar projects, one project specification will include items not neededand exclude items needed in another. New specifications based on them inheritany faults use with care. If used, old project specifications should first beamended to reflect instructions and variations issued, to minimise transfer offaults.

-

8/13/2019 Master Specs User Guide

14/43

NBS Educator: Specifications: an introduct ion

NBS 14 November 2008

However, reuse of old project specifications (rolling specification) is tempting(quick, at hand, free, and includes office knowledge).

Office masters: These are not often properly maintained. Even large practicesfind it hard to properly resource the maintenance of the office master, with theresult that it may be 10 years or so since they were last overhauled. Basing themon the national master reduces this problem, but doesnt solve it altogether.

They are inconsistent across offices and because designers work with differentco-consultants on every job, each of whom might have their own office master,inconsistencies in style, content and even structure are inevitable. In addition,they draw on limited experience (i.e. within the office only), and accrete badexperience clauses.

National masters: These include NBS and Amtech's NES, and are not usedenough. By no means all fabric designers subscribe to NBS specs, and NES isused much less than NBS (about 1/20th the number of subscribers). NBS is notalways used properly, and this would also apply to NES.

The most appropriate level (minor, intermediate, standard) is not always used.For example, small-system subscribers, faced with a big project, may notupgrade to the appropriate bigger system, preferring to stretch their small systeminstead (it's just for one job, after all).

For the competent specifier, national master specifications are the best bet(Delany & King, 2003).

4.6 National master specifications

Advantages:

More current than office masters.

Lower cost than office masters. Cost of subscription and maintenance (justfiling, apart from ploughing in office-specific material) is a fraction of the costof doing your own thing to the same level of quality.

Free up office expertise for project stuff.

Draw on national experience.

Deal with faults and errors.

Closer to best practice.

Consistent.

Used by co-consultants.

No need to retrain new staff.

Familiar to builders, project managers.

Software may be available.

Help service and training available.

http://www.specification-expert.co.uk/http://www.specification-expert.co.uk/ -

8/13/2019 Master Specs User Guide

15/43

NBS Educator: Specifications: an introduct ion

NBS 15 November 2008

Disadvantages:

Relevant material may not be included.

Must be subscribed to.

Must be learnt (by beginners).

Office knowledge must be added.

Relatively slow, though software can speed it up.

Master specifications appeal to some because they seem to suggest that thework has all been done the specifier doesnt need to think. This is not the caseat all master specifications can only ever provide a framework, a set ofprompts, for the project specifier to work to. They must be used critically.

Some blame the master specification for deficiencies in the project specification.This is misplaced. Master specifications are just tools. Skilled users are bound tocreate a better product than unskilled users.

National master specifications can be pre-edited by practices to deal with someof the disadvantages listed here, e.g. to include relevant material and officeknowledge.

An Australian survey found that standardisation in documentation (including useof standard specifications) was given the lowest priority by designers out of 22quality attributes, yet had seen the biggest increase over a 15-year period (Tilley& McFallan, 2000). However, mechanical subcontractors thought thatstandardisation had declined.

4.7 Key points

Specification requires adequate time and fees.Specification requires appropriate staffing, with appropriate training.

Specification can be facilitated with appropriate software.

Sources of information used by specifiers must be current and reliable. Specifiersmust be familiar with them.

Specifications can be based on proprietary specifications, project specifications,office master specifications and/or national master specifications. Each has itsadvantages and disadvantages.

It is recommended that national master specification systems are used their

advantages easily outweigh any disadvantages.

-

8/13/2019 Master Specs User Guide

16/43

NBS Educator: Specifications: an introduct ion

NBS 16 November 2008

5. Planning the process

5.1 Programme

Started at last minute: Every now and again an NBS subscriber requests materialon the Friday and access codes on the Saturday, for a specification due on the

Monday to go to tender. This example is extreme (and is generally limited tosmall works), but gives a flavour of how late designers often leave thespecification. This is really nothing more than bad management. An Australiansurvey rated late production of colour and finishes schedules 11th out of 18issues in terms of impact of documentation on contractors (Tilley & McFallan,2000).

Co-consultant specs: These are not often checked. Specifications produced byM&E consultants, for example, are rarely checked by the lead specifier(commonly the architect). One reason is that, though the architect is commonlyexpected to co-ordinate the drawings, no-one has actually been tasked withcoordinating the specification. Another reason is that these specifications are

usually submitted late there is no time to wade through them, mark them up,send them back, revise them and resubmit them. The bulk of thesespecifications, and lack of confidence in technical ability to check them, are otherfactors.

Specification preparation and use

begins with the brief. The specification begins life well before the tail end ofthe documentation phase (when it is often started officially);

runs through planning and building approval, estimating, documentation,tendering, contracting, facility management; and

ends with demolition. The specification ends its life after (practical)completion, even after demolition. For example, it may be of use indetermining the disposition of demolished materials, e.g. by answering thequestion: which are hazardous?

So dont start at the last minute! Run the specification parallel to the productiondrawings.

Systematise the process: Specifications should be project managed at theminimum this means they should be programmed (i.e. time management). Thereare 3 key stages:

Preparation: This entails gathering information, updating the source specification,

resolving format, deciding working pattern and medium (on screen, on paper, ora combination of the two?), and allocating tasks among co-consultants. Thisphase can be lengthy.

Execution: Reiterate as often as necessary, flagging unresolved issues as yougo. If in doubt, leave it out. Execution comprises:

-

8/13/2019 Master Specs User Guide

17/43

NBS Educator: Specifications: an introduct ion

NBS 17 November 2008

Deletion, from sections down to clauses. Delete the largest units of unwantedinformation first, then the smaller units. Print (if at all) only after the sourcespecification is down to a manageable size.

Completion of inserts (blanks) in master source specifications.

Addition of new material not in the source specification.

Finish: Edit the whole specification for consistency and the like, and check, e.g.cross-references and numbering. Once all has been resolved, move to the wrap-up and production phase, and distribute.

Update source specification: If this is done continually, there will be less to dowhen one is about to start a project (when time is tight). Then pre-edit the sourceif appropriate, e.g. converting NBS to a hospital-specific version (but not project-specific).

Working pattern: Across all sections equally, or focussing on some at theexpense of others, depending on availability of information, requirements of

users such as estimators, packaging of contracts, etc. For example, estimatorsprefer 50% sections 100% complete rather than 100% sections 50% complete.

5.2 Content

Practically complete: Work to the 80:20 rule (aka the law of diminishing returns orthe Pareto principle). The effort:output ratio follows a law of diminishing returns.Roughly, the last 20% of output could take 4 times the effort of the first 80% ofoutput. So there is rarely any such thing as complete documentation it isntworthwhile. Thats why documentation often seems to sit at 90% complete forsuch a long time. Cut your losses!

Thoroughness: Consider, for example, trust, innovation, risk, drawings, control onsite and quality levels required. Decisions on thoroughness should be maderationally, rather than by default. Thoroughness of the specification depends on anumber of other factors, including the general project quality level required, timeavailable, project cost or size, and fussiness of employer.

It is possible for a specification to be thorough yet set a low standard of quality,and vice versa. Thorough specifications will be longer than those that are lessthorough.

Quality level (QL): Lock the builder in to client-agreed QLs. These can be set forthe whole project and right down to individual items. A consistent approach isneeded. The employer, architect and contractor will all have different quality

levels in mind. One purpose of the specification is to define them so that there isno chance of misunderstanding, by any of the parties.

Products (manufactured, fabricated, built): The specification describes thequality, and the management of the quality, of the component products thedeliverables (which will include some services). Processes en route are notdescribed. These are down to the contractors, fabricators and manufacturers.

5.3 Key points

-

8/13/2019 Master Specs User Guide

18/43

NBS Educator: Specifications: an introduct ion

NBS 18 November 2008

Specifications are often started late, e.g. after the production drawings arecomplete.

Co-consultant specifications are often not checked.

Specification should begin early, e.g. at briefing, and should be systematic.

If in doubt, leave it out. There is no such thing as a complete specification.

The specifier should make general decisions about thoroughness.

The specification locks in agreed quality levels.

-

8/13/2019 Master Specs User Guide

19/43

NBS Educator: Specifications: an introduct ion

NBS 19 November 2008

6. Once and in the right place

Before writing the specification one needs an understanding of what informationshould be in it, and what should be covered elsewhere, or even what should notbe included at all.

6.1 Regulations

Do not schedule regulations, or stipulate compliance with them, in thespecification. The danger with a schedule is that it may be incomplete,inappropriate or inaccurate. The contractor must comply with relevantregulations, according to the contract, e.g. JCTSBC/XQ05 clause 2.1. Evenwithout such a clause, it must comply. So there is no need to mention regulationsat all.

Building Regulations Approved Documents: Deemed-to-satisfy, but notmandatory, prescriptive solutions are given in BR ADs. Because they are notmandatory, if required they must be specified. But BR ADs are designed for

guidance only (should), and cannot simply be referenced they would have littlecontractual force. Instead, they must be paraphrased and hardened (e.g. shall)in the specification if they are to apply contractually.

6.2 Contracts and annexures

Do not specify or include contractual matters in the specification these are rulesof play, not descriptions of deliverables.

Conversely, contracts invariably cover materials and workmanship, e.g.JCTSBC/XQ05 clauses 2.1, 2.3. This is the job of the specification and, ingeneral terms, the regulations (e.g. E&W Building Regulations 7). Often, as inJCTSBC/XQ05, these requirements are repetitive and/or inconsistent. Forexample, silence in the documents is dealt with for workmanship (execution), intwo places. There is a good chance that these contract-based requirements willundermine, or conflict with, the specification a major problem (Gelder, 2003b).

Subcontracts matters likewise have no place in the spec, especially because thespecification is part of contract, not subcontract, documentation.

6.3 Tendering

This does not belong in the specification. Contractual material, and onlycontractual material, should be in the contract documents. Tendering-specificmaterial has served its purpose once the contract is underway, and should not be

proliferated.6.4 Reports, e.g. site investigation report

These are provided for information, not as a requirement, and so are not a partof the specification.

6.5 Standards

Cite relevant standards in the specification, dont paraphrase them.

-

8/13/2019 Master Specs User Guide

20/43

NBS Educator: Specifications: an introduct ion

NBS 20 November 2008

Check currency, including key cross refs. Citation of standards in most specs,e.g. NBS, is quite simple only the number is given no dates, no titles, noamendments. The question of currency is dealt with in General technicalrequirements(or Preliminariessection A31). To do otherwise is to make a lot ofwork for the specifier, and is probably unwarranted.

Select options (may, either or). Standards usually offer choices, to be madeby the specifier (though sometimes they are self-selecting), e.g. grades ofstainless steel, classes of bitumen roofing sheet, types of high pressure laminate.

Check defaults. Defaults set by standards may not suit the project they may betoo tight (unusual) or too loose (quite common, standards being consensusdocuments).

Harden guidance [should]. Standards come in two flavours. Codes of practice(like BR ADs) use should throughout. They are guidance and must beparaphrased and hardened in the specification to have contractual force. Theyshould not be cited. Standard specifications are enforceable (using shall), and

can be cited.

6.6 Drawings

Dont repeat annotation or describe assembly in the specification complementthe drawings. Conversely, some things commonly given on the drawings shouldbe in the specification (e.g. margin notes about complying with relevantstandards). A common point of conflict is finishes, shown on the drawing asannotation, and in the specification in the finishes schedule.

6.7 Preliminaries

These belong in the spec, but just the clients preliminaries, not the builders. For

example: Facilities for clerk of works, architect.

Use of clients services and roads.

Security on an occupied site.

Publicity.

Sequence of work on an occupied site.

Client-supplied items.

Protection of property adjacent and on-site.

Preliminaries are often confused with general requirements (contracts), tenderingand technical material in the UK sometimes known collectively as Preambles(Doran, 2007; Finch, undated).

6.8 Work sections

These are the core of the specification. Apart from ordinary work sections, theremay be umbrella sections and reference sections, discussed in the next section.

-

8/13/2019 Master Specs User Guide

21/43

NBS Educator: Specifications: an introduct ion

NBS 21 November 2008

6.9 Schedules

Though sometimes located on drawings, it is suggested that schedules (otherthan the graphical component) be viewed as part of the specification.

6.10 Cross-referencing

This should be precise or not used at all. Imprecise is unhelpful at best, untrue atworst. For example, as specified and as detailed are of no help to anyone,even if they are true. It is much more helpful to give a precise cross-reference,e.g. to details A25-7, or to specification clause G20/102 (as recommended in Co-ordinated Project Information literature) (Waterhouse, 2004).

Of course, it may not be true anyway (the relevant detail may not have beendrawn), in which case such a cross-reference is less than helpful once thebuilder calls the CA in frustration only to be told it isnt in the specification ordrawings after all, the credibility of the documents and their authors takes a nosedive. Some argue that cross-references should be from drawings to specification

only, and not at all from specification to drawings.Where it occurs, cross-referencing must be complete and unambiguous, e.g.refer to is not a requirement for compliance. To the relevant standard isanother useless general cross-reference which ones are relevant? Whodecides? Has the specifier or CA read them? Will the builder?

6.11 Parties outside the contract

Subcontractors: Dont mention them. They are not a party to the contract with theclient, but are in contract with the contractor. One does not issue instructions tosubcontractors, nor does one issue specifications (or drawings) to them. Indirectreference to subcontractors includes phrases like co-ordinate with main

contractor and work by others, and should also be avoided.Tenderers: Dont mention them. They dont exist. Tenderers are ephemeralentities any instructions or forms just for their use must be in separate,discardable material. Use of allow for generally indicates tendering indirectly.

Avoid it.

Authorities: The contract does not bind them. They will have their own contractswith the employer. So the best you can say is that they may do something.

Other contractors: Deal with interfacing, but dont mention them. As far as aparticular contractor is concerned, work not done by it is done by the client.

6.12 Parties in the contract

The client: The specification is from the client, and is addressed to and binds onlythe contractor. The Preliminaries may need to describe some work beingundertaken by the employer, e.g. employer-supplied items such as art works.Work sections will not do this at all. So by and large the client is not mentioned.

Contract administrator: The CA need not be mentioned, except in Generaltechnical requirementsor Preliminaries, e.g. on the subject of communications.

-

8/13/2019 Master Specs User Guide

22/43

NBS Educator: Specifications: an introduct ion

NBS 22 November 2008

The CA must have a free hand to administer the contract and should not beconstrained by the dead hand of the specifier. Decisions which should be takenby the CA should be left out of the specification. For example, the specification,like the drawings, assumes and expects full compliance, so requirements toretest, or to take other action in the event of non-conformance, should not be

given.Contractor: The entire description is addressed to the contractor no-one else.That is, there is no need for the contractor shall. Just use imperative, directlanguage. So there is no need to mention the contractor at all.

Also, like the CA, the contractor should not be unnecessarily constrained, e.g. byspecifying processes (for storage, protection, execution, etc).

6.13 Key points

Say it once, and (therefore) in the right place.

Therefore don't repeat content covered in regulations, contracts, standards,

drawings, preliminaries, other work sections, and schedules.

Tendering material and reports are not part of the specification.

Cross-referencing between documents must be precise and accurate, or notused at all.

The specification only addresses, and binds, the contractor. It cannot bindsubcontractors, tenderers, authorities and other contractors these are outsidethe contract. Nor does it bind the client and contract administrator.

-

8/13/2019 Master Specs User Guide

23/43

NBS Educator: Specifications: an introduct ion

7. Structure

NBS 23 November 2008

7.1 Components

There are three main components to a specification preliminaries, worksections and schedules.

Preliminaries: This general material is important for the contractor, but is notneeded by trade subcontractors, so it is best isolated.

Work sections: Specifications are books, and like books are routinely broken up

into chapters or sections (called work sections, as they describe blocks of work).The work sections can be fairly readily distributed to others, e.g. subcontractors,though some disassembly and merging will probably be needed by varioususers. Because merging is easier than disassembly, small separate worksections are preferred to large merged sections.

General technical requirements: This is an NBS Schedulerinnovation, plannedalso for the NBS. An umbrella section, it contains general information relevant to

Specification

Preliminaries Work sections Schedules

Windows schedule

Ironmongeryschedule

Lintels schedule

Reinforcementschedule

General technicalrequirements

Doors scheduleEmployerspreliminaries

Finishes schedule

Prompts fromcontract

Demolition

Structural steelCommercial

clausesTimber windows

Gas service

-

8/13/2019 Master Specs User Guide

24/43

NBS Educator: Specifications: an introduct ion

NBS 24 November 2008

trade subcontractors. Otherwise, this information is held in various Preliminariessections, which subcontractors may not see.

Schedules: Assembly schedules could go on the drawings or, like the NBSsystem outline clauses (which are also about assembly), they could go in thespecification. If located in the specification, most assembly schedules wouldhappily sit within an appropriate work section, but some are multi-trade (e.g.finishes schedule) and would have to be located elsewhere, perhaps at the endof the specification.

Definition schedules (e.g. for lock types) are located in the relevant work section.

7.2 Structure

A specification has many users. One could produce a new structure for eachuser but, assuming this is not viable, a generic structure easily navigated,easily disassembled is best. Accordingly, the structure is as generallyaccessible as possible, rather than favouring any particular user.

Text sequence generally, both section to section, and within sections, is by worksequence. This is the rule internationally, yet there are some big differences, e.g.between the US CSI MasterFormat(2004), and the UK CAWS. Landscape worksin the first are up-front, with preparatory earthworks, and at the end of thebuilding sections in the second, in a group by themselves (Q). Likewise,plumbing is with mechanical in the first, and in a separate block in the second(S).

As well as this sequence, text also runs from the general to the particular, e.g.preliminaries then individual work sections.

Common Arrangement of Work Sections (CAWS): This is the standard UK

classification system for work sections. NBS and NES use it in the structuring oftheir material, as do most project specifiers in the UK. It generally followssequence on site, from site establishment (e.g. preliminaries), to excavation (D)to loose furniture (N). Services and external works are separated from buildingfabric.

The system includes a three-level alpha-numeric hierarchy, shown here for twomasonry sections:

F10 Brick/ Block walling.

F11 Glass block walling.

The A sections are for Preliminaries/ General conditions. Sections B to Q are forfabric. Sections R to Y are for building services, with Y sections being theServices reference specifications. Some services items are described in otherblocks, too. Z sections are the Building fabric reference specifications (Gelder,2006a).

7.3 Substructure

-

8/13/2019 Master Specs User Guide

25/43

NBS Educator: Specifications: an introduct ion

NBS 25 November 2008

Work sections are broken up into subsections, and then paragraphs (known asclauses, reflecting the legal function of the document, as does the naming andnumbering tradition). Just as overall structure traditionally follows work sequence,so does the internal work section structure from design, to ordering theproducts, execution, and then to completion.

Content of a typical NBS Engineering Serviceswork section:

System outline: System outline clauses, for assembly.

System performance: For contractor design of system.

Products: Manufactured products.

Fabrication: Fabricated products.

Execution: Built products.

Completion: Final tests, spares, etc.

Facility management: Hard FM for the system, e.g. under PFI procurement(this subsection is not yet implemented).

It is possible to develop a standard structure across all work sections. Forexample, the North American CSI SectionFormat(1997) uses just 3 subsections:

General.

Products.

Execution.

It standardises subsection structure too. NBS Buildingand Landscape, on theother hand, are not yet formally standardised, though each section has a similar

structure. NBS Engineering Serviceshas a standard section structure, as doesNES (Gelder, 2006c).

7.4 Key points

There are three main components to a specification preliminaries, worksections and schedules.

Because of the many users, the structure of the specification is generic, and isbased on CAWS in the UK.

Individual work sections can have a standard structure:

System outline.

System performance.

Products.

Fabrication.

Execution.

Completion.

-

8/13/2019 Master Specs User Guide

26/43

NBS Educator: Specifications: an introduct ion

NBS 26 November 2008

Facility management.

-

8/13/2019 Master Specs User Guide

27/43

NBS Educator: Specifications: an introduct ion

NBS 27 November 2008

8. Management

These matters should be addressed in the specification regardless of the methodof specification. Typically, covered in General technical requirements, orPreliminaries, e.g. sections A31, A32.

8.1 Conformance

The builder needs to be told about the regime for checking that the specificationhas been complied with (Gelder, 2006b; 2007; 2008b). This must be priced, andmust be understood. The appropriate regime depends on the method ofspecifying and, for some (e.g. proprietary), can be covered up front, e.g. inGeneral technical requirements, though supplementary requirements may needto be given for some instances. For others, especially tests, details should begiven for every instance.

Tests: May be type or project or custom tests. Identify agent, test method,

pass/fail points.Inspections: State whether hold or witness points.

Samples: To be provided by client or by contractor?

Documentary evidence: Specify, e.g. receipts, British Board of Agrment (BBA)certificates, BSI Kitemarks(BRE Certification, 2007).

8.2 Substitution

Anything can be substituted, not just brands. Most specifications coversubstitution of proprietary specifications, but in principle anything can besubstituted, including details, standards, test methods and the like.

Fair, clear rules are required, which should cover all eventualities, e.g. all entitiesthat can be substituted.

Do not bar substitution. This is not in the employers best interests, thoughmanufacturers may push for it (having worked hard to get their product specifiedin the first place). On the other hand, if not specified, they will often work just ashard to have their products used instead. Manufacturers want to have their cakeand eat it.

Do not invite substitution, e.g. by use of or equal (Gelder, 2004).

8.3 Key points

Requirements for verifying conformance should be specified.Procedures for substitution should be specified.

-

8/13/2019 Master Specs User Guide

28/43

NBS Educator: Specifications: an introduct ion

NBS 28 November 2008

9. Specif ication methods

9.1 Terminology and choice

In the literature, the terminology used to describe specification methods is varied

and confused. Items in a specification are either performance-based (open), orprescriptive (closed). A specification is likely to contain a mix of such items.Proprietary specifications are the most closed (i.e. least room for manoeuvre bycontractor, most responsibility taken by specifier). Silence is the most open formof specification.

Specification text can be either bespoke (custom-written) by the specifier, or itcan pre-exist and be cited (referenced) by the specifier. Bespoke and referenceare sub-methods of specifying.

Sub-methodsMethod

Bespoke Reference

Proprietary e.g. XYZBrand, Model33/A15

Manufacturersrecommendations

Descriptive e.g. 150 mmthick, greenfinish

BSs

Prescriptivemethods

Process e.g. 4 passesof a 5 tonne

roller

BS Codes ofPractice

Performance e.g. 2 hr fire-rated

BSs, BBACertificates

Price e.g. PC sum -

Performancemethods

Silence - -

Genericmethods

Choice of method: Most of the time no explicit decision is taken on whichspecification method to use. Specifiers simply revert to their customary approach.These approaches may be appropriate most of the time, but they will not beappropriate all of the time. For example, some clients may forbid the use ofoutright proprietary specification, to encourage competition. Some contracts maynot permit contractor design, in which case performance specifying cannot beused (at least for bespoke items).

Fitness-for-purpose: Where the work is specified in descriptive or proprietaryterms, probably no one is liable for fitness for purpose, because design andconstruction are well separated. Where process specifications are used, probably

-

8/13/2019 Master Specs User Guide

29/43

NBS Educator: Specifications: an introduct ion

NBS 29 November 2008

the specifier is liable for fitness for purpose design and construction aremerged.

For performance methods the builder is generally liable for fitness for purpose,though this may depend on the extent of design. For example, handover to thebuilder can be at any stage through the design process, so design to be done bythe builder can be unconstrained, to very constrained, by decisions taken byconsultants.

Builders can also become liable for FFP if substituting unilaterally, i.e. designingas well as building.

9.2 Principles

Be proactive not reactive solve problems now. The whole point of designingand documenting before construction is to reduce risk for all parties. Gooddocumentation helps the builder, too. Bad documentation doesnt help anyone.Making decisions reactively increases risk and makes tendering and project

management difficult. It is not usually in the employers best interests. Provisionalsums in particular can be used as a means of procrastination.

Ensure specification is best value enabled. Make sure that somebody will do theshopping around (Emmitt & Yeomans, 2001). This can be done by

the client, in which case the brand can be specified outright governmentdepartments often negotiate supply agreements for products or services, e.g.locks;

the architect or engineer, in which case the brand can be specified outright nominated suppliers are one consequence; or

the builder give the builder room to move, e.g. a choice of brands, or aperformance specification, or silence.

Ensure specification is integration-enabled, particularly between services andfabric. This is best managed if the one entity is responsible for all design. This isnot the case in conventional procurement, for example, where M&E usuallyrequires design by contractor, but the fabric does not.

Be positive. As far as possible, state what you want rather than what you dontwant. In particular, avoid bans (Gelder, 2005b).

Assume full conformance, e.g. dont specify retests. Documents must describewhat is required. They should not touch on what will happen if this is not provided

or not possible. Specifying for non-conformance risks generating a culture offailure, inferring that meeting the requirement is neither expected nor essential. Italso constrains the contract administrator whose job it is to deal with non-conformances.

Specify products, not processes. Processes are not the designers or employersbusiness, though designers should be cognisant of likely processes inconsidering buildability (incl. H&S considerations), cost/ time/ quality impacts andso on.

-

8/13/2019 Master Specs User Guide

30/43

NBS Educator: Specifications: an introduct ion

NBS 30 November 2008

Use one method of specifying per product per attribute, thereby avoiding conflict.Mixed methods are problematic. Complementarity across mixed methods ispossible, but ...

mixed messages are sent (e.g. who is responsible for design?);

conflict is likely; and

bulk and effort are increased.

Reference to mixed standards can also produce these problems. Some haveboth performance and deemed-to-satisfy prescriptive solutions, but not alwaysflagged as alternatives. Ideally such standards should be split so the specifiercan call up the appropriate part.

Be fair. Do not use to approval or catch-alls. The tenderer cannot price workdescribed as to approval, or neatly for example. What will be approved willdepend on circumstances and personalities. Quantify requirements.

9.3 PerformanceSpecifying performance generally requires contractor design, because the designprocess is incomplete at tender the builder is expected to complete it. This maybe a simple matter of selecting a brand with matching performance from acatalogue of type-tested products, or it may involve the much more complexprocess of designing a bespoke solution with matching performance.

But is the contractor allowed to design? See the contract and the employer-architect agreement etc. The contract should cover the risk by, in effect,combining ordinary build-only contract provisions with a client-architectagreement professional indemnity insurance, intellectual property, designapproval process and other issues.

Is the contractor competent to design? Or, more to the point, are you competentto design? Consider formal sub-consultancy if you are not.

Who is being paid to design? The employer-architect agreement, and parallelagreements for engineers, must mesh with and complement the requirements forcontractor-design in the construction contract, so the employer knows who isbeing paid for design and, therefore, how it needs to be managed.

Complete: Specify relevant properties, criteria, test methods and testing agents.Be objective. Terms such as waterproof or secure are, by themselves,meaningless and not enforceable.

Properties: Even for something as simple as high-pressure laminate, some 20properties are listed in BS EN 438-1.

Criteria: Pass/fail points must be specified, otherwise how will you be able toagree that what is provided is acceptable, or not?

Test methods: Since different methods for assessing a given property will givedifferent results, methods must be specified.

-

8/13/2019 Master Specs User Guide

31/43

NBS Educator: Specifications: an introduct ion

NBS 31 November 2008

Testing agents: Should be both competent and independent, ideally (henceUKAS). Type testing may be acceptable, e.g. KiteMark.

Consider supplementing performance with deemed-to-comply, such asdescriptive or proprietary solutions (a bit like BR ADs).

Items to be designed: The JCT series of contracts (including Intermediate andMinor Works) allows for three levels of contractor design. The less contractordesign permitted, the more prescriptive the specification must be.

Minor inferred items (silence): By definition, not mentioned explicitly in thedocuments. There is no such thing as 100% complete documentation. Thecontractors response to silence must be to identify the deliverable, determinerequired properties, design against them, and build. See JCT SBC/XQ 05 clause2.3.3, for example.

JCT CDP (Contractors Designed Portion): This is an optional extra for complexitems requiring contractor design, for which proposals should be submitted at

tender pretty common in large projects (e.g. for curtain walls, air conditioning).Identifying this work unambiguously is critical. See JCT SBC/XQ 05 Recitals 7 to10, for example.

JCT D&B: Where the entire contract is to be designed and built, a special form ofcontract must be used. The contract may not be for the whole building, of course.

9.4 Description

Generally, description means bespoke, though selection of a brand might be aresponse by the builder to a descriptive specification. Consider instead:

Drawings. Lengthy descriptions can often be replaced by drawings, especiallyto the extent that they attempt to describe geometry and assembly.

Photos, e.g. steel finishes.

Samples, e.g. Constructs concrete sample panels around UK.

Prototypes.

Reference projects.

9.5 Proprietary

This method is traditional for visually important manufactured items, e.g. doorfurniture, taps, facing bricks. But is it permitted, e.g. for projects with Europeanfunding (Gelder, 2006d)? Consider offering 3 or more proprietary choices.

Consider its use for critical but non-visual items.

To complete a proprietary spec, a descriptive supplement may be needed. Oftena manufacturer and product reference is not enough to tie down the product choices are offered and must be selected, e.g. colour, texture, grades, evenmaterials used. Likewise, defaults may be able to be varied on request, for a fee.Some of this will use proprietary terms (e.g. the manufacturers own name for acolour or texture), some will be descriptive.

-

8/13/2019 Master Specs User Guide

32/43

NBS Educator: Specifications: an introduct ion

NBS 32 November 2008

Dont retain generic stuff as well, such as references to standards this is likelyto result in conflict.

Or equal: Do not use this phrase. Or equal, or or equivalent (actually requiredin some contracts or in European funded projects), is the cause of muchavoidable disputation:

Including or equal at all is an invitation to the builder to make a substitution. Ifwe simply specified the brand (or whatever) and left it at that, substitution is stillpossible (unless disallowed in the preliminaries), the item is treated no differentlyto any other, and no invitation has been made.

By telling the contractor that equal products may be used, the contractor cansubstitute without notice he or she is not attempting to vary the contract bydoing so. Indeed, it is not actually a substitution at all. A simple full stop wouldvemeant that notice was required.

Following on from this, it is left to the builder to decide what is equal. But

because the builder does not know which criteria are important, the builder maywell end up substituting something that is not equal or equivalent in the eyes ofthe CA/ specifier/ employer. The criterion (equal) has been given if it hadnt, thebuilder would have had to ask for it or them.

General technical requirements or Preliminaries section A31, has rules forsubstitution which this phrase circumvents or contradicts (Gelder, 2004).

NBS Plus: NBS Plus, and RIBA Product Selector, can assist with proprietaryspecifications (Madeley, 2005; Hamil, 2005; Hamil, 2006; Chapman, 2006;Hamil, 2007).

9.6 Reference

Common examples of reference specifications are British standards andmanufacturers recommendations. Reference documents may be prescriptive,performance or (usually) both.

Standards:

Is the standard used by industry?

Is it current (amendments, superseding ENs) (Teale, 2005)?

Is it appropriate (scope)?

Does it cover all properties?

Is it readily enforced, e.g. is third-party certification available?

Current: Use a precise reference, defining edition and amendments.

Appropriate: Assuming the standard is appropriate and a more closedspecification is not required, then reference to the standard is preferred to:

paraphrasing it;

writing your own material in lieu; or

-

8/13/2019 Master Specs User Guide

33/43

NBS Educator: Specifications: an introduct ion

NBS 33 November 2008

ignoring it and saying little or nothing.

This is because the standard will be:

cited in codes or regulations;

used by manufacturers; and/or

followed by fabricators and installers.

Other options are not. Indeed the courts may take the standards as the startingpoint, whether specified or not.

Manufacturers literature: Much more difficult than standards to use properly.

9.7 Process

This method is rarely, if ever, appropriate. Do not specify process (Gelder, 2002;2003a):

Expertise in processes lies with builder.

Responsibilities blurred between employer and builder, e.g. for H&S.

Liability for failure with specifier.

Competitiveness of builder restricted.

Contractor fettered.

Supervision required for conformance.

No guarantee that desired result will follow.

Desired result often not stated (sometimes not even known).

Specifier may be held responsible for fitness for purpose.Specify end result (product or service) instead. This is what is paid for, and is thedeliverable which can be checked before handover.

Specifying process is traditional for conservation work, but if concerned about thebuilders ability to carry out a piece of work (e.g. thatching, stone repointing), askfor a method statement at tender. If a tenderer appears not to understand what isinvolved, dont use it.

Or provide suggested methods for information only (should not shall, andseparate from the contractual documents) though this is likely to be seen ascrossing the boundary.

9.8 Key points

Within a specification a variety of specification methods will be used.

The two classes of specification method are prescription and performance.

Specifiers should choose the appropriate method, rather than reverting to habit.

Methods should be proactive, best-value enabled, integration-enabled, positiveand fair.

-

8/13/2019 Master Specs User Guide

34/43

NBS Educator: Specifications: an introduct ion

NBS 34 November 2008

Performance specification, if done properly, is not going to save the specifiertime. On the contrary.

Proprietary specification may not be permitted. Where used, do not encouragesubstitution, e.g. by adding 'or equal'.

Reference specification requires familiarity with the work referenced.Do not specify process.

-

8/13/2019 Master Specs User Guide

35/43

NBS Educator: Specifications: an introduct ion

NBS 35 November 2008

10. Editing

10.1 The seven Cs

These rules apply also to contracts, regulations, drawings, and bills. But theyare not always followed. An Australian survey found that designers rate accuracy

of documentation top priority, followed closely by clarity, final checking,coordination and completeness (Tilley & McFallan, 2000). The survey also foundthat these objectives were not always achieved, completeness suffering thebiggest decline over a 15 year period, followed by final checking, certainty,accuracy, coordination and clarity.

Clear: Use plain English. The trend in legal drafting is to avoid Dickensianlegalese and aim instead for ease of understanding by all intended audiences(not just the lawyers). But sophisticated content still requires sophisticatedexpression.

In particular, avoid ambiguity. An independent internal devils advocate review is

a useful safeguard. Trimming waffle exposes ambiguity (and redundancy) andmakes the whole thing easier to edit. But too much concision can lead toambiguity.

Concise: Avoid repetition. Use streamlining, which involves the use ofkeywords and colons, and has been around since 1939 it is not new. It isnormal practice in master specification systems the world over (Gelder, 2005a).

Correct: Develop some quality control procedures. Cross-references must becorrect check BS numbers, check currency, check scope. Requirementscovered elsewhere do not need to be stated again the builder must comply withthe contract documents as a whole, including referenced documents. Avoid

redundancy.Complete: Ensure appropriate breadth. But, note Pareto. External cross-references are often required to complete a specification, e.g. asking for a firerating of 30/30/30 makes no sense unless the relevant standard (where the 30sare given meaning) is cited as well. It cannot be left as understood.

Comprehensive: Ensure appropriate depth. For example, ensure that all relevantcharacteristics are covered in performance specifications, and that all relevantitems are described in the specification and drawings taken together.

Consistent: Watch terminology and style. Referenced documents are inevitablyinconsistent (with each other, and occasionally within themselves) so, rather than

trying to fit in with them where they are inconsistent, the specification shouldprovide independent overall consistency.

Co-ordinated: Across all work sections, and between all contract documents.

10.2 Other rules

Be logical. For example, do not specify for non-conformance. Some clauses,such as contractor shall, or equal or unless otherwise specified should, if they

-

8/13/2019 Master Specs User Guide

36/43

NBS Educator: Specifications: an introduct ion

NBS 36 November 2008

are to be used at all, be added to every clause so they are best added to none.It is a useful discipline to take ideas to their logical conclusion in this way and seeif they still make sense.

Be fair and objective. The specification must be objective. Subjective descriptionssuch as to approval, adequate, neat should be avoided as far as practicable,as they cannot be priced and may lead to dispute. Likewise, avoid everythingnecessary and other catch-alls. Be specific. Here is an example of what to avoid:

The subcontractor should, unless otherwise specified, ensure that allbrickwork is constructed to any relevant standards and to approvedmanufacturers recommendations, or equivalent, using tradesmanlikeworkmanship, and as detailed. Materials and goods shall be the best oftheir respective kinds.

Leave no gaps and no overlaps. No gaps should be understood in terms ofPareto, where a certain amount of silence in the documents might be desirable.No overlaps should be applied absolutely, to avoid the risk of conflict and double

pricing. Dead clauses are a related issue, and are best avoided.

If in doubt, leave it out. Too often, specifiers with not much confidence in theirown technical ability insert, or leave in, material that they dont understand,assuming that it might be important. But if they dont understand it, they wont beable to enforce it anyway. Besides, it might not be important, or relevant.

Do not retain material just in case it will be useful later on, e.g. in the event of asubstitution or non-conformance. The requisite material will be added in theauthorising instruction.

Editing is the role of the lead specifier. Lead specifiers rarely edit, but it is asimportant as, and similar to, the business of co-ordinating the drawings. It doesnot require the lead specifier to have technical mastery of electrical, mechanical,landscape etc. It does require a check on style and format, on quasi-contractualcontent, on reference to tenderers, on paraphrasing of standards and codes, onscope and coverage of sections, e.g. trenching, plinths; and so on.

Consider document control, particularly maintenance, tracking and archiving.

10.3 Navigation

Numbering and internal cross-references: Use of names and numbers forsections and clauses is usual, along with page numbers. Cross-references in theCPI schema (Co-ordinating Committee for Project Information, 1987) use section

and clause numbers, but mistyped numbers can be difficult for readers to correct.Accordingly, some specification systems use section and clause names forcross-referencing, as errors are more easily spotted and corrected, and thenames are unlikely to change through the drafting process (unlike clausenumbering). Although bulky, the number of such cross-references is likely to besmall.

Section names or numbers should be given on every page, on the outside topright, as an aid to navigation. Page numbers are also essential for navigation.

-

8/13/2019 Master Specs User Guide

37/43

NBS Educator: Specifications: an introduct ion

NBS 37 November 2008

Contents: Contents lists for specifications and for each work section are easilyprepared. Contents lists for sections are preferred to scope of work clauses,which tend to presuppose a certain contractual situation which may not apply,e.g. pattern of subcontracting, and which may also be incomplete etc.

10.4 Format

Readability: Better readability enhances comprehension. Line length should beoptimised for readability, as should font size, fonts (e.g. headings vs body text),leading, line spacing and so on. Left justification assists readability.

Consider users: Consider the choice of media viz. paper for post and fax;electronic for email; CD; project extranet. Not all users will have computers, CDdrives, colour printers, internet access or even fax machines:

Client and contractor: Double column, double sided (fewer pages to initial).Streamlining lends itself to this.

Tenderers and contractors: Small sections help both. The needs of

contractors vary, depending on the use of the specification. On site, theymight prefer loose leaf single-sided A4 for photocopying, a good size font forreading in poor lighting, and a wide margin for notes.

Co-consultants and contractor: Electronic.

Specifiers: Disassembly by national master specification systems should bemulti-level (e.g. domestic, small commercial, large commercial, huge) sospecifiers can choose the best starting point, to minimise their work.

Binding in other documents: Binding other documents in with the specification,e.g. for convenience in handling, does not mean that they are part of thespecification. The US term for the whole bound document is project manual.

In particular, tendering material and contract annexures may be included, but arenot part of the specification (though NBS Preliminariessection A20 deals withcontract annexures and NBS Preliminariessection A30 deals with tendering).

10.5 Key points

Specifications should follow the seven Cs: clear, concise, correct, complete,comprehensive, consistent, co-ordinated.

Specifications should be logical, fair, with no gaps or overlaps. They should beedited.

Consider navigation, e.g. clause numbers, page numbers.Consider format, e.g. font, colour.

-

8/13/2019 Master Specs User Guide

38/43

NBS Educator: Specifications: an introduct ion

NBS 38 November 2008

11. Summary

Specification is both a product and a process.

Specification is one of a nest of projects.

Specifications are written descriptions of the quality of the built product and itscomponent products.

Specifications describe products, not processes.

Fragmentation of the specification across verious documents leads to problems.

At least 9 different types of user have an interest in the specification:

Designers.

Building control officers.

Estimators and tenderers.

Contractors.

Subcontractors.

Contract administrators.

Courts.

Facility managers.

Project managers.

Each is interested in different aspects of the specification, and may requiredifferent content and/or different structures.

Specification requires adequate time and fees.

Specification requires appropriate staffing, with appropriate training.

Specification can be facilitated with appropriate software.

Sources of information used by specifiers must be current and reliable. Specifiersmust be familiar with them.

Specifications can be based on proprietary specifications, project specifications,office master specifications and/or national master specifications. Each has itsadvantages and disadvantages.

It is recommended that national master specification systems are used theiradvantages easily outweigh any disadvantages.

Specifications are often started late, e.g. after the production drawings arecomplete.

Co-consultant specifications are often not checked.

Specification should begin early, e.g. at briefing, and should be systematic.

-

8/13/2019 Master Specs User Guide

39/43

NBS Educator: Specifications: an introduct ion

NBS 39 November 2008

If in doubt, leave it out. There is no such thing as a complete specification.

The specifier should make general decisions about thoroughness.

The specification locks in agreed quality levels.

Say it once, and (therefore) in the right place.

Therefore don't repeat content covered in regulations, contracts, standards,drawings, preliminaries, other work sections, and schedules.

Tendering material and reports are not part of the specification.

Cross-referencing between documents must be precise and accurate, or notused at all.

The specification only addresses, and binds, the contractor. It cannot bindsubcontractors, tenderers, authorities and other contractors these are outsidethe contract. Nor does it bind the client and contract administrator.

There are three main components to a specification preliminaries, worksections and schedules.

Because of the many users, the structure of the specification is generic, and isbased on CAWS in the UK.

Individual work sections can have a standard structure:

System outline.

System performance.

Products.

Fabrication.

Execution.

Completion.

Facility management.

Requirements for verifying conformance should be specified.

Procedures for substitution should be specified.

Within a specification a variety of specification methods will be used.

The two classes of specification method are prescription and performance.

Specifiers should choose the appropriate method, rather than reverting to habit.Methods should be proactive, best-value enabled, integration-enabled, positiveand fair.

Performance specification, if done properly, is not going to save the specifiertime. On the contrary.

Proprietary specification may not be permitted. Where used, do not encouragesubstitution, e.g. by adding 'or equal'.

-

8/13/2019 Master Specs User Guide

40/43

NBS Educator: Specifications: an introduct ion

NBS 40 November 2008

Reference specification requires familiarity with the work referenced.

Do not specify process.

Specifications should follow the seven Cs: clear, concise, correct, complete,comprehensive, consistent, co-ordinated.

Specifications should be logical, fair, with no gaps or overlaps. They should beedited.

Consider navigation, e.g. clause numbers, page numbers.

Consider format, e.g. font, colour.

-

8/13/2019 Master Specs User Guide

41/43

NBS Educator: Specifications: an introduct ion

NBS 41 November 2008

12. References and further reading

There are plenty of books on the subject of specifying, and to a large extent theymake the same recommendations. But not always there are some differencesof opinion. Some result from the differing backgrounds of the authors, e.g. QSs,

engineers, architects. Some are cultural, e.g. US, UK, Australia all have slightlydifferent practices. Some are date-based older works and/or authors tend todescribe older practices.

12.1 Standards

BS 4940:1994 Technical information on construction products and services.

BS EN 438-1:2005 Decorative high-pressure laminates (HPL). Sheets based onthermosetting resins (usually called laminates). Introduction and generalinformation.

BS 7373:2001 Product specifications. Guide to identifying criteria for a product

specification and to declaring product conformity.

Addresses specifying in very general terms, not specifically forconstruction.

BS EN ISO 9001:2000 Quality management systems Requirements.

12.2 Other

BRE Certification (2007) 'Third party certification', NBS Journal10.

Central Unit on Purchasing (1991) Specification writing, CUP HM Treasury.

Addresses specifying in very general terms, not specifically forconstruction.

Chapman, I. (2006) Next generation NBS Plus, NBS Journal09.

Construction Specifications Institute (2004) The project resource manual: CSIManual of practice, CSI.

The bible for North American specifications practice.

Co-ordinating Committee for Project Information (1987) CPI Project specification:A code of procedure for building works, BPIC.

Cox, P.J. (1993) Writing specifications for construction, McGraw-Hill.

This book compares US and UK practice.

Crawford, M. et al (1997) Uniclass: Unified classification for the constructionindustry, RIBA Publications.