Room-temperature scavengers for macromolecular crystallography

Manage hydrogen sulfide hazards with chemical scavengers

Transcript of Manage hydrogen sulfide hazards with chemical scavengers

®

Safety DevelopmentsG. KENRECK, GE Water & Process Technologies, The Woodlands, Texas

Manage hydrogen sulfide hazards with chemical scavengers

Hydrogen sulfide (H2S) and its associated hazards are well known in the oil and gas production and refining industries. Legislation has been in place for years, imposing strict regula-tions on H2S levels of hydrocarbon streams in pipelines, and in storage and shipping containers and in marine fuels. A va-riety of chemical scavengers are available to reduce both the concentration and corresponding hazards of H2S in produced water, produced gas, crude oil and refined products. There are several pros and cons for the most common chemistries used to scavenge H2S. The associated effectiveness and the potential downstream impacts of these scavengers will be explored here. Guidelines will be presented to facilitate the selection of the most appropriate scavenger chemistry and application method to reduce H2S efficiently and in a cost-effective manner.

Toxic gas. H2S is a highly toxic, flammable and corrosive gas that dissolves in hydrocarbon and water streams, and it is pres-ent in the vapor phase above these streams. It is found in natu-ral gas. Also, it occurs naturally in oil and gas production and is produced during refining processes. Therefore, safety precau-tions must be observed during extraction, storage, transporta-tion and processing of crude oil or natural gas.

Partitioning of H2S to the oil, water and vapor phases is in-fluenced by temperature, pH and pressure. Typical partition-ing ratios are listed in TABLE 1.

Hazards. In a gaseous state, H2S is extremely hazardous to health. It is heavier than air and will, therefore, collect in low places, such as the bottom of storage or shipping vessels. The human odor-detection limit ranges from 3 parts per billion (ppb) to 20 ppb—meaning that its presence may be detected long before it reaches a hazardous level. Once concentrations exceed 150 parts per million (ppm), H2S will cause olfactory fatigue, affecting the sense of smell such that the hazard is not recognized.2 Acute effects of exposure to H2S include head-aches, nausea, convulsions, coma and death. The health ef-fects at various exposure levels are shown in TABLE 2.

The flammability limits for H2S range from a lower explo-sive limit (LEL) of 4% to an upper explosive limit (UEL) of 44%. Again, as it is heavier than air, H2S can collect in low places, where any ignition source poses a significant danger of fire and explosion.

Finally, H2S is a corrosive acid that can cause embrittle-ment or sulfide stress cracking (FIG. 1) or pitting (FIG. 2), all

of which can potentially lead to leaks or spills of petroleum products and the subsequent exposure of personnel to H2S. Furthermore, the presence of water (H2O), salts or carbon di-oxide (CO2 ) can increase the corrosivity of H2S.

MANAGEMENT MORE REGULATEDBecause exposure to H2S can have such dire health conse-

quences, including death, regulations have been promulgated to manage H2S and minimize personnel exposure. Where ex-posure to H2S is possible, personnel are required to wear por-table detection devices and appropriate personal protection equipment (PPE), taking precautions if an “action-level” con-

TABLE 1. H2S equilibrium ratios

Fluid H2S equilibrium ratios

Naphtha, gasoline 1,000, vapor/1, liquid

Crude oil 100–200, vapor/1, liquid

Gasoil (GO), #6 oil 5–10, vapor/1, liquid

Oil/water 3.0–4.1 H2S, oil/ 1 H2S, water1

TABLE 2. Health effects at various H2S concentration levels2

H2S concentration Health effects

< 20 ppb Olfactory threshold (begin to smell)

5 ppm Increase in anxiety symptoms (single exposure)

5–10 ppm Relatively minor metabolic changes in exercising individuals during short-term exposures. Long-term exposure could result in headaches, insomnia, nausea, eye or throat irritation, or shortness of breath

10 ppm–30 ppm Moderate irritation of the eyes

> 30 ppm Short-term exposure can result in olfactory fatigue (sense of smell is significantly impaired)

100 ppm Immediately dangerous to life and health concentration

150 ppm–200 ppm Olfactory nerve paralysis, eye irritation, potential damage to cornea

100 ppm–1,000 ppm Serious respiratory, central nervous and cardiovascular system effects

> 1,000 ppm Loss of consciousness and possible death

5,000 ppm Immediate death

Originally appeared in:December 2014, pgs 73-76.Used with permission.

HYDROCARBON PROCESSING DECEMBER 2014

Safety Developments

centration is detected.3 In addition, specifications are being established to reduce levels of H2S in petroleum products and to subsequently reduce the hazard of handling and transport-ing these products around the world. TABLE 3 lists some of these regulations and specifications. It is important to note that regu-lations, such as CFR 1910.1000, are enforceable by law. Other specifications, however, such as ISO 8217, are not regulated by law but are commercial requirements.

PROS AND CONSSeveral classes of chemicals effectively lessen the hazards

associated with H2S. Selection of an appropriate chemical H2S scavenger, combined with its proper application, can help meet product specifications and comply with the regulations now en-countered in the oil industry. As each application may be unique, characteristics to be considered when selecting an H2S scavenger should include treatment economics, ease of handling and use, efficiency of reaction, selectivity for H2S and irreversibility. Se-lecting the wrong scavenger can result in negative downstream impacts. For example, if a metal salt is used in a fuel oil, it may result in the ash content limit being exceeded and require the fin-

ished fuel to be discounted in price or reprocessed. Detailed de-scriptions of several types of H2S scavengers are provided here:

Triazine has been the benchmark H2S scavenger for de-cades, especially in the oil field. Triazine is a reaction product of an amine (nitrogen-based) and formaldehyde. Although formaldehyde is a listed carcinogen, in this form, the formalde-hyde reactivity is retained without the adverse health impact. Amines, such as methyl amine (MA) or monoethanolamine (MEA), are used to produce water-based triazines; whereas higher-molecular-weight amines, such as methoxypropylamine (MOPA), are used to produce a water-free (oil-soluble) version.

Triazine reactions are well documented. The primary reac-tion product is dithiazine. One mole of triazine, regardless of the amine used to produce the triazine, will generally react with two moles of H2S and liberate two moles of amine.

The weight of amine released will vary depending on the amine, but the moles of nitrogen released are identical. This is important to know since the nitrogen contribution on a weight basis to the treated fluid will be the same regardless of the amine used to create the triazine. In some cases, when a crude oil has been treated with triazine, the amines released in the reaction can stabilize emulsions and deteriorate desalter performance. They can also contribute to chloride salt formation and deposition in distillation towers, with subsequent increases in corrosion and fouling potential. The nitrogen released can ultimately end up at the wastewater treatment plant (WWTP) and negatively impact the equalization basin performance and microorganism health.

Triazines generally are more effective at higher pH ranges because, as illustrated in FIG. 3,4 triazine half-life is exponentially reduced as pH decreases. Because triazines release amines that increase the pH of a system, it has been shown that the use of tri-azine in oil production can negatively impact the performance of scale inhibitors by decreasing the solubility of calcium carbonate

FIG. 2. Localized corrosion, typical of sulfide pitting.

0.00010.001

0.01

0.1

1

10

100

1,000

0 2 4 6 8 10

Triaz

ine ha

lf-lif

e, se

c

pH

Triazine half-life as a function of pH

FIG. 3. Effect of pH on triazine.4

TABLE 3. Regulatory history for H2S

29 CFR 1910.1000 (7/1/98)

29 CFR 1915.1000 Maritime sub regulation

NIOSH; Occupational Exposure to Hydrogen Sulfide (1977) DHEW (NIOSH) Publication 77-158

US Department of Transportation, 2000 Emergency Response Guidebook, RSPA P 5800, 8th Ed.

MARPOL Annex VI

ISO 8217 H2S in marine fuels

FIG. 1. Example of sulfide stress cracking.

HYDROCARBON PROCESSING DECEMBER 2014 HYDROCARBON PROCESSING DECEMBER 2014

Safety Developments

(CaCO3 ) in produced water.5 This, in turn, can lead to an increase in the scale inhibitor needed to achieve the desired inhibition.

Finally, findings presented by the Esbjerg Institute of Tech-nology at Aalborg University6 have shown that various side re-actions can occur when H2S is the excess reactant in scavenging applications. Dithiazine can undergo further reaction to form an amorphous dithiazine (FIG. 4) and can contribute to deposition and equipment fouling. These reactions can be avoided when us-ing the correct treatment level of triazine in the application.

Due to its long-standing industry acceptance, combined with its perceived economic benefit, triazine will most likely continue to play a significant role as an H2S scavenger for years to come. However, as crudes become more sour and the H2S content in-creases, triazine treatment levels will escalate as well. When this happens, the potential negative downstream impact associated with triazine may encourage the use of other types of chemistries.

Metal salts of organic acids (iron, zinc and magnesium) typically react with H2S to form nonvolatile byproducts. In gen-eral, metal salts are water-free. Water-free scavengers may be desirable in applications where temperatures exceed 350°F. Al-though reaction kinetics may be slower, compared to other types of scavengers, these metal salts may blend more easily into hy-drocarbon streams. However, metals and their byproducts can contribute to fouling in exchangers or reactors, as well as increase the ash content in finished fuels. Therefore, this class of scav-enger is generally used for reducing H2S levels in bitumen, but would not be appropriate for use in refinery feedstocks and fuels.

Formaldehyde and acrolein are very reactive with H2S, however, they are typically not recommended as scavengers because of the health hazards associated with their use and handling. Formaldehyde is a listed carcinogen, and acrolein is a highly toxic gas. Reaction products may decompose in the refin-ery furnaces to form methyl sulfides or carbon disulfide (CS2), which may have deleterious downstream impacts, such as cata-lyst poisoning during processing of treated petroleum products.

Mixing oxidizers and organics is generally restricted by best practices; therefore, the use of oxidizers, such as hydro-gen peroxide or nitrites/nitrates, to scavenge H2S is not ap-propriate for petroleum streams but they can be used in water systems. However, they are not considered to be economically effective, and the handling of hydrogen peroxide presents ad-ditional risk of fire or explosion.

Amines are relatively safe to handle, less expensive and fair-ly effective chemicals for scavenging H2S. In fact, gas desulfur-ization units use various amines to remove H2S from the gas. Unfortunately, the reaction with H2S is reversible as tempera-tures increase or pH decreases. Amines also react with CO2 and certain acids. In many cases, these aspects limit the application of amines. The low solubility of amines in fuels and their reac-tion byproducts also tend to limit their use.

Oil-based aldehyde derivatives can be used for scaveng-ing H2S in gas or high-temperature applications. This class of chemicals may not truly be oil-soluble but are water-free and are delivered in a polar organic solvent to prevent the introduc-tion of water. The overall treatment cost of these products is generally higher than water-based alternatives.

Non-amine chemistry is the final class of scavengers ad-dressed here, and this class includes aliphatic aldehydes that re-act effectively with H2S. The treatment cost is similar to that of

triazines. These scavengers are relatively safe to handle and do not produce amines from their reaction with H2S. This avoids the problems associated with the use of triazines—specifically, nitrogen impact at the WWTP and corrosive amine chloride formation in refining process equipment. This chemistry also minimizes the formation of CS2 and similar sulfur compounds that have been found to migrate to naphtha cuts and poison process catalysts. Non-amine H2S scavengers are especially beneficial in treating crude oils and refinery feedstocks. They have also been used in light distillate fuels to scavenge H2S when nitrogen contamination is a concern.

SCAVENGER SELECTIONThe proper selection of the chemistry and application

methodology is determined by the fluid to be treated, the sys-tem where the scavenger will be injected into the fluid, and the end use of the fluid to be treated. There are several applications and treatment options worthy of exploration.

Crude oil may be treated as it is produced to prevent per-sonnel exposure to H2S. Treatment at the wellhead, or as oil is transferred to tankage, or as containers are being loaded or unloaded, is essential to reducing the risk of exposure to H2S. However, the production of more sour crudes and higher-sulfur crudes results in increased scavenger levels in the crude oil. This may amplify the negative downstream impacts. The oil producer may understand the value of treatment, but may not fully grasp the magnitude of the downstream impacts that those chemicals can have in the refining process and even in finished fuel quality. Triazines have been successfully used to reduce H2S in crude oil, but, they can also contribute to mul-tiple downstream issues. The use of non-amine scavengers can help avoid many of these problems.

Gas produced at the wellhead may be high in H2S. How-ever, treatment at the point of production can be costly, and can also cause fouling, corrosion or scale deposition in gas pro-cessing and transmission systems. Typically, natural gas is de-

OH

HO+H2O+

SH

HSSH

SHO

N

S S

OH

OH

HNHS

S S

N

S S

N

S SHN

S S

N

SH SHSO SO

S S

SS

O SS

S S

FIG. 4. Formation of amorphous dithiazine.6

HYDROCARBON PROCESSING DECEMBER 2014 HYDROCARBON PROCESSING DECEMBER 2014

Safety Developments

sulfurized in amine absorbers. Where this is not possible, scav-engers may be needed. In this case, attention should be given to the potential downstream impacts. Triazines have been used in gas systems, but, when they are injected into an H2S-rich environment, they may form amorphous dithiazine or trithi-ane. This, in turn, can cause fouling or deposition in control valves or compressors. Oil-based scavengers have been used in these applications; however, proper liquid removal equipment is required downstream of the application to prevent the reac-tion products from carrying down the pipeline. Triazines and amines have been successfully used in liquefied light petro-leum fractions where water-based reaction products are easily removed and the H2S is effectively reduced.

GO and heavy cuts of petroleum products, such as fuel oils, are processed at elevated temperatures. Application of scaven-gers above 350°F may require water-free chemistry. Amines can be used, provided the fluid will not be further processed or refined, due to the deleterious effects previously described. Water-based triazines have been successfully used in high-tem-perature applications when the injection point is located in a rundown line and the temperature is below 350°F. Since these hot streams are usually below the saturation limit for water, the water from the scavenger can solubilize, thus minimizing the potential for steam formation and the associated pressure and flashing or foaming in the storage tanks. Distribution of the scavenger into viscous fluids is also a challenge; therefore, a properly installed injection system that distributes the additive into the fluid to be treated is essential for effective performance.

Gasoline and naphtha occasionally require treatment to reduce H2S levels. In some cases, the petroleum fluid is well be-low the saturation limit for water. In these cases, special atten-tion must be taken to ensure efficient reaction and prevent de-hydration of the scavenger. Amines, triazines and non-amines have been used to effectively scavenge H2S in these streams.

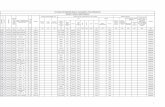

The different H2S scavenger chemistries are summarized in TABLE 4, along with application areas and typical treat rates.

APPLICATION METHODOLOGYThe application methodology for H2S scavengers is very

important for effective performance, and each application is unique. Therefore, site-specific application methodologies and dose requirements should be established by an application expert. Proper treatment levels for H2S scavengers depend on many factors such as system size, unit operating conditions and system design. In most cases, for consistent effectiveness, H2S scavengers should be fed continuously by a chemical propor-

tioning pump. Injection location and feedrates vary depend-ing on system design and stream composition. For best per-formance, H2S scavenger programs should be conscientiously evaluated by routinely recording critical unit parameters in-cluding feed composition, temperature and program targets. Use this information to make adjustments to the chemical feed rate and the measured H2S concentrations in the treated fluid.

The application methodology is critical for both effective performance and optimum economics. For example, either under-treatment or overtreatment with triazines can have se-rious consequences. Either case could occur if the application system for the scavenger is not properly designed to optimize the amount of scavenger that is to be used. Under-treatment could leave H2S residuals and not fully mitigate the risks asso-ciated with H2S. Overtreatment can stabilize emulsions, nega-tively impacting desalter performance. If additional amine content is added, this increases the potential for chloride salt formations in process equipment. It also boosts nitrogen load-ing to the wastewater plant.

MAKE THE FINAL DECISIONProper selection and application of H2S scavengers can ef-

fectively lower H2S levels in hydrocarbon fluids and reduce the risk of personnel exposure to the potentially lethal hazards of H2S. The properties, effectiveness and impacts of chemicals used to reduce H2S are important factors to consider when se-lecting an H2S scavenger. Selecting the proper injection system and location can improve the efficiency of the treatment of H2S and the performance of the application. An experienced appli-cation specialist who understands the aspects of scavengers and appropriate application methodology can design an effi-cient and effective program that can reduce the overall treat-ment cost and risks associated with H2S, while also meeting H2S specifications.

LITERATURE CITED 1 Eden, B., P. J. Laycock and M. Fielder, Oil Field Reservoir Souring, HSE Books,

ISBN 0-7176-0637-6, 1993. 2 Skrtic, L., “Hydrogen Sulfide, Oil and Gas, and People’s Health,” May 2006. 3 Wanek, R., “Monitoring H2S to meet new exposure standards,” Drager Safety. 4 Bakke, J. M., J. Buhaug and J. Riha, “Hydrolysis of 1,3,5-Tris(2-hydroxyethyl)

Hexahydro-s-triazine and its Reaction with H2S,” Ind Eng Chem Res, 2001, 40, 6051-6054.

5 Sumestry, M. and H. Tedjawidjaja, “Case study: Calcium carbonate-scale inhibi-tor performance degradation because of H2S scavenger injection in Semoga field,” Oil and Gas Facilities, February 2013.

6 Soegaard, E. G., “Investigation of Fouling Formation during H2S Scavenging with 1,3,5-tri-(2-hydroxyethyl)-hexahydro-s-triazine,” Maersk Oil and Dansk Shell, Esbjerg Institute of Technology at Aalborg University, 2012.

TABLE 4. Applications and typical treat rates for various H2S scavenger chemistries

Chemical family Applications Relative treat rate, l/kg H2Sa

Water-based triazine Crude, GO, LPG, finished fuel, gas streams 1

Water-free triazine Hot streams: bitumen, GO, fuel oil 1.6

Metal salts Bitumen 2.5

Amine GO, LPG, gas streams 0.33

Water-free aldehyde derivatives Hot streams: bitumen, GO, fuel oil 1.15

Non-amines: Water-based aliphatic aldehydes Crude, naphtha, GO, finished fuel, water 0.9a The values shown in Table 4 are normalized such that water-based triazine, considered a benchmark for H2S scavenging in the oil industry, is 1.

Eprinted and posted with permission to GE Water & Process Technologies from Hydrocarbon ProcessingDecember © 2014 Gulf Publishing Company