Large round bale feeder design affects hay utilization and beef …buskirk/Publications/JAS...

Transcript of Large round bale feeder design affects hay utilization and beef …buskirk/Publications/JAS...

Large round bale feeder design affects hay utilization and beef cow behavior1,2

D. D. Buskirk*3, A. J. Zanella*, T. M. Harrigan†, J. L. Van Lente*4,L. M. Gnagey*4, and M. J. Kaercher‡

*Departments of Animal Science and †Agricultural Engineering, ‡Extension,Michigan State University, East Lansing 48824-1225

ABSTRACT: One hundred sixty beef cows (631 ± 78kg) were used to evaluate the quantity of hay loss andfeeding behaviors from different round bale feeders.Twenty cows were allotted by weight and body conditionscore to one of eight pens with four feeder designs:cone, ring, trailer, or cradle. All feeder types providedapproximately 37 cm of linear feeder space per animal.Alfalfa and orchardgrass round bales were weighed andsampled before feeding. Hay that fell onto the concretesurrounding the feeder was considered waste and wascollected and sampled daily. At the end of a 7-d period,each feeder type was assigned to a different pen for asecond 7-d period. On four consecutive days in eachperiod, animal behavior was recorded using a time-lapse video system. Data were collected from 5-minobservational intervals from the video tapes every 0.5h each day. Feeder access, occupancy rate, and occur-

Key Words: Aggressive Behavior, Beef Cows, Behavior, Feeding, Utilization

2003 American Society of Animal Science. All rights reserved. J. Anim. Sci. 2003. 81:109–115

Introduction

Harvested feed is the largest cost contributor to main-tenance of beef cows in the upper Midwest UnitedStates and feed cost is the single largest variable influ-

1Mention of trade names or commercial products in this article issolely to provide specific information and does not imply recommenda-tion or endorsement by Michigan State University, nor does it implyapproval to the exclusion of other products.

2This research was supported by the Michigan Agric. Exp. Stn.and was funded through a grant from the Michigan Animal IndustryCoalition. The authors gratefully acknowledge K. Tjardes for hiswork in sample and data collection. We thank Weldy Enterprises,Wakarusa, IN, for use of their feeder equipment. Acknowledgmentis also given to the crews of the Michigan State Univ. Beef CattleTeaching and Research Center, and Beef Cow-Calf Teaching Centerfor care of the experimental animals.

3Correspondence: 2265 Anthony Hall (phone: 517-432-0400; E-mail: [email protected]).

4Current address: College of Veterinary Medicine, Veterinary Med-icine Center, East Lansing, MI 48824-1316.

Received May 20, 2002.Accepted August 21, 2002.

109

rence of agonistic interactions were recorded. Dry mat-ter hay waste was 3.5, 6.1, 11.4, and 14.6% for the cone,ring, trailer, and cradle feeders, respectively. Calcu-lated dry matter intake of hay ranged from 1.8 to 2.0%of body weight and was not different among feeder type(P < 0.05). Percentage of organic matter, neutral deter-gent fiber, acid detergent fiber, and crude protein wereall lower and acid detergent lignin was higher in therecovered waste compared to the hay fed (P < 0.05).Cows feeding from the cradle feeder had nearly threetimes the agonistic interactions and four times the fre-quency of entrances compared to cows feeding from theother feeder types (P < 0.05). Feed losses were positivelycorrelated with agonistic interactions, frequency of reg-ular and irregular entrances, and feeder occupancy rate(P < 0.05). Agonistic interactions by cows and frequencyof feeder entrances differed among feeders and werecorrelated to feeder design induced feed losses.

encing profitability of the cow-calf enterprise in thisregion (Miller et al., 2001). Most harvested feed is pack-aged, stored, and fed as large round hay. Storage lossesof large round hay bales can range from 2 to 18% ofthe dry matter, depending on type of forage, storagemethod, environmental conditions, and length of timestored (Huhnke, 1987; Harrigan and Rotz, 1994). Littlehas been done to characterize losses of hay due to feed-ing method, even though studies have identified thatfeed losses may reach 20 to 30% of the dry matter fed(Belya et al., 1985; Baxter et al., 1986). Many uniquedesigns of large round bale feeders exist and are oftenaccompanied by claims of reduced waste potential.There is a lack of research comparing the magnitudeof feed loss and its relationship to animal behavior.An understanding of the relationship between feederdesign and animal behavior will provide an opportunityfor more efficient feed use, and enhance animal perfor-mance and well-being.

The objectives of this study were to evaluate: 1) haydry matter loss when feeding large round bales in cone,ring, trailer, and cradle-type feeders, 2) feeding behav-

Buskirk et al.110

ior for each feeder design, and 3) the relationship be-tween feeding behavior, feeder design, and feed loss.

Materials and Methods

Two lots of second-cutting hay, one predominatelyalfalfa (Medicago sativa) and one predominately or-chardgrass (Dactylus glomerata), were baled in Juneusing a round baler (New Holland, Belleville, PA; model848) at Michigan State University (East Lansing). Thetwine-wrapped round bales were approximately 122 cmwide × 150 cm in diameter. Round bales were removedfrom the field within 24 h of baling and were placed inan enclosed barn for storage until fed.

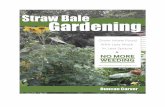

One hundred sixty nonlactating, pregnant beef cows(631 ± 78 kg) from the Michigan State University cam-pus herd were used to evaluate the quantity of hay lossand feeding behaviors from different round bale feedersduring November. Cows were weighed on two consecu-tive days and cow BCS were assigned on a 1 to 9 scale(1 = extremely thin, 9 = obese) by two experienced evalu-ators. Cows were equally divided into two weight blocks.Within a weight block, cows were allotted by BCS toone of four treatments, with 20 cows per pen. Each ofeight outside pens was assigned to one of two replicatesof four round bale feeder treatments, representing anarray of round bale feeder designs: cone (Weldy Enter-prises, Wakarusa, IN; model R7C), ring (Weldy Enter-prises, model R7), trailer (S.I. Feeders, Portage WI;Arrow Front Feeder Wagon), or cradle (Weldy Enter-prises; model 6 × 12 feet HGF) (Figure 1). The outsidemounded dirt pens were 110 × 19.5 m, and a singlefeeder was placed in the same location in each pen ona 17 × 19.5 m concrete pad. Both the ring and conefeeders were 2.34 m in diameter. The cradle feeder was3.66 × 1.83 m. The trailer feeder was 6.10 × 2.13 m;however, hay was placed only in a 3.66 m length of thefeeder. Therefore, all feeder types provided approxi-mately 37 cm of linear feeder space per animal. Therewere a total of 18, 18, and 19 feeding spaces for thecone, ring, and trailer feeders respectively. The cradlefeeder did not have defined feeding spaces. The coneand ring feeders had identical feeding spaces with barsoriented at 70° with a 35.5-cm spacing; the trailer feederbars were oriented at 50° with a 40-cm spacing. Theheight of the top rail was 191, 121, 163, and 152 cm forthe cone, ring, trailer, and cradle feeders, respectively.

Bales were sampled for compositional analysis imme-diately before feeding by boring three cores from theside of each bale using a Penn State forage sampler(Nasco, Fort Atkinson, WI). Round bales were individu-ally weighed immediately before feeding (281 ± 24 kg)and twine was removed. Cows were given ad libitumaccess to hay in the feeders. Hay that fell onto theconcrete surrounding the feeder was considered wasteand was collected in plastic barrels daily at 1530 h.Care was taken to avoid collection of manure, althoughsome contamination was unavoidable. The concretepads were scraped clean of manure after collection to

minimize contamination on the following day. All wastewas weighed and a 1-kg representative sample wasobtained daily by pen for composition analysis. Freshbales were placed in feeders within a treatment whenthe quantity of hay remaining in a feeder would havepotentially limited intake during the following 24 h. Atthe end of a 7-d period, all residual hay within the feederwas removed, weighed, and sampled. Each feeder typewas then assigned to a different pen, within a block,for the second 7-d period. Alfalfa hay was provided dur-ing the first 7-d period and orchardgrass hay was pro-vided during the second 7-d period. All experimentalprocedures were conducted according to those approvedby the Michigan State University All-University Com-mittee on Animal Use and Care (AUF# 07/98-119-00).

Behavior Analysis. On d 4 to 7 in period 1 and d 2 to5 in period 2, areas surrounding each round bale feedertype in four pens were recorded from 0800 to 1730 usinga time-lapse video recording system (Panasonic cameramodel CCT 330 and Panasonic video cassette recordermodel AG6740, Secaucus, NJ). Data were collected from5-min observational intervals of the videotapes every0.5 h each day (20 intervals�pen−1�d−1). Instantaneoussampling was carried out at the start and end of the5-min observation intervals. Using these data, feederoccupancy rate was calculated as the mean of the begin-ning and ending occupancy divided by the total numberof animals in the pen. Behavioral sampling and continu-ous recording were used to characterize access to thefeeders and occurrence of agonistic interactions duringthe 5-min observation intervals. Access to the feederswas defined as regular or irregular. A regular entrancewas defined as the positioning of the head below thetop rail, as intended by the feeder manufacturer. Anirregular entrance was defined as access to the feederabove the top rail. Agonistic interactions were broadlydefined to include behaviors of a cow that resulted inthe displacement of another cow from the feeder. Thisdefinition included threats, head butting, and pushing.To represent hourly behavior, observation interval datawere multiplied by 12. Mean behavioral data were thensummarized for the time frame directly correspondingto hay waste collection (1530 to 1730 and 0800 to 1500)for comparison of animal behavior impact on hay waste.

Sample Analysis. Air-dry content of hay from bales,hay waste, and residual hay samples were determinedby weighing samples, drying in a forced-air oven at 57°Covernight, allowing samples to equilibrate to ambientconditions for 24 h, and then weighing again. Air-drysamples were ground in a Wiley mill to pass a 1-mmscreen and composited by pen and period. Dry matterwas determined by further drying samples in a forced-air oven at 105°C for 24 h. Crude protein was deter-mined by combustion method 990.03 (AOAC, 1995; LecoFP-2000, Leco Corp., St. Joseph, MI). Neutral detergentfiber, ADF, and ADL were determined using a filterbag technique (Vogel et al., 1999) with an Ankom 220Fiber Analyzer (Ankom Technology, Fairport, NY) and

Feeder effects on hay use and cow behavior 111

Figure 1. Round bale feeder types: (a) ring, (b) cone, (c) trailer, and (d) cradle.

corrected for ash. Ash content was determined after 5h of oxidation at 500°C in a muffle furnace.

Statistical Analysis. Feed disappearance was calcu-lated as the amount of hay delivered to each pen, lessthe residual amount of hay remaining in the feeder atthe end of a 7-d period. The total amount of hay recov-ered from the concrete pad around the perimeter ofeach feeder was considered feed waste. Percentagewaste was calculated as the amount of waste dividedby feed disappearance. Feed intake was estimated asthe difference between feed disappearance and feedwaste. Video equipment failure resulted in 46 missingdata points for the 480 observation times.

The GLM procedures of SAS (SAS Inst., Inc., Cary,NC) were used to analyze feed and behavior data. Penserved as the experimental unit. The model for animalcharacteristics and feed loss data included feeder type,

replicate, period, and their two-way interactions as in-dependent variables. The model for hay nutrient dataincluded sample type (feed or waste), feeder type, repli-cate, period, and their two-way interactions as indepen-dent variables. The model for behavior data includedfeeder type, day, period, and their two-way interactionsas independent variables. The residual mean squarewas used as the error term in all analyses. The levelof probability at which the main effects were consideredsignificant was P < 0.05. Model sums of squares werepartitioned into treatment effects that were separatedusing a significant F-test.

Results and Discussion

The effect of feeder type on hay waste and intake isshown in Table 1. There was a significant difference

Buskirk et al.112

Table 1. Effect of feeder type on hay waste and intake by beef cows(least squares means)

Feeder type

Item Cone Ring Trailer Cradle SEMa

Initial cow weight, kg 628.7 631.5 632.2 629.6 4.3Initial cow body condition scoreb 5.8 5.9 5.9 5.8 0.02

DM basis

Daily hay disappearance, kg/cowc 12.0x 12.1x 13.9y 12.9xy 0.4Daily hay waste, kg/cow 0.4x 0.7y 1.6z 1.9z 0.1Hay waste, %d 3.5x 6.1x 11.4y 14.6y 0.8Daily hay intake, kg/cowe 11.5 11.4 12.3 11.0 0.4Intake/cow BW, % 1.8 1.8 2.0 1.8 0.1

aStandard error of the least squares means.b1 to 9 scale where 1 = extremely thin and 9 = obese.cHay fed less residual hay at the end of the period.dHay waste as a percentage of hay disappearance.eHay disappearance less hay waste.x,y,zWithin a row, least squares means without a common superscript letter differ (P < 0.05).

in feed loss among all feeders with the exception ofthe trailer and cradle feeders, which tended (P = 0.06)to be different from one another. Use of the ring feederresulted in nearly twice the amount of waste comparedto the cone feeder, whereas the trailer and cradle feed-ers resulted in four times the waste per animal (P <0.05) compared to the cone design. Hay waste, as apercentage of hay disappearance, was less for the coneand ring feeders compared to the trailer and cradlefeeders (P < 0.05). In addition, there was a tendencyfor a lower percentage of waste from the cone comparedto the ring (P = 0.09) and a lower percentage of wastewith the trailer compared to the cradle (P = 0.06).Comerford et al. (1994) also reported increased forageutilization when using a cone-type feeder. They com-pared the feed losses from round bale grass hay andbalage with either a metal ring-type feeder or a raisedcone-type feeder with a solid base. Dry matter feedlosses in their trial were 1.9% and 8.0% for the cone-and ring-type feeders, respectively. In the presenttrial, our observation indicated that cattle eating fromthe cone and ring feeders would have been able to moreclosely mimic a grazing position than those eating fromthe trailer and cradle feeders would, and this mayhave contributed to reduced feed losses. Feed wastagefrom cows tossing feed over their backs or along theirsides may be reduced by allowing the animals to eatin a head-down, natural grazing position from groundlevel rather than an elevated platform (Albright andStricklin, 1989). In addition, an animal’s ability tothrow its head and toss feed is limited when their headis beneath a rail, such as the top rail on the cone, ring,and trailer feeders in the present study.

The percentage of hay waste in our trial ranged from3.5 to 14.6%, which is lower than some other reports(Belya et al., 1985; Baxter et al., 1986). Some factorsthat may have contributed to relatively less waste inthis experiment were that all hay was stored insideuntil fed and that the bale diameter:feeder diameter

ratio was relatively small, causing cows to reach forthe feed with some of the designs. In addition, fly andinsect annoyance was not a problem, which could in-crease waste in summer trials.

Feed loss (refusal or waste) is influenced by storagemethod. Belyea et al. (1985) fed large round alfalfahay bales to beef cows in bunks with angled headgates.Feed losses were similar for bales stored inside (12.4%)or covered with plastic outside (13.4 to 14.5%), butwere higher for bales stored uncovered outside(24.7%). Similar results were obtained by Baxter et al.(1986) when feeding alfalfa-orchardgrass hay to dairycows in bunks with angled headgates. Feed losses av-eraged 6% for bales stored inside or covered outside,but exceeded 19% of hay fed when stored uncoveredoutside.

Round bale feeders limit access to forage and thuslimit waste from trampling and manure contamina-tion. Lechtenberg et al. (1974) reported that an aver-age of 29% more dry matter was required when feedinground-baled hay without racks. Slanted bar designsencourage animals to keep their heads in the feederopening by providing some constraint. Depending onbar angle and spacing, this design may force cows torotate their heads when entering or leaving the feeder.This design attribute may contribute to fewer feedingtransitions and less feed loss; however, optimal barangles and bar spacing for cattle have not been re-ported. Schultheis and Hires (1982) evaluated slanted-bar head gates with the use of an additional “pusher”gate placed between the slanted gate and the haybales. The purpose of the pusher gate was to forcecattle to reach further for hay and discourage backingaway while eating. Use of the slanted gate alone re-sulted in 16% waste, but when used in combinationwith the pusher gate, waste was 9% (Schultheis andHires, 1982). Likewise, Petchey and Abdulkader(1991) observed that hay utilization might be improvedwhen cattle are encouraged to reach for forage. How-

Feeder effects on hay use and cow behavior 113

Table 2. Effect of feeder type on nutrient content of hay fedand recovered waste (least squares means)

Feeder type

Item Cone Ring Trailer Cradle SEMa

Organic matter, %Hay fed 92.6b 92.6b 92.6b 92.4b 1.3Recovered waste 65.2c 65.6c 76.4d 76.2d

Neutral detergent fiber, %Hay fed 53.8b 52.1bc 53.2b 51.5bc 1.5Recovered waste 39.4e 40.3e 48.3cd 47.1d

Acid detergent fiber, %Hay fed 34.8bc 34.7bc 35.3bc 35.4b 0.9Recovered waste 26.3d 27.5d 33.5bc 32.7c

Acid detergent lignin, %Hay fed 4.3b 4.7bc 4.7bc 5.0bc 0.3Recovered waste 4.9bc 5.3cd 6.1de 6.3e

Crude protein, %Hay fed 12.6b 13.0b 12.7b 13.4b 0.6Recovered waste 10.1c 9.6c 9.8c 10.9c

aStandard error of the LS means.b,c,d,eWithin a nutrient, least squares means without a common superscript letter differ (P < 0.05).

ever, this design feature needs to be balanced withthe possibility of limiting intake, which may not bedesirable in all feeding situations. In our trial, thecone and trailer feeders had bars that centered thebale in the feeder, forcing the cattle to reach for hay.

Calculated daily intake of hay DM was not differentamong feeder type (P < 0.05). Calculated DMI of cowsin this study ranged from 1.8 to 2.0% of BW, which issimilar to that predicted from NRC (1996) equations(2.0% of BW). Collectively, this indicates that feederdesign attributes responsible for differing feed loss didnot cause significant restriction of feed intake.

Table 2 shows nutrient composition of hay fed andrecovered waste. Hay fed was similar in percentage ofOM, NDF, ADF, ADL, and CP among feeder types (P< 0.05). Percentage of OM, NDF, ADF, and CP wereall lower, and ADL was higher, in the recovered wastecompared to the hay fed (P < 0.05). The percentage ofOM, NDF, ADF, and ADL in the recovered waste wereall significantly affected by feeder type. The cone andring feeders resulted in a significantly lower percent-

Table 3. Effect of feeder type on feeding behaviorand dry matter hay waste (least squares means)

Feeder type

Item Cone Ring Trailer Cradle SEMa

Agonistic interactions/h 10.9x 7.4x 13.6x 30.7y 3.2Frequency of entrances, No./h 6.3x 8.0x 8.3x 29.8y 3.3Frequency of regular entrances, No./h 6.1xy 3.8x 8.2y 13.0z 0.9Frequency of irregular entrances, No./h 0.2x 4.2x 0.1x 16.8y 2.6Feeder occupancy, % of animals 13.5xy 7.6x 16.1y 16.7y 1.8Daily DM waste, kgb 9.5x 14.5x 26.6y 50.0z 2.8

aStandard error of the least squares means.bDaily DM waste during simultaneous behavior data collection.x,y,zWithin a row, least squares means without a common superscript letter differ (P < 0.05).

age of OM, NDF, and ADF and tended (P = 0.07) tohave a lower percentage of ADL in the waste comparedto the trailer and cradle feeders. Because leaves ofmature alfalfa and orchardgrass have a lower percent-age of OM, NDF, ADF, and ADL than stems (Bourquinand Fahey, 1994), our results indicate that leaves mayhave been a greater percentage of the waste from thecone and ring feeders. This may have been directlyrelated to the quantity of waste, with feed losses con-sisting of more leaves when little waste occurred andmore stems when waste was greater. A greater per-centage of leaves would result in higher CP content;however, CP was similar among feeder types (P > 0.05).Although not visually significant, some soil contami-nation of the waste likely occurred; however, differ-ences in contamination between feeder types shouldbe related only to the quantity of feed waste.

Behavioral observation data are described in Table3. Most notable is the fact that cows feeding from thecradle feeder had nearly three times the agonistic in-teractions and four times the frequency of entrances

Buskirk et al.114

Table 4. Pearson correlation coefficients among feeding behaviors and hay waste

Item 1 2 3 4 5

Agonistic interactions/h —Frequency of entrances, No./h 0.68*** —Frequency of regular entrances, No./h 0.83*** 0.80*** —Frequency of irregular entrances, No./h 0.47* 0.94*** 0.54** —Feeder occupancy, % of animals 0.63*** 0.57** 0.87*** 0.28 —Daily DM hay waste, kg 0.53** 0.67*** 0.65*** 0.56** 0.40*

*,**,***Correlations significantly different from 0 at *P < 0.05; **P < 0.01; ***P < 0.001.

compared to cows feeding from the other feeder types(P < 0.05). This may be partially due to a lack of verticalpartitions to create feeding positions in the cradlefeeder. There was no barrier to deter cows from inter-acting with one another, nor were they hindered fromentering or exiting the feeder. Bouissou (1970) foundthat manger divisions protected submissive cows’heads and enabled them to eat for longer bouts. Weobserved that a single animal more easily displacedmultiple cows eating from a rectangular feeder com-pared to a round feeder. In this manner, an animaloften relocated its pen mates along the full length ofa linear feeder, whereas this behavior was not ob-served in pens with round feeders. Because hay wasnot placed in the nose section of the trailer feeder, itis not known how feeding dynamics may have differedif the full length of the feeder were used.

Another potential difference between round andrectangular designs may involve the cows’ visual per-ception. Cattle have nearly 360° of vision, with theexception of a narrow blind spot directly behind them(Grandin, 1993). The area in which animals react toa perceived threat by moving away is their flight zone.In a competitive feeding situation, round geometry ofa feeder may allow cows to maintain a larger flightzone, thereby allowing both comfortable herd interac-tion and awareness of an agonistic cow approachingfrom behind and asserting position.

The frequency of irregular entrances, or enteringthe feeder to eat over the top bar was greatest for thecradle feeder (P < 0.05). The top bar of the cradle feederwas relatively high compared to the other designs.However, the frequency of irregular entrances mayhave been higher because the cradle feeder had nomeans by which to maintain the bale in the center ofthe feeder. Feeder occupancy at the ring feeder waslower (P < 0.05) than the trailer and cradle and tended(P = 0.06) to be lower than the cone.

Correlations between observed behaviors and feedwaste are reported in Table 4. Feed losses were posi-tively correlated with agonistic interactions, frequencyof regular and irregular entrances, and feeder occu-pancy rate (P < 0.05). The social organization of a herdis established through aggressive behavior, wherebyanimals approach, threaten, and possibly butt otheranimals with their head (Schein and Fohrman, 1955).When a competitive condition exists for available feed,

dominant cows assert their position in eating beforeless dominant cows. The amount of time feeding hasbeen positively correlated with dominance behavior(McPhee et al., 1964; Friend and Polan, 1975). How-ever, agonistic actions during feeding are not limited todominant animals. Dominance relationships of cattlebased on spontaneous aggressive interactions havebeen identified as being different than those based oninteractions motivated by competitive feeding (Arnoldand Grassia, 1983; Jezierski and Podluzny, 1984). Itwas observed from the tapes of the present study thathay often fell from the mouths of one or both animalsduring the course of an agonistic interaction. Becausethese interactions occurred outside of the feeder pe-rimeter it is not surprising that agonistic interactionswere positively correlated with feed loss.

Implications

Feed losses were significantly influenced by feedertype and ranged from 3.5 to 14.6% of hay disappear-ance. Both agonistic interactions of cows around thefeeders and frequency of feeder entrances differedamong feeders and were correlated to feed losses.Feeder design features including size, geometry, barangle and spacing, and inclusion of a top bar mayaffect cattle behavior and resulting feed utilization.Implementation of design strategies that reduce ago-nistic interactions and/or reduce feeder entranceswould be expected to reduce feed losses.

Literature Cited

Albright, J. L., and W. R. Stricklin. 1989. Recent developments inthe provision for cattle welfare. Page 149 in New Techniquesin Cattle Production. C. J. C. Phillips, ed. Butterworths,Guildford.

AOAC. 1995. Official Methods of Analysis. 16th ed. Assoc. Offic.Anal. Chem., Arlington, VA.

Arnold, G. W., and A. Grassia. 1983. Social interactions amongst beefcows when competing for food. Appl. Anim. Ethol. 9:239–252.

Baxter, H. D., B. L. Bledsoe, M. J. Montgomery, and J. R. Owen.1986. Comparison of alfalfa-orchardgrass hay stored in largeround bales and conventional rectangular bales for lactatingcows. J. Dairy Sci. 69:1854–1864.

Belyea, R. L., F. A. Martz, and S. Bell. 1985. Storage and feedinglosses of large round bales. J. Dairy Sci. 68:3371–3375.

Bouissou, M. F. 1970. Role du contact physique dans la manifesta-tion des relations hierarchiques chez les bovins. Consequencespratiques. Annal. Zootechnol. 19:279–285.

Feeder effects on hay use and cow behavior 115

Bourquin, L. D., and G. C. Fahey. 1994. Ruminal digestion andglycosyl linkage patterns of cell wall components from leaf andstem fractions of alfalfa, orchardgrass, and wheat straw. J.Anim. Sci. 72:1362–1374.

Comerford, J. W., D. R. Buckmaster, and E. H. Cash. 1994. Effectsof three storage methods on nutrient losses from harvest, stor-age and feeding of large bales. J. Anim. Sci. 72(Suppl. 2):130(Abstr.).

Friend, T. H., and C. E. Polan. 1975. Cow behavior: Varying free-stalls and bunk space. J. Anim. Sci. 41:238 (Abstr.).

Grandin, T. 1993. Behavioral principles of cattle handling underextensive conditions. Page 43 in Livestock Handing and Trans-port. T. Grandin, ed. CAB International, Walingford, Oxon,U.K.

Harrigan, T. M., and C. A. Rotz. 1994. Net, plastic, and twine-wrapped large round bale storage loss. Appl. Eng. Agric.10:188–194.

Huhnke, R. L. 1987. Large round bale alfalfa hay storage. Appl.Eng. Agric. 4:316–317.

Jezierski, T. A., and M. Podluzny. 1984. A quantitative analysis ofsocial behavior of different crossbreds of dairy cattle kept inloose housing and its relationship to productivity. Appl. Anim.Behav. Sci. 13:31–40.

Lechtenberg, V. L., W. H. Smith, S. D. Parsons, and D. C. Petritz.1974. Storage and feeding of large hay packages for beef cows.J. Anim. Sci. 39:1011–1015.

McPhee, C.P., G. McBride, and J.W. James. 1964. Social behaviorof domestic animals. III. Steers in small yards. Anim. Prod.6:9–15.

Miller, A. J., D. B. Faulkner, R. K. Knipe, D. R. Strohbehn, D.F. Parrett, and L. L. Berger. 2001. Critical control points forprofitability in the cow-calf enterprise. Prof. Anim. Sci.17:295–302.

NRC. 1996. Nutrient Requirements of Beef Cattle. 7th ed. Natl.Acad. Press, Washington, DC.

Petchey, A. M., and J. Abdulkader. 1991. Intake and behaviour ofcattle at different food barriers. Anim. Prod. 52:576-577.(Abstr.).

Ray, D. E., and C. B. Roubicek. 1971. Behavior of feedlot cattleduring two seasons. J. Anim. Sci. 33:72–76.

Schein, M. W., and M. H. Fohrman. 1955. Social dominance relation-ships in a herd of dairy cattle. Brit. J. Anim. Behav. 3:45–55.

Schultheis, R. A., and W. G. Hires. 1982. Self-feeding head gatesfor large round bales. Transactions of the ASAE. 25:1553–1555.

Vogel, K. P., J. F. Pedersen, S. D. Materson, and J. J. Toy. 1999.Evaluation of a filter bag system for NDF, ADF, and IVDMDforage analysis. Crop Sci. 39:276–279.