Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

-

Upload

dr-firas-asad -

Category

Documents

-

view

228 -

download

0

Transcript of Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

1/20

Lecture 13 137

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

In this lecture;

---------------------

A-

Source and types.

B- Properties, Specifications and

Tests.

C- Gradation.

D Blending (Combining).

Aggregates: Types, Properties and Gradation

Information listed in this lecture is mainly taken from the Iraqi General Specifications

for Roads and Bridge (SCRB, 2007), Standard Specifications for Engineering Materials

and Methods of Sampling and Testing (AASHTO, 2013), Handbook of Highway

Engineering (Fwa, 2006), http://www.pavementinteractive.org (Accessed on 2015)

and Highways (OFlaherty, 2007) and Aggregate properties (NCHRP, Report 539,

2005).

A- Source and Types

In ASTM D8 (ASTM, 2003), aggregate is defined as a granular material of mineral

composition such as sand, gravel, shell, slag, or crushed stone, used with cementing

medium to form mortars or concrete or alone as in base courses, railroad ballasts,

etc. These aggregates can be divided into three main categories natural,

processed, and synthetic (artificial) aggregates.

Natural aggregates are mined from river or glacial deposits

( ). Gravels and

sands are examples of natural aggregates. According to the AASHTO Specs M146,

stone is crushed or naturally angular particles of rock while gravel is rounded

particles of rock; both should pass a 75-mm (3-in.) sieve and be retained on a 2.00-

mm (No. 10) sieve. In Iraq, the control sieve is No. 4 (4.75 mm) sieve.

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

2/20

Lecture 13 138

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

Sand is granular material resulting from the disintegration, grinding, or crushing of

rock and that will pass the 2.00-mm (No. 10) sieve (No.4 in Iraq) and be retained on

the 0.075 mm (No. 200) sieve.

Silt-clay (minus 75-m (No. 200) material)fine soil particles that will pass the

0.075 mm (No. 200) sieve.

Processed materials include gravel or stones that have been crushed, washed,

screened, or otherwise treated to enhance the performance of the hot mix asphalt

concrete (HMAC). Processed materials tend to be more angular and better graded.

Synthetic (artificial) aggregates are not mined or quarried. Rather, they are

manufactured through the application of physical and/or chemical processes as

either a principal product or a by-product. They are often used to improve the skid

resistance of HMAC. Blast furnace slag, lightweight expanded clay, shale are

examples of artificial aggregates.

In addition to the use of traditional aggregates mentioned above, there has been an

increase in the use of waste products in HMAC. Scrapped tires and glass are the two

most commonly used waste products that have been disposed of in HMAC.

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

3/20

Lecture 13 139

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

4/20

Lecture 13 140

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

B- Properties, Tests and Specifications

Mineral aggregates make up between 80% and 90% of the total volume or 94% to

95% of the mass of hot mix asphalt (HMA). For this reason, it is important to

maximize the quality of the mineral aggregates to ensure the proper performance of

our countrys roadways. The quality of mineral aggregates for road-paving materials

has been specified by the toughness, soundness (durability), cleanliness, particle

shape, angularity, surface texture, and absorption.

This section will mainly review the key aggregates properties considered by the

Superpave mix design method. The Superpave mix design method was recently

designed -1993- to replace the Hveem and Marshall methods. The important

aggregates physical properties, tests and specifications were determined by asking

an expert group in order to determine the consensus and source aggregate

properties. The consensus properties including coarse and fine aggregate

angularity, flat and elongated particles, and clay content were chosen to ensure

that the aggregate quality was sufficient to provide satisfactory HMA performance

for the design traffic level. In contrast, the source properties - including toughness

(Los Angeles abrasion), soundness, and deleterious materialswere to be set by the

agency. This was done to allow for variances in locally available materials.

In addition to the Superpave consensus and source properties, there are other

properties that may influence the performance of aggregates in HMA particle

index, plasticity index (PI), affinity ) ( for asphalt, and absorption.

CAA; FAA;Flat & Elongated and Clay content1- Consensus (required)

Toughness; Soundness, and Deleterious

materials2- Source (optional)

Particle index; PI; Ashpalt affinity and

Absorbtion3- Other properties

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

5/20

Lecture 13 141

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

1- Consensus aggregate properties (required)

a)Coarse Aggregate Angularity (CAA)

CAA is defined as the percent by weight of aggregates retained on the No. 4

(4.75 mm) sieve with one or more fractured face. This property is determined using

ASTM D5821 Standard Test Method for Determining the Percentage of Fractured

Particles in Coarse Aggregate. In this procedure, individual aggregates are manually

examined for the presence of fractured faces.

Once the aggregates are sorted by the number of fractured faces, their percentages

of aggregate with at least one or two fractured faces are calculated. A fractured face

is defined as any angular, rough, or broken surface of an aggregate particle that

occupies more than 25% of the outline of the aggregate particle visible in that

orientation.

The percent of fractured particles in coarse aggregate can provide an indication of

inter-particle shear friction or stability.

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

6/20

Lecture 13 142

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

b) Fine Aggregate Angularity (FAA)

FAA is defined as the percent of air voids present in a loose uncompacted aggregate

sample that passes the No. 8 (2.36 mm) sieve. This property is determined using

AASHTO T304 Standard Method of Test for Uncompacted Void Content of Fine

Aggregate Method A. In this procedure, a nominal 100 cm3calibrated cylinder

measure is filled with fine aggregate through a funnel placed at a fixed height above

the measure. When the measure is overfilled, it is struck off

( ) and the mass

of aggregate inside the measure is determined by weighing.

The uncompacted void content is the difference between the volume of the

cylindrical measure and the absolute volume of the fine aggregate (calculated from

its mass and bulk dry specific gravity). For fine aggregate with a given gradation, the

higher the void content, the higher the assumed angularity and rougher the surface.

High angularity results in high internal friction of aggregate and hence high shear

strength ( = c + tan ).

Generally, angular aggregates are harder to compact due to the aggregate-interlock

(low workability), which gives the mix greater shear strength. These mixes tend to

be more stable and resistant to rutting.

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

7/20

Lecture 13 143

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

c) Flat and Elongated Particles

Flat or elongated particles are defined as aggregate having a ratio of width to

thickness or length to width greater than a specified value. This property is

determined using ASTM D4791 Standard Practice for Flat Particles, Elongated

Particles, or Flat and Elongated Particles in Coarse Aggregate.

This test is conducted on aggregates retained on the No. 4 (4.75 mm) sieve. In this

procedure, a proportional calliper ( )is used to measure the

dimensional ratio of a representative sample of coarse aggregate. Aggregates

exceeding the 5 to 1 ratio are considered flat and elongated in the Superpave mix

design system. The percent of flat or elongated aggregates is reported as a

percentage of total aggregates tested.

Aggregates used in HMA mixes should be cubicle rather than disproportionate in

their dimensions. Aggregates particles that are significantly longer in one dimension

than in the other one or two dimensions have a propensity to break during the

construction process or under traffic loading.

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

8/20

Lecture 13 144

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

d) Clay content

Clay content is defined as the percentage of clay material contained in the aggregate

fraction that passes the No. 4 (4.75 mm) sieve. This property is determined using

AASHTO T176 Standard Method of Test for Plastic Fines in Graded Aggregates and

Soils by Use of the Sand Equivalent Test.

In this procedure, a sample of fine aggregate is placed in a graduated cylinder with a

flocculating solution. The cylinder is then agitated to loosen the clayey fines within

and surrounding the aggregate particles. After allowing the constituents to

settle for a specific length of time, the height of suspended clay and sedimented

aggregate is measured. The sand equivalent value is the ratio of the sand reading to

the clay reading as a percentage.

A low sand equivalent value, or high clay content, means that there is dirt on the

surface of the aggregates. This dirt can reduce the bond between the aggregate

and asphalt cement. Consequently, the mix would have a greater tendency for

stripping. Cleaner aggregate with higher sand equivalent values will enhance the

performance of HMA. According to SCRB (2009) sand equivalent value should not be

less than 45%

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

9/20

Lecture 13 145

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

2- Source aggregate properties (optional)

a) Toughness

Toughness is the percent loss of material from an aggregate blend during the Los

Angeles Abrasion (

/

) test. This property is determined using AASHTO T96

(ASTM C131) Standard Method of Test for Resistance to Degradation of Small-Size

Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. The Los

Angeles (L.A.) abrasion test is a common test method used to indicate aggregate

toughness (impact resistance) and abrasion characteristics (hardness). These

characteristics are important because the aggregate in HMA must resist crushing

, degradation and disintegration it might face during stockpiling,

producing (in plant), placing, and compacting. Aggregates not adequately resistant

to abrasion and polishing may cause premature structural failure and/or a loss of

skid resistance.

In this procedure, aggregate is degraded (broken apart to smaller sizes) through

abrasion, impact, and grinding ( ) in a rotating steel drum ( ) containing steel

spheres. The LA abrasion loss is the difference between the original and final mass

of the sample after washing off the No. 12 (1.70 mm) screen. Typical test values

range from 10% for extremely hard rocks (e.g. basalt) to 60% for soft rocks (e.g.limestone).

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

10/20

Lecture 13 146

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

b) Soundness

The soundness test determines an aggregates resistance (durability) to

disintegration by weathering and, in particular, freeze-thaw cycles. Aggregates that

are durable are less likely to degrade in the field and cause premature HMA

pavement distress and potentially, failure.

Soundness is the percent loss of material from an aggregate blend during the

sodium sulfate Na2SO4 or magnesium sulfate MgSO4soundness test. This property is

determined using AASHTO T104 Standard Method of Test for Soundness of

Aggregate by Use of Sodium Sulfate or Magnesium Sulfate. In this procedure,

aggregate samples are put through repeated cycles of immersion in saturated

solutions of sodium or magnesium sulfate followed by oven drying. The percent loss

of material is determined by taking the difference between the original and final

masses expressed as a percentage of the original mass. This test evaluates the

aggregates ability to resist breaking down or disintegrating due to weathering (i.e.,

wetting and drying and/or freezing and thawing). ASTM D692 Standard

Specification for Coarse Aggregate for Bituminous Paving Mixtures specifies a 5-

cycle weighted loss of not more than 12% when sodium sulfate is used or 18% when

magnesium sulfate is used.

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

11/20

Lecture 13 147

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

c) Deleterious Materials

The percentage of deleterious materials in blended aggregate is determined

using AASHTO T112 (ASTM C142) Standard Method of Test for Clay Lumps

and Friable Particles in Aggregate. In this procedure, aggregates are individually

subjected to finger pressure (while soaking) to determine materials that are friable

or clay lumps. The percent of clay lumps and friable particles is determined by taking

the difference between the original and final mass retained on a No. 200 (0.075

mm) sieve, after wet sieving, expressed as a percentage of the original mass. The

percent of deleterious materials can range from 0.2 to 10%.

=========================

3- Other properties

a) Particle Index (Shape and Texture)

Particle index is an overall measure of aggregate particle shape and texture. This

property is determined using ASTM D3398 Standard Test Method for Index of

Aggregate Particle Shape and Texture. In this test method, the percent voids in the

aggregate compacted in two stages according to a specified procedure is used to

calculate the particle index (Ia) value. Typically, rounded particles with smooth

surface textures may have a particle index of 6 or 7 while a highly-angular crushed

particle with rough surface textures can have particle indices of 15 to 20 or higher.

Surface texture, similar to particle shape, influences the workability and strength of

HMA. Aggregates with rough textures, such as crushed limestone or gravel, tend to

form stronger bonds with asphalt cement and increases the strength and asphalt

cement demand of a mix. On the other hand, aggregates with smooth textures, such

as river gravels and sands, tend to form weaker bonds with asphalt cement which

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

12/20

Lecture 13 148

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

leads to reduced strength and decreased asphalt cement demand. However, smooth

aggregate surface textures may provide more workability.

b) Plasticity Index

The Plasticity Index (PI) is a measure of the degree of plasticity of fines (material

passing the No. 200 sieve). It can provide an indication of the amount and type of

fines. This property is determined using ASTM D4318 Standard Test Method for

Liquid Limit, Plastic Limit, and Plasticity Index of Soils. The PI is defined as the

difference between the liquid limit (LL) and plastic limit (PL).

c) Affinity for Asphalt

An aggregates affinity for asphalt cement is its propensity to attract and remain

attached to asphalt cement. Asphalt cement must coat the aggregate, stick to the

aggregate, and resist stripping of the asphalt film in the presence of water. It is

important to recognize that some aggregates appear to have a greater affinity for

water than for asphalt cement. These hydrophilic (water-loving) aggregates have a

tendency to get stripped (asphalt film gets detached from the aggregate) with

exposure to water. On the other hand, hydrophobic (water-hating) aggregates have

a greater affinity for asphalt cement. Limestone and dolomite are examples of

hydrophobic aggregates.

d) Absorption

Absorption is a measure of an aggregates porosity. While porosity is generally

associated with the absorption of water, a porous aggregate also tends to absorb

asphalt cement. Porous aggregates have a greater asphalt cement demand and

require additional asphalt cement for a comparable mix. Therefore, highly porous

aggregates are generally not used for HMA unless the aggregates possess certain

desirable qualities that outweigh the cost of additional asphalt cement.

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

13/20

Lecture 13 149

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

C Aggregates gradation

According to Iraqi roads specifications, Coarse Aggregate is that portion of the

combined aggregate retained on the 4.75 mm (No. 4) sieve used for asphalt

concrete. Fine Aggregate is that portion of the combined aggregate passing the 4.75

mm (No. 4) sieve shall consist of stone screenings (dust) and natural sand. Natural

sand shall not exceed 25% of the portion fines than 2.36 mm for surface and binder

courses. Mineral Filler shall consist of limestone or other stone dust, portland

cement, hydrated lime or other non-plastic mineral matter from approved sources.

It shall conform to the grading requirements shown in Table R9/1.

The plasticity index as determined by ASSHTO T90 shall not be greater than 4. The

amount of filler to be added shall be only that amount which is necessary to the

grading requirements for the completed mixture prescribed.

Aggregate gradation is the distribution of particle size expressed as a percentage of

the total sample weight. This property is determined using AASHTO T27 (ASTM

C136) Standard Method of Test for Sieve Analysis of Fine and Coarse Aggregate.

In this test, aggregate passed through sieves with progressively smaller openings.

The mass of aggregate retained is then used to determine the percent of aggregate

retained on and/or passing each sieve. Gradations can be represented graphically

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

14/20

Lecture 13 150

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

using percent passing (by weight) as the ordinate and particle size as the abscissa.

Fuller and Thompson (1907) developed one of the best-known grading charts in the

early 20th century. The equation for Fullers maximum density curve is as follows:

P = (d/D)0.45

* 100

where d is the diameter of the sieve in question, P total percent passing or finer

than the sieve, and D is the maximum size of the aggregate. Maximum size is the

smallest sieve through which 100 percent of the aggregate sample particles pass.

For example, for surface course; P(#4) = (4.75/19)0.45

* 100 = 53.58 %

for surface course; P(#200) = (0.075/19)0.45

* 100 = 8.28 %

for binder course; P(#4) = (4.75/25)0.45

* 100 = 47.36 %

for binder course; P(#200) = (0.075/25)0.45

* 100 = 7.32 %

---------------------------------------------------------

Types of Aggregate Gradation

Dense or Well-Graded: The most common HMA and PCC mix designs in the U.S.

tend to use dense graded aggregate. Typical gradations are near the 0.45 power

curve but not right on it. Generally, a true maximum density gradation (exactly on

the 0.45 power curve) would result in unacceptably low VMA (voids in mineral

aggregate).

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

15/20

Lecture 13 151

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

Gap Graded: Refers to a gradation that contains only a small percentage of

aggregate particles in the mid-size range. The curve is flat in the mid-size range.

Some PCC mix designs use gap graded aggregate to provide a more economical mix

since less sand can be used for a given workability. HMA gap graded mixes can be

prone to ( ) segregation during placement.

Open Graded: Refers to a gradation that contains only a small percentage of

aggregate particles in the small range. This results in more air voids (permeable

aggregate) because there are not enough small particles to fill in the voids between

the larger particles. The curve is near vertical in the mid-size range, and flat and

near-zero in the small-size range.

Uniformly Graded: Refers to a gradation that contains most of the particles in a very

narrow size range. In essence, all the particles are the same size. The curve is steep

and only occupies the narrow size range specified.

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

16/20

Lecture 13 152

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

D Aggregate Blending (Combining)

The first phase in any asphalt mix design is the selection and combination of

aggregates to obtain a gradation within the specification limits. This sometimes is

referred to as mechanical stabilization.

Several aggregate gradations are usually proportioned for three reasons: (1) to

obtain the desired gradation; (2) single natural or quarried materials not enough and

(3) it is economical to combine natural and process materials.

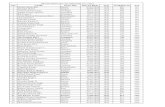

According to the Iraqi specification (SCRB, 2007, R9), the asphalt concrete mixtures

for base course (type I), binder course (type II) and surface course (type IIIA or IIIB)

shall be composed basically of coarse aggregate, fine aggregate, mineral filler (if

needed), and asphalt cement. The several mineral constituents shall be sized,

uniformly graded and combined in such proportions that the resulting blend meets

the grading requirements for the specific type under contract. The requirements for

the asphalt concrete mixtures shall conform to grading shown in the Table below.

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

17/20

Lecture 13 153

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

The Job Mix Formula (JMF)

Generally, a job-mix formula consists of two parts: (1) The combined gradation of

the aggregates to be used in the production of the asphalt concrete mixture; (2) The

asphalt content necessary to produce a satisfactory mix meeting all the specification

requirements (next lectures). The Iraqi SCRB (2009, R9) stated that contractor will

be allowed the tolerances from the approved job-mix formula shown in Table R9/4.

How to Combining Aggregates to Achieve the Target Blend?

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

18/20

Lecture 13 154

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

Proportioning Determinations

(1) Combining Two Aggregates

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

19/20

Lecture 13 155

Highway Eng. Aggregates of Road Pavements 14 15

Dr. Firas Asad

Figure 3.10 Trial-and-Error calculations for combining two aggregates.

(2) Combining Three Aggregates or More

The same procedure adopted in blinding two aggregates can be followed to

determine the adequate proportions for combining three or more aggregates. For

example, when three aggregates needs to be combined (Coarse agg. A, Fine Agg. B

and Mineral Filler C) the following Basic Formula and Trial-and-Error procedure

should be applied.

P = aA + bB + cC

a + b + c = 1

===================================

-

7/25/2019 Lec 13 Highway Engineering - Aggregate Tests Gradation and Blending

20/20

Lecture 13 156

Highway Eng. Aggregates of Road Pavements 14 15

Dr Firas Asad