M. Rades - Mechanical Vibrations 1

description

Transcript of M. Rades - Mechanical Vibrations 1

Preface

This textbook represents the Mechanical Vibrations lecture course given to students in the fourth year at the Department of Engineering Sciences (now F.I.L.S.), English Stream, University Politehnica of Bucharest, since 1993.

It grew in time from a course taught in Romanian since 1972 to students in the Production Engineering Department, followed by a special course given between 1985 and 1990 to postgraduate students at the Strength of Materials Chair.

Mechanical Vibrations, as a stand alone subject, was first introduced in the curricula of mechanical engineering departments in 1974. To sustain it, we published with Professor Gh. Buzdugan the book Vibration of Mechanical Systems in 1975, at Editura Academiei, followed by two editions of Mechanical Vibrations, in 1979 and 1982, at Editura didactică şi pedagogică. In 1984 we published Vibration Measurement at Martinus Nijhoff Publ., Dordrecht, which was the English updated version of a book published in 1979 at Editura Academiei.

As seen from the Table of Contents, this book is application oriented and limited to what can be taught in an one-semester (28 hours) lecture course. It also contains material to support the tutorial that includes the use of finite element computer programs and basic laboratory experiments. The course syllabus changed in time due to the growing use of computers. We wrote simple finite element programs to assist students in solving problems as homework. The course aims to: (a) increase the knowledge of vibration phenomena; (b) further the understanding of the dynamic behaviour of structures and systems; and (c) provide the necessary physical basis for analytical and computational approaches to the development of engineering solutions to vibration problems.

As a course taught for non-native speakers, it has been considered useful to reproduce as language patterns some sentences from English texts.

Computational methods for large eigenvalue problems, model reduction, estimation of system parameters based on the analysis of frequency response data, transient responses, modal testing and vibration testing are treated in the second volume. No reference is made to the dynamics of rotor-bearing systems and the vibration of discs, impellers and blades which are studied in the Dynamics of Machinery lecture course.

April 2006 Mircea Radeş

Prefaţă

Lucrarea reprezintă cursul de Vibraţii mecanice predat studenţilor anului IV al Facultăţii de Inginerie în Limbi Străine, Filiera Engleză, la Universitatea Politehnica Bucureşti, începând cu anul 1993. Conţinutul cursului s-a lărgit în timp, pornind de la un curs predat din 1972 studenţilor de la facultatea T. C. M. (în prezent I.M.S.T.), urmat de un curs postuniversitar organizat între 1985 şi 1990 în cadrul Catedrei de Rezistenţa materialelor.

Vibraţiile mecanice au fost introduse în planul de învăţământ al facultăţilor cu profil mecanic ca un curs de sine stătător în 1974. Pentru a susţine cursul, am publicat, sub conducerea profesorului Gh. Buzdugan, monografia Vibraţiile sistemelor mecanice la Editura Academiei în 1975, urmată de două ediţii ale manualului Vibraţii mecanice la Editura didactică şi pedagogică în 1979 şi 1982. În 1984 am publicat Vibration Measurement la Martinus Nijhoff Publ., Dordrecht, reprezentând versiunea revizuită în limba engleză a monografiei ce a apărut în 1979 la Editura Academiei.

După cum reiese din Tabla de materii, cursul este orientat spre aplicaţii inginereşti, fiind limitat la ceea ce se poate preda în 28 ore. Materialul prezentat conţine exerciţii rezolvate care susţin seminarul, în cadrul căruia se utilizează programe cu elemente finite elaborate de autor şi se prezintă lucrări demonstrative de laborator, fiind utile şi la rezolvarea temelor de casă. Cursul are un loc bine definit în planul de învăţământ, urmărind a) descrierea fenomenelor vibratorii întâlnite în practica inginerească; b) modelarea sistemelor vibratoare şi analiza acestora cu metoda elementelor finite; şi c) înarmarea studenţilor cu baza fizică necesară în modelarea analitică şi numerică a structurilor în vibraţie şi a maşinilor, pentru elaborarea soluţiilor inginereşti ale problemelor de vibraţii.

Fiind un curs predat unor studenţi a căror limbă maternă nu este limba engleză, au fost reproduse expresii şi fraze din cărţi scrise de vorbitori nativi ai acestei limbi.

În volumul al doilea se vor prezenta metode de calcul pentru probleme de valori proprii de ordin mare, reducerea ordinului modelelor, răspunsul tranzitoriu, estimarea pametrilor sistemelor vibratoare pe baza analizei funcţiilor răspunsului în frecvenţă, analiza modală experimentală şi încercările la vibraţii. Nu se tratează dinamica sistemelor rotor-lagăre şi vibraţiile discurilor şi paletelor, acestea fiind studiate în cadrul cursului de Dinamica maşinilor.

Aprilie 2006 Mircea Radeş

Contents

Preface 1

Prefaţă 2

Contents 3

1. Modelling Vibrating Systems 5 1.1 Vibrations vs. Oscillations 5

1.2 Discrete vs. Continuous Systems 6

1.3 Simple Vibrating Systems 7

1.4 Vibratory Motions 8

1.5 Damping 10

2. Simple Linear Systems 11 2.1 Undamped Free Vibrations 11

2.2 Undamped Forced Vibrations 22

2.3 Damped Free Vibrations 35

2.4 Damped Forced Vibrations 42

Exercices 73

3. Simple Non-Linear Systems 79 3.1 Non-Linear Harmonic Response 79

3.2 Cubic Stiffness 81

3.3 Combined Coulomb and Structural Damping 92

3.4 Quadratic Damping 97

3.5 Effect of Pre-Loading 103

4 MECHANICAL VIBRATIONS

4. Two-Degree-of-Freedom Systems 105 4.1 Coupled Translation 106

4.2 Torsional Systems 119

4.3 Flexural Systems 130

4.4 Coupled Translation and Rotation 145

4.5 Coupled Pendulums 151

4.6 Damped Systems 156

Exercices 179

5. Several Degrees of Freedom 183 5.1 Lumped Mass Systems 184

5.2 Plane Trusses 210

5.3 Plane Frames 220

5.4 Grillages 234

5.5 Frequency Response Functions 241

Exercices 247

6. Continuous Systems 259 6.1 Lateral Vibrations of Thin Beams 259

6.2 Longitudinal Vibration of Rods 275

6.3 Torsional Vibration of Rods 278

6.4 Timoshenko Beams 280

References 281

Index 289

1. MODELLING VIBRATING SYSTEMS

Vibrations are dynamic phenomena encountered in everyday life, from the heart beating and walking, trees shaking in gusty winds or boats floating on rough waters, vibration of musical instruments and loudspeaker cones, to bouncing of cars on corrugated roads, swaying of buildings due to wind or earthquakes, vibrations of conveyers and road drills.

It is customary to term ‘vibrations’ only the undesired repetitive motions, giving rise to noise or potentially damaging stress levels. The effect of vibrations on humans, buildings and machines are of main concern. Modelling vibration phenomena implies describing the structure and parameters of the vibrating body, the excitation function and the response levels.

This introductory chapter focuses on definitions and classifications, to give an overview of the main notions used in vibration analysis.

1.1 Vibrations vs. Oscillations

The Oxford Dictionary gives “vibration, n. Vibrating, oscillation; (phys) rapid motion to and fro, esp. of the parts of a fluid or an elastic solid whose equilibrium is disturbed”. It comes out that all matter, gaseous, liquid or solid is capable of executing vibrations and, in fact, so are the elementary particles of which the matter is composed.

Generally, oscillations are variations of a state parameter about the value corresponding to a stable equilibrium position (or trajectory). Vibrations are oscillations due to an elastic restoring force. To save confusion, a flexible beam or string vibrates while a pendulum oscillates.

For practical engineering purposes it is usual to allocate the term ‘vibration’ predominantly to unwanted periodic motions. In music, the opposite is the case, since all musical instruments use periodic vibrations to make sound. We might say that vibration in engineering is more akin to noise in acoustics: an

MECHANICAL VIBRATIONS 6

annoying, but to a degree, inescapable by-product of the machine, either in terms of external sound or damage within itself. Apart from harmful vibrations, there are installations whose operation is based on vibratory motions, namely: concrete tampers, pile driving vibrators, soil compaction machines, vibrating screens, fatigue testing machines, etc.

All bodies possessing mass and elasticity are capable of vibration. A vibrating system has both kinetic energy, stored in the mass by virtue of its velocity, and potential energy, stored in the elastic element as strain energy. A major feature of vibrations is the cyclic transformation of potential energy into kinetic and back again. In a conservative system, when there is no dissipation of energy, the total energy is constant. At the point of maximum displacement amplitude, the instantaneous velocity is zero, the system has only potential energy. At the static equilibrium position, the strain energy is zero and the system has only kinetic energy. The maximum kinetic energy must equal the maximum potential energy. Equating the two energies it is possible to obtain the natural frequency of vibration. This is the basis of Rayleigh’s method.

Vibrating systems are subject to damping because energy is removed by dissipation or radiation. Damping is responsible for the decay of free vibrations, for the phase shift between excitation and response, and provides an explanation for the fact that the forced response of a vibratory system does not grow without limit.

1.2 Discrete vs. Continuous Systems

The number of independent coordinates needed to specify completely the configuration of a vibrating system at any instant gives the number of degrees of freedom of the system.

It follows that, in order to describe the motion of every particle of a system, the number of degrees of freedom has to be infinite. However, for practical purposes, it is useful to use systems of approximate dynamical similarity to the actual system, which have a small number of degrees of freedom.

The criteria used to determine how many degrees of freedom to ascribe to any system under analysis are practical in nature. For instance, some of the possible system motions may be so small that they are not of practical interest. Some or most of the motions of particles in the system may be practically similar, allowing such particles to be lumped into a single rigid body. The frequency range of the excitation forces may be so narrow that only one, or at most a few, of the natural frequencies of the system can give rise to resonances. Groups of particles experiencing similar motions may be considered single bodies, thereby reducing the number of degrees of freedom necessary to consider. All these practical considerations lead to the concept of lumped masses which are rigid bodies

1. MODELLING VIBRATING SYSTEMS 7

connected by massless flexible members. The motions predicted by using such approximate lumped-parameter or discrete systems are often close enough to the actual vibrations to satisfy all practical demands and to provide useful design data and allowable vibration limits.

In some systems, a second approximation can be made, by taking into account the mass of the elastic members. This is necessary only when the flexible members have distributed masses which are comparable in magnitude with the masses of system components modelled as rigid bodies.

Finally, there are many systems of practical interest which have such simple shapes that they can be considered as systems possessing an infinite number of degrees of freedom. Such distributed-parameter or continuous systems may be modelled as strings, beams, plates, membranes, shells and combinations of these.

In most engineering applications, geometrically complex structures are replaced by discretized mathematical models. A successful discretization approach is the finite element method. The infinite degree of freedom system is replaced by a finite system exhibiting the same behaviour. The actual structure is divided (hypothetically) into well-defined sub-domains (finite elements) which are so small that the shape of the displacement field can be approximated without too much error, leaving only the amplitude to be found. All individual elements are then assembled together in such a way that their displacements are mating each other at the element nodes or at certain points at their interfaces, the internal stresses are in equilibrium with the applied loads reduced at nodes, and the prescribed boundary conditions are satisfied. Modelling errors include inappropriate element types, incorrect shape functions, improper supports and poor mesh.

1.3 Simple Vibrating Systems

A surprisingly large number of practical vibration problems which arise in the machines and structures designed by engineers can be treated with a sufficiently high degree of accuracy by imagining the actual system to consist of a single rigid body, whose motion can be described by a single coordinate.

In reality, the simplest imaginable system consists of the body whose motion is of interest and the fixed surrounding medium, relative to which the motion is measured. The problem of treating such a simplified system is fourfold. The first part consists in deciding what part of the system is the rigid body and what part are the flexible members. The second part consists in calculating the values of the dynamic parameters of the rigid body and flexible parts. The third part consists in writing the equations of motion of the equivalent system, Finally, the fourth part consists in solving the equations for the prescribed conditions of

MECHANICAL VIBRATIONS 8

free or forced vibrations. Alternatively, methods using the kinetic and potential energies may be used in the place of the last two stages.

The first two parts require judgement and experience which come with practice, that is, with the repeated process of assuming equivalent systems, predicting their motions and checking the predictions against actual measurements on the real systems. Model verification and validation may require updating of system parameters or even of the model structure. The adequacy of the solution depends largerly on the skill with which the basic simplifying assumptions are made. A basic choice is between linear and non-linear models. Damping estimation is another source of error, because damping cannot be calculated like the mass and stiffness properties. The last two steps consist in applying procedures worked out by mathematicians. The real engineering work lies in the first two stages, while the last two stages may be considered as mere applications of recipies.

One degree of freedom systems are considered in Chapters 2 and 3. Discrete systems are treated in Chapters 4 and 5. Chapter 6 is devoted to straight beams and bars.

1.4 Vibratory Motions

According to the cause producing or sustaining the vibratory motion, one can distinguish: free vibrations, produced by an impact or an initial displacement; forced vibrations, produced by external forces or kinematic excitation; parametric vibrations, due to the change, produced by an external cause, of a system parameter; self-excited vibrations, produced by a mechanism inherent in the system, by conversion of an energy obtained from a uniform energy source associated with the system oscillatory excitation.

If the system is distorted from the equilibrium configuration and then released, it will vibrate with free vibrations. If any part of the system is struck by a blow, the system will vibrate freely. Musical instruments like drums are struck and strings are plucked. Free vibrations exist when the forces acting on the system arise solely from motion of the system itself. The frequencies of the free vibrations are fixed functions of the mass, stiffness, and damping properties of the system itself. They are called natural frequencies. For any particular system they have definite constant values. When all particles of a body vibrate in a synchronous harmonic motion, the deflected shape is a natural mode shape.

Vibrations which take place under the excitation of external forces are forced vibrations. External forces in any system are forces which have their reactions acting on bodies which are not parts of the system isolated for study. The forcing function can be harmonic, complex periodic, impulse, transient, or random.

1. MODELLING VIBRATING SYSTEMS 9

When a system is excited by a periodic external force which has one frequency equal to or nearly equal to a natural frequency of the system, the ensuing vibratory motion becomes relatively large even for small amplitudes of the disturbing force. The system then is in a state of resonance. An example is the swing pushed at the right intervals. Other examples include vibrations of geared systems at the tooth-meshing frequency, torsional vibrations of multi-cylinder engine shafts at the firing frequency, vibrations of rolling element bearings at the ball passing frequencies, etc.

There is an effect arising from the damping which causes the resonance frequency to differ slightly from the natural frequency by an amount which increases with the damping. Fortunately the distinction in practice is very small and can be neglected in most engineering structures, unless very high damping is provided on purpose.

Resonance relates to the condition where either a maximum motion is produced by a force of constant magnitude, or a minimum force is required to maintain a prescribed motion level. A resonance is defined by a frequency, a response level and a bandwidth of the frequency response curve. Avoidance of large resonant vibration levels can be accomplished by: a) changing the excitation frequency; b) making stiffness and/or mass modifications to change the natural frequencies; c) increasing or adding damping; and d) adding a dynamic vibration absorber.

When the driving frequency is an integer multiple of the natural frequency of the associated linear system, non-linear single-degree-of-freedom systems described by Mathieu equations exhibit parametric instabilities, referred to as parametric resonances.

The principal parametric resonance occurs when the excitation frequency is twice the natural frequency. Parametric resonances of fractional order also exist. Multi-degree-of-freedom systems can experience parametric resonance if the driving frequency and two or more natural frequencies satisfy a linear relation with integer coefficients.

Parametric resonance is a state of vibration in which energy flows into the system from an external source at resonance, increasing the amplitude of the system’s response. This energy is dependent upon both the natural frequency of the system and the frequency of the parameter variation.

During resonant vibrations and self-excited vibrations, the system vibrates at its own natural frequency. But while the former are forced vibrations, whose frequency is equal to a whole-number ratio multiple of the external driving frequency, the latter is independent of the frequency of any external stimulus.

In a self-excited vibration, the alternating force that sustains the motion is created or controlled by the motion itself. When the motion stops, the alternating force disappears. Well-known examples include the vibrations of a violin string

MECHANICAL VIBRATIONS 10

being excited by a bow, the ‘chatter’ of cutting tools, of a chalk on the blackboard, of a door that screeches when opened or of a water glass whose rim is rubbed with a wet finger. One can add vortex induced vibrations of industrial smokestacks, galloping and flutter of electric transmission lines, the oil-whirl of rotors in hydrodynamic bearings, vibrations of poppet valves, the wheel shimmy, etc.

Parametric vibrations occur in systems with variable stiffness like rotating shafts with non-circular cross-section, pendulums of variable length, geared torsional systems, etc.

1.5 Damping

Damping represents the dissipation of energy from a system, generally as a result of energy of motion converted into thermal energy. The loss of energy by radiation, sometimes referred to as geometric damping, is not considered herein.

Four of the most common damping mechanisms are: a) Coulomb (sliding friction), in which the force magnitude is independent of velocity, b) viscous, where the force is proportional to velocity, c) velocity-nth power, when the force is proportional to the nth power of velocity across the damper, and d) structural (hysteretic, internal, material), in which the force is proportional to the magnitude of displacement from some quiescent position. Hereditary damping and clearance damping are other possible damping mechanisms.

From a microscopic point of view, most damping mechanisms involve frictional forces that oppose the motion (velocity) of some part of a physical system, resulting in heat loss. For example, the Coulomb friction force is caused by two surfaces sliding with respect to one another, and this sliding force is independent of velocity, once the initial static friction (stiction) is overcome.

Hysteretic damping may be viewed as a sliding friction mechanism between molecular layers in a material, or between components of a riveted or bolted structure, in which the friction force is proportional to the displacement from the undisturbed position but in phase with the velocity.

Viscous damping occurs when molecules of a viscous fluid rub together, causing a resistive force that is proportional to, and opposing the velocity of an object moving through the fluid. Actual oil dampers and shock absorbers provide friction forces proportional to some non-integer power of the relative velocity.

The influence of structural and non-linear damping mechanisms on the response of mass-excited single-degree-of-freedom systems is treated in Chapter 3. In the study of discrete vibrating systems only viscous and structural damping is considered.

2. SIMPLE LINEAR SYSTEMS

Any vibrating system has mass and elasticity. The simplest vibrating system consists of a mass attached to a linear spring. When its motion can be described by a single coordinate it has a single degree of freedom. Using this simple model, it is possible to introduce basic concepts such as natural frequency, resonance, beats and antiresonance. During vibration, energy is dissipated by damping. This limits the motion at resonance, decreases the amplitude of free vibration, and introduces phase shifts between excitation and response. Measurement of damping is an important issue because it cannot be calculated like the mass and stiffness properties.

2.1 Undamped Free Vibrations

The free vibration of a mass-spring system, that takes place in the absence of any external excitation, is a harmonic motion whose frequency depends solely upon the system parameters, the mass and the stiffness, being independent of the motion initial conditions. It is referred to as a natural frequency because it is an intrinsic (natural) system property. Calculation of natural frequencies is based on values of the stiffness of spring elements and of inertia of mass elements.

2.1.1 The Mass-Spring System

The system shown in Fig. 2.1 consists of a linear spring of stiffness k and a weight W having a mass gWm = , where g is the acceleration of gravity. The weight is restricted to move in the vertical direction without rotation. The stiffness k is defined as the change in force per unit change in length of the spring.

Figure 2.1, a shows the unstretched spring. When the mass m is suspended from the spring (Fig. 2.1, b), its lower end moves downwards and stops in the static equilibrium position, determined by the spring static deflection stδ . In this position, the gravitational force mgW = acting on the mass downwards is

MECHANICAL VIBRATIONS 12

balanced by the spring force stkδ acting upwards (Fig. 2.1, c), so that the static deflection is

kgm

st =δ . (2.1)

If the mass is disturbed from the rest position, the system free vibrations will take place. In order to write the equation of motion, the origin of vibration displacements is chosen at the static equilibrium position, so that only forces due to displacement from this position need be considered.

Fig. 2.1

Letting all vector quantities in the downward direction be positive, in position x the elastic force acting on the mass is xk− (Fig. 2.1, d). Its motion is described by Newton’s second law

xx km −=&& ,

which can be written

0km =+ xx&& , (2.2)

where a dot above a letter denotes differentiation with respect to time.

Equation (2.2) is a homogeneous second order differential equation. Its general solution has the form

tCtC nn ωω cossin 21 +=x , (2.3)

where mkn =ω [rad/sec] (2.4)

is the undamped natural circular frequency of the system.

The undamped natural frequency is

mkfn 2π

1= . [Hz] (2.5)

2. SIMPLE LINEAR SYSTEMS 13

The arbitrary constants 1C and 2C are evaluated from the initial conditions of the motion. In the most general case, the system may be started from position 0x with velocity 0v so that the general solution becomes

txt nnn

ωωω

cossin 00 +=vx . (2.6)

Another form of the general solution is

( )φω += tA nsinx (2.7)

where the two arbitrary constants are given by

( ) 20

20 nA ωvx += ,

0

01 tanvxnωφ −= . (2.8)

Equation (2.7) indicates that the free vibration of the spring-mass system is harmonic and occurs at a natural frequency nf . The quantity A represents the displacement amplitude from the static equilibrium position and φ is the phase angle. The circular frequency nω defines the rate of vibration in terms of radians per unit time, π2 rad being equal to one complete cycle of vibration.

The frequency of vibration is the number of complete cycles of motion in a unit of time, and is the reciprocal of the period

nnfT ω2π1 == . [sec] (2.9)

The period of vibration is the time required for the motion to begin repeating itself.

The undamped natural frequency may be expressed as a function of the static deflection using equation (2.1)

stn

gfδπ2

1= , [Hz] (2.10)

where 2sm9.81=g .

2.1.2 Stiffness of Elastic Elements

Although it is convenient to model a single-degree-of-freedom system as a mass attached to a single helical spring, in many actual systems the spring can take different forms and can also represent an assemblage of several elastic elements.

In Fig. 2.2 the stiffnesses of several elastic elements are calculated as the applied force divided by the displacement of its point of application.

MECHANICAL VIBRATIONS 14

Fig. 2.2

In Fig. 2.3 two general types of spring combinations are shown.

Fig. 2.3

For the series arrangement (Fig. 2.3, a) there is a condition of equal force in each spring. Two linear springs, having stiffnesses 1k and 2k , will deflect statically when loaded by a weight W by an amount

⎟⎟⎠

⎞⎜⎜⎝

⎛+=+=

2121

11kk

WkW

kW

stδ .

2. SIMPLE LINEAR SYSTEMS 15

The equivalent spring constant, representing the combined effect of 1k and

2k , is

21

111

kk

Wkst

S+

==δ

. (2.11)

For a system with n springs connected in series, the equivalent stiffness Sk is given by

nS k...

kkk1111

21+++= . (2.12)

The parallel spring arrangement (Fig. 2.3, b) must satisfy the condition of equal displacement in each spring and the sum of forces in each spring must equal the weight W :

stst kkW δδ 21 += .

Thus, for parallel springs, the equivalent stiffness is

21 kkWkst

P +==δ

. (2.13)

In general, a system with n parallel springs has an equivalent stiffness given by

nP k...kkk +++= 21 . (2.14)

These rules for compounding spring stiffnesses are exactly the same as those for finding the total capacitance of series or parallel circuits in electrical engineering.

2.1.3 Torsional System

Consider the torsional system of Fig. 2.4 consisting of a disc of mass moment of inertia J, 2mkg , suspended from a bar or wire of torsional stiffness K,

radmN . The system is restricted to undergo angular vibrations around the vertical axis.

If the instantaneous angular position of the disc is given by the angle θ , the torque acting on the disc is θK− so that Newton’s second law for angular motion is

θθ KJ −=&& ,

which can be written

MECHANICAL VIBRATIONS 16

0=+ θθ KJ && , (2.15)

where a dot above a letter denotes differentiation with respect to time.

Fig. 2.4

Equation (2.15) has been established by Ch. O. Coulomb in 1784. It has the general solution of the form

( ) tCtCt nn ωωθ cossin 21 += ,

where

JKn =ω [rad/sec] (2.16)

is the undamped natural circular frequency of the torsional system.

The undamped natural frequency is

JKfn π2

1= . [Hz] (2.17)

From Mechanics of Materials it is known that a uniform shaft of diameter d and length l , from a material with shear modulus of elasticity G, acted upon by a

torque tM will twist an angle p

tIG

M l=θ , where

32π 4dI p = is the polar second

moment of area of the shaft cross section. The torsional stiffness is then

l

pt IGMK ==

θ.

In fact, there is complete analogy between systems in axial and torsional vibration, with the counterparts of springs and masses being torsional springs and rigid discs possessing polar mass moments of inertia.

2. SIMPLE LINEAR SYSTEMS 17

2.1.4 The Energy Method

Assuming that the vibrational motion is harmonic, the frequency can be calculated from an energy consideration. When there is no dissipation of energy, the system is called conservative. At any instant, the energy of a conservative system is the constant sum of potential and kinetic energies

.constTU =+ (2.18)

The maximum potential energy, which occurs in an extreme position, where the mass stands still for a moment, must equal the maximum kinetic energy, which occurs when the mass passes through the static equilibrium position with maximum velocity.

The spring force is xk , and the work done on an infinitesimal displacement xd is xxk d . The potential energy in the spring, when stretched over

a distance x , is 2

021d xkxxkU

x

== ∫ . Assuming the vibratory motion of the form

tAx nωsin= , the maximum potential energy is 2

21 AkUmax = .

The kinetic energy at any instant is 2

21 vmT = . The velocity is

tA nn ωω cos=v , so that the maximum kinetic energy is 22

21 AmT nmax ω= .

Equating maxmax TU = , we obtain 222

21

21 AmAk nω= wherefrom the

natural frequency mkn =ω is obtained, independent of the amplitude A .

Example 2.1 Determine the natural frequency of the fluid oscillations in a U tube

(Fig. 2.5).

Solution. Let the total length of the fluid column be l , the tube cross section be A and the fluid mass density be ρ .

Assuming all fluid particles to have the same speed at any instant, the

kinetic energy can be written 2

21 xAT &lρ= . If the fluid oscillates back and forth,

the work done is the same as if the fluid column of length x has been transferred from the left side to the right side of the tube, leaving the remaining fluid undisturbed.

MECHANICAL VIBRATIONS 18

The instantaneous potential energy is 2xAgU ρ= . Substituting the two energies in the condition that the rate of change of total energy must be zero

( ) 0dd

=+UTt

and dividing out x& , we obtain the differential equation of motion of the fluid

02=+ xgx

l&& .

Fig. 2.5

Therefore the natural frequency

lgn 2=ω

is independent of the kind of fluid used, of the tube shape and its cross-sectional area.

2.1.5 Rayleigh’s Method

An application of the energy method to systems with distributed mass and/or elasticity is Rayleigh’s method. It is used to reduce a distributed system into an equivalent spring-mass system and to determine its fundamental natural frequency.

The kinetic and potential energies are calculated assuming any reasonable deflection curve that satisfies the geometric boundary conditions. If the true deflection curve of the vibrating system is assumed, the fundamental frequency found by Rayleigh’s method will be the correct frequency. For any other curve, the frequency determined by this method will be higher than the correct frequency. This is explained by the fact that any deviation from the true curve requires additional constraints, a condition that implies greater stiffness and higher

2. SIMPLE LINEAR SYSTEMS 19

frequency. In the following, Rayleigh’s method is applied to beam flexural vibrations. A prismatic beam has a bending rigidity IE (where E is Young’s modulus and I is the second moment of area of the cross section) and a mass per unit length Aρ (where ρ is the mass density and A is the area of the cross section). The lateral deflection is assumed harmonic, with frequency 1ω , synchronous in all points along the beam

( ) ( ) txt,xy 1cosωv= .

The instantaneous potential energy is

xxyIE

IEdxMU d

21

2

2

2

22

⎟⎟⎠

⎞⎜⎜⎝

⎛

∂∂

== ∫∫

where the linearized differential equation (5.65) of the beam elastic line ( )22 xyIEM ∂∂= has been used.

Its maximum value is

xx

IEUmax d21

2

2

2

⎟⎟⎠

⎞⎜⎜⎝

⎛

∂∂

= ∫v .

The instantaneous kinetic energy is

∫∫ =⎟⎟⎠

⎞⎜⎜⎝

⎛∂∂

= xd21

21 22

1

2

yAdmtyT ρω ,

with the maximum value

∫= xv d21 22

1 ATmax ρω .

Equating the maximum potential energy to the maximum kinetic energy, we obtain the expression of the fundamental natural frequency

( )∫

∫ ∂∂=

xv

v

d

dω

2

22221

A

xxIE

ρ. (2.19)

Example 2.2 Determine the fundamental natural frequency of the uniform cantilever

beam shown in Fig. 2.6.

Solution. Consider the deflection curve of the form

MECHANICAL VIBRATIONS 20

⎟⎠⎞

⎜⎝⎛ −=

l2cos10

xπvv .

It can be seen that this function satisfies the boundary conditions 0=x , 0=v , 0dd =xv , and l=x , 0dd 22 =xv , but not the condition l=x ,

0dd 33 =xv (zero shear force), so that it is an approximate admissible function.

Fig. 2.6

The maximum potential energy is 203

4

64π v

l

IEUmax = . The maximum

kinetic energy is ⎟⎠⎞

⎜⎝⎛ −=

πωρ 2

432

021 lvATmax , or 0.23

220

21 ⋅= lvωρ ATmax .

Equating the two energies, the fundamental frequency of vibration (in rad/sec) is obtained as

AIE

ρω 21

3.6638l

= .

The true solution (6.16) is AIE

ρω 21

3.515l

= , so that the value based on

Rayleigh’s solution is 4 % higher.

If the assumed function is the static deflection curve of the massless cantilever beam with a concentrated load at the end

⎥⎥⎦

⎤

⎢⎢⎣

⎡⎟⎠⎞

⎜⎝⎛−⎟

⎠⎞

⎜⎝⎛=

32

0 321

ll

xxvv ,

the maximum potential energy is 20

203 2

123 vv kIEUmax ==l

and the maximum

kinetic energy is ( ) 201

20

21 2

1140

3321 vv ωωρ

redmax mAT =⎟⎠⎞

⎜⎝⎛=

l .

Equating the two energies, the fundamental frequency given by Rayleigh’s formula is

2. SIMPLE LINEAR SYSTEMS 21

( ) AIE

mk

AIE

red ρρω 2

3

13.5675

140333

ll

l=== ,

which is only 1.47 % higher than the true solution (6.16).

The above equation indicates that, for the assumed deflection curve, the beam with uniformly distributed mass has the same natural frequency as a massless beam with a concentrated mass ( ) lAρ14033 attached at the end. This is called a reduced mass.

Example 2.3 Determine the fundamental natural frequency of the free-free uniform

beam shown in Fig. 2.7.

Fig. 2.7

Solution. The assumed deflected shape can be taken of the form

ax−=

l

πsin0vv .

The constant a has to be determined from the conservation of momentum for the free-free beam

( ) ( ) ( )( ) 0d000

===⋅ ∫∫∫lll

dxvv AdxAmassvelocity ρωρω ,

which yields π2 0v=a .

Using the deflected shape of the form

⎟⎠⎞

⎜⎝⎛ −=

π2πsin0

l

xvv ,

equation (2.19) yields the fundamental natural frequency

AIE

ρω 21

22.6l

= .

MECHANICAL VIBRATIONS 22

The true solution (6.21) is AIE

ρω 21

22.4l

= so that the discrepancy is only

0.9 %.

2.2 Undamped Forced Vibrations

Undamped forced vibrations are produced by variable forces or imposed displacements. If the mass is subjected to a harmonic force of constant amplitude and variable frequency, when the driving frequency approaches the system natural frequency, the response tends to increase indefinitely. This condition is called resonance and is characterised by violent vibrations. For undamped systems, resonance frequencies are equal to the system natural frequencies and in most cases operation at resonance has to be avoided. For damped systems, the response at resonance has finite magnitude.

A swing pushed at the right intervals exhibits resonant oscillations. Operation of soil compactors, concrete tampers, vibration conveyers, road drills and vibrating screens is often based on resonant vibrations. However, the main concern with resonance relates to its adverse effects. While operating at resonance, excessive motion and stress amplitudes are generated, causing structural fatigue and failure, harmful effects or discomfort to humans, and a decrease in product accuracy. The nuisance of a noisy component vibrating at resonance can be an obstacle to the sale of a car or a household appliance.

When the harmonic force is applied to the spring, the driving point displacement decreases to zero at the system natural frequency. This condition is called antiresonance. Generally, it is a local property, dependent upon the driving location. It helps obtaining points with very low vibration amplitudes.

2.2.1 Mass Excitation with Arbitrary Force

Consider a force ( )tF with an arbitrary general time variation (Fig. 2.8).

During the short time interval τd , the force ( )τF can be considered constant. The cross-hatched area represents an infinitesimal impulse ( ) ττ dF which produces a velocity variation

( )m

Fx ττ dd =& .

The response of mass m due to the differential impulse, over the entire response history for τ>t , is

2. SIMPLE LINEAR SYSTEMS 23

( ) ( )τωω

ττ−= t

mFx n

nsin1dd , (2.20)

which can be deduced from (2.6) considering that at τ=t , 00 =x and x&d=0v .

The entire loading history may be imagined to consist of a succession of such infinitesimal impulses, each producing its own differential response of the form (2.20).

Fig. 2.8

For a linear system, the total response can be obtained by summing all the differential responses developed during the loading history, that is, by integrating equation (2.20) as follows

( ) ( ) ( )∫ −=t

nn

tFm

tx0

dsin 1 ττωτω

. (2.21)

Equation (2.21) is generally known as the Duhamel integral for an undamped system.

2.2.2 Mass Excitation with Harmonic Force

The mass-spring system from Fig. 2.9, a is excited by a harmonic force ( ) tFtf ωcos0= of constant amplitude 0F and driving frequency ω , applied to

the mass.

Based on the free body diagram of Fig. 2.9, b, its motion is described by Newton’s second law

tFkm ωcos0+−= xx&& ,

which can be written tFkm ωcos0=+ xx&& . (2.22)

MECHANICAL VIBRATIONS 24

The general solution of the linear non-homogeneous equation (2.22) is the

sum of the homogeneous solution (2.3) of the equation with zero right-hand side

and a particular solution. The particular solution can be found by assuming that it

has the same form as the forcing function

( ) tXt ωcos=Px , (2.23)

where X is the amplitude of the forced response in steady-state conditions.

Fig. 2.9

On substitution of the particular solution (2.23), equation (2.22) becomes

tFtXktXm ωωωω coscoscos 02 =+−

which can be divided throughout by tωcos yielding

( ) 02 FXmk =− ω

or ( ) 22

02

0

11 n

stXkm

kF

mk

FX

ωωωω −=

−=

−= . (2.24)

In (2.24)

kF

X st0= (2.25)

is the static deflection of the spring under the (constant) load 0F and mkn =ω is the undamped natural circular frequency (2.4).

Provided that nωω ≠ , the general solution of equation (2.22) is

2. SIMPLE LINEAR SYSTEMS 25

( )( )

tXtCtCn

stnn ω

ωωωω cos

1cossin 221

−++=tx . (2.26)

Being the sum of two harmonic waves of different frequencies, the solution (2.26) is not a harmonic motion.

Let the initial displacement and velocity be given by the constants 0x and

0v . Equation (2.26) yields

( )( ) 022

10 xXCx

n

st =−

+=ωω

, ( ) 010 v== nCx ω& ,

so that the total response is

( )( ) ( )

tXtXxtn

stn

n

stn ω

ωωω

ωωω

ωcos

1cos

1sin 220

−+

⎥⎥⎦

⎤

⎢⎢⎣

⎡

−−+=

n

0vtx . (2.27)

For zero initial conditions, 000 == vx , the response (2.27) becomes

( )( )

( )ttXn

n

st ωωωω

coscos1 2 −

−=tx . (2.28)

2.2.3 Beats

The difference of cosines in equation (2.28) can be expressed as a product

( )( )

ttXm

n

st ωΔωωω

sinsin1

22−

=tx , (2.29)

where

2ωω

ω+

= nm and

2ωω

ωΔ−

= n .

In the case when ωΔ becomes very small, since mω is relatively large, the product in equation (2.29) represents an amplitude modulated oscillation. The harmonic motion with higher frequency mω is amplitude modulated by the harmonic motion with lower frequency ωΔ (Fig. 2.10). The resulting motion, which is a rapid oscillation with slowly varying amplitude, is known as beats.

The terminology is derived from acoustics. For instance when two strings for the same note on a pianoforte are slightly out of tune, a listener hears the sound waxing and waning (beating). The beats disappear when the strings are in unison, and there is then only one frequency audible.

MECHANICAL VIBRATIONS 26

Fig. 2.10

Beats can be heard in an airplane when the two engines have slightly different speeds. It occurs also in electric power stations when a generator is started. Just before the generator is connected to the line, the electric frequency of the generator is slightly different from the line frequency. Thus the hum of the generator and the hum of other generators or transformers are of different pitch, and beats can be heard.

2.2.4 Frequency Response Curves

It is of interest to examine more closely the frequency dependence of the steady-state response amplitude

( ) stn

XX 211

ωω−= . (2.30)

The absolute value of the coefficient of stX in the right hand side of Eq. (2.30) is referred to as the dynamic magnification factor.

Figure 2.11, a is a plot of the amplitude X as a function of the driving frequency ω . For 1<nωω the ordinates are positive, the force and motion are in phase, while for 1>nωω the ordinates are negative, the force and motion are

0180 out of phase (Fig. 2.11, b). Whereas for 1<nωω the mass is below the static equilibrium position when the force pushes downward, for 1>nωω the mass is above the equilibrium position while the force is pushing downward.

2. SIMPLE LINEAR SYSTEMS 27

Fig. 2.11

Usually this phase relation is considered of slight interest, therefore the resonance curve is plotted as in Fig. 2.11, c with the modulus of amplitude in the ordinate axis. This is often referred to as a frequency response curve.

2.2.5 Resonance

At 1=nωω , when the forcing frequency coincides with the system natural frequency, the amplitude becomes infinitely large (because the system is undamped). This phenomenon is known as “resonance”, and the natural frequency is sometimes also called the “resonance frequency”.

At nωω = the spring force and the inertia force balance each other and the exciting force increases the amplitude of motion of the undamped system without bound. Damped systems have finite amplitudes at resonance and the phase angle between force and displacement is 090 (Fig. 2.28).

Consider the case when, starting from rest, the mass-spring system is subjected to a force of instantaneous magnitude tF nωcos0 , where nω is the

MECHANICAL VIBRATIONS 28

natural frequency. As ω becomes exactly equal to nω , the solution (2.27) is no longer valid. Substitution of ( ) τωτ nFF cos0= into equation (2.21) yields

( ) ( )∫ −=t

nnn

tmFtx

0

0 dsin cos ττωτωω

,

( )⎥⎥⎦

⎤

⎢⎢⎣

⎡−= ∫ ∫

t t

nnnnn ttmFtx

0 0

2

n

0 dsin coscosd cossin ττωτωωττωωω

,

( ) ttmF

tx nn

P ωω

sin2

0= . (2.31)

Thus, when excited at resonance, the amplitude of an undamped system increases linearly with time. Because the excitation is a cosine function and the response is a sine function, there is a 090 phase angle between them. The same result can be obtained using the limit theorems from calculus.

Fig. 2.12

The total solution for non-zero initial conditions is now of the form

( ) ttmFtxt n

nnn

nω

ωωω

ωsin

2cossin 0

00 ++=vtx . (2.32)

A plot of ( )tx versus time is given in Figure 2.12 for zero initial conditions. It can be seen that ( )tx grows without bound, but it takes a time for the displacement amplitude to build-up.

2. SIMPLE LINEAR SYSTEMS 29

2.2.6 Acceleration through Resonance

For most practical vibrating systems, the steady amplitude is achieved quickly and the rate at which it is approached is of little interest.

However, when a vibrating system is driven through the resonance, i.e. when the forcing frequency is swept with some speed tddωε = , there is no time to reach a steady-state condition and the resonance amplitude is finite even for undamped systems. Thus the response to a force of variable frequency may be of major interest when running through a resonance.

The response exhibits a resonance-like peak, sometimes followed by a beating-like response. If the sweep is upwards in frequency (Fig. 2.13), the peak frequency is higher that that obtained for steady-state conditions, the peak amplitude is lower and the width of the resonance curve is larger. If the sweep is downwards in frequency, the peak frequency is lower than the steady-state

resonance frequency. In Fig. 2.13, ( ) ⎟⎠⎞

⎜⎝⎛ +=

221sin 2

0πε tFtf and .const=ε

Fig. 2.13

The effect of sweep rate is dependent on the system damping, because the lighter the damping, the longer the time to reach the steady-state level of vibration. Figure 2.13 is plotted for zero damping.

2.2.7 Resonance for Constant Displacement Amplitude

Resonance relates to the condition where either a maximum motion is produced by a force of constant magnitude, or a minimum force is required to maintain a given motion amplitude.

MECHANICAL VIBRATIONS 30

When the force amplitude F is variable and the displacement amplitude 0X is kept constant, equation (2.24) can be written

( )[ ]20 1 nXkF ωω−= . (2.33)

Figure 2.14 is a plot of the force modulus as a function of the driving frequency for const.X =0 For an undamped system, the force at resonance is zero, because the spring force is balanced by the inertia force.

Fig. 2.14

Resonance is a condition whereby a minimum of excitation is required to produce a maximum of dynamic response.

2.2.8 Excitation with Unbalanced Rotating Masses

For many systems, vibrations are produced by driving forces from unbalanced rotating masses. In contrast to the constant-force-amplitude case previously discussed, the rotating-mass-type force has an amplitude proportional to the square of the frequency of vibration. The vibratory force is thus tem 2 ωω cos1 , where 1m is the eccentric mass located at an eccentricity e (Fig. 2.15, a).

The amplitude of the forced vibrations produced by such a force can be obtained by a substitution of 2em ω1 for 0F in equation (2.24). Then

( )( )

( ) 2

2

2

21

2

21

11 n

n

ne

kem

mk

emX

ωωωω

ωω

ω

ω

ω

−=

−=

−= . (2.34)

2. SIMPLE LINEAR SYSTEMS 31

It should be pointed out that m is the total vibrating mass and includes the mass 1m .

a b

Fig. 2.15

Figure 2.15, b is a plot of the absolute value of X from equation (2.34) as a function of the circular frequency ω , for .conste = The curve starts from zero, goes to infinity at resonance and decreases to e for high frequencies.

2.2.9 Antiresonance

Consider the mass-spring ungrounded system from Fig. 2.16, subjected to a harmonic force applied to the base. The equations of motion can be written

( ) tFxkm ωcos0122 =−=− xx&& .

The magnitude of the driving point displacement is given by

( )( ) 2

20

2

20

11

n

nkF

mmk

kFX

ωωωω

ωω −

=−

= .

For constant force amplitude .constF =0 , its modulus has a minimum zero value at the natural frequency.

This is a condition of antiresonance. Generally, it takes place at a frequency at which a maximum of force magnitude produces a minimum of motion.

Unlike the resonance, which is a global property of a vibrating system, independent of the driving point, antiresonance is a local property, dependent on the driving location.

MECHANICAL VIBRATIONS 32

Fig. 2.16

In the absence of damping, the antiresonance frequency of the base excited sprung-mass system is the same as the resonance frequency of the grounded mass-excited system. If a second mass is attached at the driving point, the resulting mass-spring-mass system exhibits both a resonance and an antiresonance in the driving-point response.

2.2.10 Transmissibility

If the mass-spring system is excited by a prescribed motion tXx ωcos 11 = applied to the spring end not connected to the mass, then the

motion transmitted to the mass tXx ωcos 22 = is defined by the amplitude ratio

( ) 21

2

11

nXX

ωω−= . (2.35)

The ratio 12 XXTR = is called transmissibility and is plotted in Fig. 2.17 as a function of the frequency ratio nωω .

For 2>nωω , the transmissibility is less than unity and the sprung mass is said to be isolated from the base motion. Vibration isolation is possible only above resonance, for frequencies nωω 2> . The spring between the mass and the vibrating base can be designed to ensure a given degree of isolation, by imposing the value of TR . This shows how much the motion of the isolated mass is reduced with respect to the case when it had been directly mounted on the vibrating base.

2. SIMPLE LINEAR SYSTEMS 33

Fig. 2.17

2.2.11 Critical Speed of Rotating Shafts

Consider the rotor shown in Fig. 2.18, consisting of a single rigid disc symmetrically located on a uniform massless shaft supported by two rigid bearings. The disc centre of mass G is at a radial distance e from its geometric centre C. The centre line of the bearings intersects the plane of the disc at point O.

As the shaft starts to rotate about the bearing axis, the disc rotates in its own plane about its geometric centre C. A centrifugal force 2

Grm ω is thus applied to the disc, where ω is the speed of rotation, m is the mass of the disc and

OGrG = . This force causes the shaft to deflect in its bearings and the shaft is said to be in a state of unbalance. The shaft reacts with a restoring force Crk acting in C, where k is the stiffness of the shaft at the disc and OCrC = .

Neglecting the effect of gravity and damping, the disc is under the action of only these two forces. In order to be in equilibrium, these forces must be collinear, equal in magnitude, and opposite in direction

( )ermrk CC += 2ω .

Solving for Cr , we obtain

( )( ) 2

2

2

2

1 n

nC

emk

emrωω

ωωω

ω−

=−

= . (2.36)

where mkn =ω is the natural circular frequency of the rotor lateral vibration at zero speed.

MECHANICAL VIBRATIONS 34

This expression represents the radius of the orbit along which the point C moves about the bearing axis with an angular velocity ω . Because at the same time the disc rotates in its own plane about C with the same angular velocity, the shaft whirling is called synchronous precession.

Fig. 2.18

The radius of the circular orbit of point G is

( ) 21 nCG

eerrωω−

=+= . (2.37)

A plot of Cr (solid line) and Gr (broken line) as a function of ω is given in Fig. 2.19. At a speed nωω <1 the system rotates with the heavy side 1G outside

1C , whereas for nωω >2 the light side, or the side opposite 2G , is outside 2C . For very high speeds, nωω >> , the radius Cr becomes equal to the eccentricity and the points O and G coincide; the disc rotates about its centre of gravity.

When nωω = , the radii Cr and Gr grow without bound, a state defined as a critical speed. Equations (2.36) and (2.37) indicate that the critical speed of the shaft is equal to the natural frequency of the lateral vibration of the rotor.

The sudden change of the relative position of points O, C and G at the critical speed is due to the neglection of damping. In damped systems, the segment CG rotates continuously with respect to OC, when the shaft speed varies, so that the “high point” does not coincide with the “heavy point”. At the critical speed, the angle between the two segments is 090 (see Sec. 2.4.11)

2. SIMPLE LINEAR SYSTEMS 35

Fig. 2.19

Although there is an obvious analogy between the analytical results (2.36) and (2.37) on one hand, and the steady-state response of a linear mass-spring system (2.30) and (2.34) on the other hand, the forced motion of the shaft is not a genuine vibration. The shaft does not experience any alternating stresses while executing this motion. It just bows out in a simple bend. The bend is greatest when the angular speed is equal to the circular frequency of bending vibration that the shaft would have if it did not rotate and were simply executing free undamped flexural vibrations.

2.3 Damped Free Vibrations

During vibration, energy is dissipated by friction or other resistances. The motion amplitude in free vibration diminishes with time, while the steady amplitude can be maintained only by external forcing. The dissipation of energy is generally termed damping. It is produced by internal friction in materials, by friction between structural components, by fluid-structure interactions, by radiation or by movement in electric or magnetic fields.

The simplest damping mechanism is due to movement in a viscous medium, and the viscous damping force is directly proportional to velocity. It is convenient to replace all damping forces by a single equivalent viscous damping force based on the same value of energy dissipated during a cycle of vibration. Structural or hysteretic damping is described by a damping force in phase with velocity but proportional to the displacement. Experience has indicated that in aircraft structures the damping loss is better represented by the hysteretic damping. More complicated mechanisms, such as hereditary damping, can be used to better describe the behaviour of actual systems.

MECHANICAL VIBRATIONS 36

2.3.1 Viscous Damping

The system shown in Fig. 2.20, a consists of a linear spring of stiffness k, a mass m and a viscous damper or dashpot. The force in the dashpot is directly proportional to velocity and of opposite sign. The proportionality coefficient is referred to as the viscous damping coefficient, c, having units of ( )secmN .

Fig. 2.20

For free vibrations, the differential equation of motion can be obtained by use of Newton’s second law and the free body diagram from Fig. 2.20, b

xx kxcm −−= &&& ,

which can be written

0=++ xx kxcm &&& . (2.38)

Assuming solutions of the form tsx e= , we obtain the characteristic equation

02 =++mks

mcs , (2.39)

which has two roots

mk

mc

mcs −⎟

⎠⎞

⎜⎝⎛±−=

2

21, 22. (2.40)

The general solution for the damped free vibrations is

( ) tsts eCeCtx 2121 += , (2.41)

where the integration constants are determined from the initial conditions.

As a reference quantity, we define critical damping as corresponding to the value of c for which the radical in (2.40) is zero

2. SIMPLE LINEAR SYSTEMS 37

nc

mk

mc ω==2

,

or nc mmkc ω22 == . (2.42)

The actual damping of the system can be specified by a dimensionless quantity, which is the ratio of the actual system damping to the critical system damping

ccc

=ζ (2.43)

referred to as the damping ratio (or percent of critical damping)

Using this notation, equation (2.40) becomes

ns ω⎟⎠⎞⎜

⎝⎛ −±−= 1ζζ 2

21, . (2.44)

Three possible cases must be considered for the above equations, depending on whether the roots (2.44) are real, complex, or equal.

Case I: Underdamped system, 1ζ <

For 1ζ < , equation (2.44) can be written

ns ω⎟⎠⎞⎜

⎝⎛ −±−= 2

21, ζ1iζ . (2.45)

Substitution of (2.45) into (2.41) and conversion to trigonometric form with the aid of Euler’s formula βββ sinicosei += , yields

( ) ⎟⎠⎞

⎜⎝⎛ += −−− t-tt nnn eCeCetx ωωω 22 ζ1i

2ζ1i

1ζ ,

or

( ) ⎟⎠⎞⎜

⎝⎛ +−= − φωω teAtx n

tn 2ζ ζ1sin . (2.46)

Equation (2.46) indicates that the motion is oscillatory with diminishing amplitude. The decay in amplitude with time is proportional to tnωζe− , as shown by the dashed curves in Fig. 2.21.

The frequency of the damped oscillation

nd ωω 2ζ1−= (2.47)

is less than the undamped natural frequency nω and is called the damped natural frequency. As 1ζ → , dω approaches zero and the motion is no more oscillatory.

MECHANICAL VIBRATIONS 38

Equation (2.44) can be written

ds ωσ i21, ±−= (2.48)

where nωσ ζ= (2.49)

is the rate of decay of amplitude (slope of tangent to the exponential curve at 0=t ).

Fig. 2.21

The following equations are useful

22ζ

σω

σ

+=

d

, 22

ζσωσω +== dn . (2.50)

Fig. 2.22

2. SIMPLE LINEAR SYSTEMS 39

Case II: Overdamped system, 1ζ >

For 1ζ > , substitution of (2.44) into (2.41) yields

( )tt nn

eCeCtxωω ⎟

⎠⎞⎜

⎝⎛ −−−⎟

⎠⎞⎜

⎝⎛ −+−

+=1ζζ

21ζζ

1

22

.

The motion is no longer oscillatory (Fig. 2.22) and is referred to as aperiodic.

Fig. 2.23

Case III: Critically damped system, 1ζ =

Critical damping represents the transition between the oscillatory and nonoscillatory motions. In this case, the general solution is

( ) ( ) tntCCtx ω−+= e21 .

The motion is similar to that with damping greater than critical (Fig. 2.23) but returns to rest in the shortest time without oscillation. This is used in electrical instruments whose moving parts are critically damped to return quick on the measured value.

2.3.2 Logarithmic Decrement

A way to determine the amount of damping in a vibrating system is to measure the rate of decay of oscillations. This is conveniently expressed by the logarithmic decrement, which is defined as the natural logarithm of the ratio of any two successive amplitudes. For viscous damping, this ratio is a constant.

Consider the recorded curve of a damped vibration (Fig. 2.24), expressed by equation (2.46).

MECHANICAL VIBRATIONS 40

Fig. 2.24

The decaying sinusoid is tangent to the exponential envelope at points that are slightly to the right of the points of maximum amplitude, where the sine function is equal to 1. However, this difference is negligible, so the ratio of two successive amplitudes can be replaced by the ratio of exponential ordinates at a period distance

( )dn

dn

nT

Tt

te

eA

eAxx ω

ω

ωζ

ζ

ζ

2

1 ==+−

−

where the period of the damped vibration is

dndT

ωω

2π

ζ1

2π2

=−

= .

The logarithmic decrement is

22

1

ζ1

ζπ2ζln−

=== dn Txx ωδ . (2.51)

For 1ζ << , ζ2πδ ≅ .

Sometimes the decay after one cycle of vibration is too small so that it is possible to distinguish a smaller amplitude only after n cycles. The ratio

⋅⋅=3

2

2

1

1

00

xx

xx

xx

xx

n( ) δδ nn

n

n eex

x==−1

so that the logarithmic decrement is given by

nxx

n0ln1

=δ . (2.51, a)

2. SIMPLE LINEAR SYSTEMS 41

If the peak amplitude of vibration is plotted on a logarithmic scale against the cycle number on an arithmetic scale, the points will fall on a straight line if the damping is of viscous type as assumed in equation (2.38).

In practice, the envelopes of peaks and troughs are first drawn (Fig. 2.25). The height between the envelope lines is then measured at each peak and trough. The height is plotted on a logarithmic scale against the number of semicycles and the best line is drawn through the points. The slope of this line is then used to determine the damping ratio.

Fig. 2.25

For 1ζ << , equation (2.51, a) yields

MECHANICAL VIBRATIONS 42

nxxn ⋅−= πζ2lnln 0

so that the damping ratio ζ is equal to the slope of the line divided by π2 (or by π , if measurements are made at heights and troughs as in Fig. 2.25).

2.3.3 Loss Factor

A convenient measure of damping is obtained by the loss factor which is defined as the ratio of energy lost per cycle (or energy that must be supplied to the system to maintain steady-state conditions) UΔ to the peak potential energy U stored in the system during that cycle

UUη Δ

= . (2.52)

In general, the loss factor depends on both the amplitude and frequency of the vibration, and can be applied also to nonlinear systems and to systems with frequency-dependent parameters.

If 1X and 2X are two consecutive amplitudes of a damped free vibration,

the energy stored in the spring at maximum displacement is 211

21 XkU = ,

222

21 XkU = . The loss of energy divided by the original energy is

δδ 2111 22

1

2

1

2

1

21 ≅−=⎟⎟⎠

⎞⎜⎜⎝

⎛−=−=

− −eXX

UU

UUU

where δ is the logarithmic decrement. Hence, for small damping, the loss factor is approximately twice the logarithmic decrement

δη 2≅ . (2.52, a)

2.4 Damped Forced Vibrations

During damped forced vibrations, the response lags the excitation due to the energy dissipation by damping. The response at phase resonance has finite magnitude and is 090 phase shifted with respect to the forcing. The amplitude of motion at resonance is related to damping and the width of the resonance curve is directly proportional to the system damping. In the case of harmonic vibrations, the displacement-force diagram is a closed hysteretic loop which for viscous damping is an ellipse whose area is a measure of the energy dissipated by damping.

2. SIMPLE LINEAR SYSTEMS 43

2.4.1 Steady State Vibrations with Viscous Damping

Consider the spring-mass-dashpot grounded system subjected to a harmonic force tF ωcos0 applied to the mass (Fig. 2.26, a).

Fig. 2.26

Based on the free body diagram from Fig. 2.26, b the differential equation of motion can be written as

tFkxcm ωcos0=++ xx &&& . (2.53)

The complete solution of equation (2.53) consists of the sum of the solution (2.46) of the homogeneous equation (2.38) and a particular solution which corresponds to the type of excitation in the right hand side.

Due to the damping, the homogeneous solution soon dies out, leaving only the particular solution which is a harmonic motion having the same frequency as the exciting force and a phase lag due to damping

( ) ( )ϕω −= tXtx cos . (2.54)

The displacement amplitude X and the phase shift ϕ between displacement and force are found by substituting the above solution into the equation (2.53).

Shifting all the terms to the right hand side, we obtain

( ) ( ) ( ) 0coscossincos 02 =+−−−+− tFtXktXctXm ωϕωϕωωϕωω .

The terms in the above equations are projections of force vectors on a (horizontal) line at an angle tω with respect to the force vector (Fig. 2.27).

The force vector 0F is ϕ degrees ahead of the displacement vector X . The spring force Xk is opposite to the displacement, while the inertia force

MECHANICAL VIBRATIONS 44

Xm 2ω is in phase with the displacement. The damping force Xcω is 090 ahead the spring force. The vectors remain fixed with respect to each other and rotate together with angular velocity ω . The rotating vector (phasor) diagram in Fig. 2.27 is drawn for a forcing frequency lower than the resonance frequency.

Fig. 2.27

Summation of vector projections in the displacement direction and in the normal direction provides the equilibrium equations

ϕω cos02 FXmXk =− , ϕω sin0FXc = . (2.55)

A component of the driving force balances the damping force while the other component is necessary to balance the reactive force, i.e. the difference between the elastic force and the inertia force.

Solving for X and ϕ yields the amplitude of the forced vibration

( ) ( ) ( )[ ] ( ) 2 2 2222

0

ζ21 nn

stX

cmk

FXωωωωωω +−

=+−

= , (2.56)

and the phase shift

( )22 1ζ2tan

n

n

mkc

ωωωω

ωωϕ

−=

−= , (2.57)

where mkn =ω and mkc 2ζ = .

These expressions are plotted in Fig. 2.28 for several values of the damping ratio ζ .

2. SIMPLE LINEAR SYSTEMS 45

The amplitude-frequency diagrams are called resonance curves or frequency response curves. Such a curve starts at a value stX , increases to a maximum at the resonance frequency, decreases through the damped natural frequency (2.47) and the undamped natural frequency (2.4), and continues to decrease, approaching zero asymptotically, as the frequency increases.

Fig. 2.28

The phase angle between the force and the displacement varies from zero, at zero frequency, through 090 at the undamped natural frequency, to approach

0180 asymptotically as the frequency increases. When the damping is small, the rate of change of phase shift in passing through a natural frequency is very sharp.

For subcritical damping, the frequency response diagram (Fig. 2.28, a) exhibits a resonance peak which is said to occur at the resonance frequency. For

7070ζ .> , the resonance peak is completely smoothed. Overcritically damped systems do not exhibit resonances.

It is important to note that “amplitude resonance” is defined at the peak

frequency 2ζ21−= nr ωω where the peak value 2ζ1ζ2 −

= stmax

XX of the

steady-state response occurs.

MECHANICAL VIBRATIONS 46

The “phase resonance” is defined to occur at the undamped natural frequency nωω = (when the phase shift is 090 ) when the displacement amplitude

is ζ2st

resX

X = . For small values of damping the two resonances coincide.

Fig. 2.29

The force vector diagram at phase resonance is shown in Fig. 2.29. The spring force balances the inertia force of the mass, and the excitation force overcomes the damping force only. There is a continuous interchange of potential and kinetic energy between the spring and the mass. The only external force that has to be applied to maintain the system vibrating is that needed to supply the energy dissipated by damping.

At resonance, the reactive energy (in spring and mass) is zero and the active energy (actually dissipated) is maximum. That is why a minimum of force is required to maintain a given displacement amplitude. On a plot of the dynamic stiffness (force required to produce unit displacement at the driving point) versus frequency, the resonance appears as a trough (as in Fig. 2.14).

2.4.2 Displacement-Force Diagram

Consider for convenience the steady-state displacement

( ) tXtx ωcos= (2.58)

lagging by an angle ϕ the driving force applied to the mass

( ) ( )ϕω += tFtf cos0 . (2.59)

2. SIMPLE LINEAR SYSTEMS 47

The two equations above are the parametric equations for an ellipse. Eliminating the time between equations (2.58) and (2.59) yields

ϕϕ 2

02

0

2

2

2sincos2 =−+

Ff

Xx

Ff

Xx . (2.60)

The displacement-force response forms an elliptical hysteresis loop as shown in Fig. 2.30, which is traversed in the anticlockwise direction.

Fig. 2.30

The area inside this loop is the energy dissipated during a cycle of motion. It is equal to the work done by the force (2.59) acting on the displacement (2.58)

( ) ( )tttFXttxfxfWd ωωϕω

πωπ

dsincosdddd

2

00

2

0∫∫∫ +−=== ,

ϕsinπ 0 XFWd = .

Using the second equation (2.55), the above expression becomes 2π XcWd ω= . (2.61)

In order to produce work, the damping force tXxcfd ωω sin=−= & must

be 090 phase shifted with respect to the displacement ( ) tXtx ωcos= .

If the displacement and force are measured with appropriate transducers and the signals are fed to an oscilloscope (displacement as ordinate and force as abscissa) the resulting image is a Lissajous’ figure. At low frequencies the figure is a straight line, its slope depending on the ratio of amplitudes of the two signals (Fig. 2.31, a). As the frequency increases the straight line opens into an ellipse (Fig. 2.31, b) whose major axis increases with frequency. At the undamped natural frequency (Fig. 2.31, c) the ellipse major axis is very large and vertical. As the

MECHANICAL VIBRATIONS 48

frequency continues to increase, the major axis continues rotating but decreases in magnitude (Fig. 2.31, d). The width of the ellipse decreases until at frequencies well above resonance the ellipse is again reduced to a line which lies almost parallel to the horizontal axis (Fig. 2.31, e).

Fig. 2.31

At the phase resonance, nωω = , 090=ϕ , kFX res ζ20= , the ellipse major axis is vertical and the energy dissipated by damping is

20 ππ resnresd XcXFW ω== . (2.62)

The energy dissipated per cycle by viscous damping is directly proportional to the excitation frequency (eq. 2.61).

2.4.3 Structural Damping

Experiments with aircraft structures and various materials indicate that the energy dissipated per cycle of vibration is independent of frequency and proportional to the square of displacement amplitude. Damping values for engineering structures are relatively low even at high resonant frequencies. Also, if all damping were viscous, then small, high frequency bells would react to a strike with a dull thud, instead of a clear tinkle.

This means that the viscous damping, adopted first for its mathematical tractability, should be replaced by a model in which the energy dissipated by damping is independent of frequency. This type of damping is called hysteretic or structural damping.

2. SIMPLE LINEAR SYSTEMS 49

The use of the term “hysteretic” damping is somewhat confusing, since all damping mechanisms involve a hysteresis curve of some sort. Thus the word “structural” is preferred herein to describe this particular mechanism. It implies a resisting force which is in phase with velocity but, unlike the viscous damping, has a magnitude which is not proportional to the velocity but to the displacement. The damping coefficient is inversely proportional to frequency so that the damping force is ωxh &− (rather than xc&− ). Equation (2.53) becomes

tFkxhm ωω

cos0=++ xx &&& , (2.63)

where h is the coefficient of structural damping. The inclusion of ω in the

coefficient of x& implies that only solutions with this frequency may be thought.

Alternatively, this equation of motion may be written in terms of the complex

stiffness hkk i+=∗ , since it is decided that a harmonic solution is required

( ) teFhkm ωi0i =++ xx&& . (2.64)

Since c is replaced by ωh , the dissipation of energy per cycle is

2π XhWd = , (2.65)

which is independent of frequency.

Equations (2.56) and (2.57) become

( ) ( )[ ] 222222

0

1 g

X

hmk

FX

n

st

+−=

+−=

ωωω, (2.66)

( )22 1tan

n

gmkh

ωωωϕ

−=

−= , (2.67)

where khg = is the structural damping factor.

2.4.4 The Half-Power Points Method

The resonance curve of the spring-mass-dashpot system can be used to determine the damping ratio (Fig. 2.32).

When nωω = the resonant amplitude is ζ2st

resX

X = . For small values of

damping, the peak M coincides with the point of phase resonance. The points B and

MECHANICAL VIBRATIONS 50

C, of ordinate ( ) resX22 are referred to as the half-power points. The amplitude

squared is ( ) 221 resX , so that the power dissipated by damping at the corresponding frequencies 1ω and 2ω is half the power dissipated at resonance.

Fig. 2.32

Substituting into equation (2.56) we obtain

( )( ) ( ) 222

2

ζ21

1ζ2

1 21

nn ωωωω +−=⎟⎟

⎠

⎞⎜⎜⎝

⎛,

which yields the equation

( ) ( ) ( ) ( ) 0ζ81ζ212 2224 =−+−− nn ωωωω .

Solving, we obtain the frequencies of half-power points

( ) ( ) 22221 ζ1ζ2ζ21 +±−=,nωω

which for 1ζ << can be approximated by

( ) ζ21221 ±≅,nωω .

Denoting ( )ζ21221 −≅ nωω and ( )ζ2122

2 +≅ nωω , we obtain

2. SIMPLE LINEAR SYSTEMS 51

21

22

21

22ζ2

ωω

ωω

+

−≅ (2.68)

or

nnnn ωωω

ωωω

ωωω

ω

ωω 1212122

21

22

22ζ2

−≅

+−=

−≅

so that the damping ratio is given by

nωωΔ

2ζ ≅ , (2.69)

where 12 ωωωΔ −= is the bandwidth of the resonance curve.

From the shape of the resonance curve it is difficult to establish if the damping is really of the viscous type. If only a single degree of freedom is considered, and the motion is to be harmonic, it is most convenient to use the concept of “equivalent viscous damping”, in which the viscous damping coefficient has such a value that the energy dissipated in a harmonic displacement cycle of a certain amplitude and frequency is the same as that of the actual damping mechanism in the same displacement cycle. In equation (2.43) the coefficient c is then the coefficient of equivalent viscous damping.

2.4.5 The Added Mass Method

In the neighbourhood of an isolated resonance, the behaviour of a general vibrating system resembles the response of a single-degree-of-freedom system. The equivalent mass and equivalent stiffness of the substitute system can be determined by the additional mass method.

Fig. 2.33

Two frequency response curves are experimentally drawn, one for the actual system, and the other for the system with a known additional mass am

MECHANICAL VIBRATIONS 52

(Fig. 2.33). The natural frequencies 1nω and 2nω are determined at peak displacement amplitudes.

From the corresponding equations (2.4) 21nmk ω= , (2.70)

( ) 22nammk ω+= , (2.71)

it is possible to obtain the equivalent mass

( ) 122

21 −

=nn

ammωω

, (2.72)

then, from equation (2.70), the equivalent stiffness k.

Note that the resonance response of the system with added mass is larger because for the actual system

km

cF

cF

kFX

nres

0

1

0

1

0ζ21

1===

ω

and for the system with the added mass

kmm

cF

cF

kFX a

nres

+=== 0

2

0

2

0ζ21

2 ω.

If the system operating frequency is near 1nω , then the forced response of the vibrating system may be decreased by adding a mass am .

2.4.6 Solution by Complex Algebra

For harmonic excitation, the force acting on the mass of the system of Fig. 2.26 can be written

( ) teFtf ωi0= , (2.73)

so that the steady-state solution (2.54) becomes

( ) teXtx ωi= , (2.74) where

IR XXeXX ii +== θ (2.75)

is the complex displacement amplitude.

In equation (2.75), X is the modulus, θ is the phase angle, RX is the real

2. SIMPLE LINEAR SYSTEMS 53

(in-phase) component, and IX is the imaginary (in-quadrature) component

θcosXX R = , θsinXX I = , (2.76) 22IR XXX += , RI XX=θtan . (2.77)

For structural damping, the equation of motion (2.63) becomes

teFkxhm ω

ωi

0=++ xx &&& . (2.78)

Substitution of (2.74) in (2.78) yields

( ) 02 i FXkhm =++− ω .

The complex amplitude X is determined as

( ) gX

hmkFX

n

st

i1i 220

+−=

+−=

ωωω, (2.79)

where mkn =ω , khg = , so that

( )( )[ ] st

n

nR X

gX

222

2

1

1

+−

−=

ωω

ωω , ( )[ ] st

n

I Xg

gX2221 +−

−=

ωω (2.80)

( )[ ] st

n

Xg

X2221

1

+−=

ωω,

( )21tan

n

gωω

θ−

−= . (2.81)

Eliminating ω between the expressions of RX and IX yields 2

22

21

21

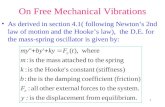

⎟⎟⎠