Louet Bookbinding Tools2

Transcript of Louet Bookbinding Tools2

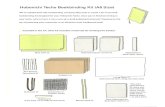

Rubber Back Binding Press

This press has been created for book binding without sewing and allows the user to glue loose sheets to a book. Maximum back side length is 34cm. The press is made of birch plywood with a brown non-adhesive melamine top coating. Two table clamps are included for binding oblong.

Universal Pricking Gauge This gauge has a row of 1.8 mm wide awl holes at 16 mm for 15 mm binding ribbons. The knurled bolt at the end allows for adjusting the position of the pricking holes in regard to the back of the magazine. Using a pencil, the user can mark the selected holes to simplify the pricking. The holes in the triangular prick bar guide the awl straight into the back of the magazine.

The gauge is made of lacquered beech. This is a terrific tool for clean binding work.

Bookbinding equipment

Louët BV - Kwinkweerd 139 - 7241 CW Lochem - Holland T: +31 (0)573-252229 - F: +31 (0)573-253858 - W: www.louet.nl - E: [email protected]

Case binding tool One of the most difficult actions which have to be done precisely is the assembly of the book block into the case. The squares must be equally adjusted and the pasting process has to be executed quickly because the moist of the glue curls fly-leafs. With this tool you adjust the position of the book block in the case for assembling. The squares of the book can be adjusted by sliding the stops with the knurled knobs. These stops accept a maximum of 3.5 mm cardboard thickness for the case. The two square top stops control the parallel position of the case.

Book blocks in thickness measuring from 7.5 to 60 mm can be assembled in their cases on this tool. The assembling tool measures 360 x 250 mm and is made of unlacquered birch plywood.

Vertical Plough

The Louët vertical plough (a stationary version of a plough) is a very useful tool for hobby bookbinders, schools and small printers. This cutting tool enables the user to make a clean cut through paper up to a maximum thickness of 45 mm and 430 mm length. With the table clamps it can be attached to a table. The easy-to-operate knife holder runs smoothly over a rail on ball bearings. The cutting blade is made of high grade HSS steel and can be moved down the paper by adjusting a knurled nut at the top while cutting. The guide rail is extremely stable and will not bend. It guides the blade perfectly straight and vertical through the paper. The result is a smooth cut without mark which can sometimes appear when cut by machine. The tip of the blade runs into a nylon strip in the worktable which ensures that the blade remains sharp.

When the nylon strip becomes deeply notched, it can be easily removed, turned and installed again. This can be repeated 8 times before it must be replaced. Two springs support the guide rail and allows it to remain open while the paper is positioned onto the work table. Two large knurled nuts positioned below the work table can be tightened to clamp the paper securely in place while cutting. A graduated (metric) ruler is located on a right angle with the guide rail and acts as a stopper for the paper stack. A parallel guide is attached to the ruler and can be positioned as needed. The cutting blade runs precisely at the edge of the guide rail. After repeated use, the moon-shaped cutting blade can be sharpened with a simple tool (included). The wooden parts are made of lacquered birch plywood and ash hardwood.

Universal Cutting Board

This cutting board is designed to cut various kinds of paper, board, cloth and buckram in accurate straight lines and right angels. The hard plastic laminated work table measures 50 x 80 cm. The maximum cutting size is 80 cm. The graduated stop ruler runs to 45 cm. The cutting rail pivots in a 90 degree angle with the stop ruler and clamps (to) the board. A rubber strip under-neath prevents the material from slipping while cutting.

The supplied hobby knife fits precisely into the cleft of the cutting rail and guides it to a straight line. It is possible to cut a perfectly straight line through thick board without difficulty. The tip of the knife runs through a plastic strip within the work table, which ensures that the blade remains sharp. When the strip becomes deeply notched, it can be removed simply, turned and installed again. This can be repeated 8 times before it must be replaced. New strips are available.

Procedure

• Lift the cutting rail and place the board against the stop ruler.

• Press the cutting rail down and cut the board with the provided knife.