Manual de Operador - Bucyrus - R30C.pdf

-

Upload

pablo-maldonado -

Category

Documents

-

view

360 -

download

15

Transcript of Manual de Operador - Bucyrus - R30C.pdf

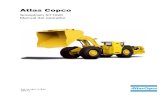

Operator and Maintenance Manual P/N 435120

Model R30CHydraulic Track Drill

Bucyrus Mining Equipment, Inc.3501 S. FM Hwy 1417 Denison, Texas 75020 USA

IDENTIFICATION OF THE MACHINEAlways furnish the Model Number and Serial Number when ordering parts. This informa-tion is found on the machine nameplate.

PART NUMBER AND DESCRIPTIONIn addition to the Model and Serial Number, always give the part number and description of each part ordered. If there is any doubt as to the correct part number and description, furnish a dimensioned sketch or return the part to be replaced, transportation charges prepaid. Your cooperation in furnishing as much information as possible will assist us in filling your orders correctly and in the shortest possible time.

SHIPMENTUnless otherwise instructed, all shipments will be made via motor freight collect, freight forwarder or UPS prepaid and charged on our invoice. Shipments cannot be made on open account until your credit has been approved by our accounting department.

Bucyrus Mining Equipment, Inc.3501 S. FM Hwy 1417, Denison, TX 75020www.bucyrus.com

© 2010 Bucyrus International, Inc.All Rights Reserved

PARTS ORDERINGIn North America Telephone 1-800-854-9030 or Telefax 1-800-582-6570Telephone (903) 786-2981Telefax (903) 786-6407

PRODUCT SERVICE AND WARRANTYIn North America Telephone 1-800-258-0009Telephone (903) 786-2981Telefax (903) 786-6408

PARTS ORDERING AND PRODUCT SUPPORTUse only genuine Bucyrus parts in the maintenance, rebuild or repair of these machines. The manufacturer shall have no liability as to any unauthorized modification of machines or parts. The manufacturer is also not obligated or liable for amachines or parts that have been improperly handled; that have not been operated, maintained or repaired according to furnished manuals or other written instructions, and that have been operated with other than genuine Bucyrus partsor authorized OEM components.

Introduction i

Introduction

This safety alert symbol indicates important SAFETY MESSAGES in this manual. When you see this symbol, carefully read the message that follows and be alert to the possibility of personal injury or property damage.

Before Starting Engine, Study Operator's Manual * Read and understand the warnings and cautions shown in Section 1 * Practice All Safety Precautions * Make Pre-Operations Check * Learn Controls Before Operating It is Owner/Operator's responsibility to understand and follow manufacturer's instructions on ma-chine operation and service, and to observe pertinent safety precautions, laws and regulations.

Intended Use This machine and its approved attachments are designed to drill blast holes for surface and underground

quarry, mining and construction applications. Use of this machine in any other way is prohibited and con-trary to its intended use.

The following warning applies to equipment supplied with lead-acid batteries:

Battery posts, terminals and related accessories contain lead and lead compounds, chemicals known to the State of California to cause cancer and reproductive harm. Wash hands after han-dling.

The following warning applies to equipment supplied with diesel powered engines:

Diesel engine exhaust and some of its constituents are known to the State of California to cause cancer, birth defects, and other reproductive harm.

California Proposition 65 Warnings

DO NOT weld on any part of this machine without fi rst disconnecting the negative battery cable or place the battery disconnect switch in the open position. Disconnect the connections to the Electronic Control Module (ECM) on the engine before welding.

Specifi cations are subject to change without notice.Information contained in this manual was current at the time of printing.

Revised 05/13/2010

ii Introduction

INTRODUCTION

SAFETY ...................................................................................................................SECTION 1

GENERAL INFORMATION .....................................................................................SECTION 2

OPERATOR CONTROLS .......................................................................................SECTION 3

START-UP, TRAMMING AND SHUTDOWN ...........................................................SECTION 4

DRILLING PROCEDURES .....................................................................................SECTION 5

LUBRICATION AND MAINTENANCE ....................................................................SECTION 6

Contents

Drill Serial No. :

Date Drill Delivered :

Dealer :

Customer :

Section 1

Safety

Safety 1-1

Notes

1-2 Safety

Hazard Classifi cation

Safety Alert SymbolThe safety alert symbol is used to alert you to potential personal injury hazards. Obey all safety mes-

sages that follow this symbol to avoid possible injury or death.

Safety Alert Symbol

Indicates a potentially hazardous situation which, if not avoided, may result in property or equipment damage.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

The hydraulic track drill is a heavy moving machine with a boom capable of extending its reach verti-cally and horizontally. Like all moving objects and reach extending devices, there are potential hazards associated with its use. These hazards will be minimized if the machine is properly operated, inspected, and maintained. The operator's must read this manual and have been trained to use the machine in an appropriate and safe manner. Non-English speaking persons must have an interpreter explain all safety and operating procedures in this manual. Should any questions arise concerning the maintenance or operation of the machine contact the manufacturer.

Hazard Classifi cationA multi-tier hazard classifi cation system is used to communicate potential personal injury hazards.

The following signal words used with the safety alert symbol indicate a specifi c level of severity of the potential hazard. All are used as attention-getting devices on decals and labels fi xed to the machine to assist in potential hazard recognition and prevention.

Safety 1-3

Safety Alert Symbol. Used to alert you to potential personal injury haz-ards. Obey all safety messages that follow this symbol to avoid possible injury or death.

See Operator's Manual for instruc-tions. If you do not understand the information the manuals, consult your supervisor, the owner, or the manufacturer.

Explosion Hazard. Death or seri-ous injury can result from the use of ether or other high energy start-ing aids.

Explosion / Burn Hazard. Will cause death, burns or blindness due to ignition of explosive gases or contact with corrosive acid.

Entanglement Hazard. Death or serious injury can result from contact with rotating drill steel and drivelines.

Burn Hazard. Death or serious injury can result from release of hot pressurized liquids.

Explosion Hazard. Death or seri-ous injury can result from the use of ether or other high energy starting aids.

Safety Sign Symbols

Keep clear of rotating drill steel and drivelines. Switch off engine before performing service.

Potential Hazard Prevention

Keep all open fl ames and sparks away. Wear personal protective equipment, including face shield, gloves and long sleeve shirt.

READ MANUALSRead all manuals prior to opera-tion.

Do not use ether or other high en-ergy starting aids in compressor.

Entanglement Hazard. Rotating parts can cause personal injury.

Keep away from fan and belt when engine is running. Stop engine be-fore servicing.

Do not use ether or other high en-ergy starting aids. Engine equipped with grid heating system.

Keep away from fl ames.

Relieve all pressure.

Allow to cool before performing ser-vice on compressor.

1-4 Safety

Electrocution Hazard. Death or injury can result from contacting electric power lines.

Potential Hazard Prevention

Flying Object Hazard. Serious injury or death can occur if drill is operated without guards in place.

Trip & Fall Hazard. Death or seri-ous injury can result from tripping and falling.

Use the access system provided when servicing the machine.

Safety Sign Symbols

Use guards.Keep in place.

Maintain required clearance.

See Table 1-1 in this manual.

Flying Object Hazard. Serious injury or death can occur if track tension is adjusted improperly.

Read and understand the proce-dures in the Operation and Main-tenance Manual before adjusting track tension

Keep off top of machine.

Fall Hazard. Death or serious injury can result from falling.

Burn Hazard. Hot fl uid under pres-sure can scald.

Allow to cool before opening.

Flying Object & Spray Hazard. Death or serious injury can result from release of pressurized liq-uids.

Shut off live air at source, and re-lieve all pressure before removing fi ller plug.

Safety 1-5

Safety Sign Symbols

Potential Hazard Prevention

Injection Hazard. Escaping fl uid under pressure can penetrate skin, causing serious injury.

Relieve pressure before disconnect-ing hydraulic lines. Keep away from leaks and pin holes. Use a piece of cardboard or paper to search for leaks. Do not use hand.

Crush Hazard. Death or serious injury can result from contact with moving feed mast.

Read and understand operator's manual and all safety signs before attempting to remove feed mast swing pin.

Drill Feed And Table Can Fall causing serious injuries or death.

Always raise the drill feed and feed table clear of all obstacles before moving the machine. Raise them high enough to allow for rough ground or small hills.Do Not allow anyone under the drill feed or feed table unless machine parts are not moving and are sup-ported.Do Not attempt to repair a pivot pin that has failed or has been sheared.

Caution. Do not use high pressure spray by electrical connections.

Crush Hazard. Death or serious injury can result from contact with moving machine.

Keep clear of moving machine.

Keep clear of moving centralizer. Do not actuate centralizer until person-nel are clear.

Crush Hazard. Death or serious injury can result from contact with moving centralizer.

Inhalation Hazard. Compressor discharge air is hazardous if inhaled. Death or serious injury may result.

Keep clear of compressor air dis-charge area.

1-6 Safety

Safety Information

Before Operation• Do study this manual and fully understand the controls.• Do be sure all safety guards are securely in place. Replace any damaged or missing guards.• Do be sure all nameplates and decals pertaining to safety, operation, and maintenance are in place

and not damaged. Replace any damaged or missing nameplates or decals. Refer to decal locator drawings in this section.

• Do be sure all personnel are clear of the machine and work area before starting the engine or operat-ing the machine.

• Do be sure drill area is clear of all obstructions before operating machine.• Do attach safety chain when using towbar.• Do wear safety helmet, glasses and hearing protection when operating or working on machine.• Do Not operate machine with:

• Hydraulic or air leaks.• Damaged hydraulic hoses or fi ttings.• Broken or damaged electrical wiring.• Damaged or missing guards and shields.• Damaged structural members.• Worn or damaged mechanical parts.• Damaged or missing fasteners.• Broken, damaged, or malfunctioning controls.

Operation• Do examine the surface before drilling to determine the possible presence of unfi red explosives.• Do provide suffi cient ventilation when running the engine in an enclosed area. Exhaust gases contain

carbon monoxide, a deadly poison, which is colorless and odorless.• Do keep work area clean and clear of mud, snow, ice, fl uids, hand tools and other objects. • Do raise the drill feed before moving the machine. Raise it high enough to allow for rough ground or

small hills. Drill feed can fall causing serious injury or death.• Do wear seat belt and operate machine with door closed on cab machines.• Do use PPE (personal protection equipment) appropriate for the conditions you are working in; e.g.

safety helmet, safety glasses, hearing protection, gloves, respirator.• Do maintain minimum clearance from high voltage wires (see Table 1-1). Check with power

company and local regulations for specifi c guidelines and safety information.• Do Not use the machine for any other purpose than what it was designed for.• Do Not wear loose clothing or jewelry; keep clothing and hands clear of moving parts.• Do Not travel on steep inclines, soft or unstable ground, or close to unsupported excavations.• Do Not move boom or machine if it is in a potentially unstable position.• Do Not stand directly under a boom or feed.• Do Not drill into or near a "bootleg" hole or any hole that may contain explosives.

Safety 1-7

Equipment TransferIf all or part of the equipment is shipped to a new destination, always include a complete Operator's

Manual or a copy of the following topics:• Safety Section• Operation Instructions including: Pre-Start Checks Start-up After Start Checks Shutdown Procedure Tramming Machine

Safety Information

Maintenance• Two people shall be present when performing service work, both being fully trained on safety issues.

One person shall supervise from the operator's position and have immediate access to an emergency stop in all situations. Visual, audible or verbal communication signals shall be established and under-stood by both persons.

• Do relieve pressure in the hydraulic or pneumatic systems before loosening connections or parts.• Do use only proper tools to make repairs or adjustments.

• Do be sure of adequate lighting when performing service work at night.

• Do maintain a metal-to-metal contact between the fi ll nozzle and fuel tank when fi lling the fuel tank. This will prevent sparks and the possibility of explosion.

• Do be sure each person is adequately trained to perform service and maintenance procedures.

• Do place a warning tag on starting controls to alert personnel that someone is working on the machine and disconnect battery before making repairs or adjustments to machine.

• Do be sure machine and components are well supported before servicing or replacing parts.

• Do Not service, or perform maintenance, while machine is running, or capable of being started.• Do Not hammer bit or drill steel. Use only proper tools to make repair or adjustments.• Do Not weld or grind near oil, air, fuel lines, or batteries.• Do Not smoke or use an open fl ame near batteries. Batteries can give off hydrogen which is a highly

explosive gas.• Do Not direct high pressure cleaning agents or water on electrical connections.

Clearances from High Voltage LinesLine Voltage Minimum Clearance0 to 50 kv 10 ft (3 m)50 to 200 kv 15 ft (4.6 m)200 to 350 kv 20 ft (6.1 m)350 to 500 kv 25 ft (7.6 m)500 to 750 kv 35 ft (10.7 m)750 to 1000 kv 45 ft (13.7 m)

Table 1-1 Minimum safe distances from high voltage lines.

After Operation• Follow Shutdown Procedures given in Section 4 of this manual.

1-8 Safety

Safety Sign List

Refer to Figures 1-1 to 1-4 for locationsItem Description Part No. Qty.1 DANGER - Electrocution Hazard 429116 1 2 WARNING - Flying Object Hazard 429082 23 WARNING - Operation/Maintenance, Read Manual 428892 34 WARNING - Flying Object & Spray Hazard 429141 25 DANGER - Entanglement Hazard, Rotating Drill Steel 429115 26 NOTICE - Hydraulic Oil Requirements 429106 17 DANGER - Explosion Hazard 428896 18 NOTICE - Fueling 429471 19 WARNING - Burn Hazard, Hot Fluid 428897 110 DANGER - Inhalation Hazard 429491 111 WARNING - Burn Hazard 429405 112 DANGER - Flying Object Hazard 429119 213 WARNING - Fall Hazard, Operator's Seat 429087 114 WARNING - Drill Feed and Table Can Fall 409485 115 WARNING - Crush Hazard, Centralizer 429438 116 WARNING - Crush Hazard, Feed Mast 429084 117 NOTICE - Do Not Weld 429489 118 NOTICE - Grease Instructions 427967 119 WARNING - Explosion Hazard, Engine 429494 120 WARNING - Explosion Hazard, Compressor 429493 121 WARNING - Entanglement Hazard, Fan and Belt 428893 123 CAUTION - High Pressure Spray on Elect. Connections 429468 224 DANGER - Crush Hazard 428884 426 WARNING - Injection Hazard 428898 227 WARNING - Crush Hazard, Centralizer (Clear) 429938 128 DECAL - R30 Maintenance Summary 435214 1

(Ref. 431329 rev. C)

Machines Without Enclosures

Safety Sign MaintenanceReplace any missing or damaged safety signs. Keep operator safety in mind at all times. Use mild

soap and water to clean safety signs. Do not use solvent-based cleaners as they may damage the safety sign material.

Safety 1-9

Safety Sign Location

Fig. 1-2 Left Side of Machine

Fig. 1-1 Right Side of Machine

Without Enclosures

1-10 Safety

Safety Sign Location

Fig. 1-3 Top View of Machine

Fig. 1-4 Front and Rear of Machine

Without Enclosures

Safety 1-11

Notes

1-12 Safety

Refer to Figures 1-5 to 1-9 for locationsItem Description Part No. Qty.1 DANGER - Electrocution Hazard 429116 12 WARNING - Flying Object Hazard 429082 23 WARNING - Operation/Maintenance, Read Manual 428892 34 WARNING - Flying Object & Spray Hazard 429141 25 DANGER - Entanglement Hazard, Rotating Drill Steel 429115 26 NOTICE - Hydraulic Oil Requirements 429106 17 DANGER - Explosion Hazard 428896 18 NOTICE - Fueling 429471 19 WARNING - Burn Hazard, Hot Fluid 428897 110 DANGER - Inhalation Hazard 429491 111 WARNING - Burn Hazard 429405 112 DANGER - Flying Object Hazard 429119 213 WARNING - Fall Hazard, Operator's Seat 429087 114 WARNING - Drill Feed and Table Can Fall 409485 115 WARNING - Crush Hazard, Centralizer 429438 116 WARNING - Crush Hazard, Feed Mast 429084 117 NOTICE - Do Not Weld 429489 118 NOTICE - Grease Instructions 427967 119 WARNING - Explosion Hazard, Engine 429494 120 WARNING - Explosion Hazard, Compressor 429493 121 WARNING - Entanglement Hazard, Fan and Belt 428893 122 WARNING - Fall Hazard 428885 123 CAUTION - High Pressure Spray on Elect. Connections 429468 224 DANGER - Crush Hazard 428884 425 WARNING - Trip & Fall Hazard 429548 426 WARNING - Injection Hazard 428898 227 WARNING - Crush Hazard, Centralizer (Clear) 429938 128 DECAL - R30 Maintenance Summary 435214 1

(Ref. 431331 rev. B)

Machines With Enclosures

Safety Sign List

Safety 1-13

Safety Sign Location

With Enclosures

Fig. 1-6 Left Side of Machine

Fig. 1-5 Right Side of Machine

1-14 Safety

Safety Sign Location

With Enclosures

Fig. 1-7 Top View of Machine

Fig. 1-8 Front and Rear of Machine

Safety 1-15

Safety Signs

429119

428884

429491

429116

429115

428896

1-16 Safety

Safety Signs

429493

428892

429082

429494

429405

428893

Safety 1-17

Safety Signs

428898

429141

429438429938–Clear Background

428897

429548–Enclosure Machines Only428885–Enclosure Machines Only

1-18 Safety

Safety Signs

429468

429084

409485429087

Safety 1-19

Safety Signs

429489

429471

429106

427967

4352141-20 Safety

General Information 2-1

Section 2

General Information

2-2 General Information

This manual contains detailed instructions, maintenance information, and technical data which the op-erator will need in order to properly operate the R30C Track Drill, and to perform the various maintenance services that are required for keeping the equipment in good working condition at all times. Included herein are complete descriptions of each operating control and step-by-step instructions on how to start, operate, and stop the equipment, and recommended operator's maintenance procedures.

The maintenance procedures and service instructions in this manual are included as recommenda-tions only and are based on normal equipment working conditions. Changes should be initiated by the user in order to compensate for other than normal conditions and to meet the working requirements of any specifi c job application.

By faithfully using this manual as a guide, and observing the instructions and recommendations, the R30C Track Drill will provide many years of dependable and effi cient service at a minimum cost for opera-tion.

Introduction

R30C Hydraulic Track Drill

Receiving and InspectionUpon receipt of the machine, Owner/Operator is required to inspect the machine and all items listed

on the Warranty Registration/Delivery Service Report included with the machine, complete the report and return to the manufacturer within 15 days of the In Service date.

General Information 2-3

Track Undercarriage

Two (2) hydraulic motor-driven compact planetary gear drives with manual disconnect for towing. Complete with hydraulic released, spring applied automatic disc brakes, 15 in. (38 cm) wide, overlap-ping, triple grouser tracks with mud/snow relief. Tram speed is 2.4 mph (4 km/hr.)

Engine

Caterpillar C9 300 hp (224 kW) diesel engine, 6-cylinder, water cooled, air-to-air aftercooled turbo-charger. The engine speed is automatically controlled by power demand.

Cab

Certifi ed ROPS/FOPS pressurized fi xed cab complete with heater, air conditioner, wiper, drilling lights, electronic two axis angle indicator and all necessary drilling controls. AM/FM stereo with CD player.

Hydraulic System

The system consists of two (2) direct driven pressure-compensated variable displacement, axial pis-ton pumps, two (2) two-speed variable displacement traction drive motors. SmartDrill drilling control system.

Air System

350 cfm @ 150 PSI (8.2 m3/min @ 10.2 bar) Gardner-Denver Rota-Screw Compressor driven by a fi xed displacement axial piston hydraulic motor.

Feed System

Model UHF16 Chain Feed, powered by a hydraulic piston motor complete with a power centralizer. The feed will accept a 20 ft. (6.1 m) drill steel for single pass without a hose reel.

Rock Drill

Model HPR45 hydraulic percussion drill, 25 hp (19 kW), standard on R30C. For drilling holes up to 5 in. (127 mm) diameter. .

Boom

A 12.5 ft. (3.81 m) swing boom with 5 ft. (1.5 m) telescopic system complete with a drill positioner, a 3 ft. (0.9 m) feed extension and a feed table with retaining device. Boom swing angle capability of 70 L, 33 R deg.

Component and Machine Specifi cations

2-4 General Information

Component and Machine Specifi cations

Rod Changer

Linear rod changer for 5 (45 mm) or 4 (51 mm) 12 or 14 ft. (3.7 or 4.3 m) round rods for up to 72 ft.* (21.9 m) drill steel capabiltiy.

Carousel rod changer for 5 (38 mm), 5 (45 mm) or 4 (51 mm) 12 or 14 ft. (3.7 or 4.3 m) round rods for up to 88 ft.* (26.8 m).

A single rod changer is also availabe for starter and one rod.

* Depth capacity includes a 20 ft. starter rod.

Additional Standard Features

• Fully Enclosed Canopy

• Power Pickup Pot

• Angle Inclinator

• Dust Collector

Options

• Detergent System

• HPR51 Hydraulic Percusion Drill, 30 hp (23 kW)

General Information 2-5

Component and Machine Specifi cations

Fig. 2-1 Right Side View of R30C1. Detergent Tank 9. Feed Table Assembly2. Engine Air Filter 10. Dust Collector Precleaner3. Hydraulic Tank Filters 11. Feed Swing Cylinder4. Cab Air Filter 12. Boom Lift Cylinder5. Dust Collector 13. Air Receiver Tank6. Boom Swing Cylinder 14. Hydraulic Tank7. Feed Dump Cylinder 15. Hydraulic Pumps (2)8. Feed Extend Cylinder 16. Pump Drive

Fig. 2-2 Left Side View of R30C 17. Drill Slide Assembly 24. Track Oscillation Cylinder (2) 18. Feed Assembly 25. Outer Boom Tube 19. Upper Rod Rack 26. Inner Boom Tube 20. Cab 27. Positioner 21. Electrical Enclosure 28. Hydraulic Rock Drill 22. Engine Radiator Shunt Tank 29. Rod Wrench 23. Radiator/Cooler

2-6 General Information

Component and Machine Specifi cations

Fig. 2-3 Top View of R30C 30. Feed Drive Assembly 34. Fuel Tank 31. Breather, Hydraulic Tank 35. Air Receiver Tank 32. Batteries 36. Air Compressor 33. Caterpillar C9 Diesel Engine

Fig. 2-4 Lower Boom/Feed1. Lower Rod Rack 4. Pendulum2. Rope Pull Shutdown Switch 5. Centralizer3. Pickup Pot

Fig. 2-5 Boom Mounted Angle Indicator

General Information 2-7

Fig. 2-6 Valve Locations1. Tram Valve2. Boom/Feed Valve

Fig. 2-7 Manifold Locations1. Rod Changer Manifold2. Auxiliary Manifold

Component and Machine Specifi cations

2-8 General Information

Fig. 2-8 Dust Collector Regulator and Blow Air Valve1. Regulator (set at 80 PSI (5.5 bar))2. Ball Valve

Fig. 2-10 Hose Reel

Fig. 2-91. Electronic Control Module (ECM)2. Plug-Ins–Disconnect from ECM before welding

Component and Machine Specifi cations

Operator Controls 3-1

Section 3

Operator Controls

3-2 Operator Controls

Notes

Operator Controls 3-3

Fig. 3-1 Cab Control Panel

1. Cab Temperature Control – Adjusts temperature for heater/air conditioner

2. Air Conditioner ON/OFF – Turns air conditioner on/off

3. Cab Fan Speed – Controls fan speed

4. Warm Oil ON/OFF – Warms the hydraulic oil in cold conditions 32o F (0o C) or less

5. Washer FRONT/TOP – Turns on windshield washer

6. Rear Drill Lights ON/OFF – Turns rear drill lights on and off

7. Front Drill Lights ON/OFF – Turns front drill lights on and off

8. Control System ON/OFF – Powers up machine electronic controls; must be OFF when starting engine

9. Not Used —

10. Feed Force – Rotate knob CW to increase pressure on drill bit, CCW to decrease pressure

11. Dust Collector ON/OFF – Turns dust collector on; with air on, dust collector is fully operational, with air off, dust collector operates in pulse mode to clean dust collector fi lters

12. Engine Idle LOW/HIGH – Switch on LOW–engine runs at 1000 RPM (for startup/shutdown), increases to 1500 RPM (for system load) Switch on HIGH–engine runs at 1800 RPM (for drilling/tramming functions)

13. Rod Changer/Setup – Selects rod changer or setup mode while in drill mode.

14. Tram/Neutral/Drill – Selects tram or drill mode; tram is disabled in drill mode; drill is disabled in tram mode; must be in neutral position when starting engine

15. Water ON/OFF – Turns on detergent system (if supplied), dust collector must be off

16. Oscillation LOCK/UNLOCK – Locks or unlocks track oscillation cylinders for different tramming conditions

17. Smart Drill ON/OFF – Switch ON activates automatic drilling

18. Engine Stop Switch – Shuts down machine engine in case of an emergency

19. Cold Start Lamp – Lights when engine start is engaged; shuts off when engine is warmed to start

20. Engine Start Switch – Starts engine

Control PanelOFF to Start, ON to Tram

NEUTRAL to Start

3-4 Operator Controls

Joystick Controls–Linear Rod Changer

One Joystick Tram1. L.H. Joystick Controller – Located on the left arm rest, the L.H joystick performs the following functions (ref. fi g.3-3):

Tram/Drill switch in TRAM (14, fi g. 3-1) – tram, oscillation, counter rotate, 2-speed

Tram/Drill switch in DRILL, Rod Changer/Setup switch in SETUP (13, fi g. 3-1) – feed dump, feed swing, feed extend

Tram/Drill switch in DRILL, Rod Changer/Setup switch in ROD CHANGER – rod lock, rod unlock, rod wrench in, rod wrench out

2. R.H. Joystick Controller – Located on the right arm rest, the R.H joystick performs the following functions (ref. fi g.3-3):

Tram/Drill switch in TRAM (14, fi g. 3-1) – boom down, boom up, boom swing left, boom swing right Tram/Drill switch in DRILL, Rod Changer/Setup switch in SETUP (13, fi g. 3-1) – boom down, boom up, boom swing left, boom swing right, boom extend

Tram/Drill switch in DRILL, Rod Changer/Setup switch in ROD CHANGER – carriage out, carriage in, car riage unlock

3. Drill Joystick Controller – Located on the right arm rest, the drill joystick performs the following functions (ref. fi g.3-3):

Tram/Drill switch in DRILL (14, fi g. 3-1), Rod Changer/Setup switch in SETUP or ROD CHANGER (13, fi g. 3-1) – feed up, feed down, rotation forward, rotation reverse, coupling grease, collar, full hammer, synchronized threading

Fig. 3-2 Joysticks

L.H. Tram Joystick

Operator Controls 3-5

Joystick Controls–Linear Rod Control

Fig. 3-3 Joystick Functions and L.H Armrest Switches

1. Air ON/OFF – Adjusts amount of air down the hole by holding the switch ON

2. Centralizer OPEN/CLOSE – Opens and closes centralizer

3. Pickup Pot UP/DOWN – Raises or lowers pickup pot

One Joystick Tram

3-6 Operator Controls

Fig. 3-2 Joysticks

Two Joystick Tram1. L.H. Joystick Controller – Located on the left arm rest, the L.H joystick performs the following functions (ref. fi g.3-4):

Tram/Drill switch in TRAM (14, fi g. 3-1) – tram left track forward/reverse, oscillation forward/backward, 2- speed

Tram/Drill switch in DRILL, Rod Changer/Setup switch in SETUP (13, fi g. 3-1) – feed dump, feed swing, feed extend

Tram/Drill switch in DRILL, Rod Changer/Setup switch in ROD CHANGER – rod lock, rod unlock, rod wrench in, rod wrench out

2. R.H. Joystick Controller – Located on the right arm rest, the R.H joystick performs the following function (ref. fi g.3-4):

Tram/Drill switch in TRAM (14, fi g. 3-1) – tram right track forward/reverse Tram/Drill switch in DRILL, Rod Changer/Setup switch in SETUP (13, fi g. 3-1) – boom down, boom up, boom swing left, boom swing right, boom extend

Tram/Drill switch in DRILL, Rod Changer/Setup switch in ROD CHANGER – carriage out, carriage in, car riage unlock

3. Drill Joystick Controller – Located on the right arm rest, the drill joystick performs the following functions (ref. fi g.3-4):

Tram/Drill switch in DRILL (14, fi g. 3-1), Rod Changer/Setup switch in SETUP or ROD CHANGER (13, fi g. 3-1) – feed up, feed down, rotation forward, rotation reverse, coupling grease, collar, full hammer, synchronized threading

Joystick Controls–Linear Rod Changer

Tram Joysticks

Operator Controls 3-7

Fig. 3-4 Joystick Functions and L.H Armrest Switches

1. Air ON/OFF – Adjusts amount of air down the hole by holding the switch ON

2. Centralizer OPEN/CLOSE – Opens and closes centralizer

3. Pickup Pot UP/DOWN – Raises or lowers pickup pot

Two Joystick Tram

Joystick Controls–Linear Rod Control

3-8 Operator Controls

Joystick Controls–Carousel Rod Changer

One Joystick Tram1. L.H. Joystick Controller – Located on the left arm rest, the L.H joystick performs the following functions (ref. fi g.3-3):

Tram/Drill switch in TRAM (14, fi g. 3-1) – tram, oscillation, counter rotate, 2-speed

Tram/Drill switch in DRILL, Rod Changer/Setup switch in SETUP (13, fi g. 3-1) – feed dump, feed swing, feed extend

Tram/Drill switch in DRILL, Rod Changer/Setup switch in ROD CHANGER – jaw clamp, jaw unclamp, carousel swing in, carousel swing out

2. R.H. Joystick Controller – Located on the right arm rest, the R.H joystick performs the following functions (ref. fi g.3-3):

Tram/Drill switch in TRAM (14, fi g. 3-1) – boom down, boom up, boom swing left, boom swing right Tram/Drill switch in DRILL, Rod Changer/Setup switch in SETUP (13, fi g. 3-1) – boom down, boom up, boom swing left, boom swing right, boom extend

Tram/Drill switch in DRILL, Rod Changer/Setup switch in ROD CHANGER – carousel counterclockwise, carousel clockwise

3. Drill Joystick Controller – Located on the right arm rest, the drill joystick performs the following functions (ref. fi g.3-3):

Tram/Drill switch in DRILL (14, fi g. 3-1), Rod Changer/Setup switch in SETUP or ROD CHANGER (13, fi g. 3-1) – feed up, feed down, rotation forward, rotation reverse, coupling grease, collar, full hammer, synchronized threading

Fig. 3-2 Joysticks

L.H. Tram Joystick

Operator Controls 3-9

Joystick Controls–Carousel Rod Control

Fig. 3-3 Joystick Functions and L.H Armrest Switches

1. Air ON/OFF – Adjusts amount of air down the hole by holding the switch ON

2. Centralizer OPEN/CLOSE – Opens and closes centralizer

3. Pickup Pot UP/DOWN – Raises or lowers pickup pot

One Joystick Tram

RIGHT JOYSTICK

RIGHT JOYSTICK

BOOM UP

RIGHT JOYSTICK

BOOM DOWN

DECAL P/N: 440863

REVERSE

LEFT JOYSTICK

FORWARD

TRAM MODE

LEFT JOYSTICK

ROD CHANGER MODE

BOOMSWING LEFT

LEFT JOYSTICK

SET-UP MODE

BOOMSWING RIGHT

OSC FORWARD

OSC BACKWARD

2-SPEED COUNTER ROTATE

LEFT RIGHT

BOOM UP

BOOMSWING RIGHT

BOOM DOWN

BOOMSWING LEFT

FEED DUMP OUT

FEED DUMP IN

FEED SWING LEFT

FEED SWING RIGHT

FEED EXTEND UP

FEEDEXTEND DOWN

BOOMEXTEND IN

BOOM EXTEND OUT

SWING IN

SWING OUT

CAROUSELCLOCKWISE

CAROUSEL COUNTER CLOCKWISE

JAWUNCLAMP

JAWCLAMP

ROTATION FORWARD

FEED DOWN

FEED UP

COUPLING GREASE

SYN THREAD

FULLHAMMERCOLLAR

ROTATION REVERSE

ROTATION FORWARD

FEED DOWN

FEED UP

CENTRALIZERAIR

OFF

ON

PICK-UP POT

CLOSE DOWN

OPEN UP

ON

OFF

AIRPICK-UP POT

CLOSE

OPEN

DOWN

UP

CENTRALIZER

FULLHAMMER

COUPLING GREASE

COLLAR

SYN THREAD

JOYSTICKBUTTONS

L.H. ARMRESTSWITCHES DRILL JOYSTICK

2 31

3-10 Operator Controls

Fig. 3-2 Joysticks

Two Joystick Tram1. L.H. Joystick Controller – Located on the left arm rest, the L.H joystick performs the following functions (ref. fi g.3-4):

Tram/Drill switch in TRAM (14, fi g. 3-1) – tram left track forward/reverse, oscillation forward/backward, 2- speed

Tram/Drill switch in DRILL, Rod Changer/Setup switch in SETUP (13, fi g. 3-1) – feed dump, feed swing, feed extend

Tram/Drill switch in DRILL, Rod Changer/Setup switch in ROD CHANGER – jaw unclamp, jaw clamp, carousel swing in, carousel swing out

2. R.H. Joystick Controller – Located on the right arm rest, the R.H joystick performs the following function (ref. fi g.3-4):

Tram/Drill switch in TRAM (14, fi g. 3-1) – tram right track forward/reverse Tram/Drill switch in DRILL, Rod Changer/Setup switch in SETUP (13, fi g. 3-1) – boom down, boom up, boom swing left, boom swing right, boom extend

Tram/Drill switch in DRILL, Rod Changer/Setup switch in ROD CHANGER – cariage counterclockswise carousel clockwise

3. Drill Joystick Controller – Located on the right arm rest, the drill joystick performs the following functions (ref. fi g.3-4):

Tram/Drill switch in DRILL (14, fi g. 3-1), Rod Changer/Setup switch in SETUP or ROD CHANGER (13, fi g. 3-1) – feed up, feed down, rotation forward, rotation reverse, coupling grease, collar, full hammer, synchronized threading

Joystick Controls–Carousel Rod Changer

Tram Joysticks

Operator Controls 3-11

Fig. 3-4 Joystick Functions and L.H Armrest Switches

1. Air ON/OFF – Adjusts amount of air down the hole by holding the switch ON

2. Centralizer OPEN/CLOSE – Opens and closes centralizer

3. Pickup Pot UP/DOWN – Raises or lowers pickup pot

Two Joystick Tram

Joystick Controls–Carousel Rod Control

L.H. ARMRESTSWITCHES DRILL JOYSTICK

1 2 3

RIGHT JOYSTICK

RIGHT JOYSTICK

RIGHT JOYSTICK

DECAL P/N: 440864

LEFT JOYSTICK

TRAM MODE

LEFT JOYSTICK

ROD CHANGER MODE

LEFT JOYSTICK

SET-UP MODE

BOOM UP

BOOMSWING RIGHT

BOOM DOWN

BOOMSWING LEFT

FEED DUMP OUT

FEED DUMP IN

FEED SWING LEFT

FEED SWING RIGHT

CAROUSELCLOCKWISE

CAROUSEL COUNTER CLOCKWISE

JAWUNCLAMP

JAWCLAMP

ROTATION FORWARD

FEED DOWN

FEED UP

ROTATION REVERSE

ROTATION REVERSE

ROTATION FORWARD

FEED DOWN

FEED UP

CENTRALIZERAIR

OFF

ON

PICK-UP POT

CLOSE DOWN

OPEN UP

ON

OFF

AIRPICK-UP POT

CLOSE

OPEN

DOWN

UP

CENTRALIZER

FORWARD

REVERSE

LEFT TRACK

REVERSE

FORWARD

OSC FORWARD

OSC BACKWARD

2-SPEED

FEEDEXTEND DOWN

FEED EXTEND UP BOOM EXTEND OUT

BOOMEXTEND IN

COUPLING GREASE

FULLHAMMER

SYN THREAD

COLLAR

COUPLING GREASE

FULLHAMMER

SYN THREAD

COLLAR

SWING OUT

SWING IN

3-12 Operator Controls

Joystick Button Controls

Fig. 3-6 R.H. and Drill Joystick ButtonsTRAM MODE DRILL/ROD CHANGER MODE1. Not Used 1. Full Hammer2. Not Used 2. Coupling Grease3. Not Used 3. Collar4. Not Used 4. Synchronized Threading5. Not Used 5. Not Used6. Not Used 6. Not Used7. Not Used 7. Not Used8. Not Used 8. Carriage Unlock DRILL/SET UP MODE1. Full Hammer2. Coupling Grease3. Collar4. Synchronized Threading5. Boom Extend In6. Boom Extend Out7. Not Used8. Not Used

Fig. 3-5 L.H. Joystick ButtonsTRAM MODE9. Oscillation Backward10. Counter Rotate11. Oscillation Forward12. 2-Speed

DRILL/SET UP MODE9. Not Used10. Not Used11. Feed Extend Up12. Feed Extend Down

DRILL/ROD CHANGER MODE9. Rod Wrench Out OR9. Carousel Sing Out10. Rod Wrench In OR10. Carousel Swing In11. Not Used12. Not Used

Operator Controls 3-13

Cab Displays

Fig. 3-7 Control Panel Drilling Pressure Readings1. Hammer Pressure2. Feed Pressure3. Rotation Pressure4. Air Pressure

Drilling Displays

Fig. 3-8 Cab Mounted Angle Indicator

3-14 Operator Controls

Cab Displays

Engine Displays

Fig. 3-9 Control Panel Engine Readings1. Engine RPM 5. Engine Temperature in Fahrenheit2. Engine Hours 6. System Operating Voltage3. Compressor Temperature in Fahrenheit 7. Engine Oil Presure4. Drill Hours 8. Fuel Quantity in Percent

Operator Controls 3-15

Remote Operation

For Emergency Use Only. Owner/Operator must contact manufacturer for proper opera-tion.

Fig. 3-10 Tram Control Valve

Fig. 3-11 Boom/Feed Control Valve

Stay clear of moving machine, death or serious injury can result

3-16 Operator Controls

Notes

Start-up, Tramming and Shutdown 4-1

Section 4

Start-up, Trammingand Shutdown

4-2 Start-up, Tramming and Shutdown

Notes

Start-up, Tramming and Shutdown 4-3

BE SURE all hydraulic controls are in the OFF or NEUTRAL position BEFORE placing the control system ON/OFF switch to ON.DO NOT operate the machine unless thoroughly familiar with controls and functions.WEAR a protective helmet and eye protection when on or near the machine.WEAR noise reducing ear protectors when near the machine for extended periods while the machine is running.CHECK operation of the brakes before tramming.REMOVE the drill steel and center the drill over the positioner before tramming over rough terrain.

CHECK FOR obstructions before moving feed or machine.DO NOT allow any part of the machine to contact or come near electrical power lines (see Table 4-1).BE SURE the feed is high enough to clear ground obstacles and low enough to clear overhead obstacles when tramming.

BEFORE attempting to operate or service this machine, read and understand the warn-ings and cautions listed in Section 1. BE SURE machine is OFF and the hydraulic and pneumatic systems are not pressurized before loosening any connections or parts.SHUT OFF engine BEFORE refueling. Clean up any fuel spills immediately. Failure to observe this warning may result in fi re.

Pre-Start Checklist

Clearances from High Voltage LinesLine Voltage Minimum Clearance0 to 50 kv 10 ft (3 m)50 to 200 kv 15 ft (4.6 m)200 to 350 kv 20 ft (6.1 m)350 to 500 kv 25 ft (7.6 m)500 to 750 kv 35 ft (10.7 m)750 to 1000 kv 45 ft (13.7 m)

Table 4-1 Minimum Safe Distances From High Voltage Lines

4-4 Start-up, Tramming and Shutdown

Overall MachineA. Check underside of machine. Look for broken or loose hoses. Tighten any loose hose connections

and any loose bolts. If dripping fuel, oil or water is evident, do not operate the machine until the leak is found and corrected.

B. Replace any missing or damaged bolts, pins or other retainers.C. Check tracks for proper tension and clear any debris.D. Lubricate machine according to Maintenance Schedule and Grease Points chart in Section 6.E. Check battery cable connections and battery electrolyte level. Switch battery disconnect switch

(located behind battery box) to the ON position.

FuelA. Always shut off engine before refueling.B. Wipe up any fuel spills immediately or fi re may result.C. Use No. 2-D diesel fuel. Consult engine manual for specifi c recommendations.

Engine, Gearcases and Hydraulic Fluid TypesA. Check engine crankcase oil level. Add oil if necessary. Do not mix types of oil. The machine is fac-

tory fi lled with 15W-40 motor oil unless specifi ed otherwise.B. Check radiator coolant level. Add a 50/50 mixture of anti-freeze and water if necessary.C. Check battery electrolyte level and fi ll with distilled water if necessary. Check for clean, tight con-

nections.D. Check for adequate diesel fuel. To avoid priming and restarting problems, do not allow engine to run

out of fuel. Drain water from water separator prior to starting.E. Check oil level in feed planetary drive assembly. Add HD 80W-90 wt. gear oil if necessary. Do not

mix types of oil. Set feed in upright position and remove plug at the 3 o'clock position. Oil level should be at bottom of plug hole. Fill through plug at the 12 o'clock position.

F. Check oil level in track planetary drive. Add gear oil if required. Do not mix types of oil. Machine is factory fi lled with HD 80W-90 wt. gear oil (see Service Manual for list of approved gear oils). With machine on level surface, position unit so drain plug is at bottom, fi ll plug will be at about the 2 o'clock position. Oil level should be at bottom of fi ll plug.

G. Check alternator/water pump drive belt condition. Replace if cracked or worn. See engine manual.H. Check oil level in hydraulic reservoir. Add oil if necessary.

When checking hydraulic fl uid level, be sure: • Reservoir is level• Boom is retracted and level• Feed is dumped back and extended

Do not overfi ll. Machine was factory fi lled with Chevron AW MV ISO 100 unless specifi ed otherwise. Do Not Mix Hydraulic Fluid Types.

Pre-Start Checklist

NOTE

Start-up, Tramming and Shutdown 4-5

Pre-Start Checklist

DO NOT operate the hydraulic drill until accumulators have been charged.

Drill Accumulators

Because of Federal regulations, the accumulators on the drill cannot be charged at the factory. Both the high and low pressure accumulators on the drill must be charged before the initial round is drilled and checked periodically thereafter. Refer to the Service Manual for pressures and procedures.

Pneumatic SystemA. Be sure hydraulic and pneumatic systems are not pressurized before loosening any connections

or parts. Check oil level in compressor receiver. Add oil only if gauge reads in the Add Oil range. Machine is factory fi lled with Chevron ATF.

Boom, Feed and DrillA. Operator must be sure to check all pivot points for signs of wear or damage and grease daily.B. Check for loose drill hose retainers.C. Check feed chain for proper tension (see service manual).D. Drill Chuck–Check for excessive shank side play indicating chuck wear. Grease chuck end cap

after shank is inserted (see Drill Service Manual).E. Drill Shank–Inspect shank threads often. Badly worn threads can cause tight steel and premature

coupling breakage.F. Centralizer–Check centralizer alignment with drill shank. Clamp a coupling between the centralizer

jaws. Lower the drill so the shank aligns with the coupling. Adjust centralizer as necessary.

4-6 Start-up, Tramming and Shutdown

Pre-Start Checklist

Fig. 4-1 Feed Table Pivot Pin1. Grease Fittings (2)2. Retaining Bolts (6)–Torque to 282 ft. lbs. (384 Nm)3. Retaining Cap, Feed Table Pin

Feed Table Pivot Pin

BE SURE to check the feed table pivot pin for wear and any signs of damage. Pin failure could cause severe injury or death.

Weekly Checks1. Be sure to check torque on the six pivot pin cap retaining bolts weekly. Torque to 282 ft. lbs. (384

Nm). Check for excessive play, cracking or other damage.2. Check for end play by inserting a feeler gauge between the retaining cap and positioner casting.

The gap should be in the range of 0.005 to 0.015 in. (0.13 to 0.38 mm). Retaining cap will have to be removed and shims installed until the correct clearance is obtained. Procedure in service manual must be followed.

3. Check for side play by raising the feed to a 45 degree angle. Have someone watch the pivot pin while you dump the feed back and forth. There should be no rocking of the pin. If so, report to maintenance personnel. Feed table will have to be removed and pin and bushing inspected and necessary repairs made.

Start-up, Tramming and Shutdown 4-7

Batteries give off fl ammable fumes that can explode.DO NOT smoke when observing the battery electrolyte levels.Improper jumper cable connections can cause an explosion resulting in personal injury.Prevent sparks near the batteries. Sparks could cause vapors to explode. DO NOT al-low jumper cable ends to contact each other or the engine.ALWAYS wear protective glasses when working with batteries.Electrolyte is an acid and can cause personal injury if it contacts skin or eyes.

Jump Starting Instructions1. Turn start switch OFF and turn off all electrical accessories. Turn battery disconnect switch ON (fi g.

4-2).2. Always use the same voltage system for jump starting, in this case, 24V negative ground.3. Connect one end of the cable to the POSITIVE (+) terminal of the battery being started (fi g. 4-3).

Connect the other end to the POSITIVE (+) terminal of the power source.4. Connect one end of the cable to the NEGATIVE (–) terminal of the power source. Connect the other

end to the engine block or chassis ground. This prevents sparks from igniting combustible gases produced by some batteries.

5. After starting engine, disconnect NEGATIVE (–) cable from engine block or chassis ground. Discon-nect other end from the NEGATIVE (–) terminal of the power source.

6. Disconnect the cable from the POSITIVE (+) terminal on the battery of the engine being started. Disconnect the other end from the POSITIVE (+) terminal of the power source.

Engine Starting With Jumper Cables

Fig. 4-3 Battery Connections on Model R30CFig. 4-2 Battery Disconnect Switch(OFF disconnects batteries)

4-8 Start-up, Tramming and Shutdown

Start-up Procedure

Fig. 4-4 Cab Control Panel1. Cab Temperature Control 11. Dust Collector ON/OFF2. Air Conditioner ON/OFF 12. Engine Idle LOW/HIGH3. Cab Fan Speed 13. Rod Changer/Setup 4. Warm Oil ON/OFF 14. Tram/Drill5. Washer FRONT/TOP 15. Water ON/OFF6. Rear Drill Lights ON/OFF 16. Oscillation LOCK/UNLOCK7. Front Drill Lights ON/OFF 17. Smart Drill ON/OFF8. Control System ON/OFF 18. Emergency Stop Switch9. Not Used 19. Cold Start Lamp 10. Feed Force 20. Engine Start Switch

Fig. 4-5 Hydraulic Tank Temperature Gauge Fig. 4-6 Hydraulic Pumps and Gauges1. Pump No. 12. Pump No. 23. Dust Collector Pump4. Pump No. 1 Gauge5. Pump No. 2 Gauge

OFF to Start, ON to Tram

NEUTRAL to Start

Start-up, Tramming and Shutdown 4-9

If engine fails to start within 30 seconds, release start switch. Wait for two minutes to allow starter to cool, and then turn start switch again.

Cold Start ProcedureThe Caterpillar C9 engine is equipped with an air intake heater. DO NOT use ether to try to start this

engine. The Cold Start Lamp (19) comes on when the air intake heater is on. After the engine has started, the air inlet heater may continue to operate in the "continuous" or "inter-

mittent" mode. The air inlet heater will turn OFF when the sum of the coolant and air inlet temperatures exceed 127oF (35oC).

Allow engine to idle for about 3 minutes or until you see the water temperature reading begin to rise. Check all readings during warm-up period.

Hydraulic Oil WarmingIn cold temperatures, switch the Warm Oil Switch (4) to ON. Usually during engine warm up (15 to 30

minutes), this will allow enough time for the hydraulic oil to warm up. Turn off the switch before operation of the track drill. When hydraulic oil tank temperature gauge (fi g. 4-5) reaches 60oF (15.6oC), oil is warm enough to begin drilling.

DO NOT begin drilling until hydraulic oil has been warmed up, especially when ambi-ent temperature is below 32oF (0oC). When hydraulic oil tank temperature gauge (fi g. 4-5) reaches 60oF (15.6oC), oil is warm enough to begin drilling.

DO NOT use ether on engines equipped with an air intake heater.DO NOT put ether into compressor intake.

After completing the pre-start checklist, use the following procedure to start the machine:(ref. fi g. 4-4)1. Turn battery disconnect (fi g. 4-2) located behind battery box to ON position.2. Be sure all controls are in the OFF or NEUTRAL position. 3. Be sure the Tram/Drill Switch (14) is in the NEUTRAL (center) position. 4. Be sure Control System Switch (8) is in the OFF position.5. Turn Ignition Switch (20) to START position. When engine starts, release switch to ON position.

6. Let machine warm up for a few minutes and then switch Control System Switch (8) to ON position.7. Check pump pressure gauges (fi g. 4-6) . Normal pressure when pumps are loaded is 3200 PSI

(241 bar). If not, check hydraulic system.8. Observe engine RPM display—Low idle is 1000 RPM, System Load (Intermediate) is 1500 RPM,

and High idle is 1800 RPM.

Start-up Procedure

NOTE

4-10 Start-up, Tramming and Shutdown

DO NOT tram machine on steep inclines, or horizontal to grades; this greatly increases risk of machine rollover.DO NOT tram machine on soft or unstable ground, or close to unsupported excava-tions.When tramming on slopes with cab machines equipped with fi ve or six rod changer, the Oscillation Control Switch MUST BE in the LOCK position.

Tramming

Retract the telescopic boom when tramming over rough ground and during long moves. Place feed in horizontal position with top of feed resting on mast rest (if equipped).

DO NOT allow feed to come in contact with or come near high voltage lines. See mini-mum clearances from high voltage lines chart in Safety Section.

1. Place Tram/Drill Switch (14, fi g. 4-4) in the TRAM position.2. Place feed in horizontal position when tramming over rough ground and during long moves.

3. Oscillation Lock Switch (16, fi g. 4-4) should be in the UNLOCK position when tramming and oscil-lation is automatically locked in drill mode.

4. Engine Idle Low/High Switch (12, fi g. 4-4) controls high engine idle speed and low engine idle speed. The engine idle speed increases or decreases maximum fl ow available for tramming. High engine idle provides approximately 2.5 m.p.h. Low engine idle provides approximately 1.2 m.p.h.

5. To maneuver the machine, the Function switch must be in TRAM mode and the Control System switch must be ON.

6. Using the L.H. joystick, squeeze the dead-man switch to release the brakes, then move it forward or backward (very slowly). To turn the drill, start forward or backward fi rst and then move the joy-stick to right or left without allowing the joystick to return to the center position.

One Joystick Tram

NOTE

NOTE When tramming on side slopes, swing boom to the uphill side of the machine for better stability. Keep cab on uphill side of machine. For close maneuvering of machine place the Engine Idle Switch in LOW position.

Normally when tramming, the track oscillation cylinders are in the unlocked condi-tion, however when tramming on slopes with a cab machine equipped with a fi ve or six rod changer the track oscillation cylinders must be in the locked condition.

Start-up, Tramming and Shutdown 4-11

1. Place Tram/Drill Switch (14, fi g. 4-4) in the TRAM position.2. Place feed in horizontal position when tramming over rough ground and during long moves.

Normally when tramming, the track oscillation cylinders are in the unlocked condi-tion, however when tramming on slopes with a cab machine equipped with a fi ve or six rod changer the track oscillation cylinders must be in the locked condition.

3. Oscillation Lock Switch (16, fi g. 4-4) should be in the UNLOCK position when tramming and oscil-lation is automatically locked in drill mode.

4. Engine Idle Low/High Switch (12, fi g. 4-4) controls high engine idle speed and low engine idle speed. The engine idle speed increases or decreases maximum fl ow available for tramming. High engine idle provides approximately 2.5 m.p.h. Low engine idle provides approximately 1.2 m.p.h.

5. To maneuver the machine use the L.H. and R.H. joystick controls. To turn machine, push one joystick forward while pulling the other joystick back. Pushing both joysticks forward will move the machine forward, pulling both joysticks back will move the machine in reverse.

When tramming on side slopes, swing boom to the uphill side of the machine for better stability. Keep cab on uphill side of machine. For close maneuvering of machine place the Engine Idle Switch in LOW position.

Tramming

Two Joystick Tram

NOTE

NOTE

4-12 Start-up, Tramming and Shutdown

BEFORE attempting to operate or service this machine, read and understand the warn-ings and cautions listed in Section 1.DO NOT operate or shutdown the machine with the feed positioned over the operator. Plant (sting) the feed prior to extended shutdowns.

1. Set feed on ground.2. Place all tramming and drilling controls in the OFF or NEUTRAL position.3. Place Control System ON/OFF Switch to OFF, this will allow engine to run at low idle. 4. Switch Drill/Tram switch to NEUTRAL or OFF position.5. Let engine idle at low speed for about 3 minutes, then turn ignition switch to OFF position.6. If machine will be shut down for an extended period, switch the Battery Disconnect switch to OFF

(fi g. 4-2). This will prevent excess battery drain.

Shutdown Checklist

Drilling Procedures 5-1

Section 5

Drilling Procedures

5-2 Drilling Procedures

Linear Rod Changer

Fig. 5-1 L.H. Joystick Control

Fig. 5-2 R.H. and Drill Joystick Controls

Fig. 5-3 Cab Control Panel

Drilling Procedures 5-3

Loading Drill Rod

ALWAYS check for obstructions before moving feed or machine.DO NOT allow any part of the machine to contact or come near electrical power lines.

Apply adequate lubricant to all couplings and drill rod threads before loading.

1. Do not lay drill rod on ground. Put wood blocks under drill rod and keep threads clean.2. Grease threads with coupling grease on upper end of drill rod and install coupling. Make sure each

piece of drill rod has a coupling on the upper end.3. Select DRILL position with switch (14, fi g. 5-3). Select ROD CHANGER position with switch (13, fi g.

5-3).4. Push lower left button (8) on R.H. joystick to UNLOCK rod rack carriage. Move R.H. joystick FOR-

WARD to move carriage out. Use Drill joystick to run drill to bottom of feed so drill shank is positioned just above centralizer. Be sure drill shank is aligned with centralizer when it is closed, if not refer to Service Manual for alignment procedure. Open centralizer jaws.

5. Tilt the feed to a suitable angle which will allow insertion of drill rod through dust collector pick-up pot and be able to align with the drill shank.

6. Open the centralizer (L.H. armrest middle switch) and position drill rod through dust collector pickup pot and hold in alignment with the shank.

7. Use Drill joystick and synchronize thread button (4) to thread the shank into the coupling.8. Raise the drill and rod so coupling is above the centralizer and close the centralizer. 9. Move L.H. joystick to LEFT to swing wrench IN and clamp the drill rod. Move L.H. joystick RIGHT

slightly to open the wrench so it is not clamped on the drill rod. The wrench is now in the "guide" position for the drill rod. Continue to raise the drill up towards the top of the feed so the top coupling is above the upper rack.

10. Press and hold button (8) to UNLOCK rod rack carriage. Move R.H. joystick BACK to move rod car-riage IN towards feed. Position rod rack so drill rod is aligned with the outermost socket (farthest from the feed). Release button (8) lock pin will lock into next position.

11. Using the Drill joystick, lower the drill rod until the coupling is level with the upper rod rack.12. Move the L.H. joystick to RIGHT to LOCK drill rod. This pulls the rod lock bar to lock on the coupling.

Slowly reverse the rotation and raise the drill to unthread the shank from the coupling.

NOTE

Linear Rod Changer

Never wear loose fi tting clothing when working around machinery.

Three people are required to perform this procedure. One operator and two people loading drill rod.

5-4 Drilling Procedures

Linear Rod Changer

Fig. 5-1 L.H. Joystick Control

Fig. 5-2 R.H. and Drill Joystick Controls

Fig. 5-3 Cab Control Panel

Drilling Procedures 5-5

Linear Rod Changer

13. Push L.H. joystick button (9) to unclamp and swing rod wrench OUT.14. Press and hold lower left button (8) to UNLOCK rod rack carriage. Move R.H. joystick FORWARD to

move rod rack carriage OUT.15. Using Drill joystick, run drill down the feed and repeat steps 5–13 until all drill rod is loaded in rod

rack.16. Leave the last rod coupled to the drill. Grease the threads and install drill bit.

Loading Drill Rod (cont.)

5-6 Drilling Procedures

Fig. 5-1 L.H. Joystick Control

Fig. 5-2 R.H. and Drill Joystick Controls

Fig. 5-3 Cab Control Panel

Carousel Rod Changer

Drilling Procedures 5-7

Loading Drill Rod

ALWAYS check for obstructions before moving feed or machine.DO NOT allow any part of the machine to contact or come near electrical power lines.

Apply adequate lubricant to all couplings and drill rod threads before loading.

1. Do not lay drill rod on ground. Put wood blocks under drill rod and keep threads clean.2. Grease threads with coupling grease on upper end of drill rod and install coupling. Make sure each

piece of drill rod has a coupling on the upper end.3. Select DRILL position with switch (14, fi g. 5-3). Select ROD CHANGER position with switch (13, fi g.

5-3).4. Move L.H. joystick RIGHT and push the yellow button (9) to swing jaws into store position. Move R.H.

joystick FORWARD to move carriage out. Use Drill joystick to run drill to bottom of feed so drill shank is positioned just above centralizer. Be sure drill shank is aligned with centralizer when it is closed, if not refer to Service Manual for alignment procedure. Open centralizer jaws.

5. Tilt the feed to a suitable angle which will allow insertion of drill rod through dust collector pick-up pot and be able to align with the drill shank.

6. Open the centralizer (L.H. armrest middle switch) and position drill rod through dust collector pickup pot and hold in alignment with the shank.

7. Use Drill joystick and synchronize thread button (4) to unthread the coupling.8. Raise the drill and rod so coupling is above the centralizer and close the centralizer. 9. Push the white (10) to swing the jaws in and then move the L.H. joystick to the LEFT to clamp the drill

rod. Move L.H. joystick RIGHT slightly to open the jaws so they are not clamped on the drill rod. The jaws are now in the "guide" position for the drill rod. Continue to raise the drill up towards the top of the feed so the top coupling is above the upper rack.

10. Move L.H. joystick LEFT to clamp rod with jaws.11. Push the white (10) button to swing rod into the carousel. Move L.H. joystick RIGHT until jaws are

fully open.12. Push R.H. joystick back to rotate carousel clockwise to move rod out of the way of the jaws.13. Move the L.H. joystick to RIGHT to LOCK drill rod. This pulls the rod lock bar to lock on the coupling.

Slowly reverse the rotation and raise the drill to unthread the shank from the coupling.

NOTE

Never wear loose fi tting clothing when working around machinery.

Three people are required to perform this procedure. One operator and two people loading drill rod.

Carousel Rod Changer

5-8 Drilling Procedures

Fig. 5-1 L.H. Joystick Control

Fig. 5-2 R.H. and Drill Joystick Controls

Fig. 5-3 Cab Control Panel

Carousel Rod Changer

Drilling Procedures 5-9

14. Using Drill joystick, run drill down the feed and repeat steps 5–12 until all drill rod is loaded in rod rack.

15. Leave the last rod coupled to the drill. Grease the threads and install drill bit.

Loading Drill Rod (cont.)

Carousel Rod Changer

5-10 Drilling Procedures

Drill Positioning Procedure

To Position Feed for Vertical Drilling

1. There are two options available: A. The vertical indicator (fi g. 5-4)—Follow the instructions for setting the feed plumb. B. Pendulum (fi g. 5-5) —Position feed plumb by watching the pendulum. When pendulum is centered

in the ring, feed is plumb.2. When feed is plumb, plant the stinger fi rmly into ground using the Drill joystick. This will prevent the

feed from "kicking out" when collaring the hole.

Vertical IndicatorThe angular display is connected to the sensor mounted on the feed. There are 10 display lights in

each axis (Y+, Y–, X+ and X–). The maximum angle from plumb is + or – 6 degrees, thus each light rep-resents 0.6 degrees. The lights remain lit if the feed is more than 6 degrees from plumb. The lights will go out successively as the feed approaches plumb in each direction.

Vertical Adjustment

1. Position feed vertical (plumb) and adjust the sensor to indicate plumb (no lights on).2. Move feed to non-vertical position, then move back until all lights go out (plumb). Feed should be

plumb within + or - 0.6 degrees.

Fig. 5-4 Vertical Indicator Mounted in Cab

Fig. 5-5 Feed Assembly1. Pendulum2. Stinger

Drilling Procedures 5-11

To Position Feed for Angle Drilling

1. There are two options available: A. The use of an electronic angle indicator is recommended if much angle drilling is to be done. B. If only a few angle holes are required, you can measure the feed angle with magnetic base ad-

justable protractor.2. When feed is set at desired angle, plant the stinger fi rmly into ground using the Drill joystick. This will

prevent the feed from "kicking out" when collaring the hole.

When machine is in position and feed is set at the desired angle for drilling you are ready to begin drilling the fi rst hole. Refer to drilling procedures in this section.

Check to be sure that:• Track Oscillation Cylinders are Locked.• Drill/Tram Selector Switch is in DRILL position.• System display readings are in normal operating range.• Drill steel is loaded and secured in rod rack.• Adequate supply of sharp drill bits.• Adequate supply of coupling grease is on hand for greasing drill steel, shank and coupling threads.• Grease gun and grease (PG55, P/N 312810 recommended) on hand to grease drill front end every

two hours of drill operation.• Drill accumulator charge pressure has been checked.

Final Checks

Drill Positioning Procedure

5-12 Drilling Procedures

Drilling Practices

Tips for top drilling performanceCollaring

The collar of the drill hole will directly determine the quality of the hole.

Hole DeviationThe major cause of drill steel breakage is deviation of the drill hole. There is very little tolerance in

the drill string for any deviation, due to the high energy output of the rock drill.

Feed Pressure"Under-feeding" is a particularly common and bad practice. Feed pressure must be kept to the bit at

all times while drilling. "Free-hammering" (hammering with no load on the bit) and "under-feeding" will shorten the drill string life and the hammer seals.

Drill PressuresFeed and hammer pressures and rotation fl ow can and should be adjusted to suit different rock

conditions. Optimum settings are reached when the maximum penetration rate is achieved with minimal heat and vibration being generated through the drill string. Incorrect drill pressure settings can be directly related to hole deviation and drill string damage and breakage.

Adjusting Drill Pressure and Monitoring the MachineThe operator should attempt to maintain a minimum amount of feed pressure, just enough to keep

the drill steel couplings tight. This will ensure smooth drilling and maximize penetration rate by:• Minimizing heat in the drill string• Eliminating "under and over feeding"• Minimizing rotation pressure

Rotation fl ow should be increased in softer rock and decreased in harder rock as indicated by the penetration rate.

Monitoring of the machine is critical at all times. Monitoring of the machine gauges is especially critical for those unfamiliar with the drill. Increases in air and /or rotation pressures indicate developing blockage and / or jamming situations.

Plugged Bit and Stuck Drill SteelAlways be alert of air and cuttings coming out of the hole, if not STOP DRILLING. If bit becomes

plugged. When blowing air is stopped by a plugged bit, the drill string can become stuck quickly. Work the bit up and down the hole with hammer and rotation on until air and cuttings can be seen coming out of the hole. If bit remains plugged, raise bit out of hole and place bit against solid rock or hard wood and turn hammer on in short bursts with air on to dislodge obstruction. If bit still remains plugged, shut down machine and relieve all air pressure before removing bit. Clear bit manually and reinstall.

If drill steel becomes stuck, use the reverse percussion option (if equipped) to "hammer out" of the hole. If machine is not equipped with this option, use the feed override lever to apply extra reverse feed pressure. Work the drill string up and down using slow rotation speed with blowing air on until it is free.

Using the "smart drill" option (if equipped) will help prevent stuck steel due to bad ground. Refer to "smart drill" system operation in this section.

Drilling Procedures 5-13

Drilling Practices

System Readings for Clay or Soft Ground.Clay or soft ground may need lower feed pressure. To maintain the correct differential pressure between feed and hammer pressure, and to avoid shortened hammer seal and consumable life, the hammer pressure needs to lowered accordingly.

System Readings for Solid Rock.To maximize penetration rate in solid rock, higher hammer pressure is required. To maintain the correct dif-ferential between hammer and feed pressures, and to prevent "under-feeding", the feed pressure needs to be raised accordingly.

5-14 Drilling Procedures

Manual Drilling

Fig. 5-1 L.H. Joystick Control

Fig. 5-2 R.H. and Drill Joystick Controls

Fig. 5-3 Cab Control Panel

Drilling Procedures 5-15

Manual Drilling

KEEP all non-essential personnel away from the hole and machinery while drilling is in progress.DO NOT re-drill a hole that has contained explosives.DO NOT strike drill rod to dislodge it while drill is operating. Fragmentation of the drill rod may result.

WORN THREADS on the drill string can cause premature wear and breakage to new parts mated with the drill string.USE sharp bits. Check for broken or loose carbides. Dull bits can cause stress in drill components.APPLY adequate lubricant to all couplings and drill rod threads before loading.CHECK rock conditions before operating drill rotation and feed at full throttle. Over feeding and over rotation can cause breakage of drill rotation parts and drill string.Place WARM OIL switch (4) in ON position before starting to drill. Drill will not operate when oil is cold. Leave control in WARM OIL position for a few minutes until oil reach-es a minimum of 60oF (15.5oC).

Collaring the HoleIt is not normally possible to immediately start drilling a new hole at full rotation and feed pressure.

At full power the bit will tend to jump around enlarging the hole and possibly changing the sting location and angle. Collaring allows accurate drilling by eliminating bit jumping. Initial drilling is performed at low rotation and feed pressure until the hole is deep enough so that the bit is guided by the hole. Hole depth should be about 3 in. (76.2 mm) deep in solid rock.

1. Turn dust collector switch (11, fi g. 5-3) to ON position or turn water switch (15, fi g. 5-3) ON and adjust metering valve (behind seat) to regulate water fl ow if using detergent system.

2. Slowly start forward drill rotation by placing Drill joystick in LEFT position about 1/2 way.3. Slowly engage feed DOWN with Drill joystick (back) to lower drill. Stop when bit contacts ground.4. Position air switch so blowing air is about 1/2 way open. Push collar button (3) on Drill joystick after

oil has warmed up. Apply some feed pressure, using Drill joystick (back) to collar the hole. Stay in "collaring" mode until the hole is about 3 in. (76.2 mm) deep in solid rock.

5-16 Drilling Procedures

Manual Drilling

Fig. 5-1 L.H. Joystick Control

Fig. 5-2 R.H. and Drill Joystick Controls

Fig. 5-3 Cab Control Panel

Drilling Procedures 5-17

1. Once hole is collared, move air switch to fully OPEN position.2. Move Drill joystick to full LEFT position and push full hammer button (1).3. Maintain proper feed pressure. If rod starts to bow, you are using too much feed pressure. If drill starts

to bounce, or excessive heating in coupling is evident, you are not using enough. Use feed force knob (10, fi g. 5-3)) to adjust feed pressure.

• If air and cuttings stop coming out of the hole, the bit is becoming plugged and must be pulled back immediately. When the blowing air is stopped by a plugged bit, the bit and drill rod can become stuck very quickly.

• Work the bit up and down with the drill and rotation ON until cuttings can be seen coming from the hole.

• If the bit cannot be cleared, the drill rod and bit must be pulled out of the hole. Try placing bit on solid rock or hard wood and push full hammer button (1) on Drill joystick to clear bit. If bit remains plugged, you will have to shutdown the machine and let the air pressure bleed off and then remove bit and manually unclog bit and or drill rod.

• If the downward movement of the drill rod increases suddenly, this may mean that the bit has drilled into a void, crack or some soft material. Use Drill joystick to slow down the forward travel of the bit.

• If the rotation begins to slow down or stops, the bit must be pulled back immediately. Reduce the feed speed to drill through broken ground.

• If bit keeps getting plugged or the rotation continues to jam, pull out the drill rod and start another hole a safe distance away.

4. As drill rod coupling approaches centralizer, open centralizer to allow the coupling to pass through.5. When drilling cycle is complete, turn off feed, hammer, rotation and air. If required, add another piece

of drill rod (described in detail, following) and continue drilling or raise drill up until bit clears the hole and move to next hole.

ALWAYS shutdown machine and let air pressure bleed off before removing a plugged bit.NEVER hammer on drill bit or rod. Fragmentation may occur, causing serious injury.

Never continue drilling if cuttings stop coming from the hole. Always pull back the bit. Do not restart drilling again until air is coming from the hole.Shut off dust collector if water is coming out of the hole. This will plug the dust col-lector fi lters. Turn dust collector on after water stops coming out of the hole.It may be necessary to remove the dust collector hose from the pickup pot to avoid clogging the hose with mud. Connect the hose when dry drilling resumes.

Manual Drilling

NOTE

5-18 Drilling Procedures

Smart Drill Feature

Fig. 5-1 L.H. Joystick Control

Fig. 5-2 R.H. and Drill Joystick Controls

Fig. 5-3 Cab Control Panel

Drilling Procedures 5-19

Smart Drill Feature

1. Once hole is collared, move air switch to fully OPEN position.2. Move Drill joystick to full LEFT position.3. Turn smart drill switch (17, fi g. 5-3) ON.

• If bit keeps getting plugged or the rotation continues to jam, pull out the drill rod and start another hole a safe distance away.

4. As drill rod coupling approaches centralizer, the centralizer must be opened to allow the coupling to pass through.

5. When the drilling cycle is completed, turn off feed, hammer, rotation and air. If required, add another piece of drill rod (described in detail, following) and continue drilling or raise drill up until bit clears the hole and move to next hole.

ALWAYS shut down machine and let air pressure bleed off before removing a plugged bit.NEVER hammer on drill bit or rod. Fragmentation may occur, causing serious injury.

General DescriptionThe "Smart Drill" feature allows for assisted drill control. The system senses rotation and air pres-

sure changes and automatically adjusts feed force and hammer power output. It operates as an anti-jam system and greatly reduces the possibility of stuck drill rod. If the bit becomes plugged, the air pressure rises and shuts off the hammer and reverses the direction of the feed. If the drill rotation slows, rotation pressure rises which sends a signal to the feed. The feed force is then adjusted accordingly until normal drill rotation resumes. This system greatly enhances drilling effi ciency and reduces operator error. The driller can override the "Smart Drill" system by turning off the smart drill switch (17, fi g. 5-3) and manually adjusting the feed force with the Drill joystick.

OperationBegin drilling the same as you would for manual drilling as described previously.

Never continue drilling if cuttings stop coming from the hole. Always pull back the bit. Do not restart drilling again until air is coming from the hole.Shut off dust collector if water is coming out of the hole. This will plug the dust col-lector fi lters. Turn dust collector on after water stops coming out of the hole.

NOTE

5-20 Drilling Procedures

Linear Rod Changer

Fig. 5-1 L.H. Joystick Control

Fig. 5-2 R.H. and Drill Joystick Controls

Fig. 5-3 Cab Control Panel

Drilling Procedures 5-21

Linear Rod Changer

Adding Drill Rod

After the fi rst length of drill rod has been drilled to depth (coupling and shank even with top of central-izer jaws):

1. With full blowing air ON, raise the bit just above the bottom of the hole. Be sure bit is not plugged or jammed with loose material above it.

2. Move Drill joystick to NEUTRAL position and place air switch to OFF position.3. Press full hammer button (1) to turn OFF.4. Turn hammer on and off in short bursts until drill string is loose. Use some reverse (clockwise) drill

rotation if necessary. Loosening of the drill rod can be noted by a change in sound (hammer frequency) of the drill string.

5. Use the centralizer switch to close centralizer around the drill rod coupling.6. Use the synchronized threading button (4) on the Drill joystick to unthread rod. When drill shank is

in line with automatic thread grease nozzle (fi g. 5-6), push coupling grease button (2) to grease drill shank thread.

7. Raise drill towards top of feed, so drill shank is above upper rod rack.

Fig. 5-6 UFH Chain Feed1. Grease Nozzle2. Centralizer

NOTE It is a good idea to run the bit up and down the hole a few times with full blowing air on and forward rotation on. This will clear the hole of loose cuttings to prevent stuck drill rod.

5-22 Drilling Procedures

Linear Rod Changer

Fig. 5-1 L.H. Joystick Control

Fig. 5-2 R.H. and Drill Joystick Controls

Fig. 5-3 Cab Control Panel

Drilling Procedures 5-23

8. Press and hold carriage unlock button (8) on R.H. joystick to UNLOCK rod rack carriage. Move right joystick BACK to move carriage IN towards feed to position fi rst drill rod under drill shank. Release unlock button (8) on R.H. joystick, locking pin will automatically locate the drill rod position.

9. Use synchronized threading button (4) on Drill joystick to thread rod. Continue until coupling is tight.

10. Push L.H. joystick button (10) to move Rod Wrench to IN position. This swings wrench into position and clamps around the drill rod. Push L.H. joystick button (9) slightly to open the wrench so it is not clamped on the drill rod. The wrench is now in the "guide" position for the drill rod.

11. Raise the drill to clear the coupling from the upper rod rack.12. Move R.H. joystick to LEFT to UNLOCK drill rod. This moves the lock bar IN towards feed to release

the drill rod.13. Press and hold carriage unlock button (8) on R.H. joystick to UNLOCK rod rack carriage. Move the

right joystick FORWARD to move rod carriage OUT. Release the carriage unlock button (8), the locking pin will automatically engage in next position in the rod rack.

14. Move R.H. joystick to RIGHT to LOCK drill rod. This moves the lock bar OUT away from feed to lock the drill rod in place.

15. Lower the drill until the threads of the drill rod are in line with the automatic thread grease nozzle (fi g. 5-4), activate coupling grease button (2) on Drill joystick to grease threads.