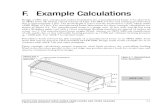

Load Calculation and Design of Purlin

-

Upload

sushmit-sharma -

Category

Documents

-

view

42 -

download

2

description

Transcript of Load Calculation and Design of Purlin

-

Note: this sheet only contains load computation and design of purlin. For desing of truss refer another attachment

Grade of steel tubular pipe used Yst25 As per IS 1106-1963

Purlin size 101.60mm (M)

Height of Truss 2.5 mLength of Top Chord 7.844 mEqual spacing of purlins on chord 1.310 m

Unit wt of materialCGI sheet 0.142 KN/m2

CGI sheet 0.199 KN/m2 = 0.142+0.142*40/100=0.1988KN/m2 (40% additional for lapping of CGI sheet )

1. DEAD LOADTruss Spacing 5.080 mEqual spacing of purlins on chord 1.310 mBottom Chord Length 14.870 mHalf of bottom chord due to symmetical 7.435 mLength of Top Chord 9.005 mRoof slope 0.322 radSelf weight of Purlin/m (Out dia 101.6x4.5 M) 0.0975 KN/m

Weight of CGI Sheet 1.324 KNSelf wt. of purlin 0.495 KNTotal dead load 2.002 KN 10% increased due to cleat plates, nuts, bolts

Total dead load on purlin (Wd) 0.394 KN/m (Total dead load /spacing of purling)Total dead load on truss 2.002 KN (dead load on purlin*length of purlin pipe)

LOAD COMPUTATION: Case-1 (101.6M purlin pipe)

-

2. LIVE LOADLive load 0.75 KN/m2 Minimum imposed load roof where access not provided IS 875Live load as per IS 875 for roof slope >10 0.581 KN/m2 = 0.75-0.02*(18.44-10) refer IS 875Live load on purlin 0.722 KN/m = 0.581*cos*spacing of purlin (1.306m)Live load on truss structure 2.446 KN = 2/3*0.581*cos*spacing of purlin*spacing of truss

(reference IS 875 & LS Negi book)3. WIND LOAD

Pz = 0.6 Vz2

Where, Vb = basic wind speed in m/s at 10m height.k1 = Probability factor (or risk coefficient)k2 = Terrain, height and structure size factork3 = Topography factor

= 1 for upwind slope >3 =

Slope less than 3 k3=1Slope greater than 3 k3=1+C.s 1 to 1.36 for upwind slope >

C=Z/LWhere, Z Height of crest or hillL Projected length of upwind zone from avg. ground level to crest in wind direction.s factor, it is dermined from cliff and escarpment fig.

F = (Cpe - Cpi)*ApzWhere,Cpe = external pressure coeffientCpi = internal pressure coefficent

-

Basic wind speed (Vb) 47 m/sk1 1.07 Probability factor of risk (refer table)k2 1 Terrain, height, structure size factor (refer table)k3 1.054VZ 53.006 m/s

Pz 1685.760 N/m2

Pz 1.686 KN/m2

Width of building w 15.1 mLength of building l 31.8 mHeight of building h 12.5 mh/w 0.8278146 m 0.5 < h/w < 1.5

=18.447

Wind angle 0 0 90 90Face EF GH EG FHCpe -0.7621 -0.515 -0.8 -0.6

Assuming the building to be of medium permeability

Cpi 0.5 -0.5

= Cpe+Cpi -0.2621 -0.015 -0.3 -0.1 = Cpe-Cpi -1.2621 -1.015 -1.3 -1.1

-0.442 -0.025 -0.506 -0.169 KN/m2upward upward upward upward-2.128 -1.711 -2.191 -1.854 KN/m2upward upward upward upward

Wind ward Lee ward

Wind pressure

-

Design wind load intensity 2.1915 KN/m2 upwardWind load on purlin 2.871 KN/mWind load on truss (nodal load) 14.584 KN upward

Design of purlin

Permissible bending stress in extreme fibres in Tension and Compression as per IS:806-1968Grade Fb

kgf/cm2 N/mm2

Yst21 1400 137Yst25 1655 162 Selected material for design of Purlin and Truss Yst32 2050 201

Case-1 (DL+WL)Select 101.6mm dia. medium pipeModulus of section 29100 mm3

Dead load 0.394 KN/m vertical

Total vertical load W2 0.296 KN/m W2= 0.393/1.33 (if wind is load considered combination of dead load Wind load W1 -2.159 KN/m W1=2.576/1.33 and wind load is 33% less effective)

Mx = (w1+w2*cos)*L*L/10 Mx 4845172.4 NmmMy= (w2*sin)*L*L/10 My 241911.14 Nmm

Maximum fibre stress= Mx/Zx+My/Zy bc or bt 174.814 N/mm2 >162 N/mm2 Not OK As per IS 806-1968

bc or bt 174.814 N/mm2 >150 N/mm2 Not OK As per IS 806-1984Case-2 (DL+LL)Select 101.6mm dia. medium pipeModulus of section 29100 mm3

-

Dead load 0.394 KN/m verticalLive load 0.722 KN/m verticalTotal vertical load W2 1.116 KN/m

Wind load W1 0 KN/m Perpendicular to CGI sheet

Mx = (w1+w2*cos)*L*L/10 Mx 2732645.5 Nmm 2.73264545My= (w2*sin)*L*L/10 My 911520.49 Nmm 0.91152049

Maximum fibre stress= Mx/Zx+My/Zy 125.22907 N/mm2