Maintenance of Deep Manhole

-

Upload

srinivasan-devi -

Category

Documents

-

view

61 -

download

0

description

Transcript of Maintenance of Deep Manhole

-

Recently installed complex sewer system access chambers (or parts thereof) were designed as reinforced concrete structures in accordance with AS3600-2009 (Concrete Structures) and in some cases as water retaining structures in accordance with AS3735-2001 (Concrete Structures Retaining Liquids). Design to these Australian Standards requires a significant amount of reinforcement at significant cost. Sinclair Knight Merz (SKM) were engaged by Yarra Valley Water to review current industry best practice and prepare guidelines for where reinforcement is required within sewer access chambers. A copy of SKMs guidelines is attached in Appendix A. SKMs investigation into industry best practice highlighted the following key points

Sewer manholes across Australia have been constructed from unreinforced concrete in accordance with accepted industry practice extending back over many decades

Yarra Valley Water's sewerage system access chambers are primarily unreinforced, some as large as 3.6 metres in diameter and 30 metres deep

Historically, our design guidelines have been based on the Colombo Plan Lectures (MMBW, 1977) which recommended the following for manholes on main sewers "as far as practicable, manhole shafts are designed to avoid the use of reinforcement" This historic design approach adopted within the Colombo Plan Lectures has served Yarra Valley Waters system very well over many years

more broadly, considerable diversity exists in sewerage infrastructure across Australian cities The attached SKM guidelines represent a risk-based approach to facilitate an understanding of when access chamber reinforcement is required. The guidelines focus on the shaft structure of circular manholes where 'shaft' refers to the cylindrical part of a manhole (below the 'top' or cone and above the 'table'). The SKM guidelines address the following items -

potential elements of risk associated with access chamber design which should be considered when assessing the need for reinforcement

a summary view of design criteria required for -

Deep Sewer Access Chamber Reinforcement Guidelines Recent design and installation of complex Yarra Valley Water access chambers (manholes) has highlighted some deficiencies in our adopted standards and understanding regarding where reinforcement may be required. In order to address this issue, Yarra Valley Water has engaged Sinclair Knight Merz to prepare guidelines for where reinforcement is required within sewer access chambers.

Issue date : September 2010

-

general design design of un-reinforced concrete design of reinforced concrete in accordance with AS3600-2009 design of reinforced concrete in accordance with AS3735-2001 a set of conclusions that establish some context of where access chamber reinforcement may be required

In summary

Many sewer shafts exist and perform adequately in Melbourne, without any reinforcement in extensive areas of the cylindrical shell and the use of plain, unreinforced concrete in shaft walls has been accepted practice for many decades

In thick unreinforced concrete sections, if temperatures and shrinkage are not controlled, there is some risk of wider cracks and greater groundwater inflow (when compared to reinforced concrete in which the reinforcement would control the crack widths). However the absence of reinforcement has other benefits such as improved access for concrete placement

Plain concrete has lower risk of structural deterioration over the long-term and durability advantages because of the absence of steel reinforcement. In terms of cost, the savings gained by adopting plain concrete need to be off-set against additional cost items such as grouting.

Reinforced concrete sections may be required to sustain unbalanced loading, significant traffic/live loads Based on SKMs Guidelines and subsequent acceptance by Yarra Valley Water, the following design principles shall be adopted for all sewer access chambers -

SKMs Sewer Manhole Reinforcement Guidelines, dated 1 March 2010, be adopted as a key reference for sewer access chamber design

design and installation of unreinforced access chambers is preferred the use of reinforcement in manholes shall be avoidable wherever practical use of reinforcement within manholes shall only be considered where either, infiltration, unbalanced loads, traffic

loads, safety or risk issues cannot be addressed more effectively using unreinforced concrete where there is potential for concrete temperature and shrinkage to occur, appropriate control measures need to

be defined to avoid concrete cracks; where perimeter shrinkage is possible, specify appropriate grouting for unreinforced manholes to ensure contact

between the concrete and the surrounding ground For more information Contact ........................................................ Kevin Dawson Telephone ......................................................... 9872 1474 Email ..................................... [email protected]

-

APPENDIX A Report by Sinclair Knight Merz Sewer Manhole Reinforcement Guidelines

-

! ! " # # $ % & ' (

# # $ ) * + ,--, . # ) +% . * / - # 0 1++) 2 ! 3 4 ,+5 6 / 3 4 ,+5+7 8 3 9 9 9 (! # ! 2 # (

!"#$%%% !#

" &'(

()* !"+,(-%*

(%

!# !((%*(#

-

3: ) 1 ) * ' ; 0 ' . % :) ! ! # ; ! # :; & ! :-% 2 # ! ( % ) >

! "

"

#$% &

'( )

#$%$

#$%

$*%$+

,%

,-

" .%

& $

) ,/-!%

0 ,/$

1 2

#$%$3

" #$%

" ,%

.#/#/# 0

11 /2

.#/#3# 044 /2

.#/#5# 0 ( /2

.#/#6# /.

" 4567% "

.#3#/# /.

.#3#3# /7

-

3: ) 1 ) * ' ; 0 ' . % :) ! ! # ; ! # :; & ! :-% 2 # ! ( % ) >

.#3#5#

/7

.#3#6# /7

.#3#2# 8 9:; /7

.#3#.#

-

3: ) 1 ) * ' ; 0 ' . % :) ! ! # ; ! # :; & ! :-% 2 # ! ( % ) >

$

! !/ ! ! !

& 29=93>>? 0#@1 0#1 29=93>>? 8 10

: 5/9=93>>? 0#@1 0#1 5/9=93>>? @

/9593>/>

! 8

79 /;3>/>

-!9 / 3>/>>52>

:%9AB8 65>/A0*(A0&-A% A>?>=5/% #

$9 01

7;9 01

Yarra Valley Water aims to develop 'business rules' for sewer manholes to; define acceptable limits in terms of size or risk for unreinforced concrete manholes, and to determine design requirements for reinforced concrete manholes. Sinclair Knight Merz was engaged to prepare a brief, desktop study.

Some recently constructed manholes (or parts thereof) were designed as reinforced concrete structures (to AS3600), and even as water retaining structures (to AS3735). Design to these Australian Standards requires a significant amount of reinforcement at significant cost.

However, sewer manholes are also constructed from unreinforced concrete in accordance with accepted practice extending back over many decades. Yarra Valley Water's system includes many unreinforced sewer manholes, some as large as 3.6 metres in diameter and 30 metres deep (refer Appendix A for details). The Colombo Plan Lectures (MMBW, 1977) recommends for manholes on main sewers: "as far as practicable, manhole shafts are designed to avoid the use of reinforcement". The historic design approach adopted within the Colombo Plan Lectures has served Yarra Valley Waters system well.

The design practice of other authorities such as ActewAGL, indicates standard drawings for unreinforced manholes can be subject to specified limits such as:

Diameter no more than 1050 or 1200 mm; Depth no more than 6.0 or 8.0 metres; Wall thickness no less than 150 or 225 mm; Sewers no larger than DN675.

However, there is considerable diversity in sewerage infrastructure across Australian cities and the limits above do not reflect Melbourne experience.

This report presents a risk-based approach to the need for reinforcement. The report is focussed on the shaft structure of circular manholes where 'shaft' refers to the cylindrical part of a manhole (below the 'top' or cone and above the 'table').

The table below summarises the main potential risks.

-

? 0 7 9 = # " # > 2 # ! ( % ) >

Risk Comments Manhole depth

Depth >= 15m. Increased manhole depth does not, by itself, justify a change from unreinforced to reinforced concrete (there is no clear 'line in the sand'). Increasing the depth of a manhole would be unlikely to increase the probability of a structural failure; however the consequences of failure would increase due to the extra depth.

Manhole diameter

MH diameter > 5000mm.

In unreinforced manholes with wall thicknesses equal to 10% of the diameter, walls 500mm thick (or more) are at risk of cracking due to the heat of hydration of the cement. Consequently, manholes with a diameter > 5 metres need either reinforcement to control cracks, or control over concrete temperatures to prevent early-age cracking.

Concrete thickness (i.e. risk of early age shrinkage cracking)

Shaft wall thickness >500mm;

Peak temperature >60CC;

Temperature differential >20CC

Restraint is also relevant to early age cracks, however CIRIA C660, A5.3.1 includes: "Cylindrical structures in which the walls are cast in complete rings are further complicated by the fact that the diameter of the ring attempts to reduce as the concrete cools down to the ambient temperature. In theory, this could result in a horizontal crack between the new and old sections in addition to any vertical cracks, but such cracks are rarely seen in practice."

Geology Rock with fracture zones, slip planes, intersecting joint planes etc.;

Soft or variable clay; "Floaters"; Silt, Sand, Fill; Erodible material.

Non-uniform geology is a major risk to unreinforced manholes.

Ground Loads > 10 % out of balance Point loads (e.g.

floaters); Unbalanced loads; Voids that do not

provide support.

Unbalanced loading induces bending and tensile stresses in shaft walls. If these tensile stresses exceed the allowable value, reinforcement or increased shaft wall thickness would be necessary.

Traffic loads M/H located in a trafficable area;

Subject to heavy, road vehicle loads;

High speeds and high frequency.

Vehicle loads represent a risk, mainly to the manhole top and the upper few metres of shaft. Reinforcing the upper few metres of shaft walls would mitigate this risk.

Unreinforced shafts located away from traffic may still be subject to mowers/tractors with low pressure tyres.

-

? 0 7 9 = # " # > 2 # ! ( % ) >

Surcharge Surcharge above groundwater level;

Surcharge to natural surface.

Surcharge higher than groundwater creates the potential for tension in shaft walls. Grouting to ensure contact with the surrounding ground, or reinforcement of the shaft walls, would be necessary to mitigate this risk.

Surcharge to natural surface creates a risk of unseating the top slab. The manhole shaft could be reinforced as part of a structural system designed to hold the top slab in place.

Limiting surcharge to sewer obvert level, a common design criterion, may avoid air pockets in sewers, but is not necessary for the structural stability of shafts.

Groundwater Level

Groundwater above invert in dry weather (risk of continuous infiltration).

Groundwater above invert in wet weather (risk of intermittent infiltration).

High groundwater creates a risk of infiltration but tends to put shaft walls into compression.

Construction joints or cracks in shaft walls, and joints around incoming sewer pipes, would be susceptible to infiltration. Attention to detail at joints and reinforcement to control cracks in shaft walls would mitigate the risk of infiltration.

Groundwater Chemistry

Salinity > 10 ppt; pH < 4.5; Corrosive or

contaminated; Langelier Index < - 2.0; Potential acid sulphate

soil.

Acidic groundwater would react with the alkaline cement mortar in shaft concrete. Groundwater with a Langelier Index less than -2 tends to dissolve calcium carbonate and soften concrete. Reinforcement would not mitigate this risk and the reinforcement itself would be at risk of eventual corrosion.

Contaminated or saline groundwater is a risk for downstream treatment plants. Reinforcement could be used to control cracks in shaft walls and reduce this risk.

H2S H2S levels > 20 PPM; No effective

ventilation; Turbulence with

possible hydraulic jumps (Fr>1.7);

Drops (tributary sewers)

H2S corrosion is a risk to reinforcement (as the concrete cover over the reinforcement is reduced with time). Reinforcement should be avoided where practicable, especially where H2S corrosion may ultimately expose it.

Manhole Shape/ Contents

Cylindrical shaft with major wall penetrations, drop structures or additional chambers.

Complex manholes are more likely to require reinforcement.

It is recommended that YVW should:

a) Avoid the use of reinforcement in sewer manholes where uniform geology and balanced loading ensure that concrete stresses remain within appropriate limits;

b) Specify appropriate controls on concrete temperature and shrinkage (to avoid cracks);

-

? 0 7 9 = # " # > 2 # ! ( % ) > +

c) Specify appropriate grouting for unreinforced manhole at risk from perimeter shrinkage gaps (to ensure contact between the concrete and the surrounding ground);

d) Provide reinforcement in manholes where infiltration, unbalanced loads, traffic loads, safety or risk issues cannot be addressed more effectively in other ways (such as by increasing concrete thickness).

-

? 0 7 9 = # " # > 2 # ! ( % ) > -

This report considers:

Risks and design criteria relevant to concrete manholes; The circumstances, or level of risk, that would justify reinforcement; Functional requirements for sewer manholes (i.e. are 0.2 mm shrinkage cracks

acceptable?); and Typical limits for unreinforced manholes (some authorities specify upper limiting

sewer diameter or manhole depth/diameter etc.). The report aims to present different risks and criteria underpinning business rules appropriate to YVW, and present a recommended option for discussion at a presentation/workshop. This workshop should involve key internal YVW stakeholders in order to consider the recommendation, and develop business rules for YVW.

The following are not included in the scope of this assignment: Sub-structures such as landings, top slabs, drops, penetrations; The preparation of any drawings; Considerations for corrosion lining options; Integration of business rules with WSAA.

The following resources were reviewed as part of the development of this report:

Sewerage Code of Australia Melbourne Retail Water Agencies Edition Version 1.0 (WSA 02-2002);

Water Industry Technical Standards Technical Standards Manual Volume 2 Sewerage;

AS3600 2001 Concrete Structures; AS3735 2001 Concrete Structures Retaining Liquids; Colombo Plan Lectures, (International Training Course in Water Supply and

Sewerage Practice - Sewerage, Melbourne and Metropolitan Board of Works, 1977);

BS5911-200:1994; Specification for Unreinforced and Reinforced Manholes and Soakaways of Circular Cross-section.

-

? 0 7 9 = # " # > 2 # ! ( % ) >

Sewers for Adoption, 5th ed., WRc (note, the 6th ed, 2006); The ActewAGL website: Technical Requirements for Sewerage

(http://www.actewagl.com.au/water/standards/standards3.aspx) Example drawings from past projects.

!

Abbreviations used in this report include:

ActewAGL The entity that manages sewerage in the ACT AS Australian Standard BS British Standard DN Nominal Diameter HGL Hydraulic Grade Line ID Internal Diameter MPa Mega-Pascals (usually the strength of concrete) WSA Water Services Association YVW Yarra Valley Water

Terms relevant to manholes and reinforcement include:

Benching Flat surface, also known as the 'table', at the bottom of a manhole but above the sewer channel;

Depth The vertical distance from access cover level to sewer invert;

Invert The lowest point inside a pipe (at a specific cross-section); Main sewers Non-reticulation sewers, including intercepting and trunk sewers, but

excluding major, deep tunnel sewers; Manhole Access chamber, also known as Maintenance Hole or M/H;

Reinforcement Steel bars, or wire fabric/mesh, used to reinforce concrete;

Surcharge The internal hydrostatic pressure within a manhole when the HGL is above the sewer obvert;

-

? 0 7 9 = # " # > 2 # ! ( % ) >

#$%

The following general risks were identified in the reference documents listed above and elsewhere.

Unbalanced earth/ground loads; Heavy vehicle loads; Wall thickness < 10% manhole diameter; Early-age thermal and drying shrinkage crack control; A tensile stress in plain concrete > 1.4 MPa; Internal surcharge pressure/hydrostatic loads; Transients such as those resulting from power failure at pumping stations; Turbulence and erosion from high velocity flows in steep sewers; Air entrapment and release during wet weather; High groundwater or flood levels; Presence of seawater or saline groundwater; Hydrogen sulphide related concrete corrosion; Unbalanced forces arising during installation and backfilling; Differential settlements between the sewer pipelines and manholes;

-

? 0 7 9 = # " # > 2 # ! ( % ) > 5

'(

RISK STANDARDS REFERENCES (MRWA, WITS, AS3600, AS3735)

Trench fill loadings and manhole depth

WSA02 Section 18.1

Referenced drawings SEW-1310, SEW-1311, SEW-1312 (Please note that drawings SEW-1311 and SEW-1312 are not endorsed for use by MRWA.)

SEW-1310 refers to permanent formwork greater than DN375 SEW-1311 refers to maintenance holes with a depth to invert 6m to 15m

(Reinforcement to be as detailed in design drawings) SEW-1312 refers to maintenance holes with a depth to invert greater

than 15m: o Design of MH to be in accordance with AS3735 exposure

condition as defined in AS3735 to be not less than condition C and shown on design drawing

o Construction details, eg. Concrete thickness, reinforcement, horizontal and vertical alignment to be shown on design drawing

WSA02 Standard drawing SEW-1300-V Precast concrete MHs are not approved for use in trafficable areas,

industrial areas, water charged ground, areas subject to surcharge, where greater than 6m in depth or on surcharged sewers

Surcharge

WSA02 Standard drawing SEW-1300-V

Precast concrete MHs are not approved for use in trafficable areas, industrial areas, water charged ground, areas subject to surcharge, where greater than 6m in depth or on surcharged sewers

Assume that reinforcement is required where sewers are to be surcharged, unless sewer is completely surrounded by rock.

AS3600 - 2001 AS3600 Section 15 has no serviceability requirements for plain concrete

-

? 0 7 9 = # " # > 2 # ! ( % ) > ,

Consideration should be given to likely groundwater inflow rates High water table will cause more infiltration

Temporary and/or fluctuating groundwater levels

WSA02 Standard Drawing SEW-1300-V

Precast concrete MHs are not approved for use in trafficable areas, industrial areas, water charged ground, areas subject to surcharge, where greater than 6m in depth or on surcharged sewers.

In water charged ground or where there is significant risk of surcharge use only cast in-situ MHs.

AS3600 - 2001 AS3600 Section 15 has no serviceability requirements for plain concrete Consideration should be given to likely groundwater inflow rates High water table will cause more infiltration

Traffic and transient loads

WSA02 Section 8.4

Traffic loads must be considered when calculating external forces that act on a pipeline

Sewer diameter

WSA02 Standard Drawing SEW-1309-V

Maintenance holes for sewers of diameter DN375 DN750 should be reinforced.

Reinforcement as per structural design with 65 minimum cover.

Precast maintenance holes not permitted on >375 mm sewers.

Drawing only applies to maximum MH depth of 6000mm (from top of lid to invert of pipe).

-

? 0 7 9 = # " # > 2 # ! ( % ) >

Surrounding soil conditions

AS3600 - 2001

Where the shaft is not to be constructed in solid rock, the shaft walls are potentially subject to stress conditions other than symmetrical compression. Drying shrinkage cracks could also occur.

AS3600 Section 15

This describes members in which a crack will not induce a collapse, and is also limited to plain concrete floors and pavements resting on the ground, footings and bored piers.

Unreinforced concrete walls can therefore not be designed to the letter of AS3600

Designing for strength

Compression shaft would be designed for axial (hoop) compression in accordance with the strength limits specified in AS3600 Section 15

Tension arising from internal surcharging

Exceptions to non-reinforcement (where shafts must be reinforced)

Shaft walls must be reinforced near the top Near drop inlets At anchorage points for landings Around openings At the base of stilling chambers

Corrosion prevention

WSA02 Section 4.7.2 Internal corrosion

Septic sewage gives rise to production of hydrogen sulphide (H2S), which is released through turbulence as hydrogen sulphide gas. H2S will corrode some metals. It can also be further converted to sulphuric acid on walls of the sewer by bacteria, leading to attack of cementitious

-

? 0 7 9 = # " # > 2 # ! ( % ) >

products. The Water Agency may therefore require lining or coating of

maintenance holes of sewers with diameters greater than DN450.

Clause 4.7.3 External Corrosion

External corrosion of sewer items is mainly affected by aggressive environments through which the sewer may traverse. Ground contaminated by organic compounds (eg hydrocarbons, and chlorinated hydrocarbons) may have an adverse effect on:

Properties of materials Corrosion resistance of metallic components

Corrosion prevention measures may include:

Selection of corrosion resistant materials Coatings for metallic components

Acidic soils, very high salinity soils and sulphate bearing groundwater will attack concrete pipe and maintenance structures. Sulphate resistant cement will provide resistance to neutral sulphates. Use of calcareous aggregates combined with increased cover will reduce the rate of attack in acidic ground conditions.

-

? 0 7 9 = # " # > 2 # ! ( % ) >

#$%$

Increasing manhole depth does not, at any depth, cause a 'step-change' in risk (just a pro-rata change). However, external loading and the associated thickness of shaft walls increase with depth, so the risk of early age shrinkage and thermal cracking also increases.

#$%

Similarly, increasing manhole diameter does not, at any diameter, cause a 'step-change' in risk. However the required thickness of shaft walls increases with diameter, so the risk of early age shrinkage and thermal cracking also increases.

$*%$+

Concrete sections thicker than 500mm are regarded as 'thick' and susceptible to early age shrinkage and temperature cracking. However there are several mitigation strategies as follows: Include supplementary cementitious materials (such as fly-ash) in the concrete mix to mitigate

the heat of hydration and reduce thermal shrinkage; Control the temperature of the concrete on placement by scheduling thick pours early in the

morning, using chilled mix water, cooled aggregate or limiting temperatures in the specification;

Use water curing to ensure a humid atmosphere and avoid drying the concrete; and Include expansion additives in the concrete mix.

,%

Non-uniform geology represents a significant risk to unreinforced manholes. Rock with fracture zones, slip planes, intersecting joint planes etc.; soft or variable clay; basalt "floaters"; silt or sand lenses and fill all introduce the possibility of out of balance loading on the shaft. Erodible material could also lead to voids and uneven loading around a manhole, especially where infiltration carries silt into the sewer from where it is transported away.

,-

The Colombo Plan Lectures recommend the calculation of horizontal ground and hydrostatic pressures on a shaft using the equation:

Horizontal Pressure (P) = ksoil.Soil.g.HSoil + Water.g.HWater

Maximum and minimum values for this pressure are calculated in orthogonal directions using upper and lower limiting values for 'k' as shown in the following table.

-

? 0 7 9 = # " # > 2 # ! ( % ) >

Case kmin kmax Description 1 0.3 0.5 Variable ground 2 0.3 to 0.35 0.45 to 0.5 Normal ground 3 0.35 0.45 Uniform ground

The method finds that for shaft walls: "In normal ground, the stresses in a lining with thickness 10% of the shaft diameter are found satisfactory at depths to 15 metres assuming that ground pressure is developed by the full depth from the surface without arching, and the maximum permissible tensile stress is 1.4 MPa."

Based on the above, manhole depths in excess of 15 metres would need careful analysis.

" .%

Traffic loads and the associated risk to sewer manholes must be carefully evaluated. Manholes in roadways would be subject to impact and vibration. Manholes at some distance from roads may still be subject to heavy earthmoving or construction equipment.

& $

Internal surcharge will only occur in exceptional circumstances. Crack width control is not required for internal surcharge reasons;

AS3735 applies mainly to structures acting in tension to 'retain' the liquid (i.e. tanks). This is directly the opposite of the normal shaft condition where external water pressures tend to put the cylindrical shell into compression (tending to close cracks);

) ,/-!%

High groundwater levels represent a risk of infiltration. Groundwater above invert in dry weather creates a risk of continuous infiltration. Groundwater above invert in wet weather creates a risk of intermittent infiltration.

0 ,/$

Geotechnical investigations should include an assessment of the risk of saline or acidic groundwater.

12

The bacterial conversion of H2S gas delivers sulphuric acid to the internal surfaces of sewer structures. This sulphuric acid reacts with the alkaline cement matrix in concrete and the resulting corrosion products can be effortlessly washed away. The addition of steel reinforcement to sewer manholes only serves to increase the risk of deterioration of the manhole.

-

? 0 7 9 = # " # > 2 # ! ( % ) > +

#$%$3

Complex manholes, containing additional structural elements, would be more likely to involve some risk of structural failure and should therefore be reinforced.

-

? 0 7 9 = # " # > 2 # ! ( % ) > -

"#$%

" ,%

" .$

Concrete elements thicker than about 500mm are generally regarded as 'thick' and subject to significant temperature rise due to the heat of hydration of the cement and, subsequently, greater cooling back to ambient temperature.

Combined with drying shrinkage, thermal shrinkage represents a risk of early age cracking and needs to be addressed through: Controlling the cement content of the concrete; Limiting the temperature of concrete on placement and during hydration; and Considering other issues such as shading, water curing, restraint, removal of forms etc.

Drying shrinkage is more likely if: Concrete is exposed to an above ground environment and subject to the drying effects of sun,

wind, and higher humidity (not likely in an underground manhole); Parameters such as water:cement ratio and slump are not controlled by the specification; or Concrete curing is inadequate.

" %=$=7

In unreinforced concrete manholes, internal surcharge pressures must be transferred directly to the surrounding ground to avoid any tensile stresses in the concrete. Grouting is used to ensure the cylindrical concrete shaft remains in contact with the surrounding ground.

" #$%..%

Manhole tops (conical) and top slabs (flat) should be designed to meet the expected loads in accordance with Australian Standards such as AS1170 and with standard drawings and guidelines. Reference can also be made to past standard drawings such as "Manhole Tops - General Arrangement", drawing no. S 2.020.30.10. Loads could include:

Uniformly distributed live load e.g. 10kPa; or Worst case vehicle loads e.g. W80 wheel load, A160 Axle Load or SM1600 Truck Load. The design of manhole tops and top slabs is not addressed further in this report.

-

? 0 7 9 = # " # > 2 # ! ( % ) >

" $

Concrete strength and other parameters should be specified after taking into account the requirements of Australian Standards such as AS3600 and AS3735 (however some of the requirements of these standards are focussed on the protection of reinforcement and may not be relevant). In accordance with AS3735, exposure classifications B1 and B2 can be addressed with 32 MPa concrete. Typically, concrete strength has increased over time and current grades may be more than sufficient for sewer manholes. For example, the MMBW standard drawing "Manholes - General Notes" dated 1981 (drawing no. S 2.020.30.01), specifies grade "MJ" concrete. This concrete had a characteristic strength (f'c) of 20 MPa.

" 4567%

" ,%

This approach acknowledges past practice for sewer manholes in Melbourne to, as far as practicable, "avoid the use of reinforcement" (refer Colombo Plan Lectures, Melbourne and Metropolitan Board of Works, 1977, Lecture 8, p14). Past practice included shaft wall thicknesses of 10% of shaft diameter in "normal ground" and maximum permissible concrete tensile stresses of 1.4MPa (for elastic analysis with working loads).

Design should be undertaken to the limiting stresses (where applicable) in the Australian Standard for Concrete Structures (AS3600) Section 15 using limit state design and ultimate load cases (Note 'plain concrete' is the terminology adopted by AS3600 for unreinforced concrete).

The scope of AS3600 Section 15 is limited to "members in which a crack will not induce a collapse". As manhole shafts are circular and surrounded by solid ground, arching action is applicable and mechanisms of collapse are limited (as evidenced by numerous unreinforced sewer manholes in Melbourne). The figure below indicates the support provided by the surrounding ground.

-

? 0 7 9 = # " # > 2 # ! ( % ) >

The scope of Section 15 is also limited to "plain concrete floors and pavements resting on the ground, footings and bored piers". Therefore, plain concrete shaft walls cannot be designed 'to the letter' of AS3600. The Victorian water industrys past practice is effectively an 'in-house' standard.

"

Unreinforced concrete shafts should be designed for axial (hoop) compression in accordance with the strength limits specified in AS3600 Section 15.

Wall thicknesses should be selected to ensure the axial compression (hoop) loads in the shaft wall do not exceed the ultimate compressive strength of the plain concrete.

" .

The axial (hoop) tension load case, where shafts may be internally surcharged to natural surface and external ground water may be at sewer invert level (an extreme load case) is assumed to transfer loads directly into the surrounding rock.

" ,

Backfill or contact grouting was specified in past projects to ensure contact between the concrete walls of the shafts and the surrounding ground. The Specification for the North Western Sewer Stages 1 & 3 for example includes in Clause 6.5(b): "The Contractor shall backfill grout all spaces ... in the walls of the shafts remaining unfilled after placing the concrete lining against rock has otherwise been completed".

Grouting should reduce tensile cracking due to internal surcharge loads. Grout 'takes' may be minimal depending on concrete shrinkage and rock quality. Grouting could be omitted given the risk of internal surcharge is relatively small.

" >%%3?

The joint between the shaft wall and the manhole base needs to be checked for shear stress as the external loads are close to their maximum and the cross-sectional area of the wall is limited. Deep manholes may need thicker walls.

"" '(

Nominally unreinforced shafts may still need some targeted reinforcement for specific situations such as:

At the top of the shaft to support out-of-balance soil or vehicle loads; In flat (planar) elements subject to bending (e.g. landings);

-

? 0 7 9 = # " # > 2 # ! ( % ) > 5

Around penetrations in the cylindrical shell; At points of concentrated load such as anchorage points for landings; and At the manhole base especially around stilling chambers.

"& ! %7%

As AS3600 Section 15 has no serviceability requirements for plain concrete (there is no reinforcement). Consideration should be given to likely groundwater inflow rates, autogenous healing of cracks, H2S corrosion and groundwater chemistry.

") .$%$

The potential for shrinkage cracks to form in plain concrete shaft walls during curing was assessed. The two main factors are (a) thermal shrinkage and (b) drying shrinkage.

a) Thermal shrinkage depends on: The coefficient of thermal expansion (assumed to be 11 x 10-6 /C but with basalt

aggregate could be 8 x 10-6 /C ); and The fall in temperature from the hydration peak to minimum ambient (a fall of about

30C). Anecdotal evidence suggests cracks are uncommon. The apparent absence of significant cracks in similar, previously constructed shafts may be due to the method of construction or the specification. A review of the specification would be required to ensure appropriate limitations for heat of hydration and temperature of concrete on placement.

b) Drying shrinkage is not likely to be severe as: One surface of the shaft wall will be cast against rock (or against the temporary support); Much of the surface cast against rock will be below the water table; The other surface will be exposed to an underground environment, with limited exposure

to the drying effects of the sun, wind and low humidity; The water-cement ratio of the concrete mix is limited in the specification; The application of water for curing is under the control of the contractor; and Ultimately the shaft is in a moist environment (unlike most other structures).

Also, Supplementary Cementitious Materials (SCMs) and low water/cement ratios mean that the quantity of water ultimately lost from the concrete as-placed, is minimised.

It can be concluded that there is potential for shrinkage cracks. It also seems apparent that past practice resulted in few, if any, reported cracks.

-

? 0 7 9 = # " # > 2 # ! ( % ) > ,

" "11

AS3600 requires reinforcement to be designed for (a) strength, (b) serviceability and (c) durability as follows:

a) Design for bending and shear strength finds, in most cases, the reinforcement required is less than the minimum required for serviceability (i.e. reinforcement design is not often determined by loading);

b) Design for serviceability mainly relates to crack control and basically requires a minimum reinforcement area of 0.45% to 0.60% of the cross-sectional area of the concrete (with a maximum depth of 250mm); and

c) The minimum requirements for durability relate mainly to cover and have no impact on reinforcement quantities.

" &

The scope of AS3735 specifies that it does not apply to the design of "aqueducts, hydraulic tunnels or similar structures". AS3735 is aimed mainly at tanks and similar structures in which the walls retain liquids using tension or flexure. The applicability of AS3735 to shaft structures (which mainly exclude liquids using compression) is marginal.

AS3735 requires reinforcement to be designed for (a) minimum reinforcement ratio and (b) limiting stresses.

a) The minimum reinforcement ratio differs for restrained and unrestrained concrete. Based on an assumption of full restraint, a minimum reinforcement ratio of 0.48% to 1.28% of the cross-sectional area of the concrete, depending on bar diameter (with a maximum depth of 250mm) is required. Partial restraint is allowed a 25% reduction in reinforcement ratio. This provision is intended to achieve a mean crack width of 0.15mm.

b) Reinforcement design to limit stresses specifies stress limits of 110 to 150MPa (compared to 200 to 240MPa in AS3600). This provision is intended to limit mean crack widths to 0.10mm in direct tension or 0.15mm in flexure.

The above requirements significantly increase the quantity of reinforcement required. However where reinforcement would be in an oxygen free environment (i.e. in the base of the shaft below the invert level of the sewer), crack width control and the durability provisions of AS3735 should not apply.

-

? 0 7 9 = # " # > 2 # ! ( % ) >

&%

Many sewer shafts exist and perform adequately in Melbourne, without any reinforcement in extensive areas of the cylindrical shell and the use of plain, unreinforced concrete in shaft walls has been accepted practice for many decades.

In thick unreinforced concrete sections, if temperatures and shrinkage are not controlled, there is some risk of wider cracks and greater groundwater inflow (when compared to reinforced concrete in which the reinforcement would control the crack widths). However the absence of reinforcement has other benefits such as improved access for concrete placement.

Plain concrete has lower risk of structural deterioration over the long-term and durability advantages because of the absence of steel reinforcement. In terms of cost, the savings gained by adopting plain concrete need to be off-set against additional cost items such as grouting.

It is concluded that:

a) There are numerous examples of unreinforced concrete shafts that have provided acceptable performance for up to 50 years;

b) There is some risk of shrinkage cracking in concrete shaft walls, particularly where the wall thickness exceeds 500mm. Shrinkage cracks in a plain concrete manhole would tend to be wider than in an equivalent reinforced concrete manhole even if the shrinkage was the same, as reinforcement is designed to limit crack widths and distribute cracks; If cracks develop, and autogenous healing does not occur, repairs could be implemented before commissioning the sewer;

c) Past specifications included contact grouting and temperature restrictions on concrete. A specification for plain concrete in manholes should include temperature limits to reduce the likelihood of thermal shrinkage (e.g. a specified maximum temperature on placement, a specified absolute maximum temperature and a specified maximum temperature differential from interior to surface). The specification could include sufficient water curing to virtually prevent drying shrinkage;

d) Shrinkage cracks in an unreinforced cylindrical manhole are unlikely to result in any viable mechanism of collapse as the surrounding ground prevents any outward deflection and arching action transfers the loads into axial compression within the shaft wall. The cost of contact grouting and possible crack repairs would reduce savings associated with plain concrete;

e) As the depth and diameter of manholes increase, so do the consequences of structural failure. However there is no 'line-in-the-sand' beyond which reinforcement becomes absolutely necessary.

-

? 0 7 9 = # " # > 2 # ! ( % ) >

f) Balanced soil and hydrostatic loads do not induce bending in shaft walls and reinforcement is not necessary to support these loads (however axial stresses need to be within appropriate limits).

g) Direct tension in unreinforced shaft walls (due to internal surcharge) can be addressed by grouting to ensure contact with the surrounding ground or by reinforcement.

h) The design of unreinforced concrete manholes is addressed in the Colombo Plan Lectures (MMBW, 1977). The use of AS3600 to design unreinforced manholes would require some assumptions and interpretation. The Clients or the designer would need to accept any risks associated with plain concrete (such as the uncertainty as to whether AS3600 Section 15 is applicable) before approving any design which excludes reinforcing steel in the shaft walls.

i) The geology surrounding a manhole and any unbalanced or concentrated ground loads on the manhole structure is one of the main issues to consider in determining the need for reinforcement.

j) Heavy vehicles and associated vibrations or issues of safety or unacceptable risk may dictate the need for reinforcement, especially in the upper portion of a manhole.

k) Infiltration, and the potential impact on groundwater or on the sewerage system (e.g. salt water at the treatment plant) could also determine the need for reinforcement.

l) The design of reinforcement in manhole shafts should respond to specific requirements for infiltration flow rates (including salt load and associated crack widths), ground and vehicle loads, safety and environmental risks. References such as AS3600, AS3735 and guideline documents such as CIRIA C660 may be required to achieve a rational design.

m) The inclusion of reinforcement in manholes represents a long-term durability risk as carbonation, chloride ingress etc. would eventually reduce the protection that concrete provides reinforcing steel, and corrosion and spalling would result. Possible future costs for rehabilitation of corroded reinforcement could be substantial;

-

? 0 7 9 = # " # > 2 # ! ( % ) >

)

It is recommended that YVW should:

a) Avoid the use of reinforcement in manholes where practicable;

b) Specify appropriate controls on concrete temperature and shrinkage (to avoid cracks);

c) Specify appropriate grouting for unreinforced manholes at risk from perimeter shrinkage gaps (to ensure contact between the concrete and the surrounding ground);

d) Provide reinforcement in manholes where infiltration, unbalanced loads, traffic loads, safety or risk issues cannot be addressed more effectively in other ways (such as by increasing concrete thickness).

-

? 0 7 9 = # " # > 2 # ! ( % ) >

( '(4#$%

Background data gathered to support the findings of this report is presented in the table below. Drawings from a range of sewers designed in the past but still in operation were reviewed and sample data collected. The manholes listed were selected to represent the upper end of the size range normally managed by Yarra Valley Water.

Item Sewer M/H no.

Date Depth (m)

Internal Dia.

(mm)

Wall Thickness

(mm)

Un reinforced cylindrical

shaft?

Reinforcement Location

Sewer Dia

(mm)

1 Balwyn Br. RS 1983 13.5 2100 300 yes Top slab and drop pipe surround

525

2 Bolton St. Br. 1982 2.8 1800 300 yes Top slab 300 3 Bower Br. RS 1980 6.3 2400 325 yes Top slab, vortex

and drop pipe surround

525

5 Cardinal Rd Br. RS

34A 1982 5.0 2400 min 250 yes Top slab, landing

750

4 Darling Br. 3 1987 2.5 1500 225 yes Nil (top slab not shown)

450

6 Eltham MS 26 1980 10.0 1800 300 yes Top slab, landing

900

7 Gardiners Ck. Main RS

75 1975 29.5 3650 380 - 450 yes Top slab, vortex, landings and base to 2m above top of pipe

1800

8 Kew Nth 1976 13.0 1600 225 yes Top slab, landing, mesh at table

450

9 Keilor Br. 24 1979 8.0 1070 150 yes Landing (cone top)

300

10 Koonung Ck. MS

22 1980 6.6 2400 300 yes Top slab 1200

11 Kororoit Ck MS

141 1970 9.5 2000 250 yes Top slab, landing and around sewer pipe penetration

975

12 Kyle Rd MS Sect 4

20 1979 8.5 1800 300 yes Top slab, landing and around sewer pipe penetration

750

13 Merlynston Br. RS

6 1981 15 2200 300 yes Drop pipe surround, internal wall

600

14 Merri Ck. Main RS

18 29

1964 11.0 1500 225 yes Top slab, landing, vortex

1050

15 Moreland Br. 1981 3.6 1500 150 yes 600 16 Pascoe Vale Rd

MS std 1958 3.5 -

4.5 1350 225 yes Around cast

insitu sewer 750

17 Prahran East Br. RS

1983 9.2 2000 225 yes Drop pipe surround

450

18 Preston IS 7 1984 30.0 1500 225 yes Landing, vortex 600 19 Queen's Lane

Br. RS typ 1984 3.0 -

9.0 1220 225 yes Landings 450

20 Trafalgar Av, Br.

1 1984 10.9 1800 250 yes Landing, top slab.

700

-

? 0 7 9 = # " # > 2 # ! ( % ) > +

It can be seen from the table above that manholes ranging in size up to approximately 30 metres deep, 3.6 metres in diameter and on sewers to 1800mm diameter have been successfully constructed in plain concrete (where "plain concrete" is the term applied in AS3600 to unreinforced concrete (or concrete containing some reinforcement but assumed to be unreinforced).

It is assumed that the manholes described above have performed satisfactorily as reports on defects are rare.

Generally, reinforcement is only used in flat/planar elements where bending is possible (i.e. elements such as landings, top slabs and around penetrations). In circular manholes subject to uniform loading, the cylindrical shaft of the manhole is mainly subject to compression and consequently reinforcement would not be stressed.

Larger, basically unreinforced manholes also exist along many of Melbourne's trunk sewers.

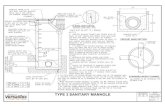

Zone D3 of Western Trunk Sewer drawing C.3.250.04.36, 'Old Sneydes Rd. Shaft Wall Reinforcement Details' (see adjacent figure), specifies "reinforcement not required" over much of the height of the 35 metre high x 6.2 metre diameter shaft.

The drawing is dated 1988 and illustrates the design approach typically adopted for the plain, cylindrical portion of trunk sewer shafts. Reinforcement was specified at sewer level and at top slab level.

Deep Sewer MH Reinforcement Guidelines_finalYVWSewerMHReinforcementGuidelines_vC